Light compound side fascia and its manufacturing method

A composite exterior wall panel and lightweight technology, which is applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of limited types of exterior wall panels and cannot meet market demand, and achieve superior performance, high bearing strength, The practical effect of the manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

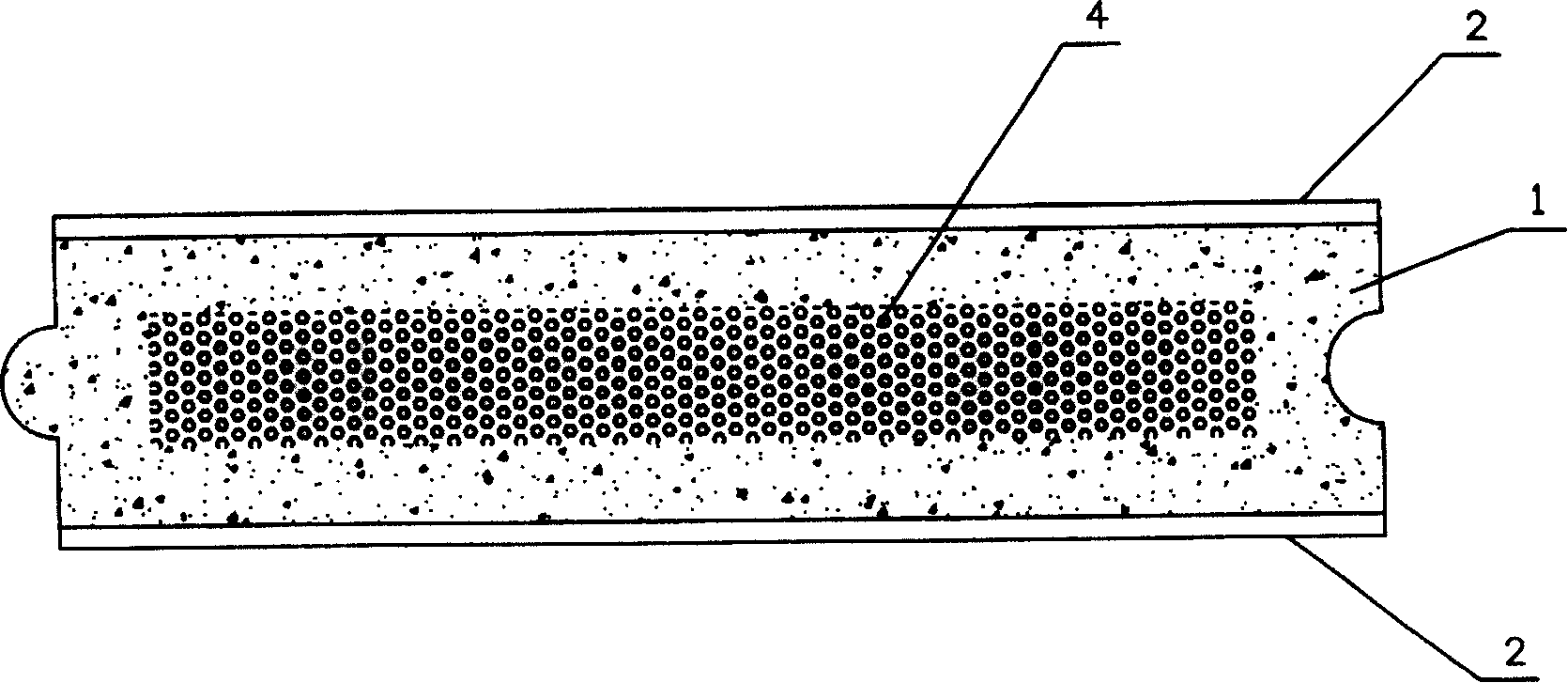

[0039] refer to figure 1 and figure 2 , a lightweight composite exterior wall panel provided by the present invention, which is composed of a fiber-reinforced cement plate 2 and a load-bearing layer 1, the load-bearing layer 1 is a lightweight aggregate concrete layer reinforced by double-layer steel mesh 3, double-layer steel bars The net 3 is supported and connected by short steel bars 31. The two sides of the bearing layer 1 are compounded with fiber reinforced cement slabs 2. There is a cavity surrounded by light aggregate concrete in the bearing layer 1. The cavity is filled with thermal insulation material 4 , the thermal insulation material 4 of this example is a polystyrene foam board, and the middle part of this composite exterior wall panel is a five-layer structure: fiber-reinforced cement plate 2+bearing layer 1 (built-in steel mesh 3)+thermal insulation material 4+ load-bearing layer 1 (built-in steel mesh 3) + fiber-reinforced cement slab 2, and its two ends ar...

Embodiment 2

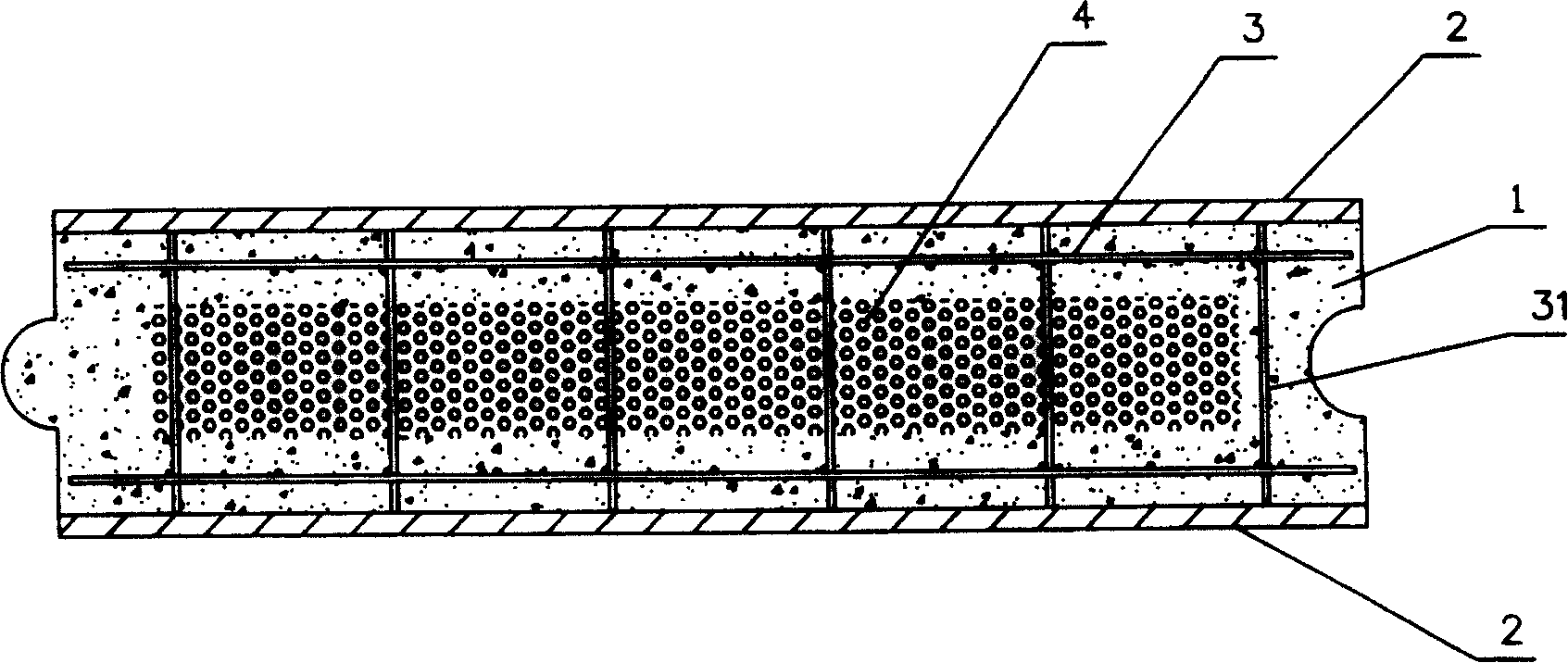

[0042] refer to image 3 and Figure 4 , a kind of lightweight composite exterior wall panel provided by the present invention, its structure is basically the same as the above-mentioned embodiment 1, the difference is that the double-layer steel mesh 3 uses cement to wrap the short-column steel bars 31 for oblique support connection, this double-layer steel mesh There are two approaches:

[0043] 1. Prepare the cement-wrapped short-column steel bar 31 in advance, connect the cement-wrapped short-column steel bar 31 with the double-layer steel mesh 3 to form a whole, and sandwich the thermal insulation material 4 at the same time;

[0044] 2. Use the short steel bars 31 without cement wrapping to connect with the double-layer steel mesh 3 to form a whole, and at the same time sandwich the thermal insulation material 4, and reserve gaps at the thermal insulation material 4 where the short steel bars 31 pass through, so that these gaps When the wallboard is made, it is filled ...

Embodiment 3

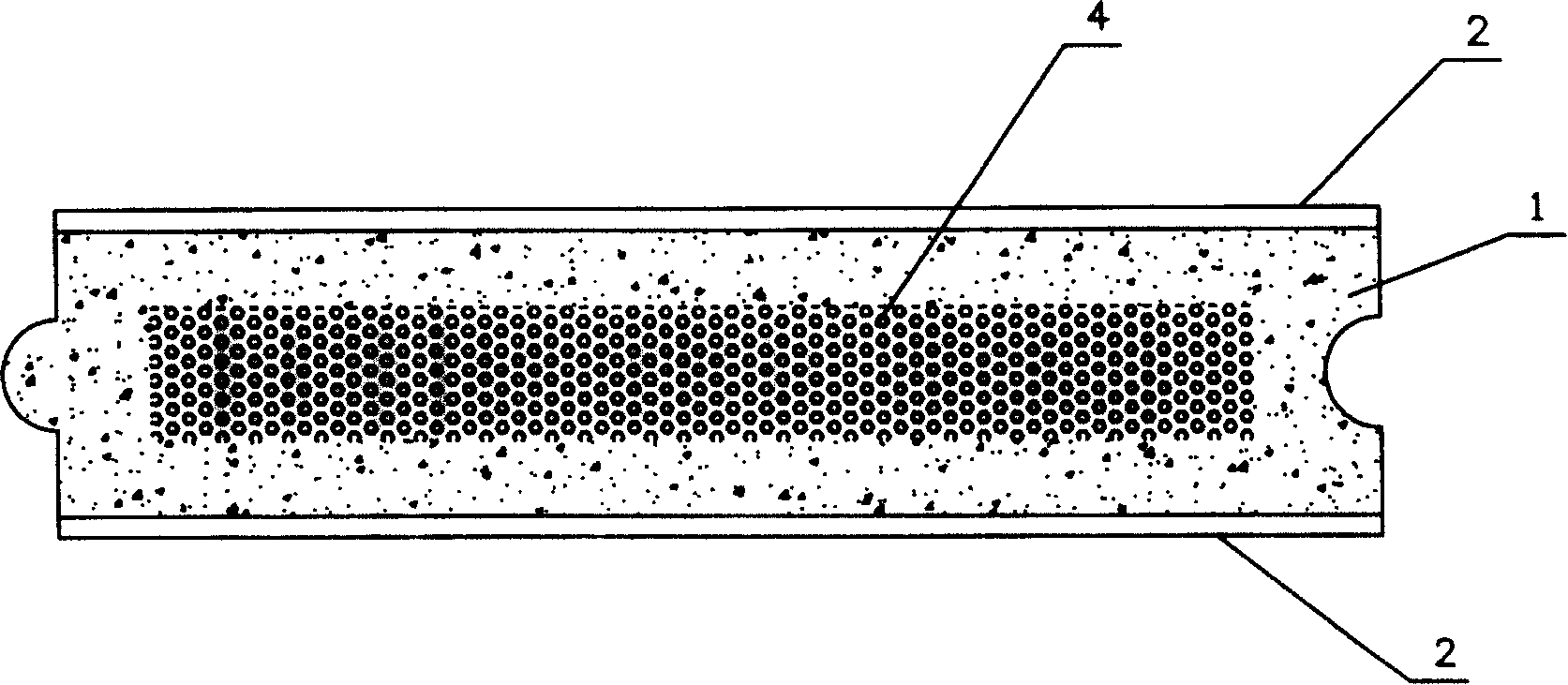

[0046] refer to Figure 5 and Figure 6 , a lightweight composite exterior wall panel provided by the present invention, which is composed of a fiber-reinforced cement plate 2 and a load-bearing layer 1, the load-bearing layer 1 is a light aggregate concrete layer reinforced by a steel mesh 3, and one part of the load-bearing layer 1 Fiber-reinforced cement slabs 2 are composited on the sides, and the two ends of the bearing layer 1 are provided with tenons and grooves for easy assembly.

[0047] The concrete used to make the load-bearing layer 1 is lightweight high-strength concrete composed of cement, sand and light aggregate. The light aggregate used in the concrete is ceramsite, and the cement used is preferably sulphoaluminate cement. Ordinary Portland cement, the steel mesh 3 used is a double-layer steel mesh supported by corrugated steel bars 31.

[0048]When using this kind of wallboard, the side without the cement slab should be placed on the outer wall, and other f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com