Patents

Literature

99results about How to "Smooth wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

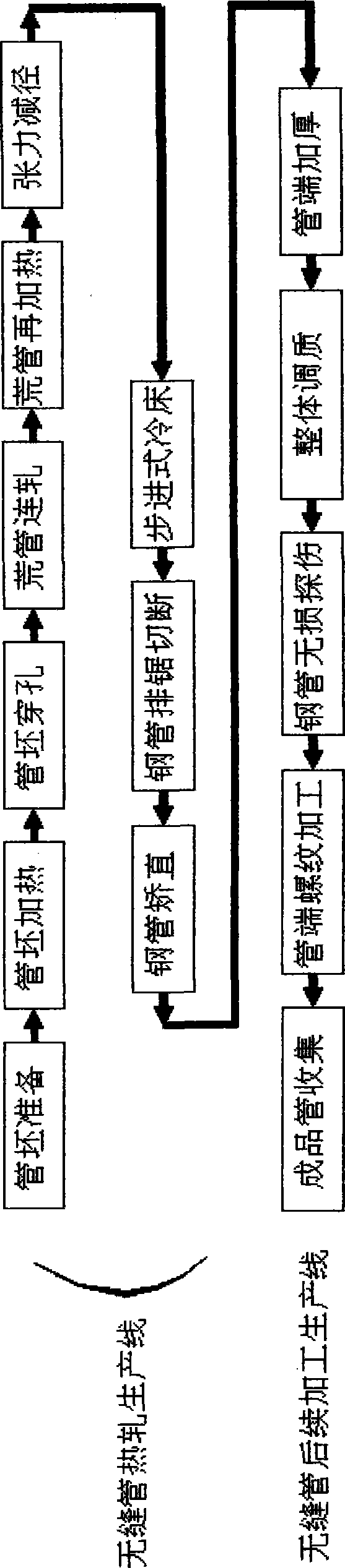

High steel level petroleum casing pipe and oil pipe manufacturing process

InactiveCN101481995AUniform wall thicknessSmooth wallDrilling rodsFurnace typesIntermediate frequencyLength measurement

The invention discloses a preparation method of high-grade steel petroleum casing pipes and oil pipes, and relates to a manufacturing method of petroleum casing pipes and oil pipes; hot rolled steel coils are taken as raw material for manufacturing the steel pipes, and ERW welded pipe material is firstly manufactured by the processes such as longitudinal-shearing striping, band steel formation, high-frequency welding, burr cleaning inside and outside of the welding seams, welding seam detection, intermediate-frequency welding seam annealing, sizing, cutting off, straightening and the like; and the processes such as post-welding finishing, end upsetting (heavy wall tubing needs the process), integral hardening and tempering, medium-temperature straightening, pipe end detection, pipe threading processing, collar screw coupling, hydraulic pressure test, path test, pipe body detection, length measurement, weighting, oiling and the like are carried out, thus producing the high-grade steel petroleum casing pipes and oil pipes. The steel grade of the steel pipe can reach the steel grade specified in API 5CT standard for manufacturing N80Q, L80, C95, P110 and Q125 with a welding method. The high-grade steel petroleum casing pipes and oil pipes manufactured by the invention has the advantages of high production efficiency, low production cost, high lumber recovery, and high product quality.

Owner:江苏嘉宝科技制管有限公司

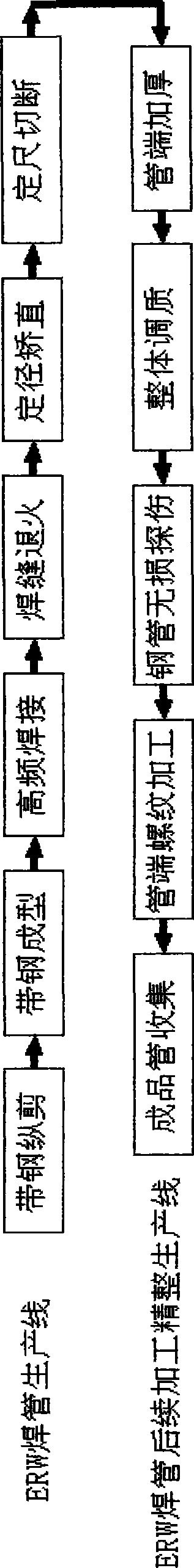

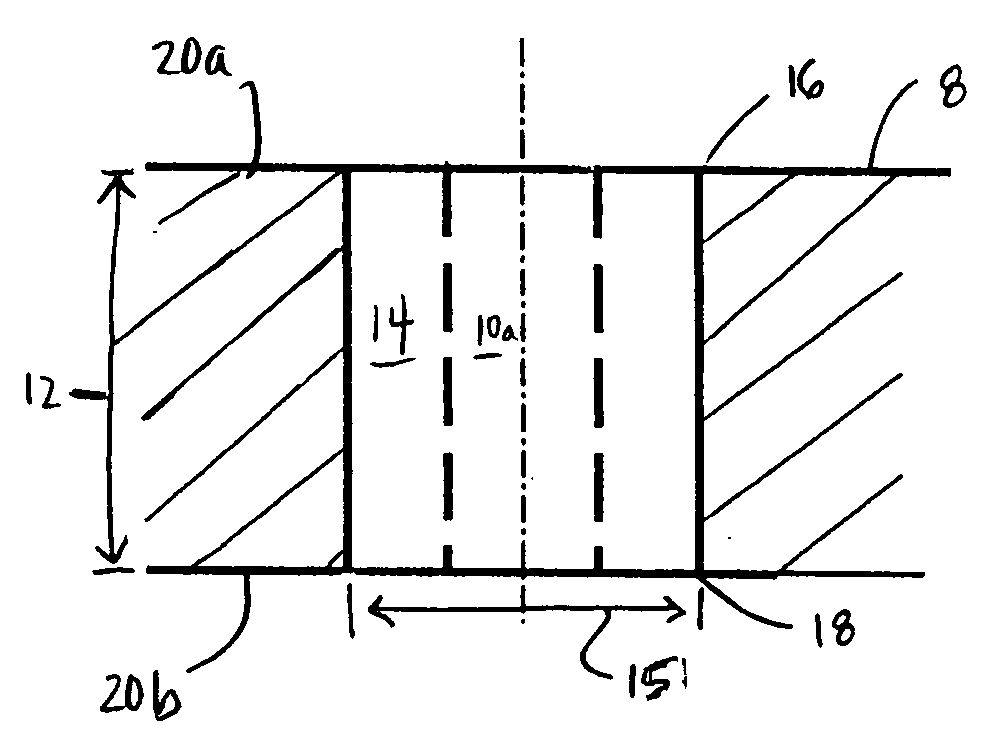

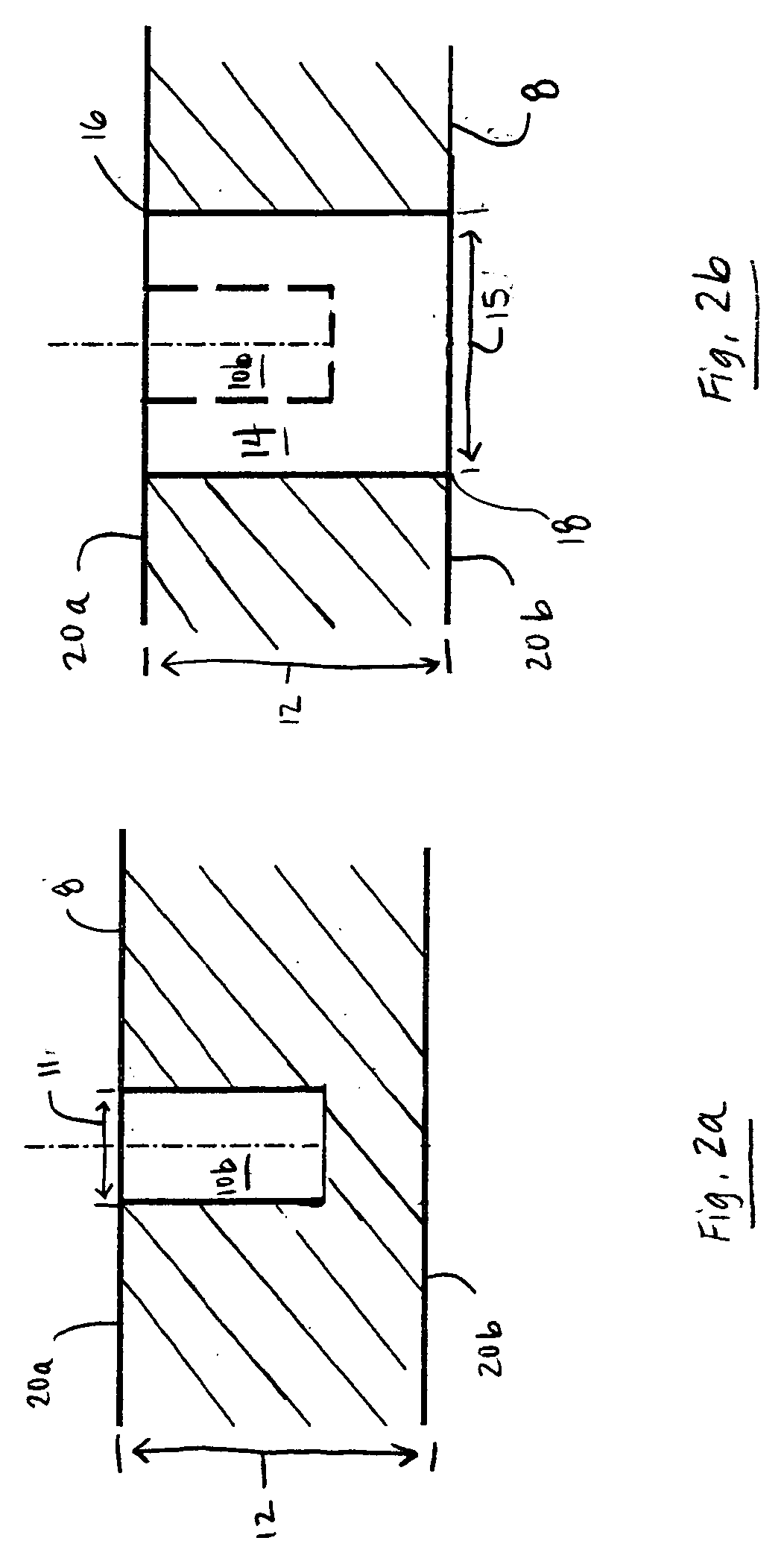

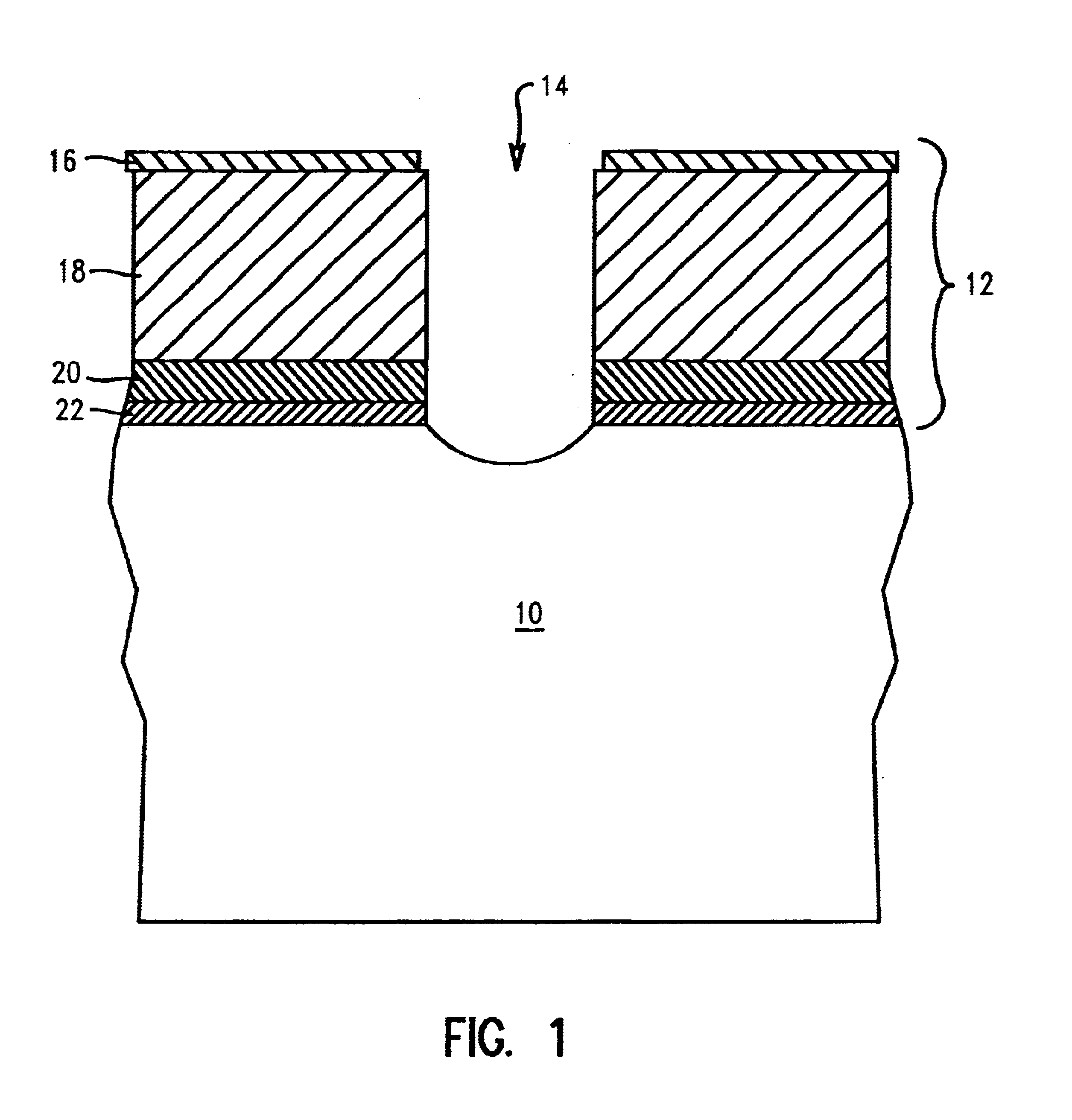

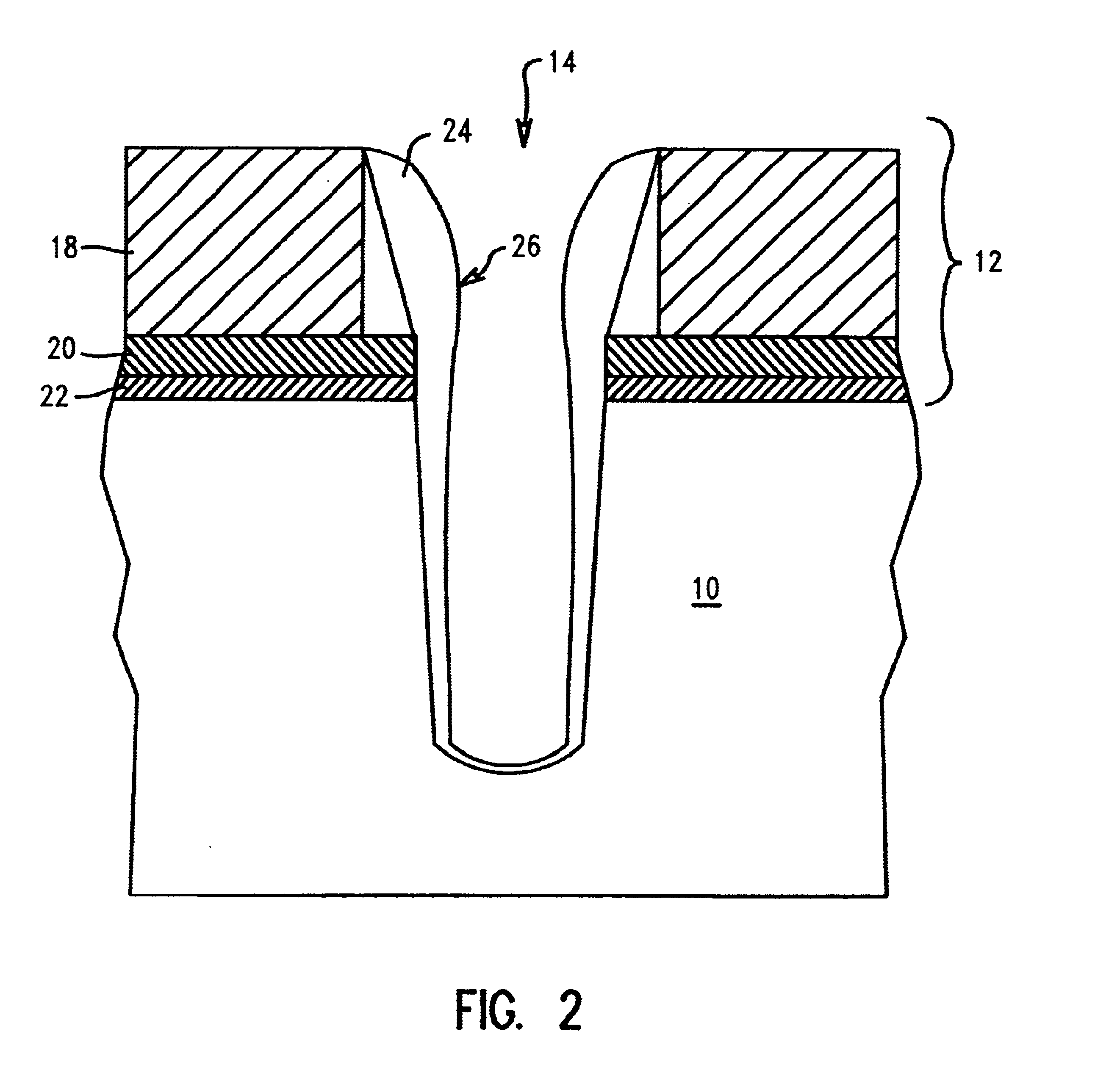

Methods of drilling through-holes in homogenous and non-homogeneous substrates

InactiveUS20050230365A1Minimum thermal damageImprove performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energyPilot hole

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

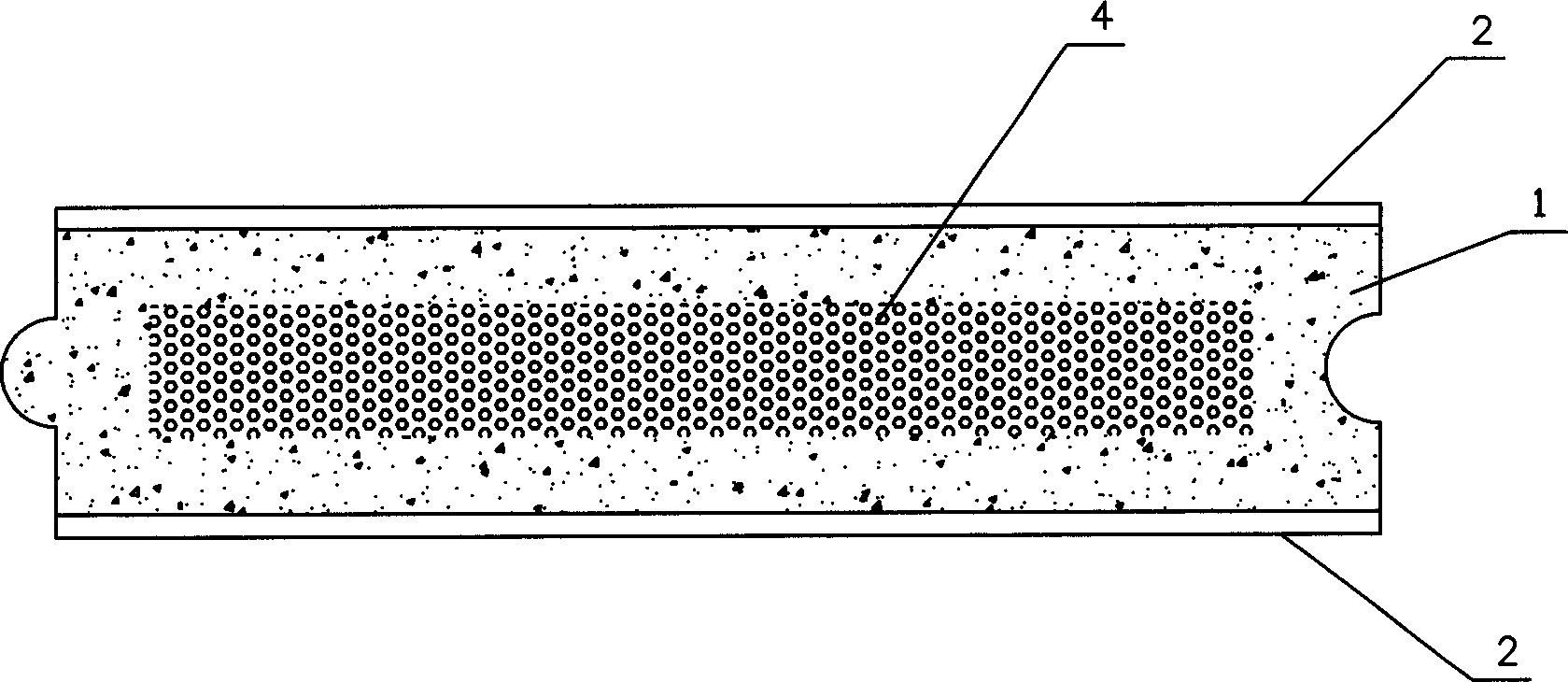

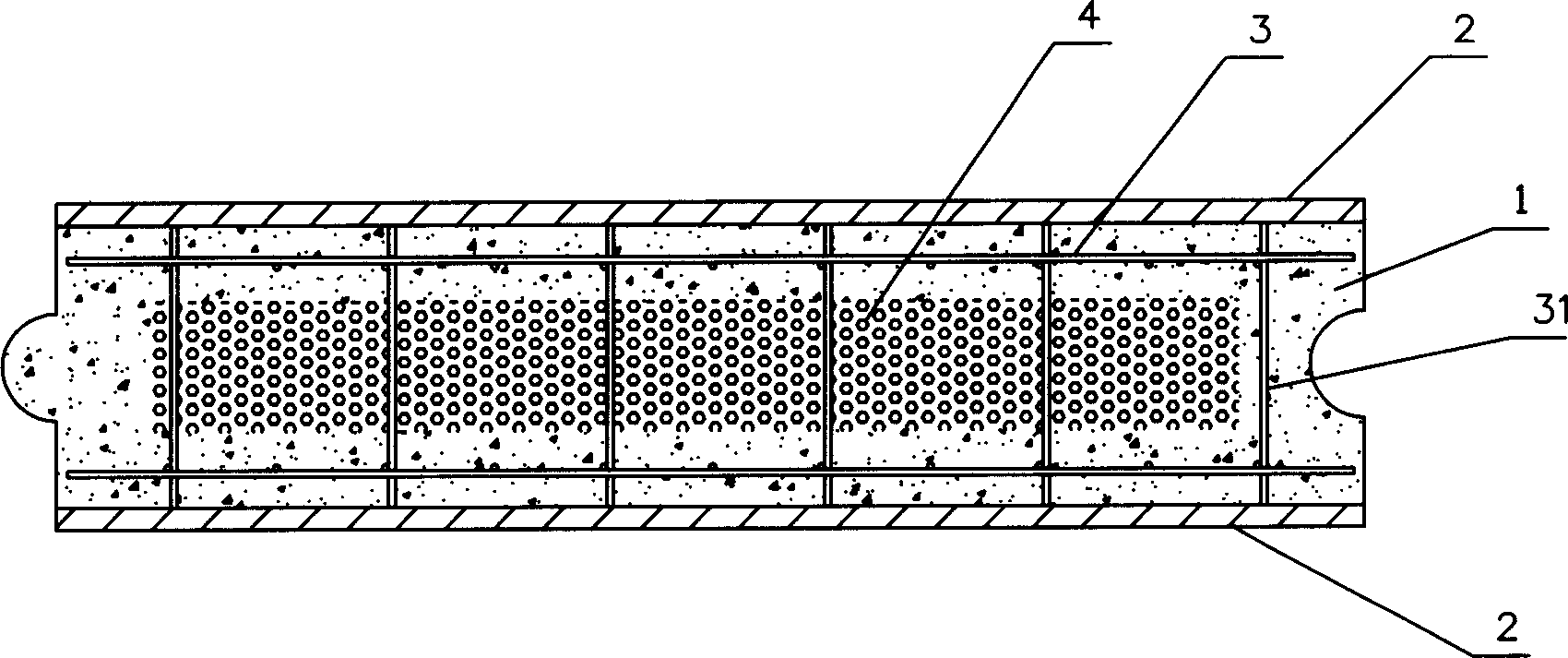

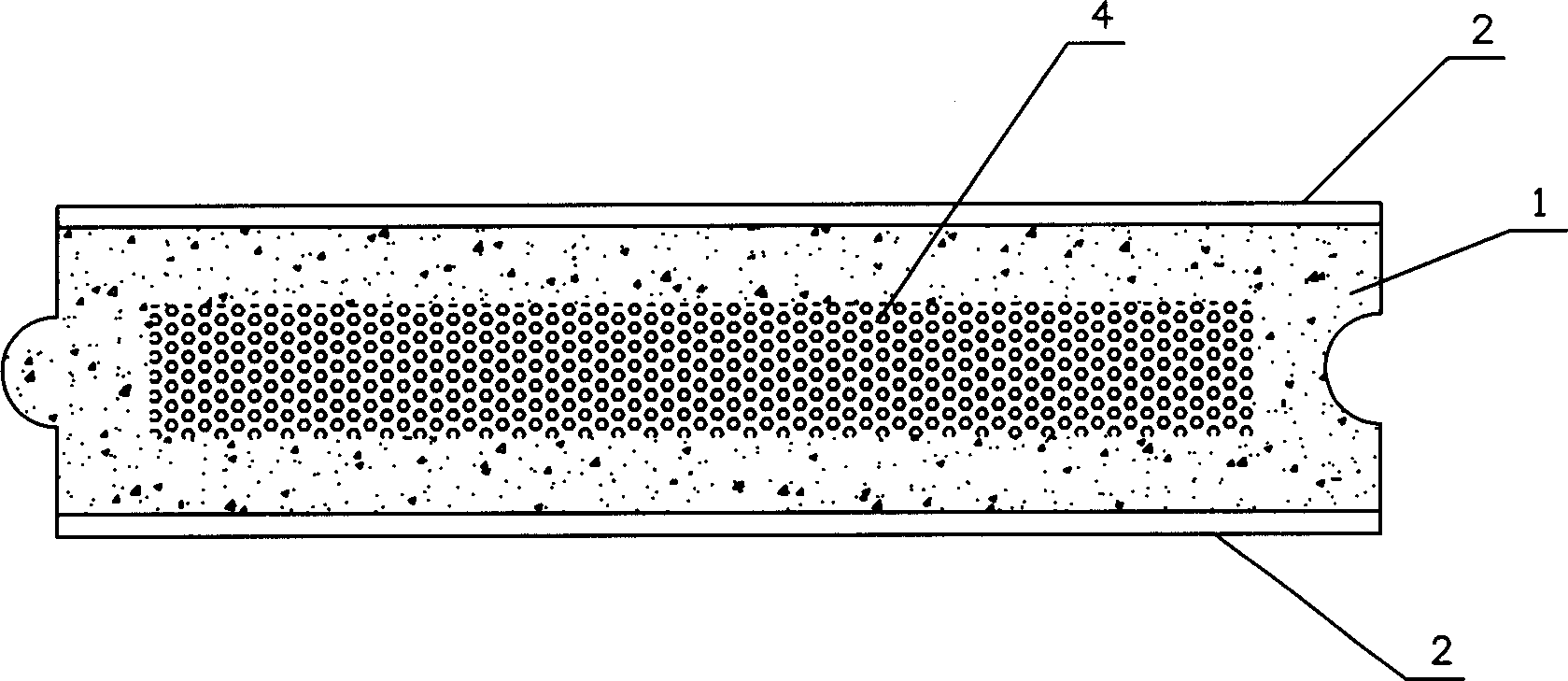

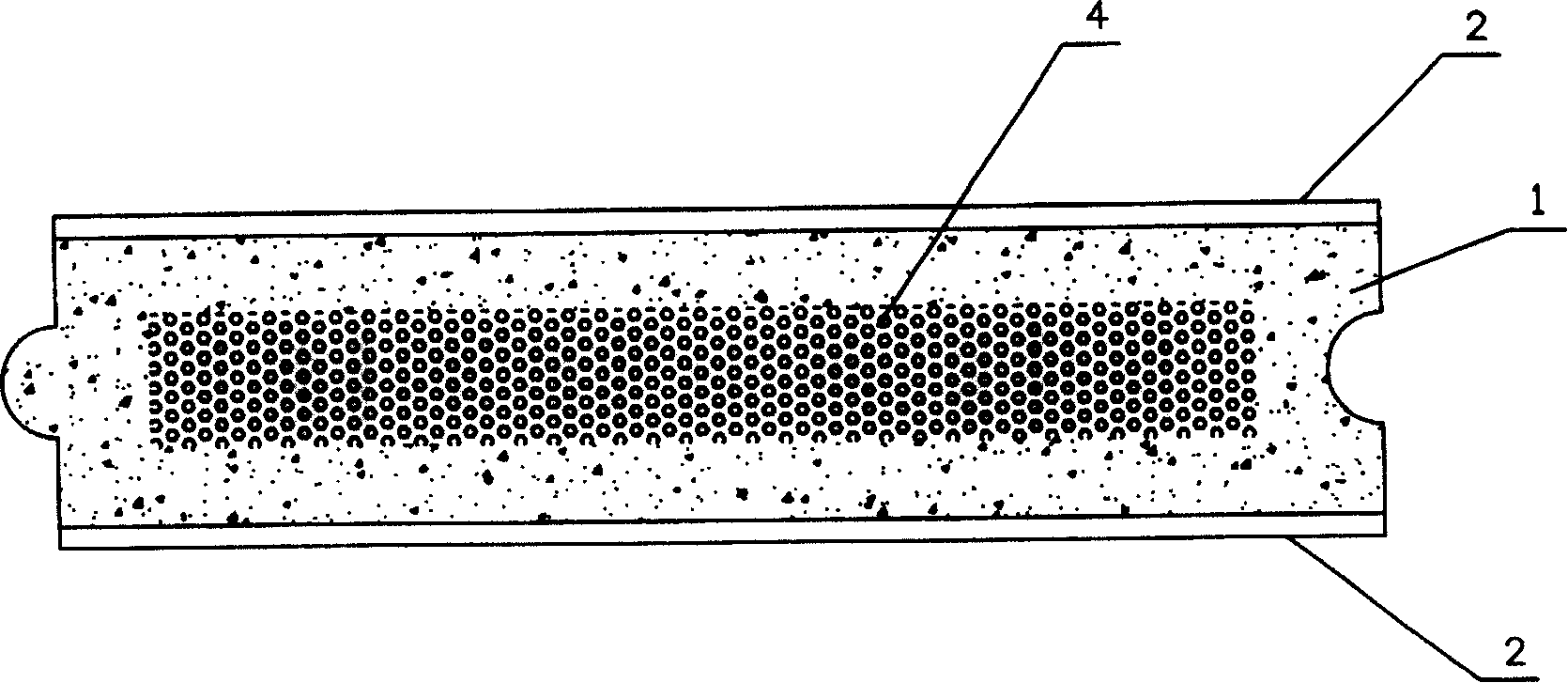

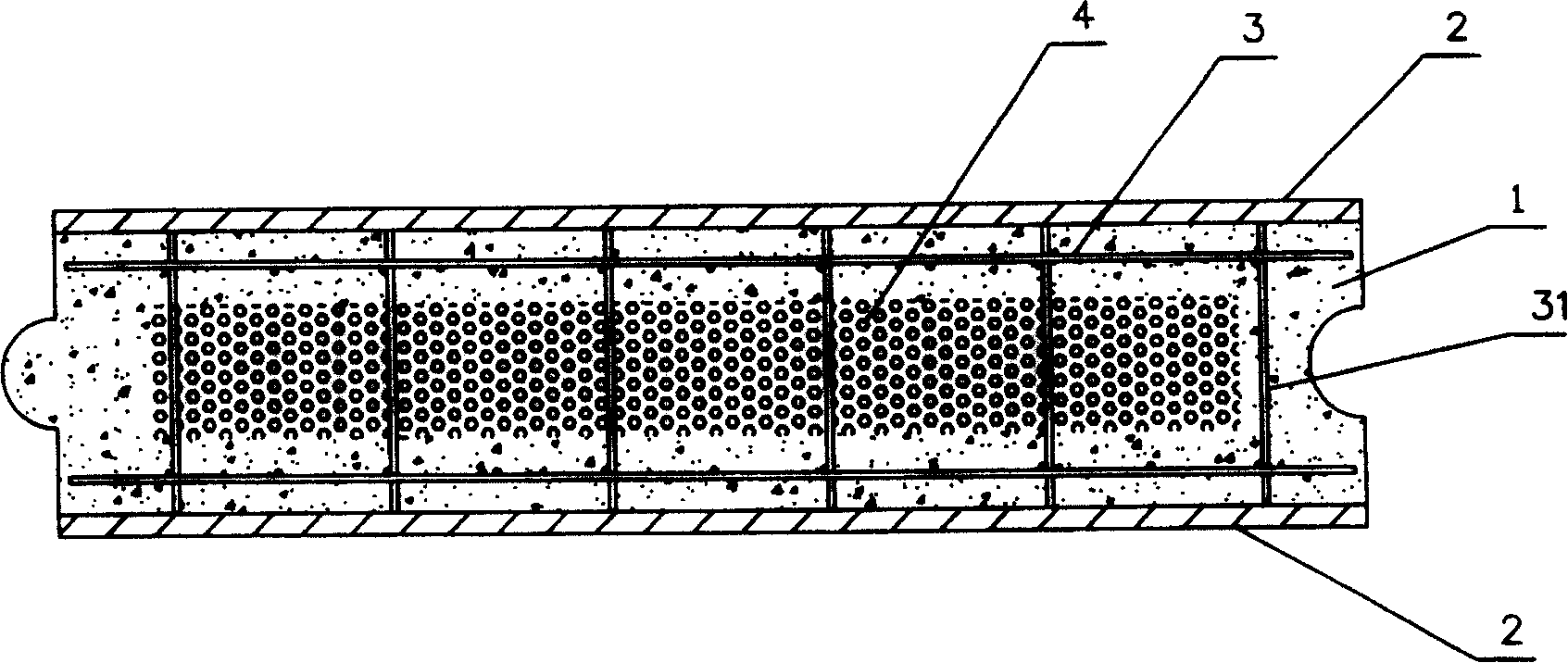

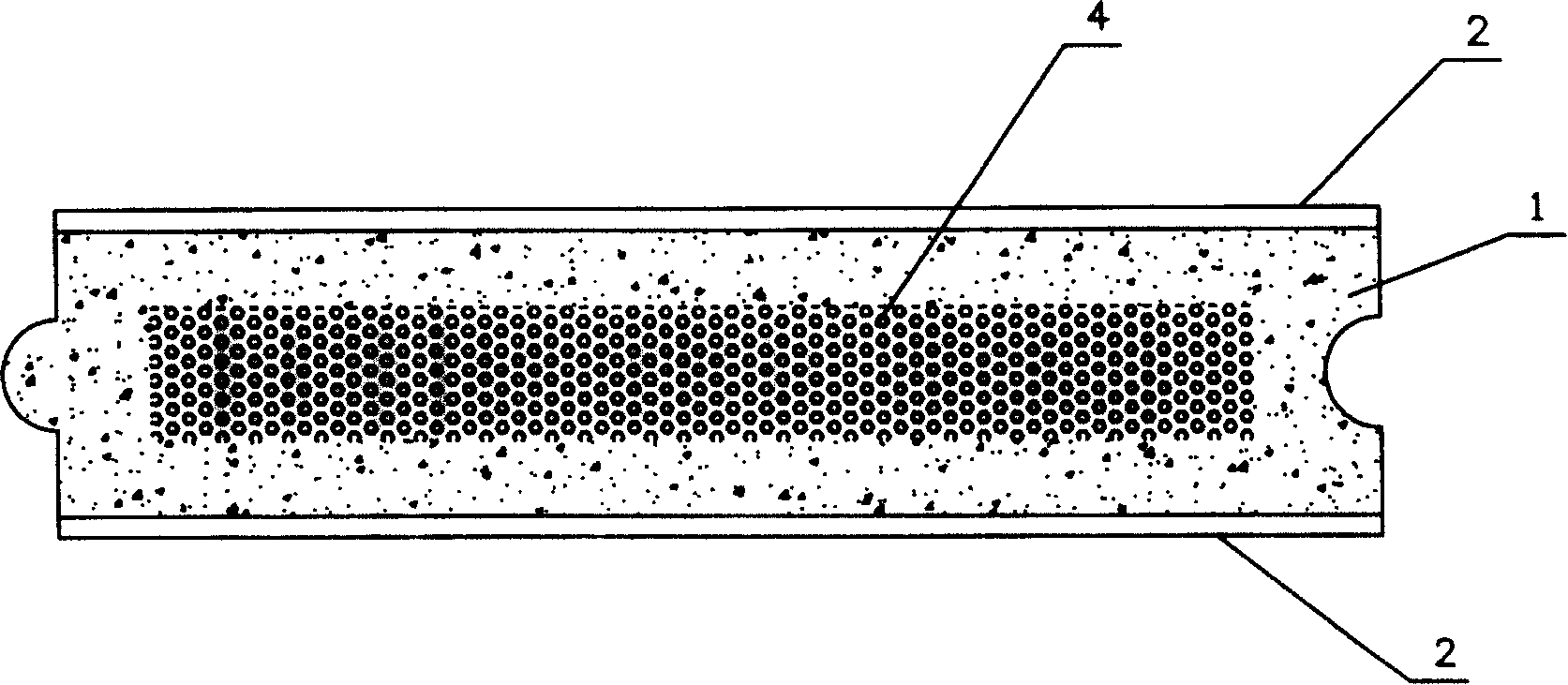

Light compound side fascia and its manufacturing method

ActiveCN1831270AReasonable structureSuperior performanceConstruction materialMouldsRebarHigh intensity

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

Ceramic fibre thermal-insulating boara and making method thereof

InactiveCN1385388AImprove mechanical propertiesImprove insulation effectHeat proofingFiberRefractory

The ceramic fibre heat-insulating board is made up by using ceramic fiber, inorganic binding agent, organic binding agent and additive according to the weight ratio of 40-60:20-30:0.5-1.5:20-30. Its preparation method includes the following steps: using ceramic fibre as base material, adding inorganic binding agent, organic binding agent, additive and water, fully making pulp, adopting mechanicalextrusion forming process or manual forming process to produce wet blank, and drying treatment at 100-150 deg.C so as to obtain the invented heat-insualting board which is high mechanical property and heat-insulating property, can be used as back liner of permanent furnace lining of various kiln and furnaces.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

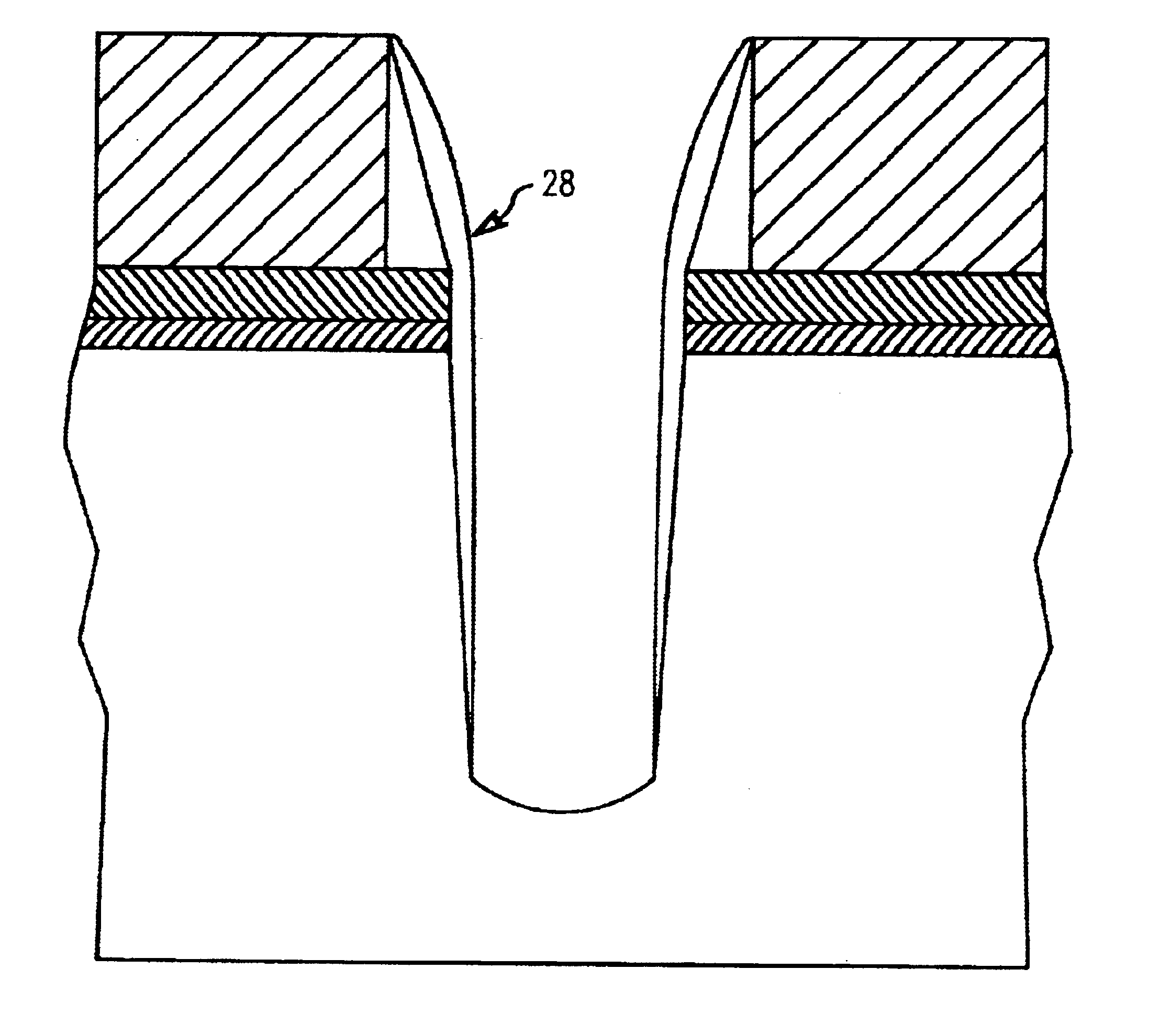

Method of etching high aspect ratio openings

InactiveUS6743727B2Smooth wallDecorative surface effectsSemiconductor/solid-state device manufacturingSilanesOxygen

Owner:INFINEON TECH AG +1

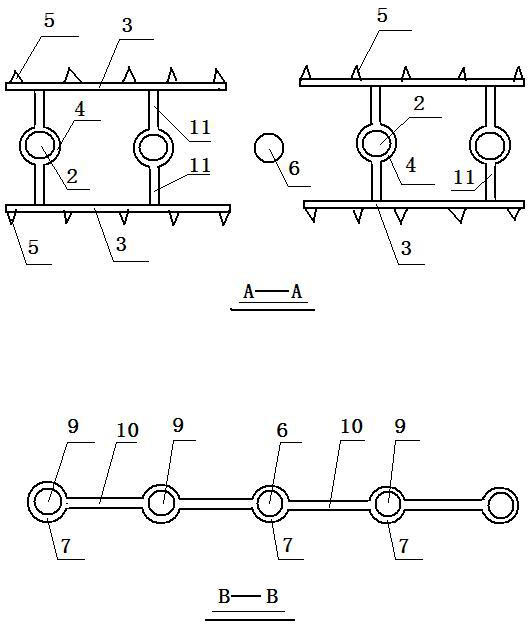

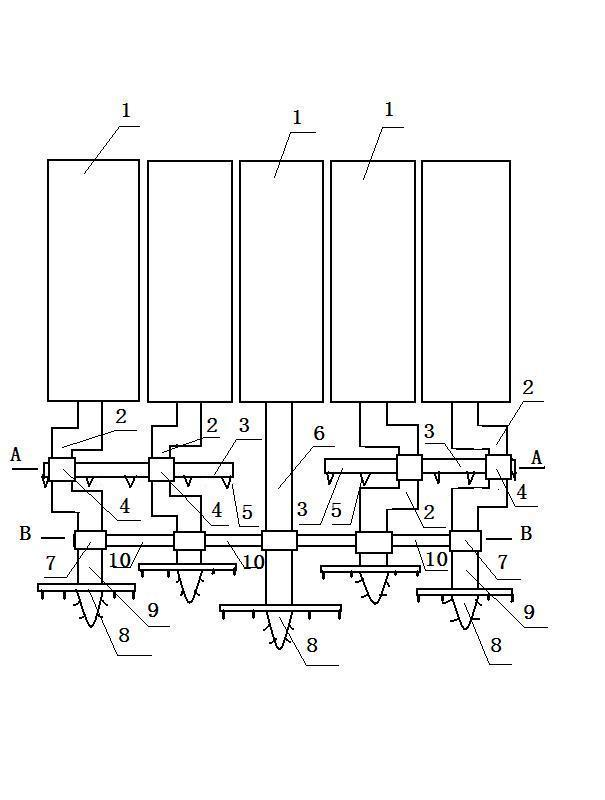

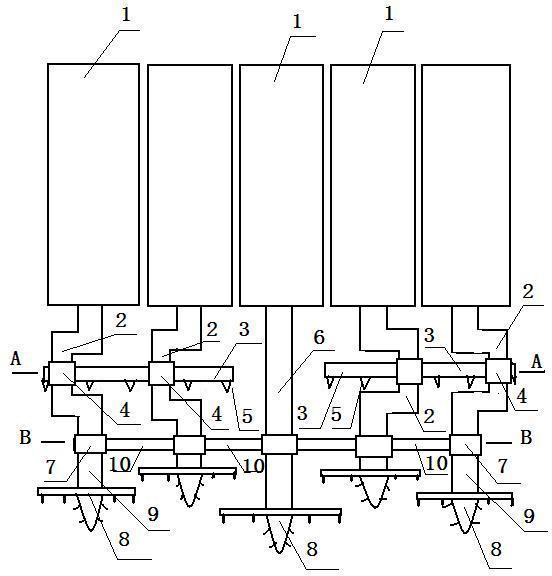

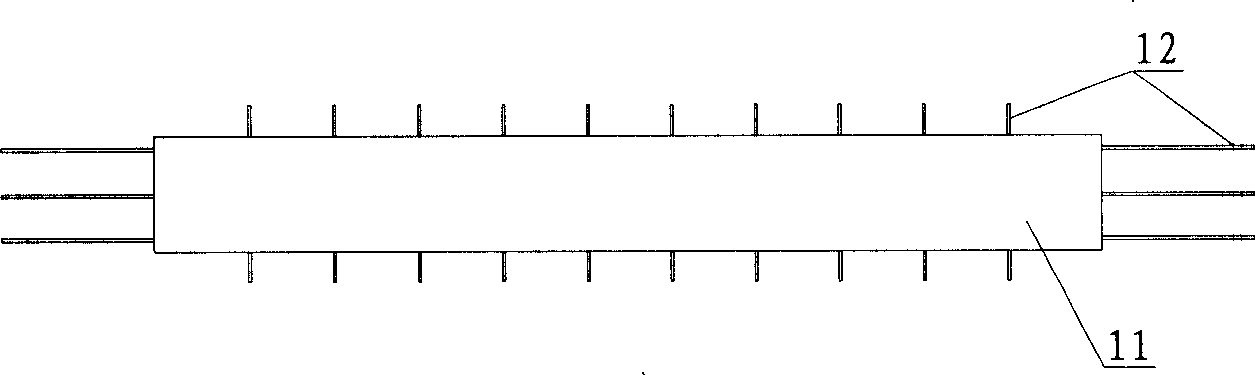

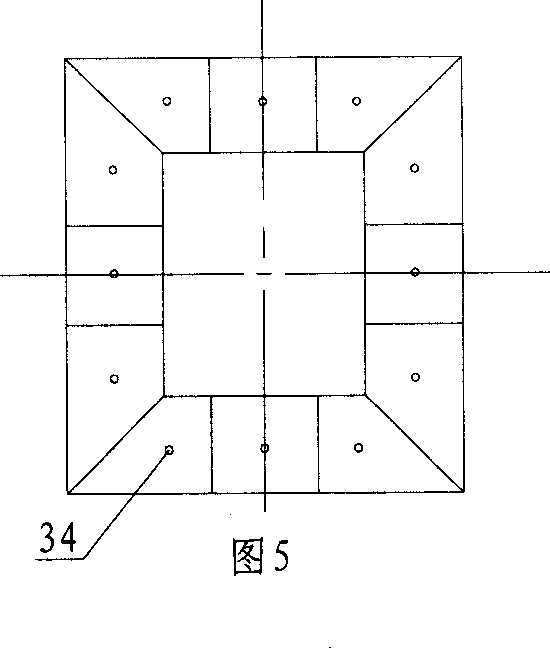

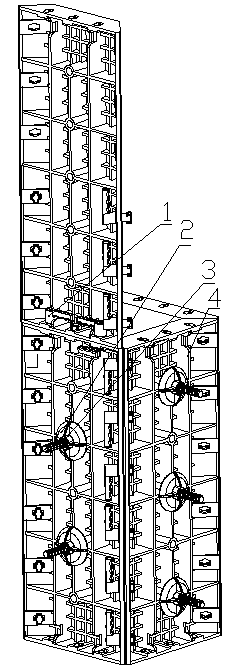

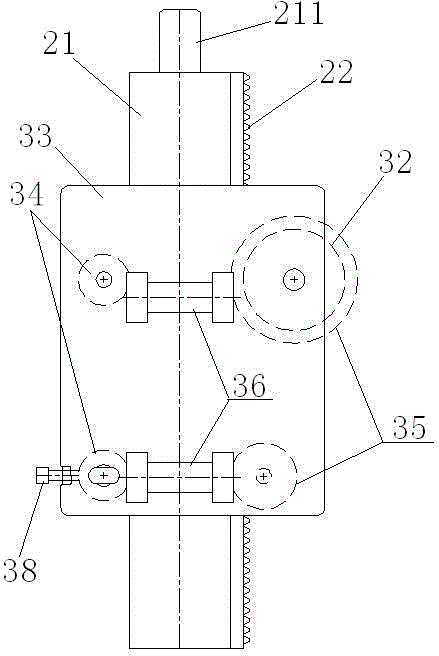

Multi-bit drill corrector

ActiveCN102691326AWall rulesSmooth wallSoil-shifting machines/dredgersStructural engineeringCrankshaft

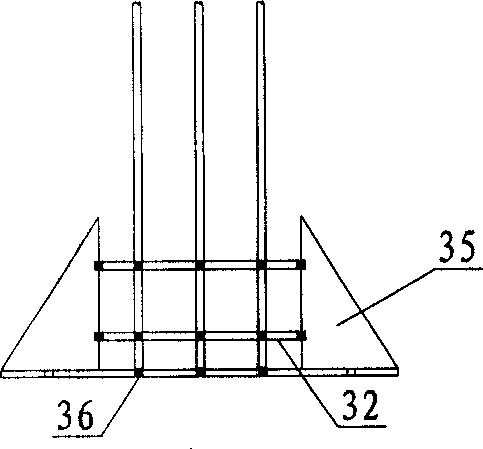

The invention relates to a multi-bit drill corrector for grooving for an underground concrete continuous wall. The multi-bit drill corrector comprises five motors, wherein the five motors are arranged side by side at the upper end of a multi-bit drill; a drill rod A is arranged at the lower end of the middle motor; a drill bit is arranged at the lower end of the drill rod A; crank shafts are arranged at the lower end of the four motors on two sides respectively; the lower ends of the crank shafts are connected with drill bits through drill rods B; sliding sleeves B are arranged on both the drill rod A and the drill rods B; and each sliding sleeve B is connected through a connecting rod A. The multi-bit drill corrector is characterized in that sliding sleeves A are arranged on the four crank shafts; the two sliding sleeves A on the left side are connected with two cutter arbors on the left side through left connecting rods B; and the two sliding sleeves A on the right side are connected two cutter arbors on the right side through right connecting rods B; and cutter bits are arranged on each cutter arbor.

Owner:张家港市欧微自动化研发有限公司

Prefabricated component for residenter house, prefabricated component house and its construction method

InactiveCN101368428AShort construction timeImprove performanceStrutsConstruction materialEarthquake resistanceInsulation layer

Prefabricated pieces for residential houses, a prefabricated house and a construction method thereof are disclosed. Crossbeams, wall boards, support posts are prefabricated according to design sizes; above prefabricated pieces are designed into different shapes according to needs; all the prefabricated pieces are provided with reinforced heads in advance, so during construction, the prefabricated house can be formed only by welding the reinforced heads of the prefabricated pieces arranged in advance, thus realizing the fabrication of a building in a factory; and the finished building is a frame structure and has earthquake-resistance. The house adopts a double-layer wall board; a heat insulation layer is arranged between the two layers of the wall board, so the house is cool in summer and warm in winter. The prefabricated pieces, the prefabricated house and the construction method thereof can greatly reduce construction period, save manpower and reduce fabrication cost.

Owner:徐尉

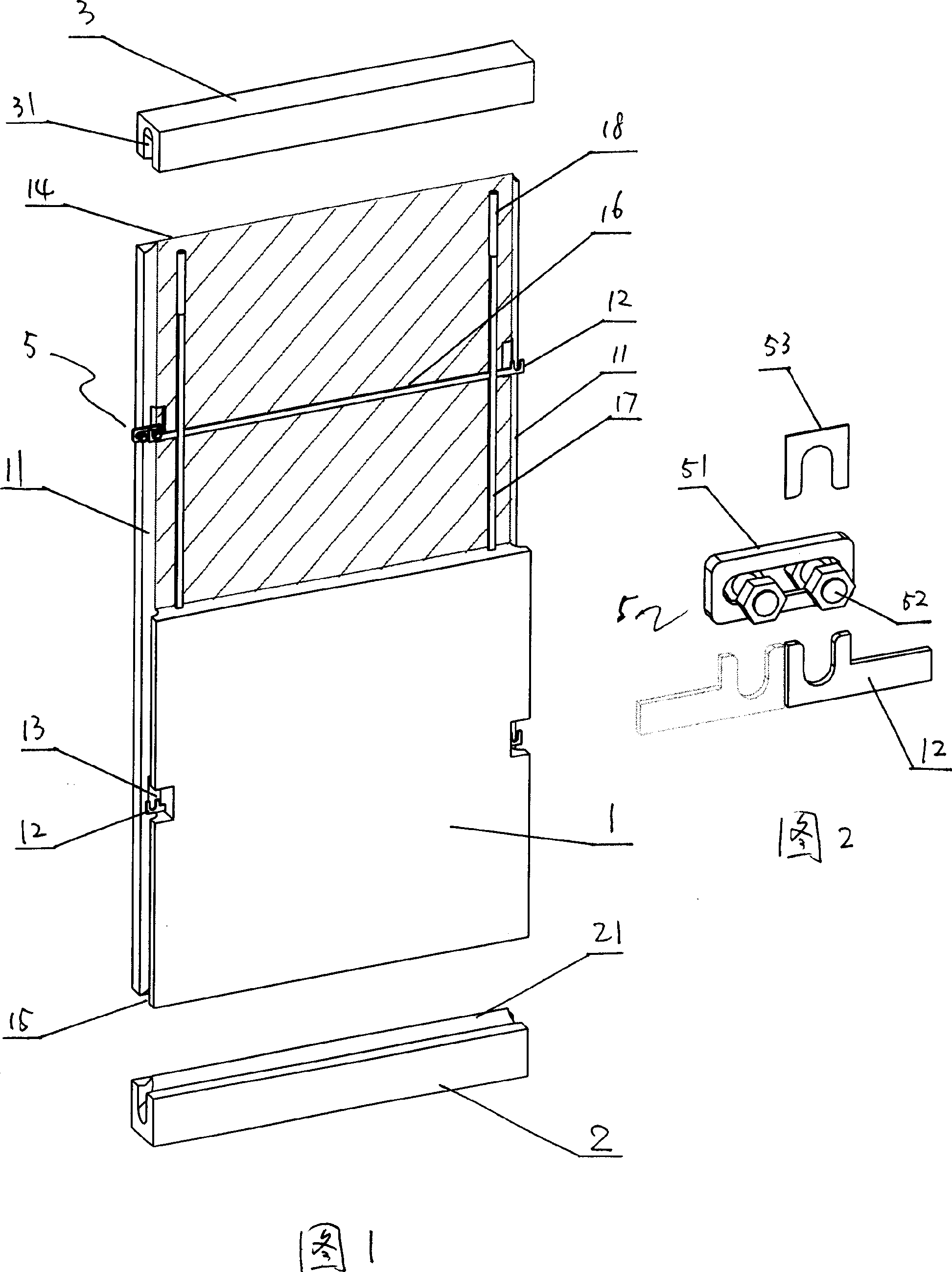

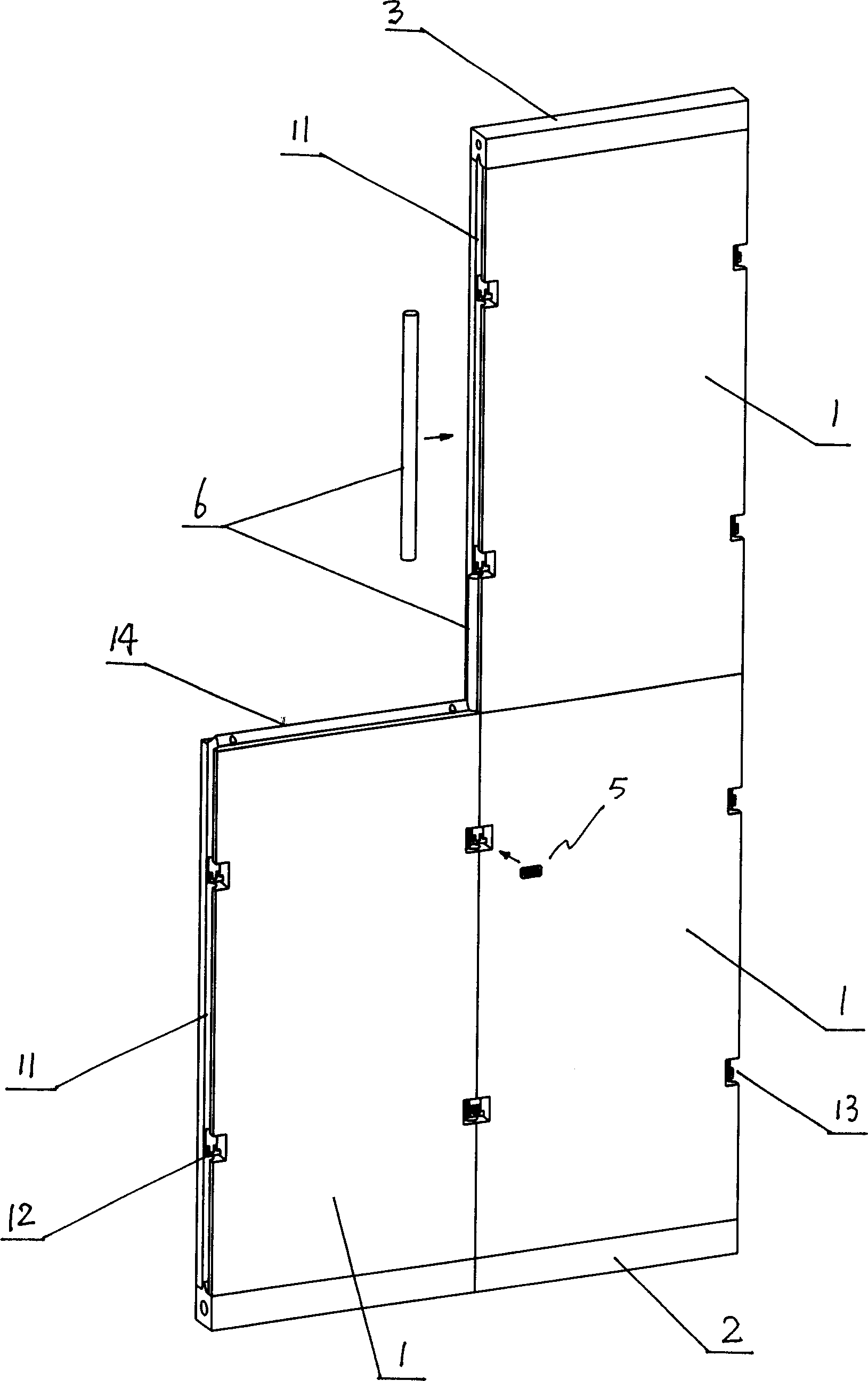

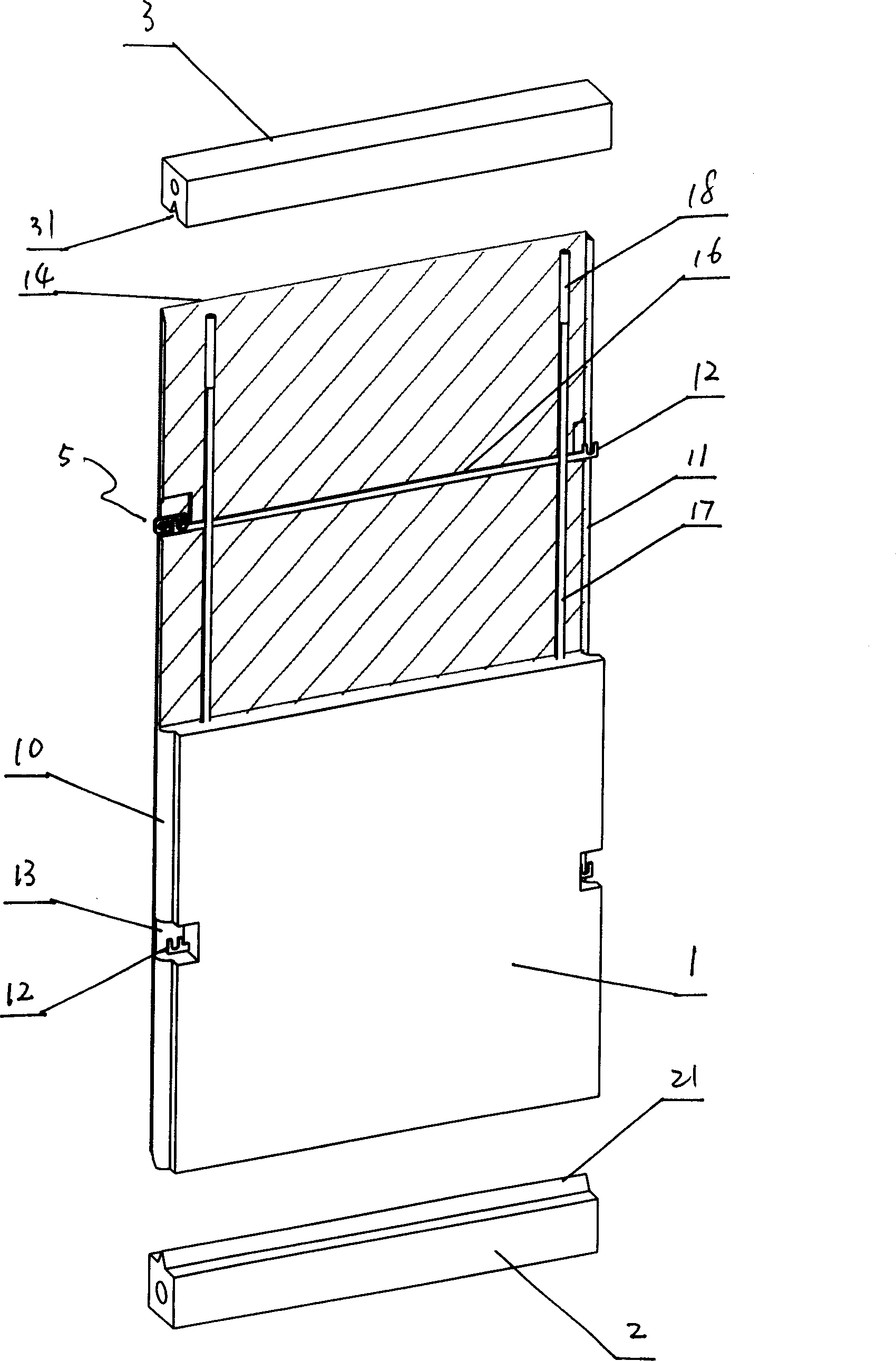

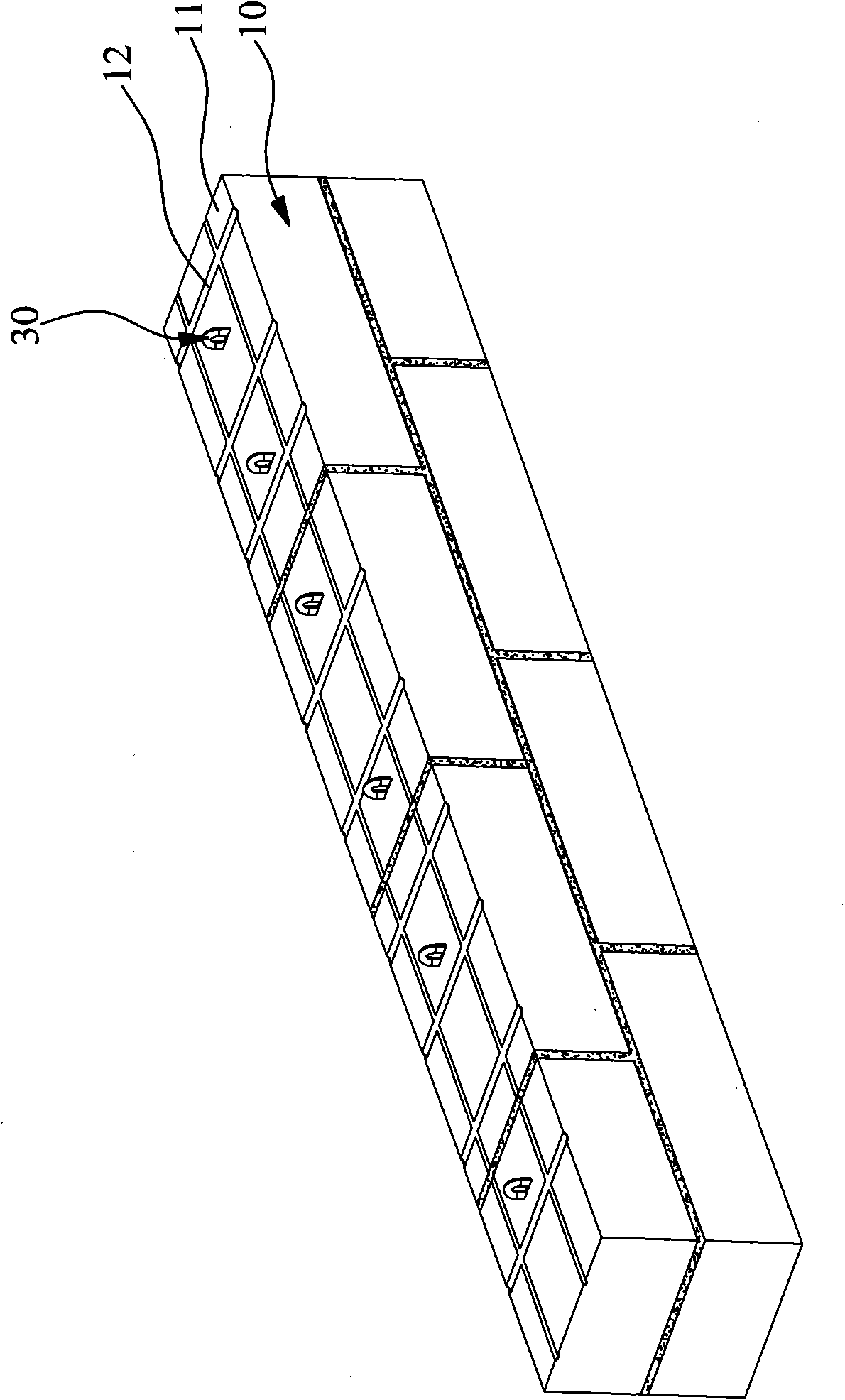

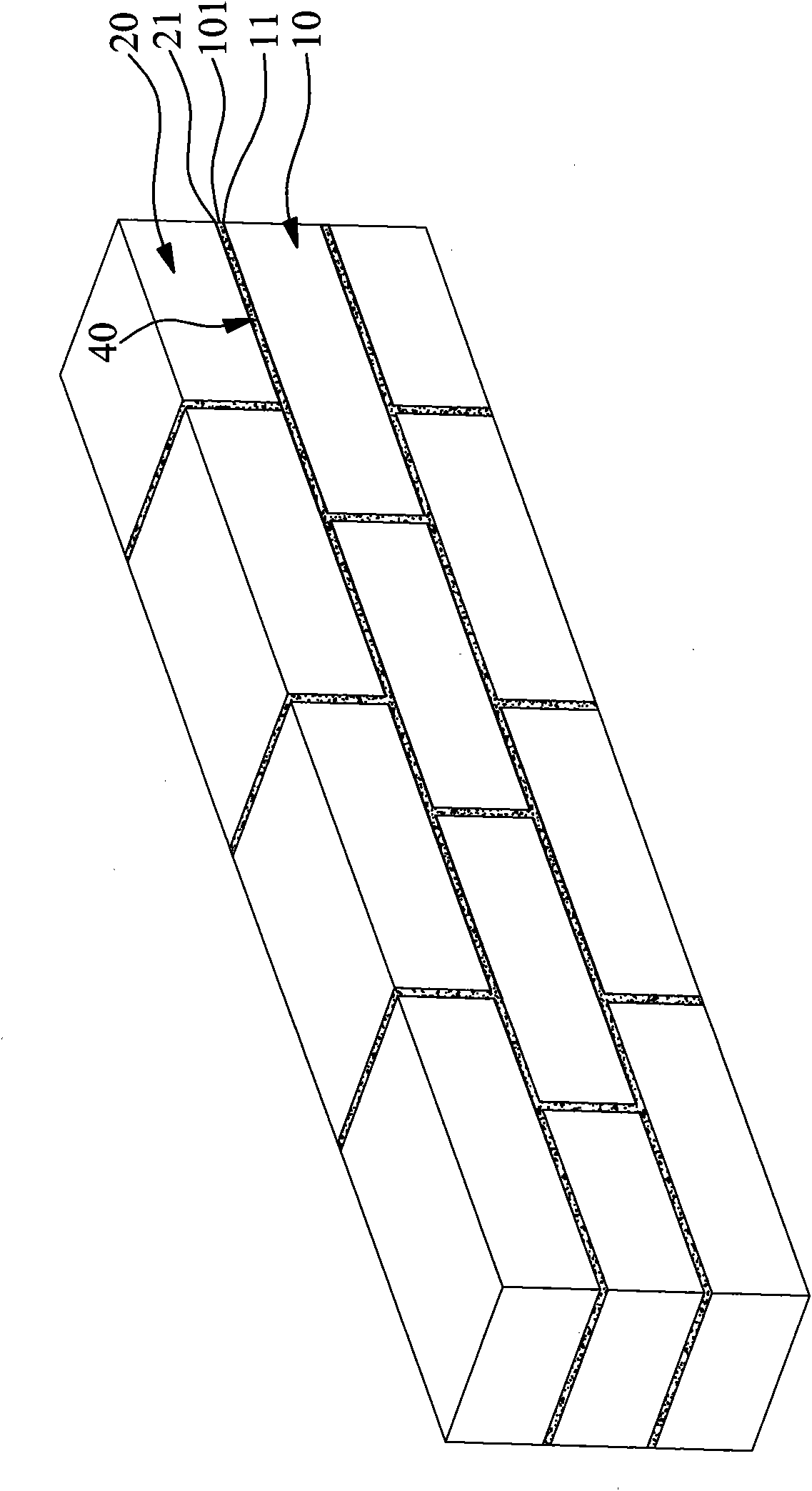

Assembled wall plate connected by metal connecting members

This invention relates to a sectioned wall plate associated by metal adapting piece, which comprises wall body, the selectable unit: lower bearing block and top block, characterized in that the vertical bilateral of the wall has symmetrical beard and metal adapting piece, and the upper and lower bilateral of the board has the intermeshing flange and beard; the wall has at least one horizontal reinforcement board used for connecting the metal adapting pieces in the two sides of the board, said adapting piece is U type clasp adapting piece, and the double bolt fastening assemblies are used to fit the adapting piece. When using, build up the wall as normal, and then use the connecting board assemblies to fasten the adapting pieces of two adjacent.

Owner:沈宪光

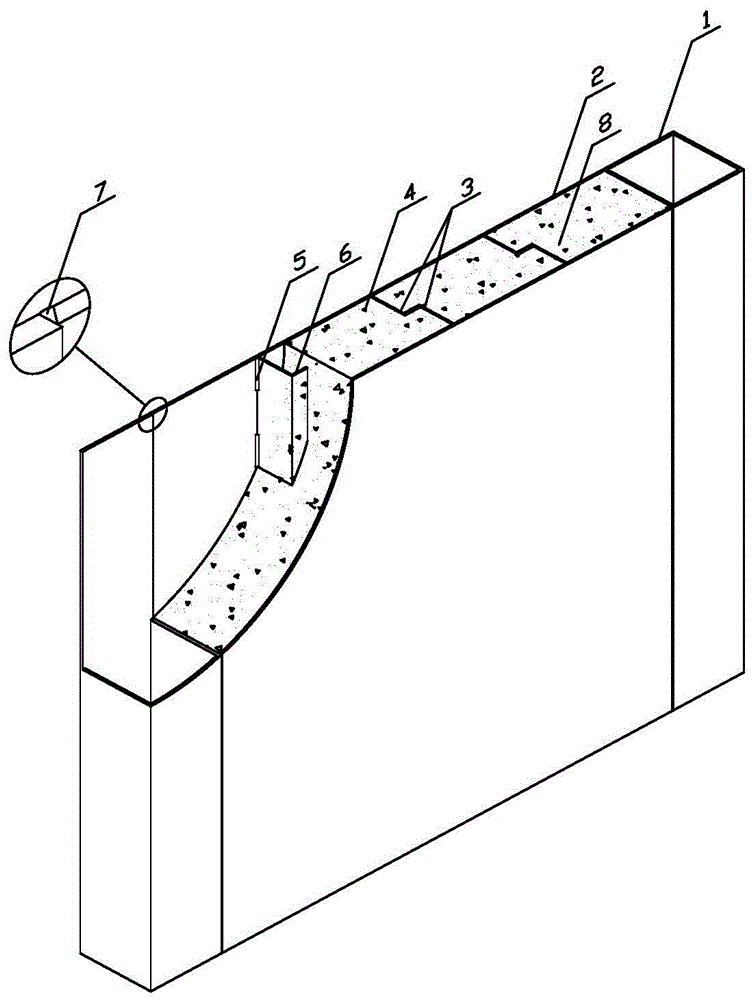

Pull-joint type double-steel-plate composite shear wall

The invention discloses a pull-joint type double-steel-plate composite shear wall, comprising steel pipe columns (steel pipe columns or concrete-filled steel tube columns) respectively arranged at the two ends, a pair of steel plates and at least one pull-joint type connecting piece. The pull-joint type connecting piece is firstly connected with the steel plates by staggered and intermittent one-side fillet welds in a welding way, and then a whole is assembled; the pull-joint type double-steel-plate composite shear wall has the advantages that the composite shear wall is simple in pull-joint structure, has a flat wall surface, and is less in welding workload, easy to operate and convenient to assemble; the stress performance of the composite shear wall is seldom affected by the welding quality since weld joints are positioned at construction parts; the composite shear wall is economical and safe; the steel plates and concrete are strong in cooperative work capability. A straight hook L shape, a sickle hook shape or hump hook shape can be adopted as the pull-joint way of the connecting piece, the pull-joint position can be positioned at the middle or side part of the thickness of the composite wall, and the pull-joint way is flexible and changeable, so that different engineering stress and use requirements are met. Riffled plates can be used as the wallboard steel plates and the pull-joint type connecting piece, so that the binding action between the wall steel plates and the concrete is effectively improved, and the co-working between steel components and the concrete is guaranteed.

Owner:HEFEI UNIV OF TECH +1

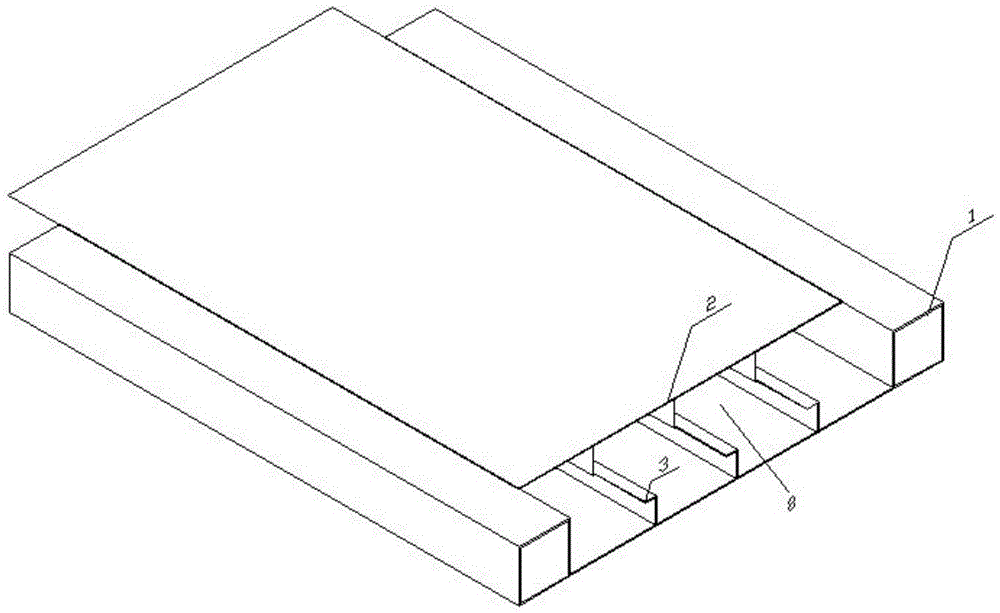

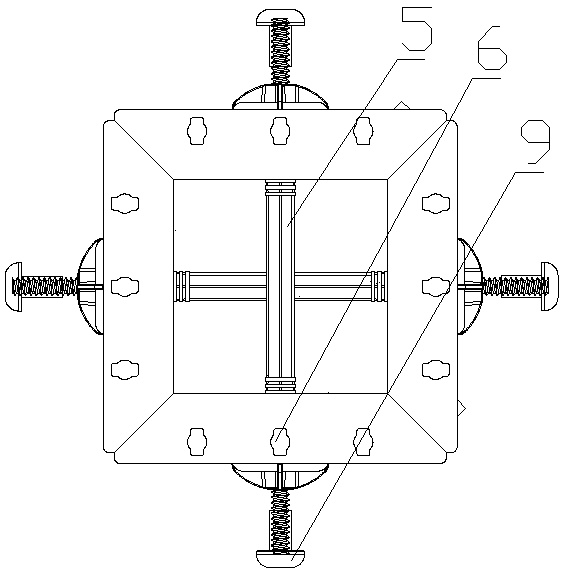

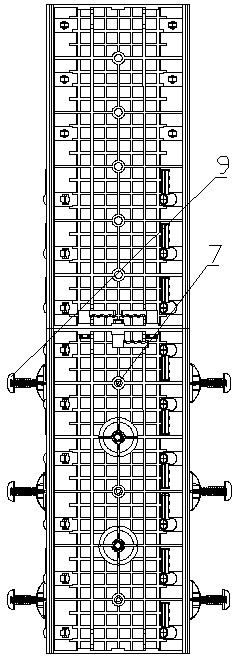

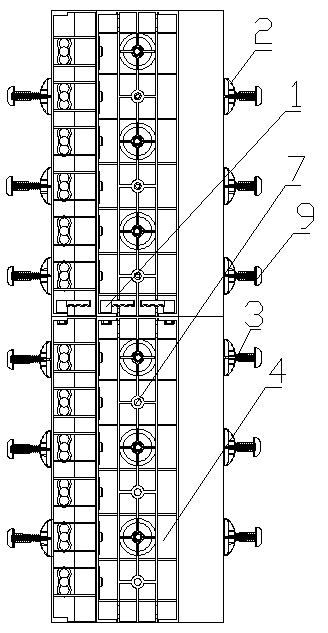

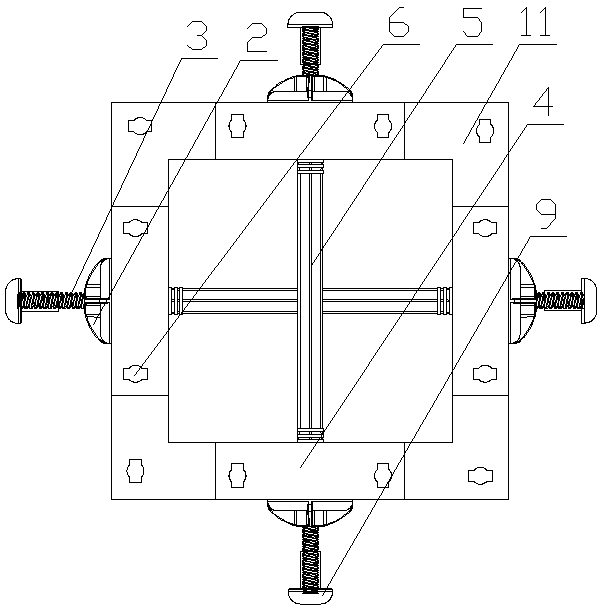

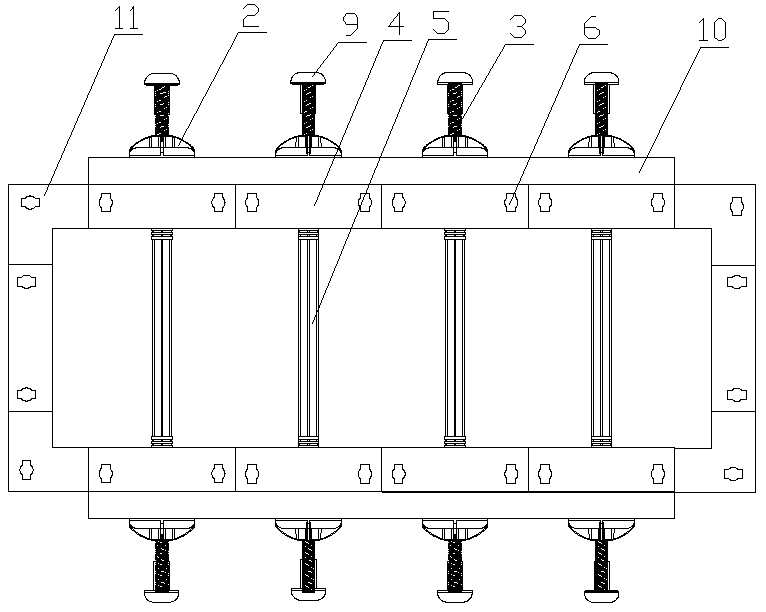

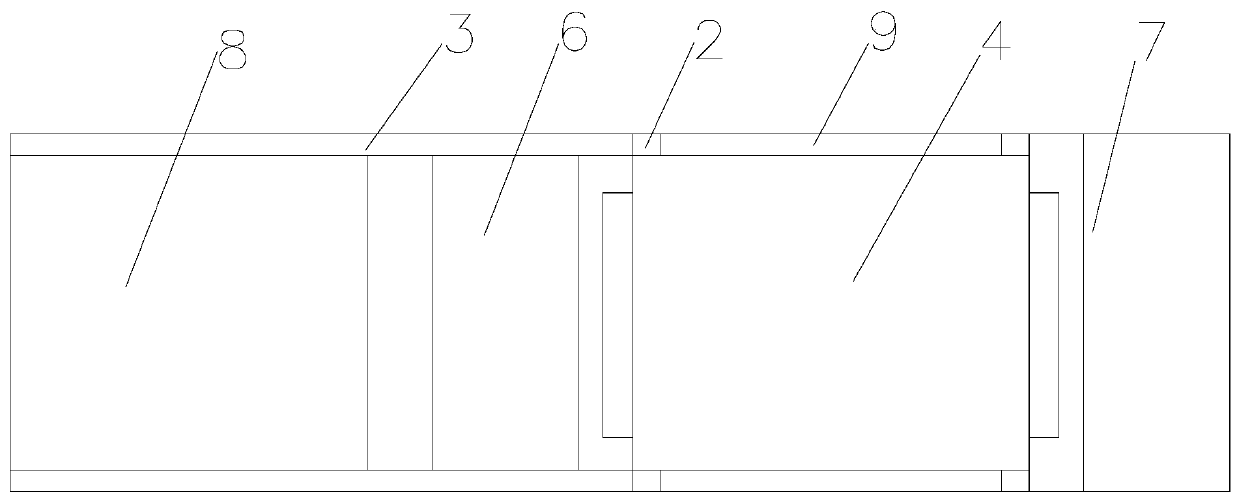

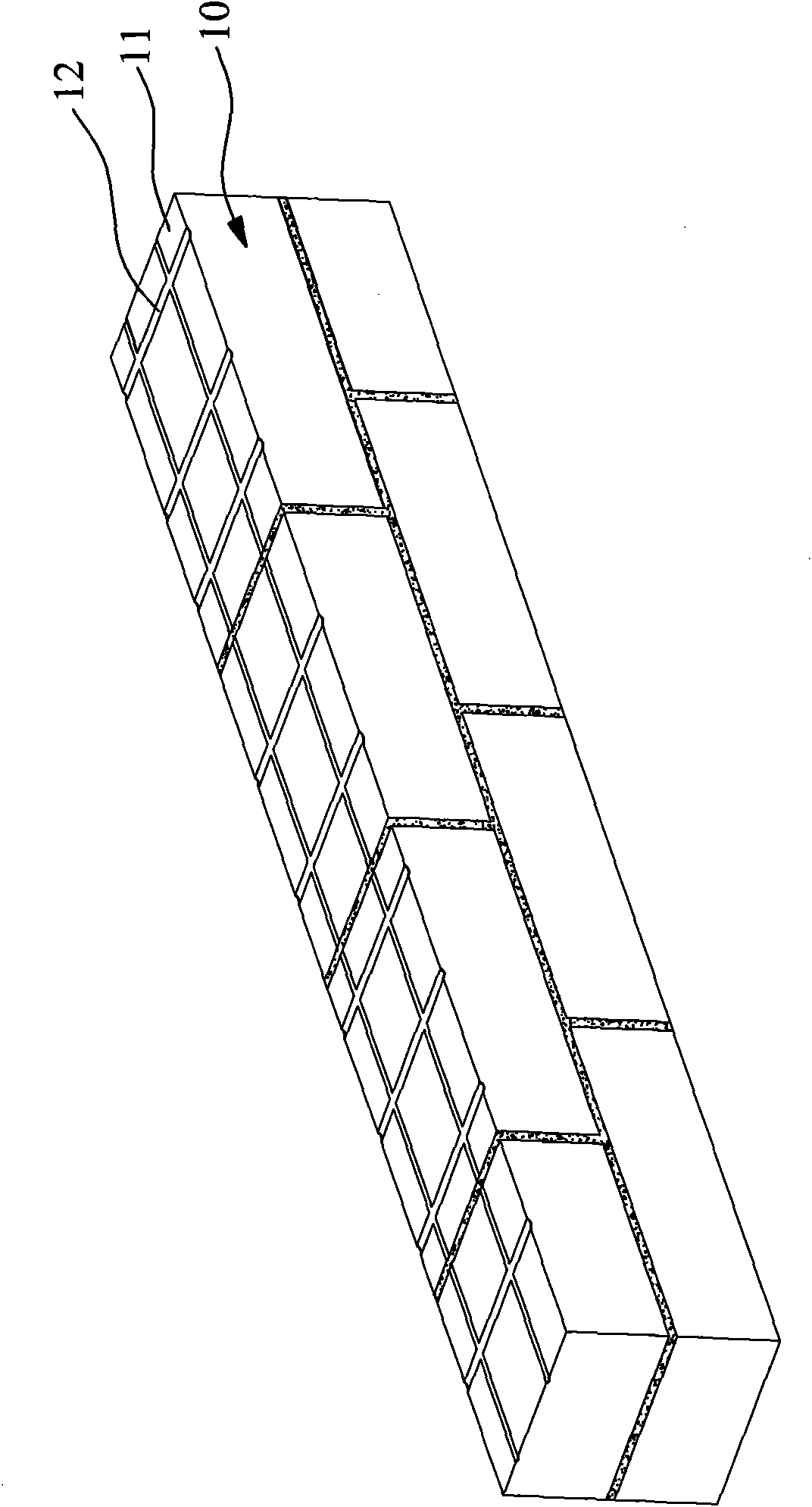

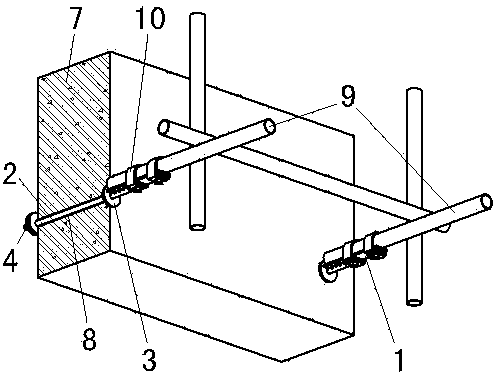

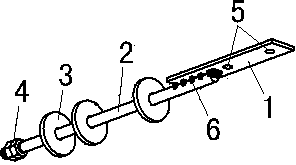

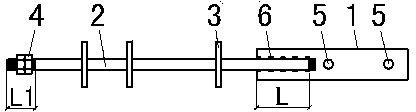

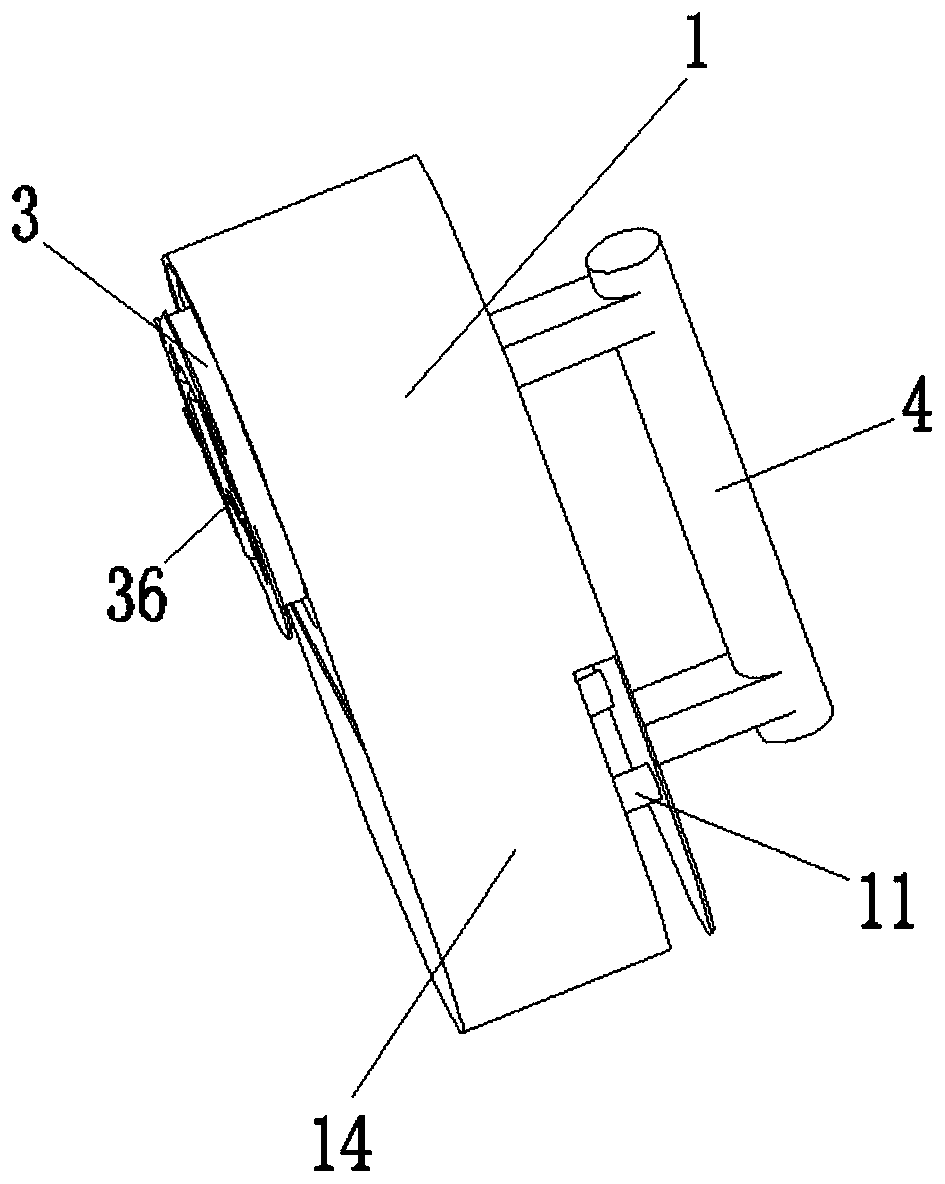

Quickly-clamped building template and concrete pouring device assembled by same

InactiveCN103243903AHigh reuse rateQuick installationAuxillary members of forms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringStructural engineering

Provided are a quickly-clamped building template and a concrete pouring device assembled by the same. The building template comprises a main body board and reinforcing ribs located on one side of the main body board deviating from the concrete surface. The reinforcing ribs on the edges of the main body board are provided with kidney-shaped through holes (6), and the middle of the main body board is provided with a through hole. The concrete pouring device comprises a plurality of building templates (4), two adjacent building templates (4) are tightly locked and connected together through handles (1) penetrating through the kidney-shaped through holes (6), and the two adjacent building templates (4) are tightly locked with screw plates (2) through screw rods (3) and support pipes (5) provided with hollow inner cavities, and the screw rods (3) penetrate through the hollow inner cavities of the support pipes (5).

Owner:HUNAN PUYUN INTELLIGENT TECH

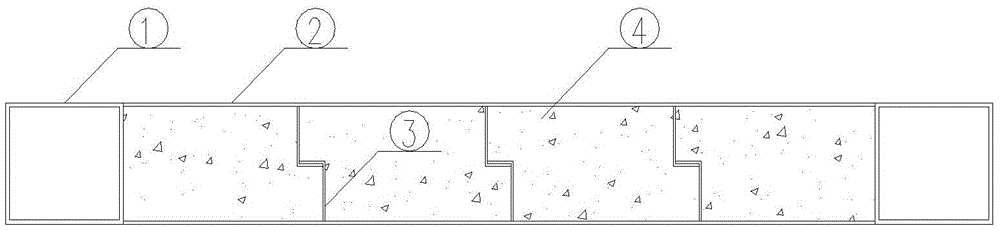

Quickly-clamped concrete pouring device

InactiveCN103243909AHigh reuse rateQuick installationForms/shuttering/falseworksArchitectural engineeringEngineering

A quickly-clamped concrete pouring device is provided with at least more than one bent building template (11), more than one flat building template (4), more than one screw rod (3), more than one support pipe (5) provided with a hollow inner cavity and more than one screw plate (2) in threaded connection with the screw rod (3). Adjacent building templates are detachably connected together, the middle portions of the flat building templates (4) are provided with through holes, two opposite flat building templates (4) and the screw plates (2) located on the outer sides of the flat building templates (4) are tightly locked through the screw rods (3) penetrating through the through holes and the support pipes (5) located between the two flat building templates (4), and the screw rods (3) penetrate through the hollow inner cavities of the support pipes (5).

Owner:HUNAN PUYUN INTELLIGENT TECH

Preparation method of environmentally-friendly interior wall putty powder

InactiveCN103351691AImprove water resistanceHigh bonding strengthFilling pastesSodium BentonitePolyvinyl alcohol

The invention discloses a preparation method of environmentally-friendly interior wall putty powder. The preparation method comprises the following steps: S1. performing gelatinization treatment on cassava starch through a conventional method to obtain gelatinized cassava starch for future use, and treating calcium bentonite through sodium carbonate to obtain sodium bentonite for future use; S2. putting the following ingredients into a diffuser provided with a stirrer: 15-18 parts of white cement, 3-5 parts of sierozem powder, 6-8 parts of gelatinized cassava starch, 22-26 parts of heavy calcium carbonate powder (320 meshes), 3-5 parts of expanded perlite (200 meshes), 1.5-2.5 parts of polypropylene fiber (3-5mm), 2-4 parts of polyvinyl alcohol, 2-3 parts of sodium carboxymethyl cellulose, 2.5-3.5 parts of three-grade fly ash, 5-7 parts of sodium bentonite and 1-2 parts of sodium fluosilicate, and stirring the ingredients for 10-20 minutes; and S3. adding 2-4 parts of dispersing agent, 0.4-0.6 parts of antifoaming agent and 0.2-0.4 parts of parts of mildew preventive, and stirring for 30-40 minutes. The putty prepared by the preparation method disclosed by the invention is anti-cracking, free of peeling, dropping and toxic and harmful substances and is capable of properly perfecting the environmental quality.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Powder metallurgy fabrication method of hollow metal sphere

The invention discloses a powder metallurgy fabrication method of a hollow metal sphere, which comprises the following steps of placing a polystyrene sphere in a centrifugal mold, preparing slurry 1 with metal powder, adhesive solution and a defoaming agent, pouring the slurry 1 into the centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in an oven for drying together with the centrifugal mold, preparing slurry 2 with the metal powder, the adhesive solution and the defoaming agent, pouring the slurry 2 into the dried centrifugal mold, centrifuging, putting the centrifuged polystyrene sphere in the oven for drying together with the centrifugal mold, taking out the dried polystyrene sphere from the centrifugal mold, embedding the polystyrene sphere into alumina packing, and then putting in a vacuum furnace for pyrolysis and sintering, thereby obtaining the hollow metal sphere. The method is reasonable in design, simple in process and low in cost. The hollow metal sphere fabricated by the fabrication method has the advantages of uniform, smooth and complete spherical shell wall thickness, facilitation of sphere dimension selection, easiness in overall structure control and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

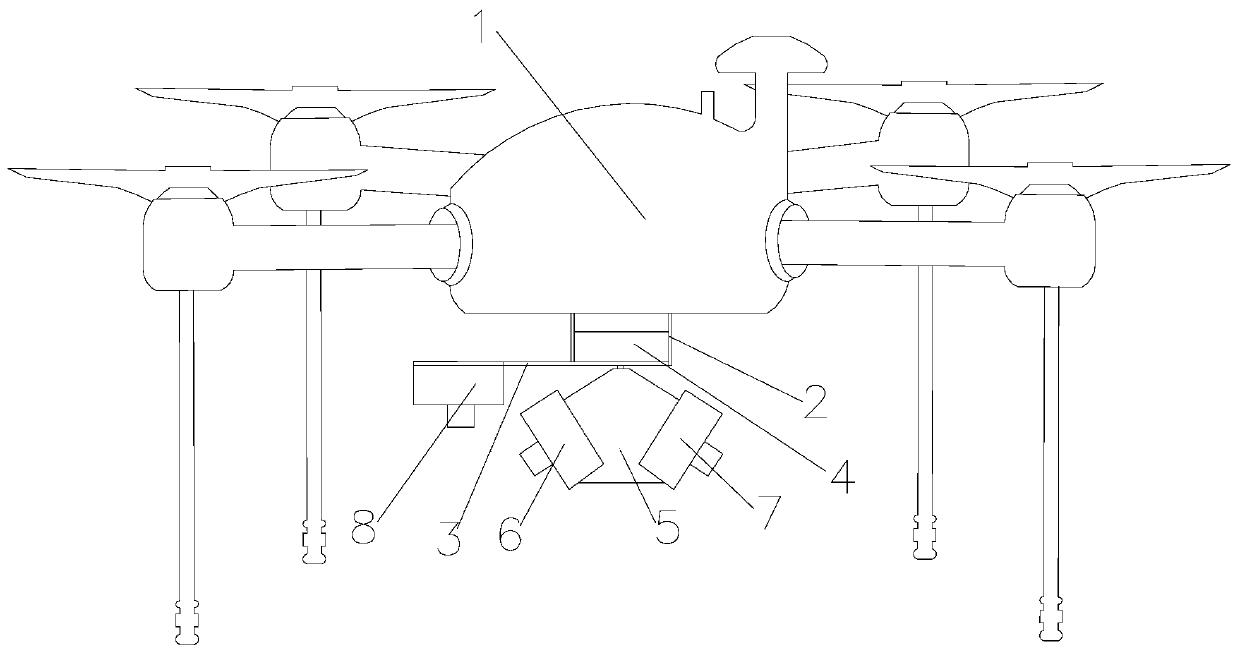

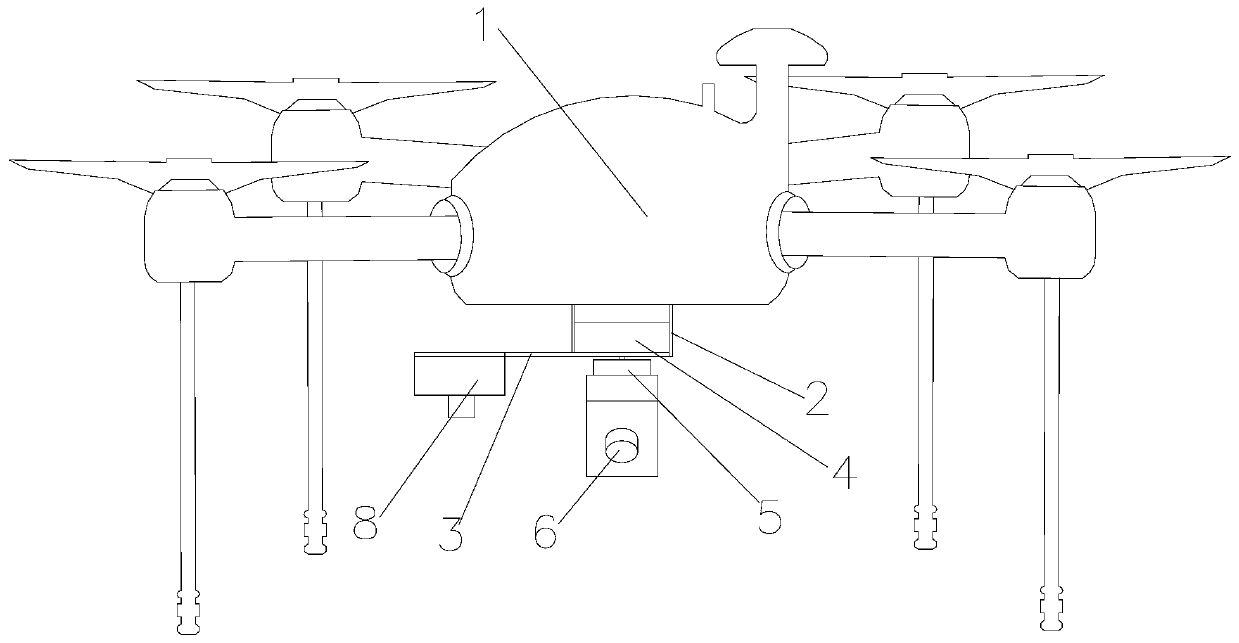

High-precision real estate measurement method based on multi-rotor unmanned aerial vehicle

InactiveCN110487253AEasy to useAchieve acquisitionAircraft componentsPicture taking arrangementsMeasurement deviceData acquisition

The invention discloses a high-precision real estate measurement method based on a multi-rotor unmanned aerial vehicle. The method comprises the following steps: 1, a multi-rotor unmanned aerial vehicle high-precision real estate measurement device is constructed; 2, photo control points are arranged and the geographic coordinates of the photo control points are obtained; 3, route planning is carried out; 4, data acquisition is carried out; 5, data processing is carried out; 6, a live three-dimensional model for a to-be-measured real estate measurement area is established; 7, mapping is carried out; and 8, precision check is carried out. The multi-rotor unmanned aerial vehicle is used to carry an oblique camera and a vertical camera to acquire high-definition three-dimensional image data,the live three-dimensional model is generated, naked-eye three-dimensional mapping is carried out in the live three-dimensional model, the real estate geographic information is rapidly obtained, the labor intensity and the workload of operators are greatly reduced, and the efficiency is high.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

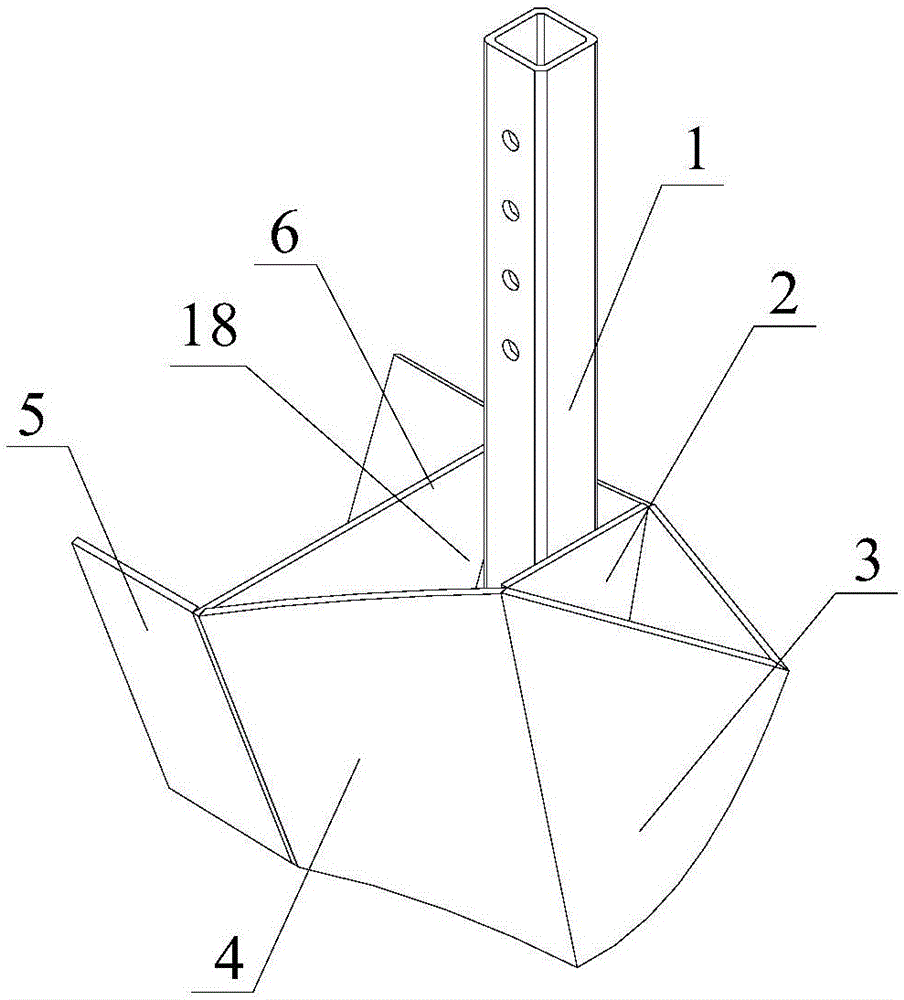

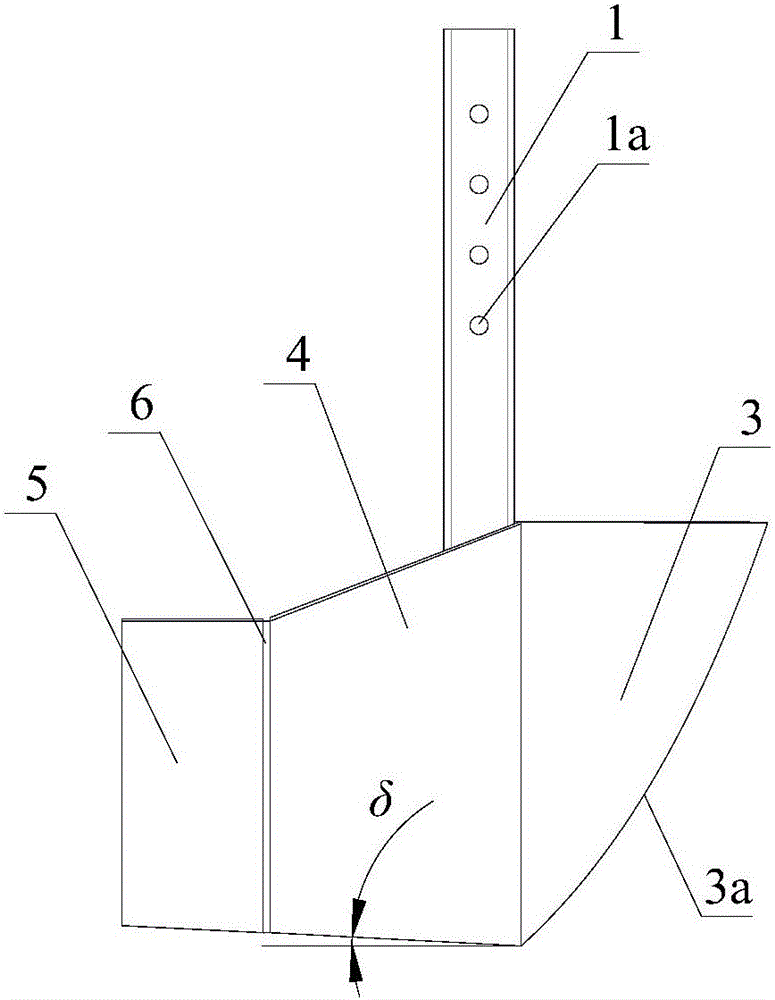

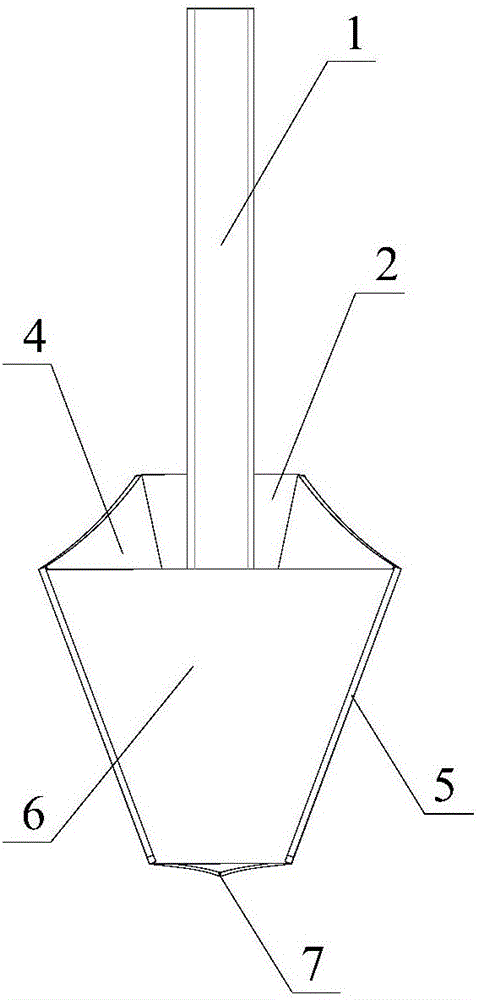

Boat furrow forming device for synchronous furrowing in seeding

ActiveCN106105500AInhibit refluxMeet the requirements for planting furrowsConstructionsSoil drainageEngineeringMoisture

The present invention discloses a boat furrow forming device for synchronous furrowing in seeding, comprising a plow post and a forming frame for mounting the plow post; the forming frame includes two soil breaker plates, two shaping plates and two soil flattening plates, intersecting curves of soil breaking surfaces of the two soil breaker plates are edge curves, and every two of the two soil breaker plates, the two shaping plates and the two soil flattening plates are arranged symmetrically along a plane of the edge curves; the edge curves are exponential function curves, and surfaces of the two shaping plates are each a plow body surface. Furrows are formed through the action of the soil breaker plates, shaping plates and soil flattening plates upon soil, multiple experiments show that made furrows are trapezoidal furrows having clean bottom, smooth walls and uniform depth, and soil reflow can be effectively inhibited; during operation for viscous heavy caked high-moisture-content soil, the boat furrow forming device shows good trafficability, blocking and adhesion during equipment and soil acting are overcome, and the boat furrow forming device is convenient to mount to a combine harvester for use.

Owner:HUAZHONG AGRI UNIV

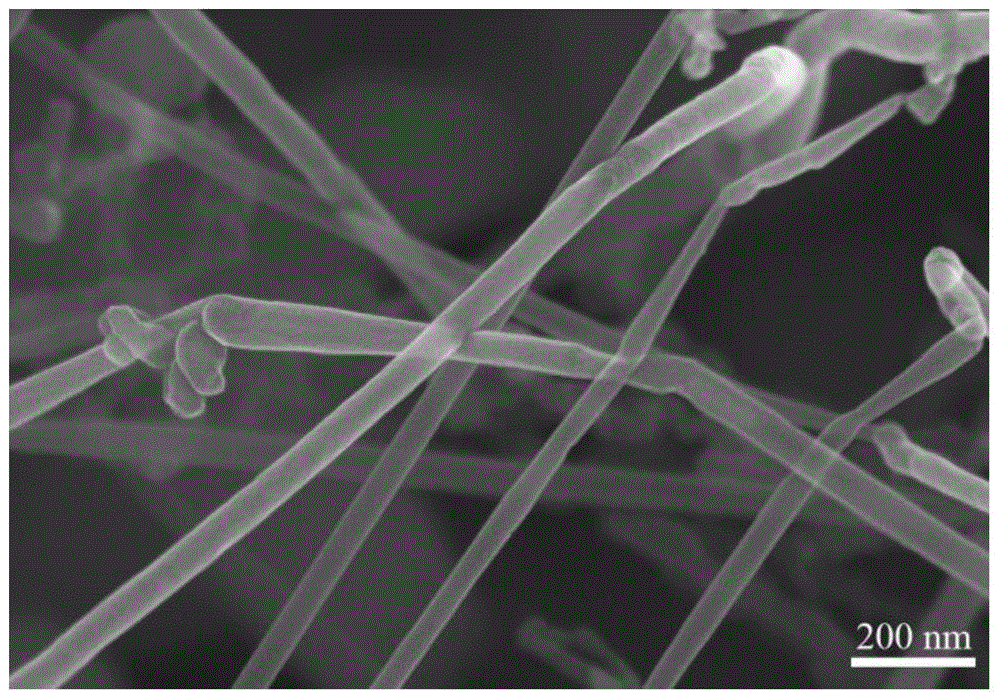

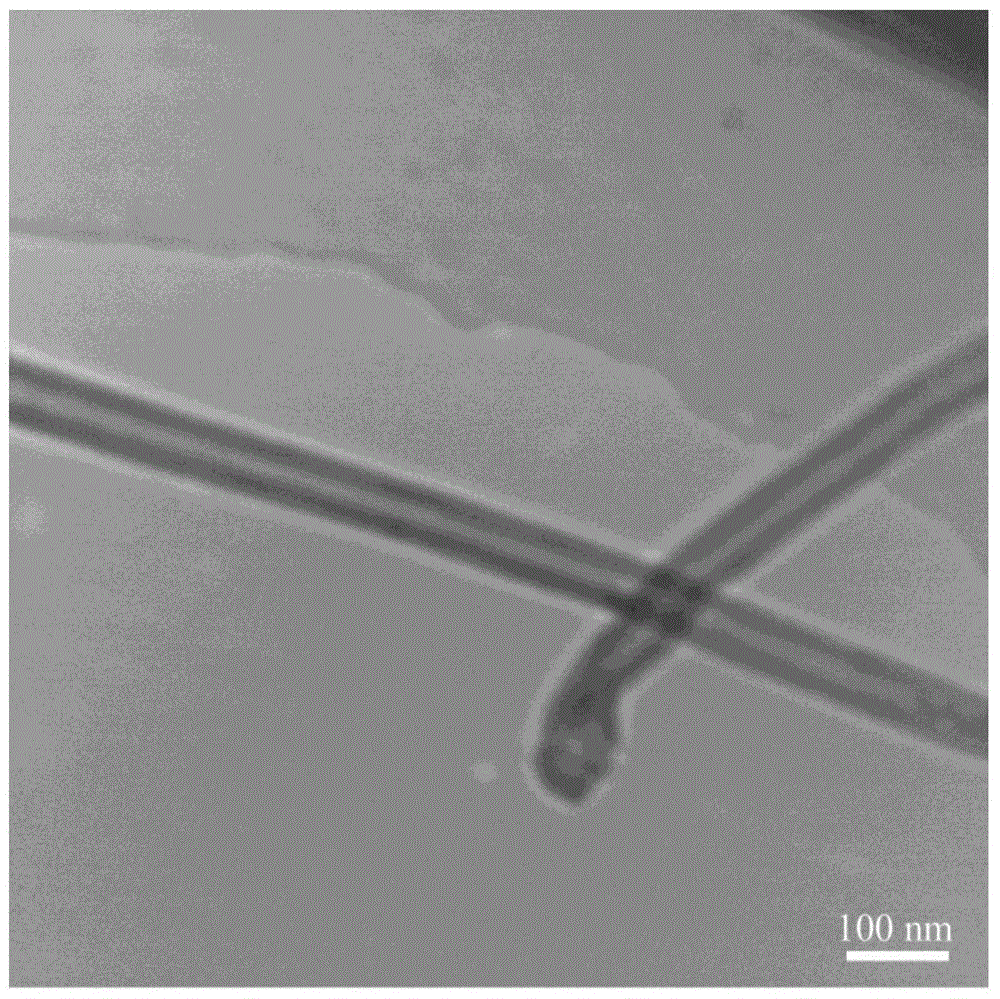

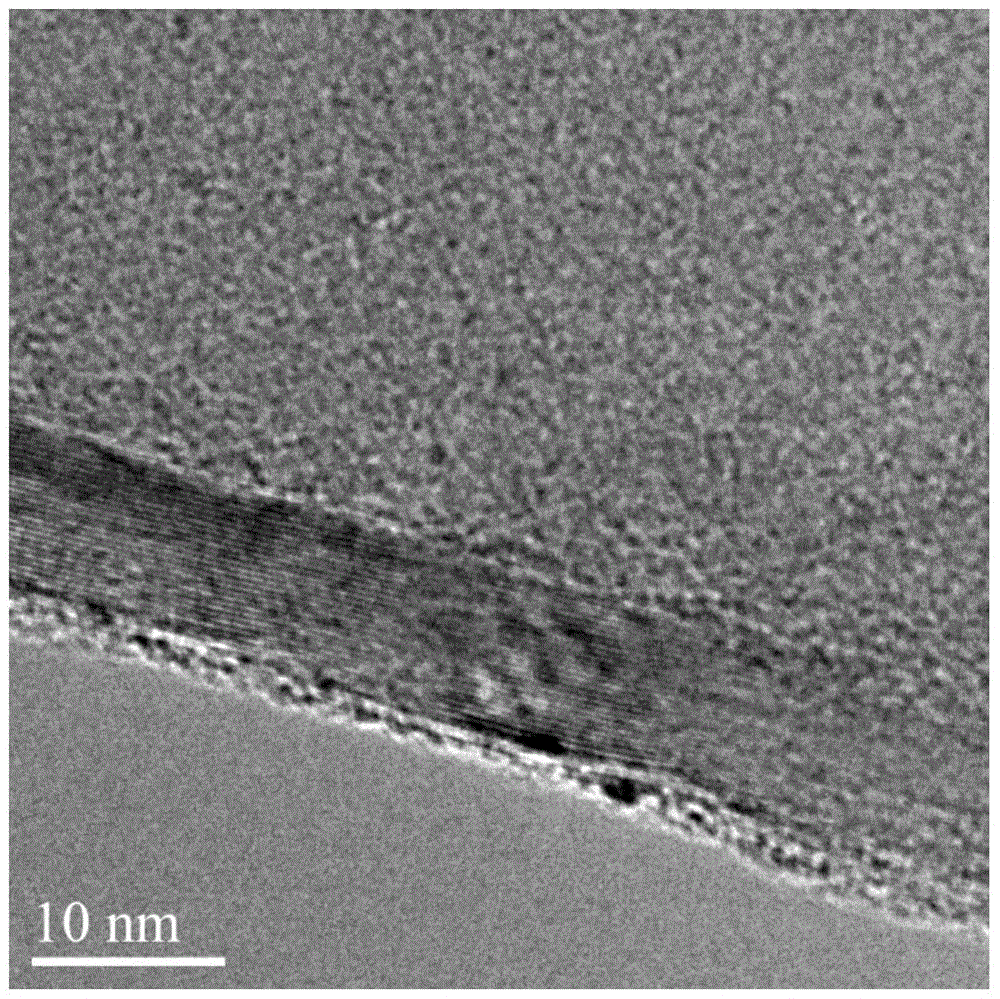

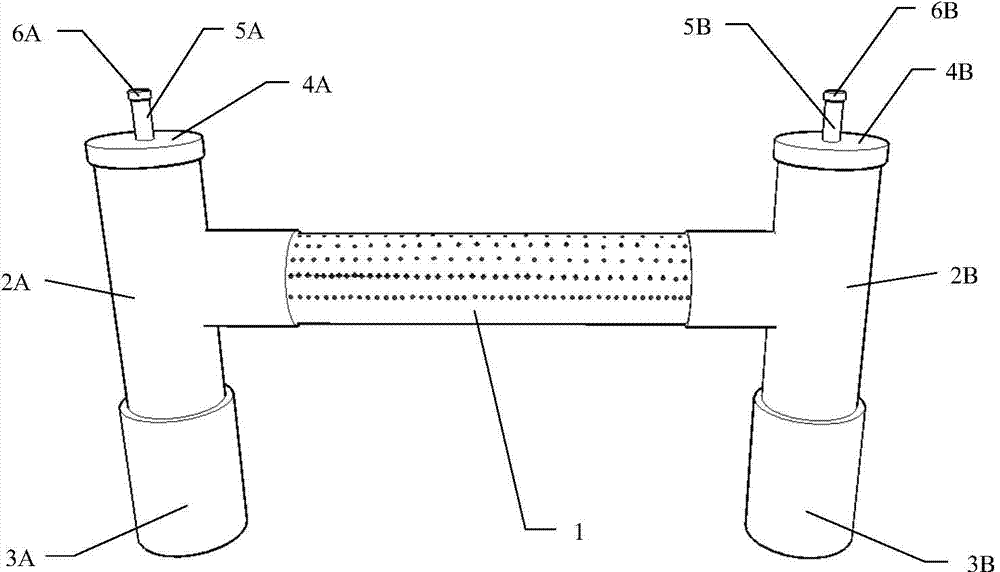

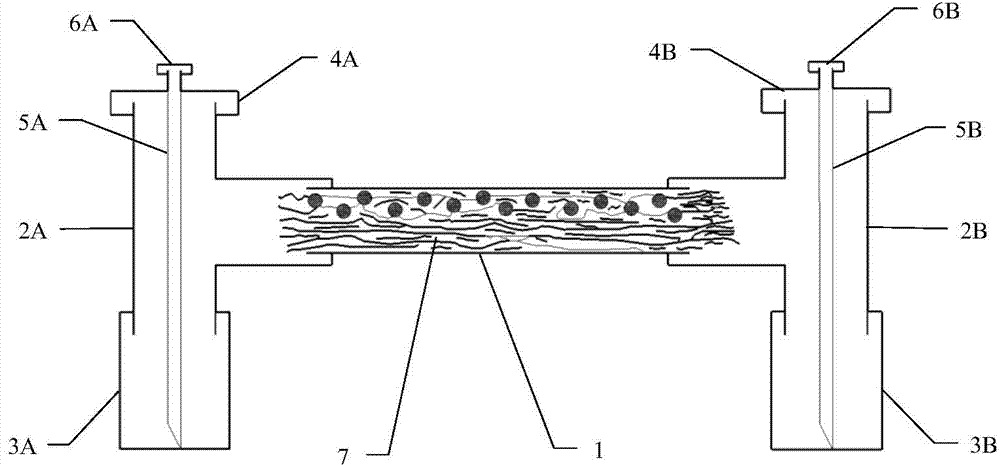

Method and device for preparing carbon nano tube by taking high-sulfur heavy oil as carbon source

ActiveCN105776172AEasy reunionAvoid inactivationMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeFuel oil

The invention provides a method and device for preparing a carbon nano tube by taking high-sulfur heavy oil as a raw material, and belongs to the technical field of petrochemical industry and carbon materials.The invention provides a method for preparing the carbon nano tube by taking the heavy oil of which the mass fraction of sulfur ranges from 2.11% to 4.9% as a carbon source and taking a 304 stainless steel substrate of which the surface is loaded with nickel and magnesium oxide as a catalyst through a chemical vapor deposition method, and provides the device needed in preparing the carbon nano tube by taking the high-sulfur heavy oil as the carbon source simultaneously.The method and device for preparing the carbon nano tube by taking the high-sulfur heavy oil as the carbon source have the advantages that the prepared catalyst is suitable for directly preparing the carbon nano tube by taking the high-sulfur heavy oil as the raw material, the diameter of the prepared carbon nano tube ranges from 30 nm to 90 nm, the tube cavity is large, the tube wall is smooth, and the purity and the degree of graphitization are high; the method has the advantages that the raw materials are low in price and rich in source, the problem that high sulfur content in the carbon source makes the catalyst inactivated is solved, and a new way is provided for high value added utilization of the heavy oil.

Owner:BEIJING UNIV OF CHEM TECH

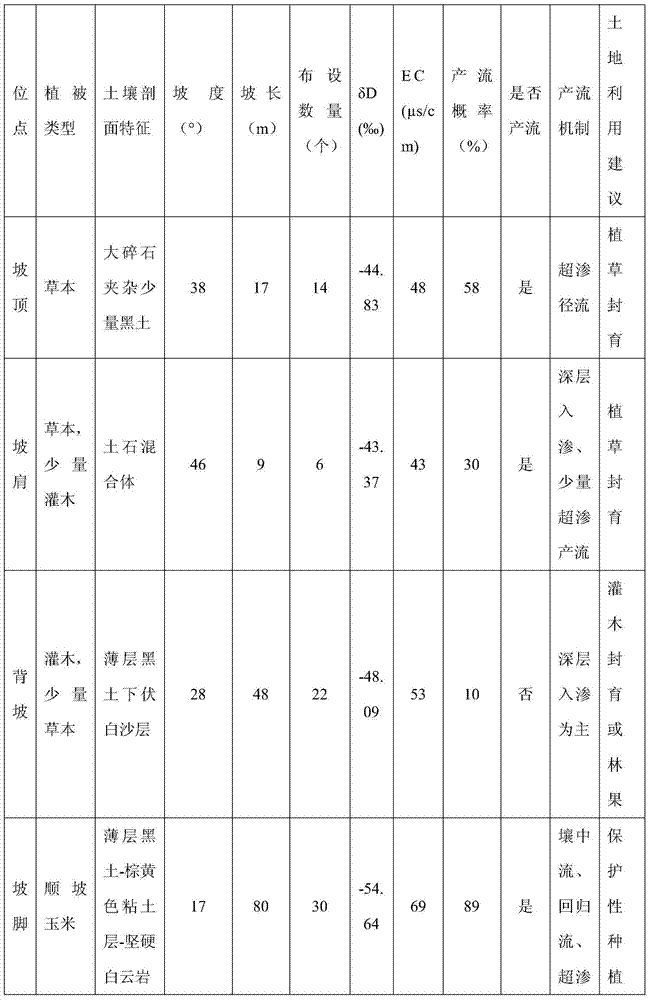

Device and method for detecting runoff producing positions on karst slope surface

InactiveCN103594020ALess adhesion lossDoes not affect concentrationEducational modelsKarstEngineering

The invention discloses a device and method for detecting runoff producing positions on a karst slope surface. The two ends of a PVC pipe are arranged in tee joints in a sleeved mode, the PVC pipe is filled with a thin gauze element, a water inlet hole is drilled in the wall of the PVC pipe, two ends of the tee joints are arranged in water storage pipes with sealed ends and pipe caps respectively in a sleeved mode, and a water guide pipe with a pipe plug at the upper end is inserted into each pipe cap and extends to the lower end of the corresponding water storage pipe. Based on slope surface point selection, the device is buried according to slope positions and types of heterogeneous ecological niches; after each rainfall, the runoff producing situation is checked, a water sample is collected, and basic water chemical indexes are measured; the runoff producing possibility of each point on the slope surface in a hydrologic year and the space-time distribution of the water chemical indexes are comprehensively analyzed, and finally judgment on the runoff producing positions on the slope surface is finished. The device for detecting the runoff producing positions on the karst slope surface is simple to manufacture, small in investment, and convenient and rapid to install, solves the problems occurring when a traditional research method is used for detecting the runoff producing positions on the karst slope surface and other areas with discontinuous earth covers, and can provide a technical means for the aspects of reasonable utilization of limited water resources, reasonable distribution of land utilization, vegetation recovery strategies and the like in the areas.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

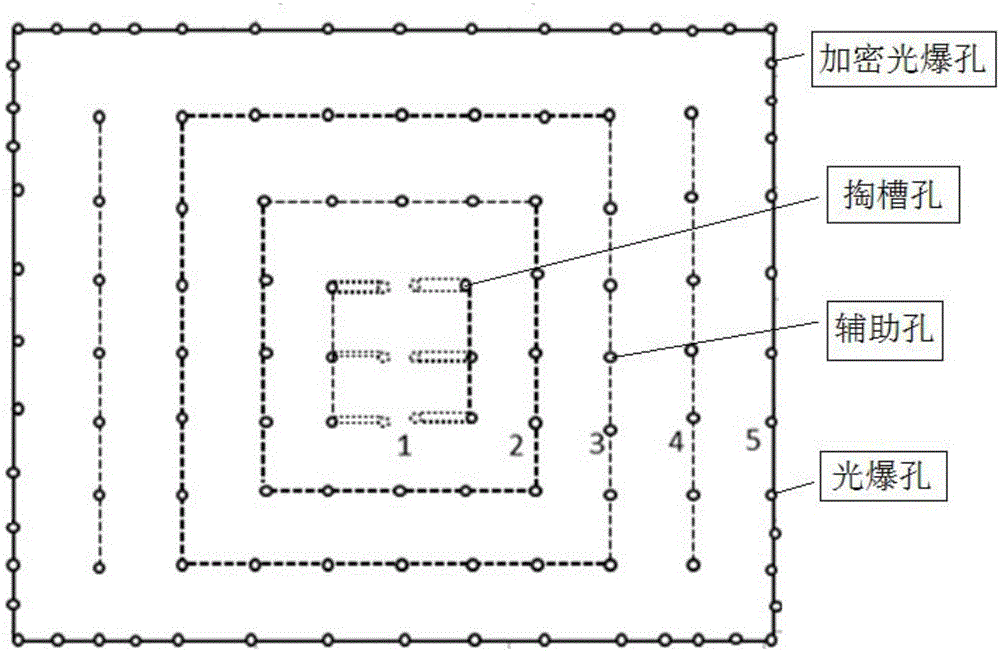

Rectangular tunnel full-section blasting excavation construction method

InactiveCN105953670AImprove blasting qualityMeet the design requirementsBlastingEncryptionDrilling and blasting

The invention discloses a rectangular tunnel full-section blasting excavation construction method. The rectangular tunnel full-section blasting excavation construction method comprises the following steps that drilling and blasting are designed through the smooth blasting principle; cut holes, auxiliary holes, smooth blasting holes and encryption smooth blasting holes are sequentially formed from inside to outside and are blasted one by one according to the smooth blasting requirements; and a standard designed rectangular section is formed finally. The rectangular tunnel full-section blasting excavation construction method is applied to construction, except that a rectangular-section tunnel is constructed according to the smooth blasting requirements, gap narrowing measures are taken for the blast holes in the corners, and thus the smooth blasting effect is improved; and on-site quality inspection shows that the formed section size of the rectangular tunnel meets the design requirement, and the rock surface flatness is smaller than the deviation value required by the specification.

Owner:杨毅

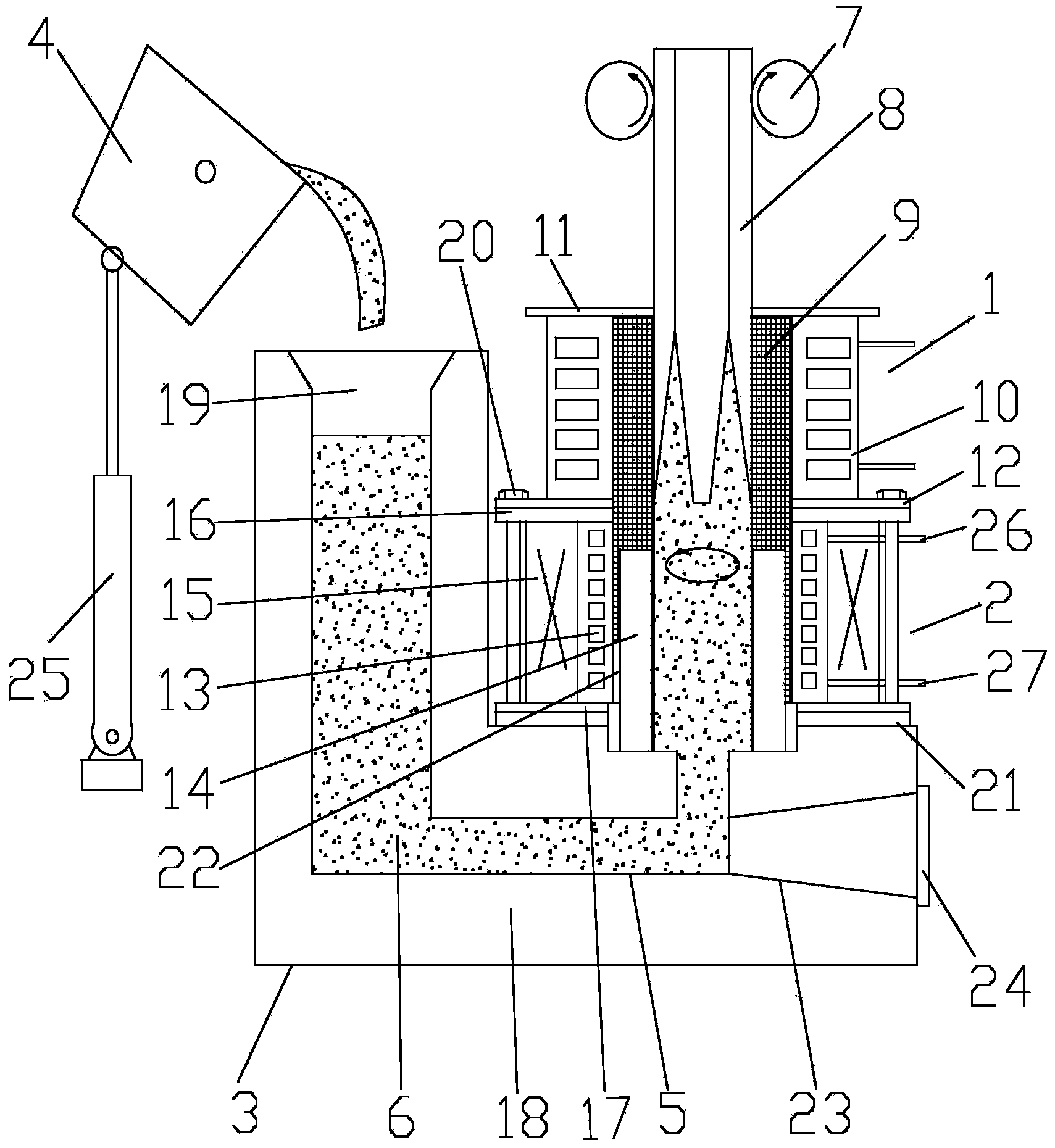

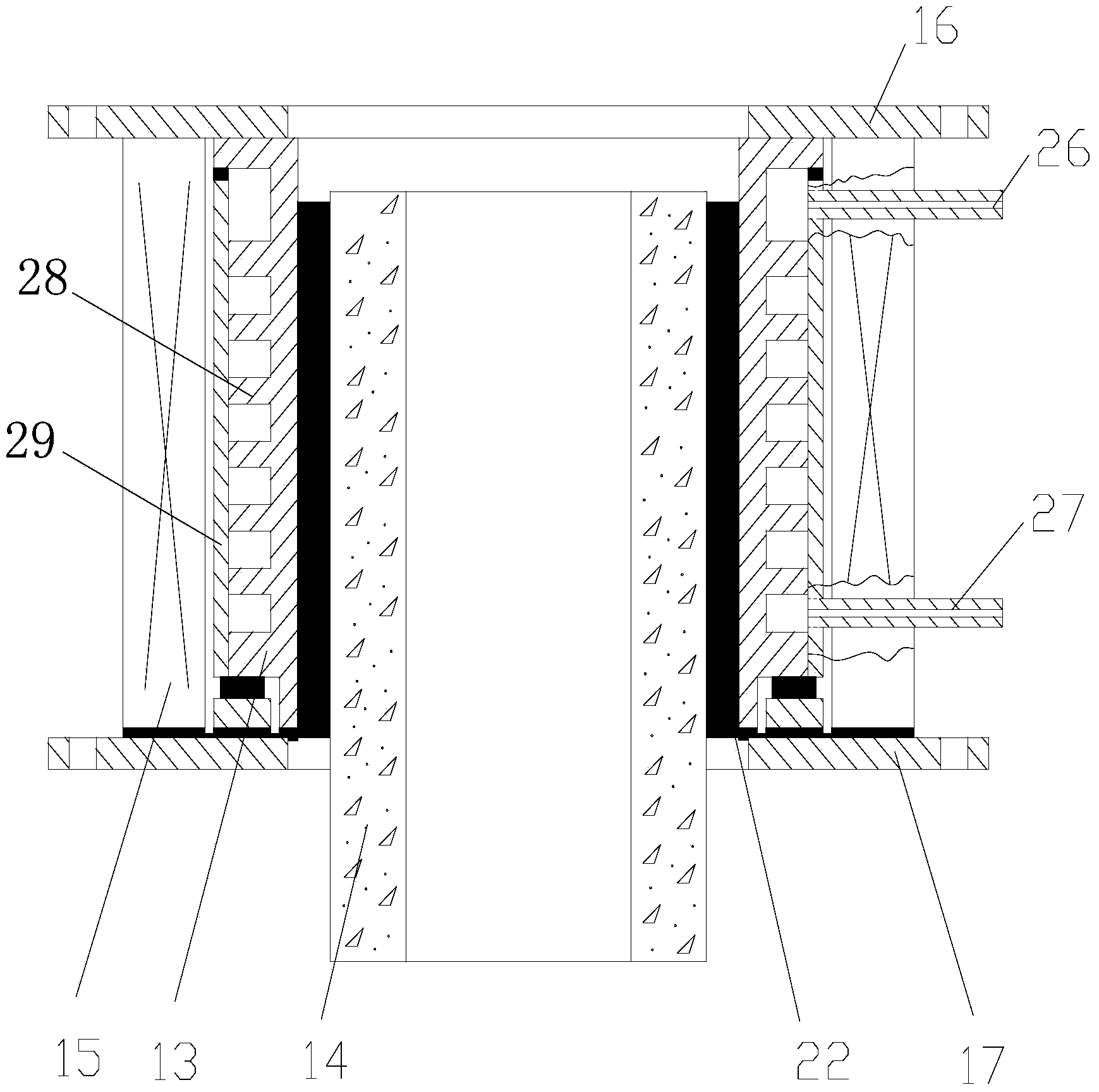

Hollow cast iron tubular product and vertical continuous casting method and special equipment thereof

Provided are a hollow cast iron tubular product and a vertical continuous casting method and special equipment thereof. An L-shaped continuous casting holding furnace, a rotating magnetic field generator and a crystallizer are connected in series to form a U-shaped channel for molten iron to flow. The rotating magnetic field generator is utilized for enabling the molten iron to rotate in the crystallizer. The produced hollow cast iron tubular product is smooth in appearance. The wall surface of the inner hole is free of hoop rings and is smooth, the internal texture is fine, the size accuracy is greatly improved, the radial growth of a primary dendritic crystal is disturbed, the proportion of an isometric crystal area is increased, the mechanical property of a hollow cast tube is improved, and the practical value is high.

Owner:SHAN XI TONGXIN LIANZHU PIPE IND

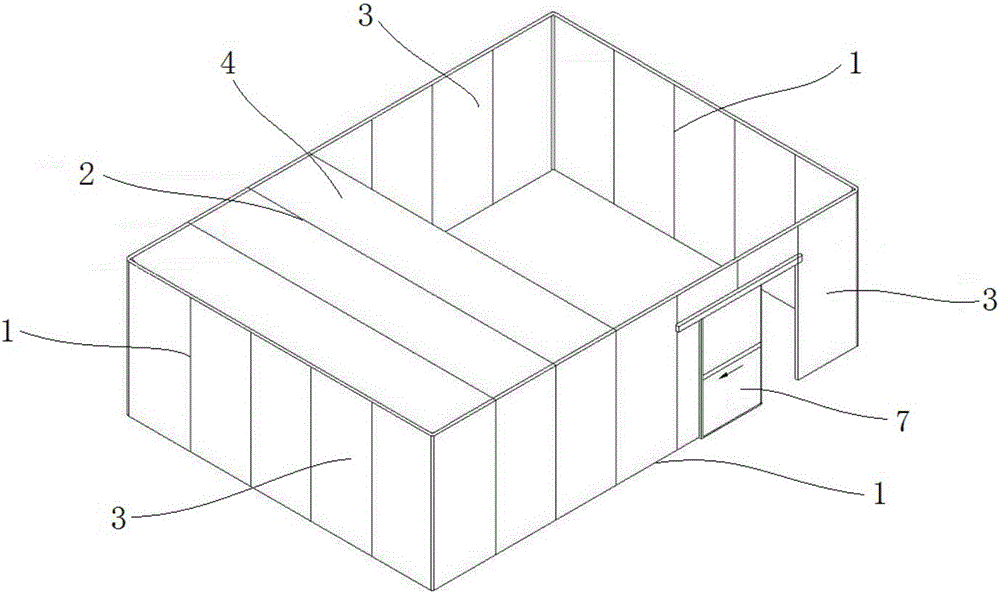

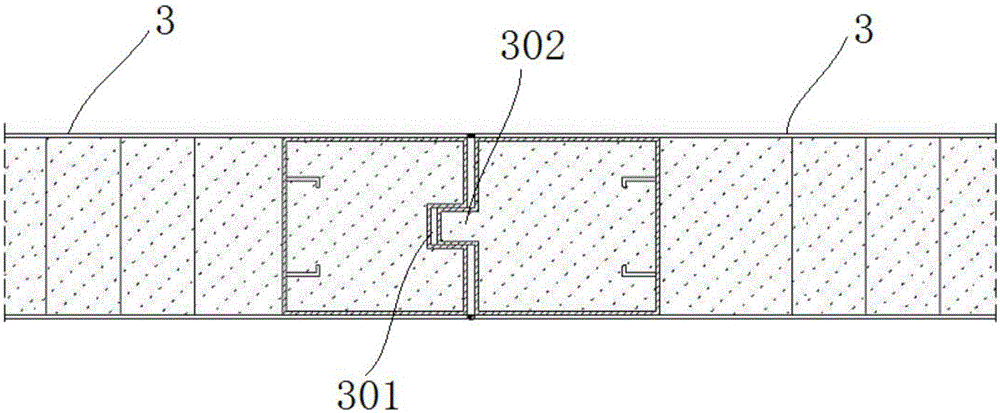

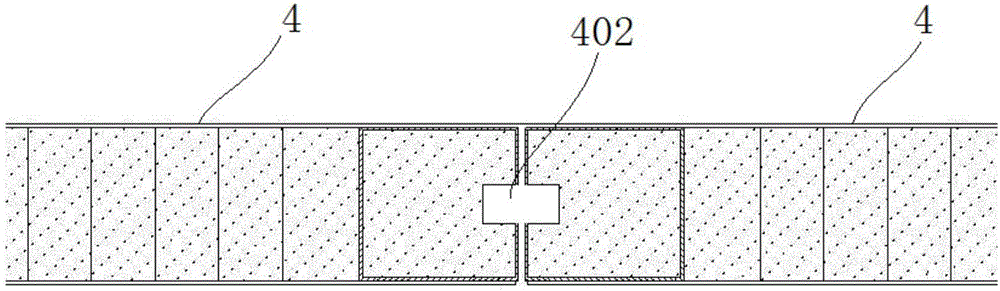

Assembled type clean space assembling room and mounting method thereof

The invention discloses an assembled type clean space assembling room. The assembled type clean space assembling house comprises side wall surfaces, a top surface and a door, wherein the side wall surfaces are assembled by a plurality of wallboards I; a bulges and a groove are formed in two corresponding sides in a horizontal direction of each wallboard I; the size of the bulges is matched with the size of the grooves; the bulges are inserted into the grooves, so that the wallboards are assembled; the top surfaces is assembled by a plurality of wallboards II; grooves are formed in two corresponding sides in a horizontal direction of each wallboard II; the grooves are oppositely assembled to form an accommodation space of a shape like a Chinese character of 'zhong'; inner edge fixing parts are arranged junctions between the top surface and the side wall surfaces; an inner edge fixing part and an outer edge fixing part are arranged at a junction between two adjacent side wall surfaces; the wallboards are made of a bacteria-resisting, bacteria-inhibiting and virus-killing material; the door is a clean door made of the bacteria-resisting, bacteria-inhibiting and virus-killing material. Through the assembled type clean space assembling room, the problems that the building material needs to be manufactured on the site, the processes are complicated, the building material is cut and is subjected to surface treatment on the site, the pollution to the environment is serious, and the bacteria-resisting, bacteria-inhibiting and virus-killing functions are lacked in the prior art can be solved.

Owner:王翊

Structure of stone wall constructed by strip stone cut by machine and method thereof

ActiveCN101949182AImprove bindingIncreased shear strength of gray jointsWallsBuilding material handlingStone wallStructure of the Earth

The invention discloses a structure of a stone wall constructed by strip stone cut by a machine and a method thereof. The structure comprises upper strip stone and lower strip stone which are cut by a machine; a lime slot is formed between the constructing interface of the upper strip stone and the constructing interface of the lower strip stone; the lime slot is filled with bonding material used for bonding the upper strip stone and the lower strip stone together; the constructing interface of the upper strip stone and the constructing interface of the lower strip stone are both provided with crossed grooved grains; a plurality of grooves are formed on the constructing interface of one row of strip stone; shear keys are convex externally on the constructing interface of the other row of strip stone; the shear keys correspond to the grooves and are meshed with the grooves; in this way, the upper strip stone and the lower strip stone can be bonded more firmly by the grooved grains arranged on both of the constructing interfaces of the upper strip stone and the lower strip stone and the grooves and the shear keys which are arranged on the two constructing interfaces and are matched; thereby, the shear strength of the lime slot of the stone wall formed by construction is largely enhanced; and the stone wall has excellent seismic performance and compressive load capacity.

Owner:HUAQIAO UNIVERSITY

Wall linking method of scaffold and wall-linking member used by scaffold

The invention discloses a wall linking method of a scaffold and a wall-linking member used by the scaffold. During pouring of a wall body, a wall penetrating casing is pre-buried in the wall body; after a pouring template is dismounted, a wall penetrating screw rod on the wall-linking member penetrates through the wall penetrating casing pre-buried in the wall body, and the connecting member is fixedly connected with the wall body through a gasket and a nut; when the scaffold is set up, one end of a wall linking steel pipe is pressed against the surface of the wall body, and the end part of the wall linking steel pipe is connected with a connecting plate on the wall linking member by virtue of a fastener. The wall-linking member disclosed by the invention is convenient to dismount, the wall surface is flat after the dismount, later outer wall decoration construction is facilitated, and quality defects such as water seepage of an outer wall can be prevented. The material of the wall-linking member is easy to obtain, the processing is easy, and onsite batch processing is convenient. The wall linking member can be used repeatedly for multiple times, so that consumption of the material is reduced. The wall-linking member can be recycled for use. The wall-linking member is applicable to occasions where the scaffold needs to be set up, and is particularly applicable to a part of a shear wall structure gable where a wall-linking member is inconvenient to arrange. The wall-linking member has promotion significance.

Owner:CCFED THE FIRST CONSTR & ENG

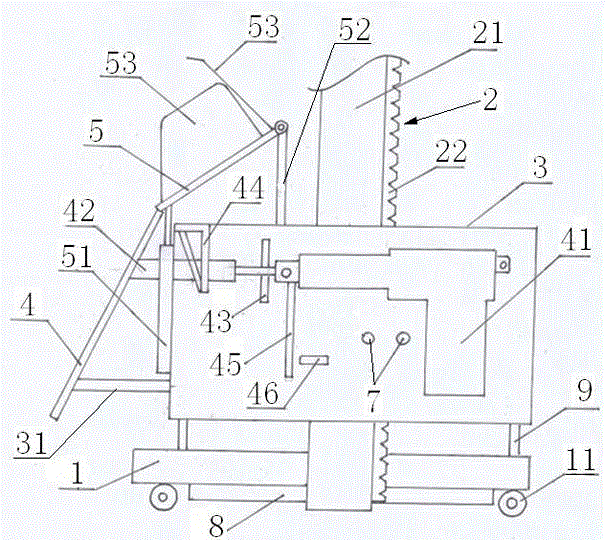

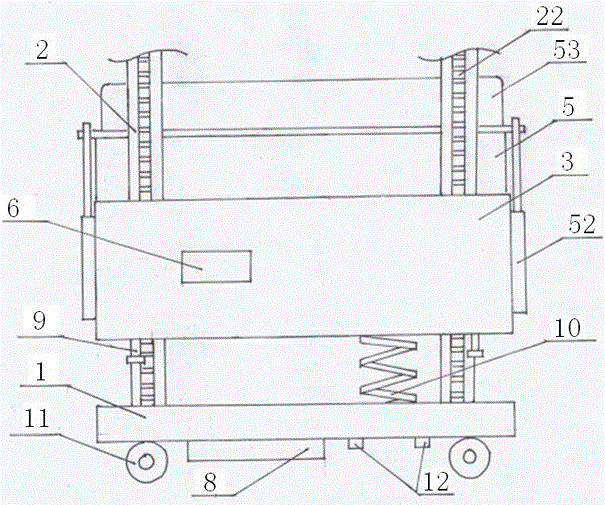

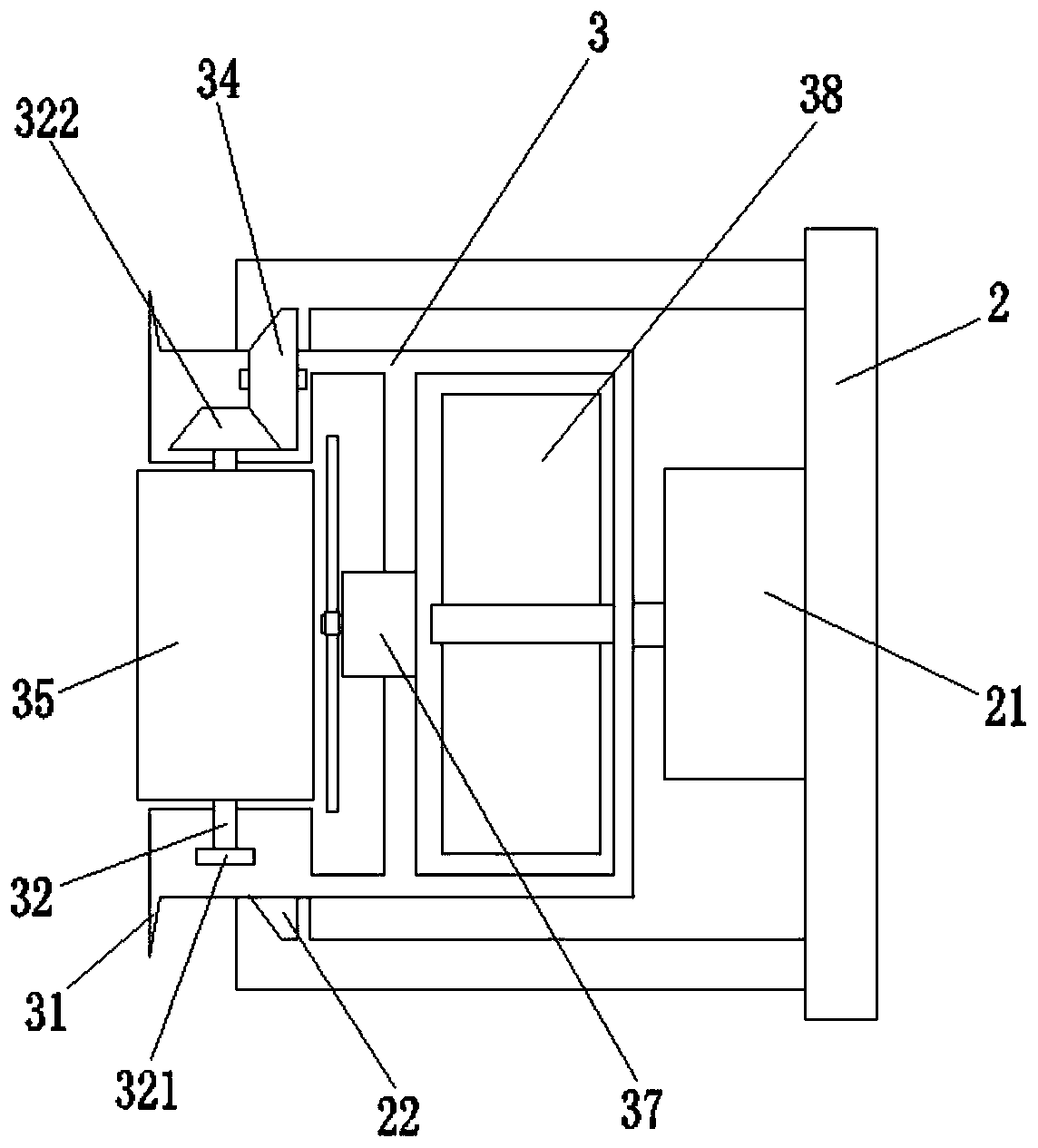

Automatic wall plastering machine

The invention provides an automatic wall plastering machine. The automatic wall plastering machine comprises a base, an upright and a moving body; the moving body moves up and down on the upright as a track; a push plate is arranged on the frontage of the moving body and hinged to the front face; an electronic push rod and a first elastic telescopic rod are mounted on the two sides of the push plate; one end of the electronic push rod is fixed with the moving body, while the other end of the electronic push rod is hinged to one end of the first elastic telescopic rod; the other end of the first elastic telescopic rod is hinged to the back surface of the push plate; a material plate is mounted above the push plate; a second elastic telescopic rod and a third elastic telescopic rod are mounted on the two sides of the moving body correspondingly to the front and rear ends of the material plate, respectively; one end of the second elastic telescopic rod is hinged to the moving body, while the other end of the second elastic telescopic rod is hinged to the front end of the material plate; one end of the third elastic telescopic rod is fixed with the moving body, while the other end of the third elastic telescopic rod is hinged to the rear end of the material plate; an included angle is formed between the material plate and the upper surface of the moving body. The automatic wall plastering machine has the advantages of stable operation, good plastering effect, high automation degree, high applicability and the like.

Owner:温宇辉

Light compound side fascia and its manufacturing method

ActiveCN100385083CReasonable structureImprove performanceConstruction materialMouldsHigh intensityRebar

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

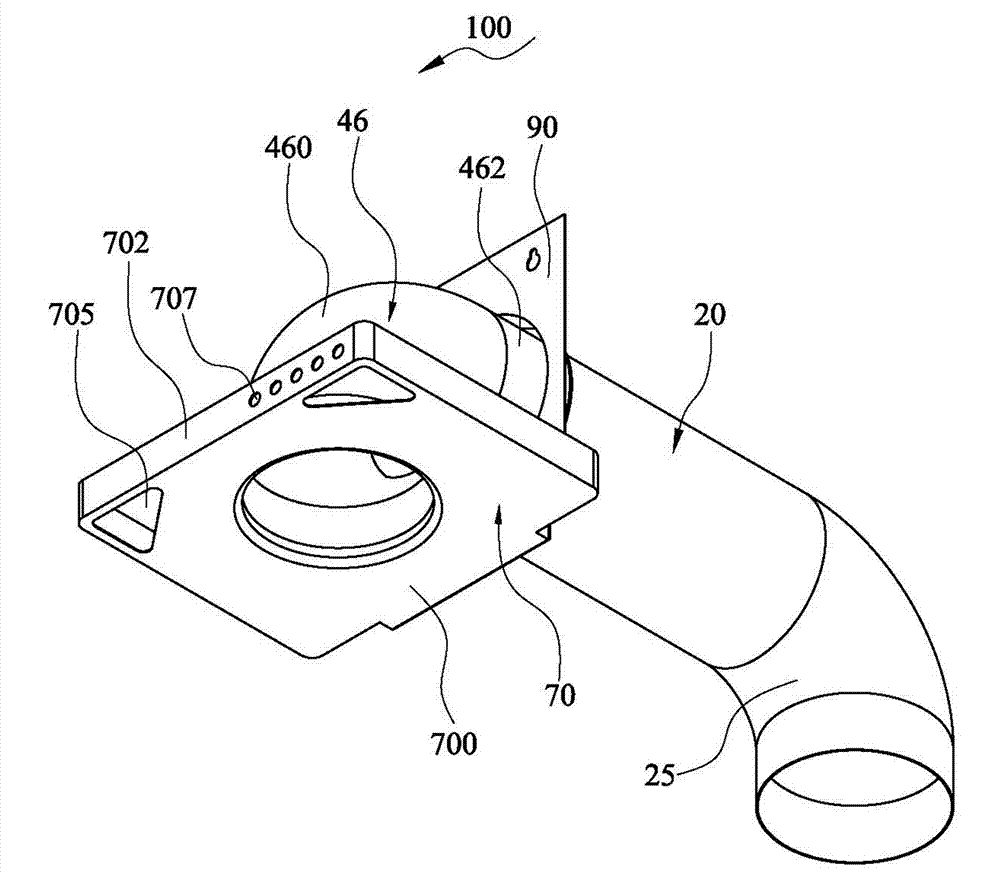

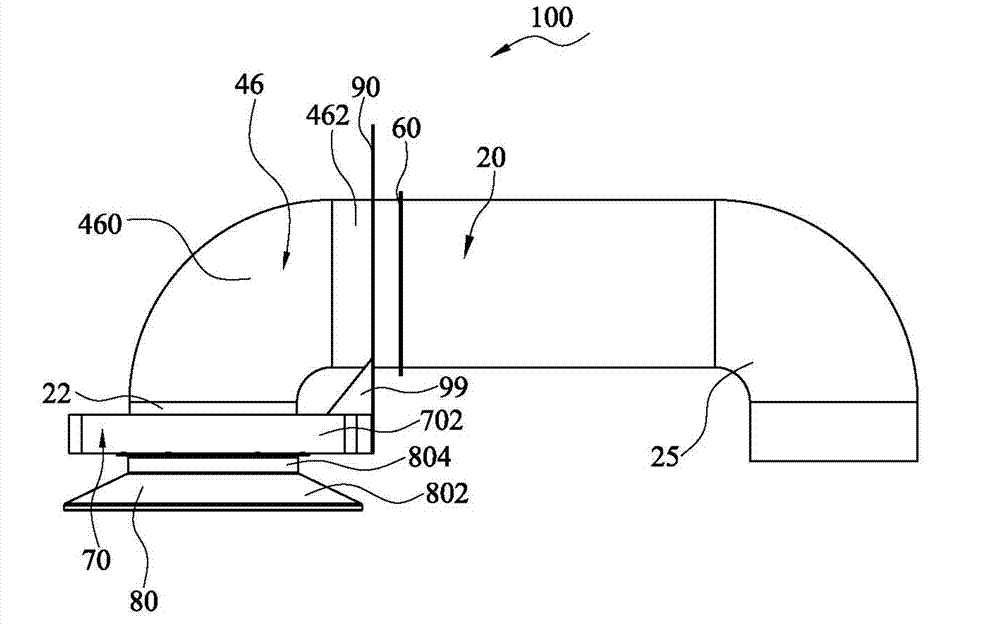

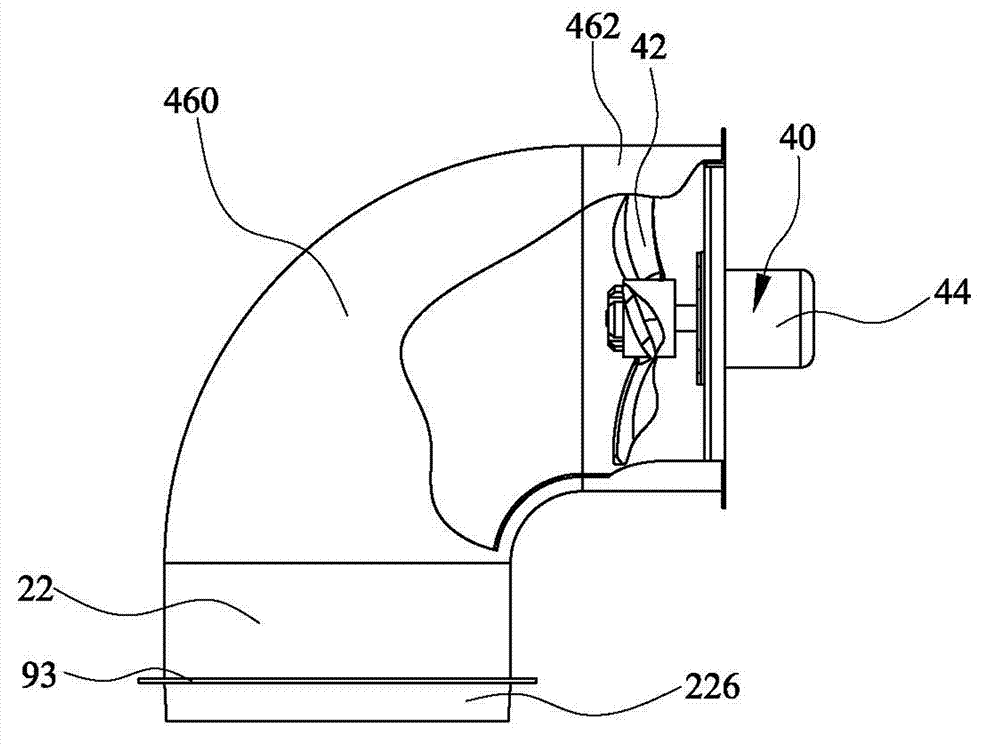

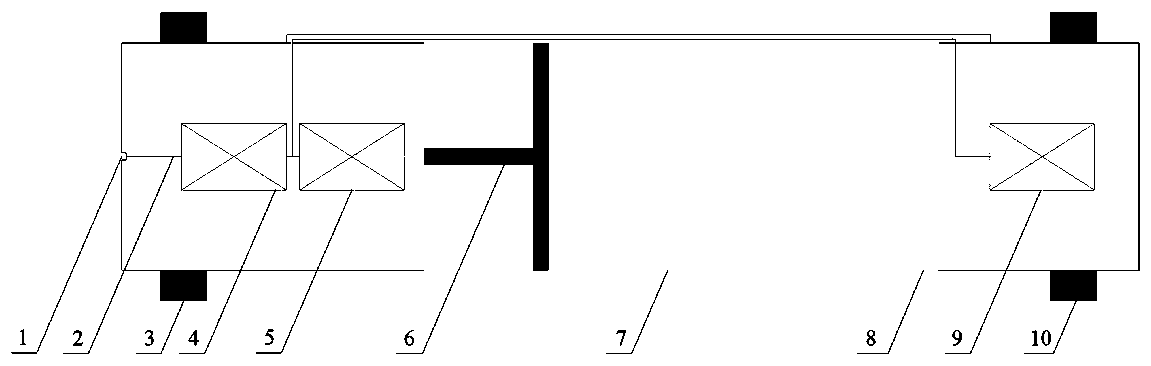

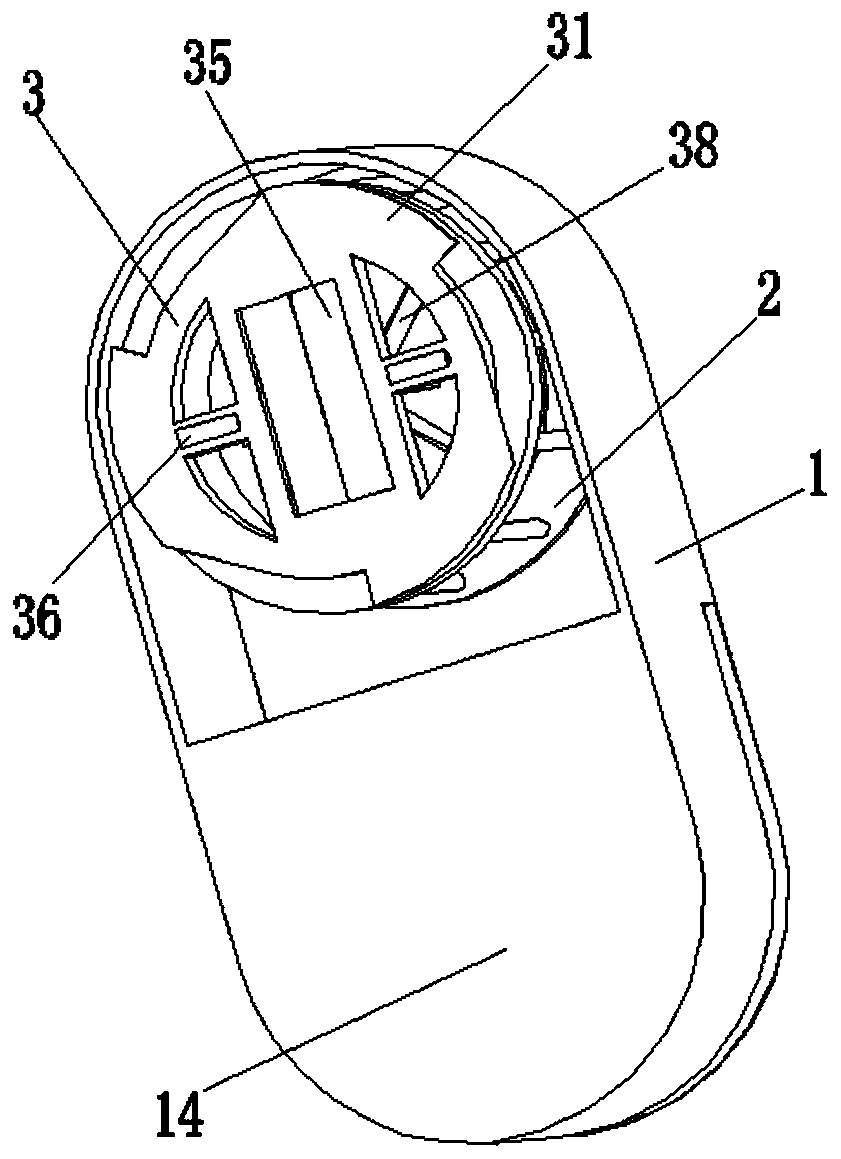

Axial flow type oil smoke ventilator

InactiveCN102901132AGreat suctionAvoid wastingDomestic stoves or rangesLighting and heating apparatusManufacturing cost reductionAir volume

The invention provides an axial flow type oil smoke ventilator which comprises a curved tube axial-flow oil smoke blower fan, a frame and an externally connected exhaust duct, wherein the curved tube axial-flow oil smoke blower fan comprises a bent pipeline, a fan motor arranged in the bent pipeline and a fan body arranged on a fan motor shaft, the fan motor is fixed in the bent pipeline through a fan motor support, the curved tube axial-flow oil smoke blower fan is mounted on the frame, and an air inlet is vertical and adown. The invention has the following beneficial effects: a brand new middle and high-grade axial flow type oil smoke ventilator can be constructed according to the invention; the axial flow type oil smoke ventilator has all the advantages of an axial-flow blower fan, e.g., great draft induction capacity and a simple structure; an ideal exhausting rate can be obtained by using a small-power motor; ceiling installation can be realized; ascending hot air during cooking can be fully utilized; a substantial energy saving effect is obtained, and manufacturing cost is substantially reduced; and a novel technical product with strong competitiveness is presented on middle and high-grade oil smoke ventilator market, and product types of middle and high-grade oil smoke ventilators are enriched.

Owner:曾德邻

Casing pipe repairing and strengthening agent construction device and using method thereof

PendingCN108798579AImprove work efficiencyUse less equipmentBorehole/well accessoriesEngineeringCylinder block

The invention belongs to the field of oil and gas development, and relates to a special tool for casing pipe repairing and strengthening agent construction and a using method thereof. The casing piperepairing and strengthening agent construction device comprises three parts of an upper part, a middle part and a lower part, wherein the upper part, the middle part and the lower part are connected in sequence. The middle part is a cylinder body, a piston is arranged in the cylinder body, and an outlet hole is formed in the side surface, close to the lower part, of the cylinder body. Packers arearranged on the outer surfaces of the upper part and the lower part, the piston and the packers are provided with driving devices separately, and the driving devices are matched with piston and the packers. According to the casing pipe repairing and strengthening agent construction device, a suspended cement plug or a lower retrievable bridge plug is not required for blocking the bottom of a damaged part, no drilling plug process exists, the process is simple, the construction time is short, and the construction cost is low.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

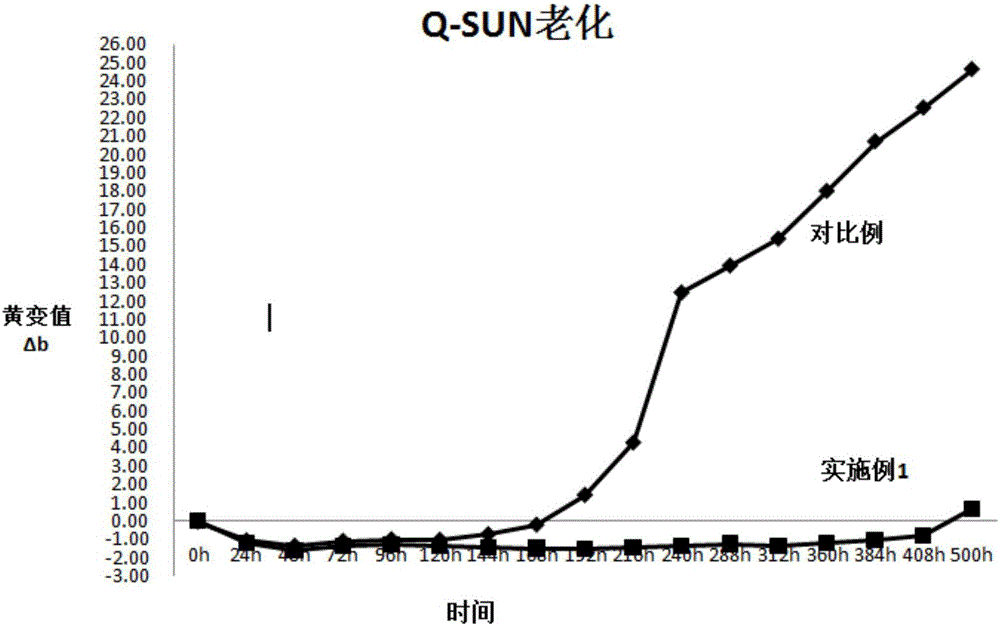

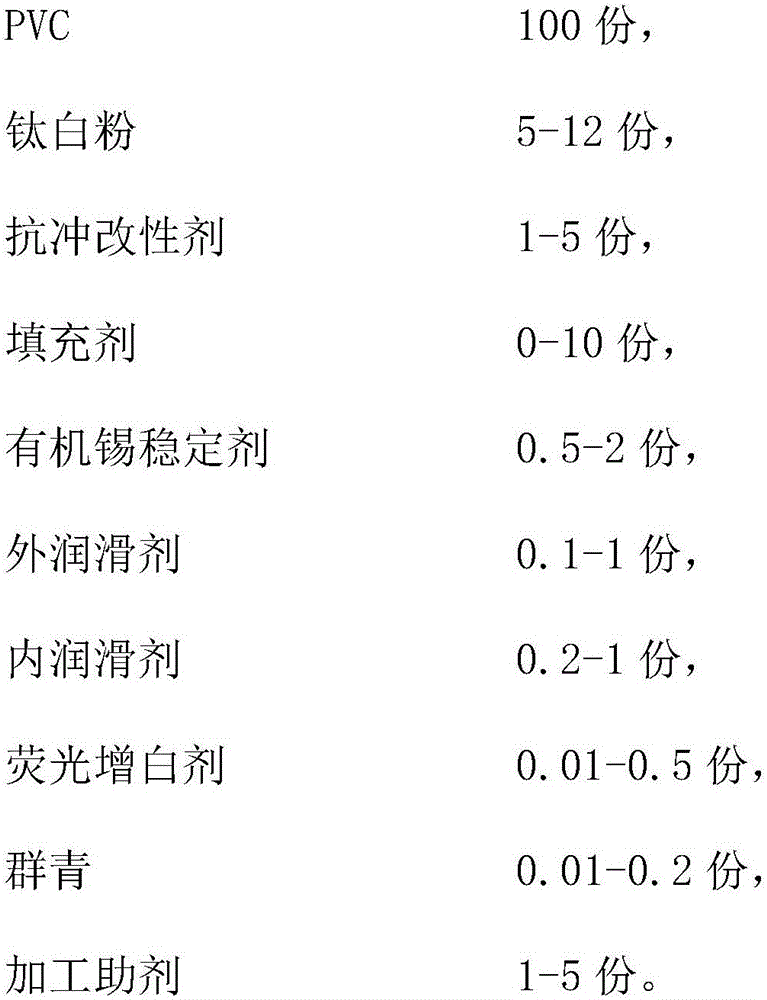

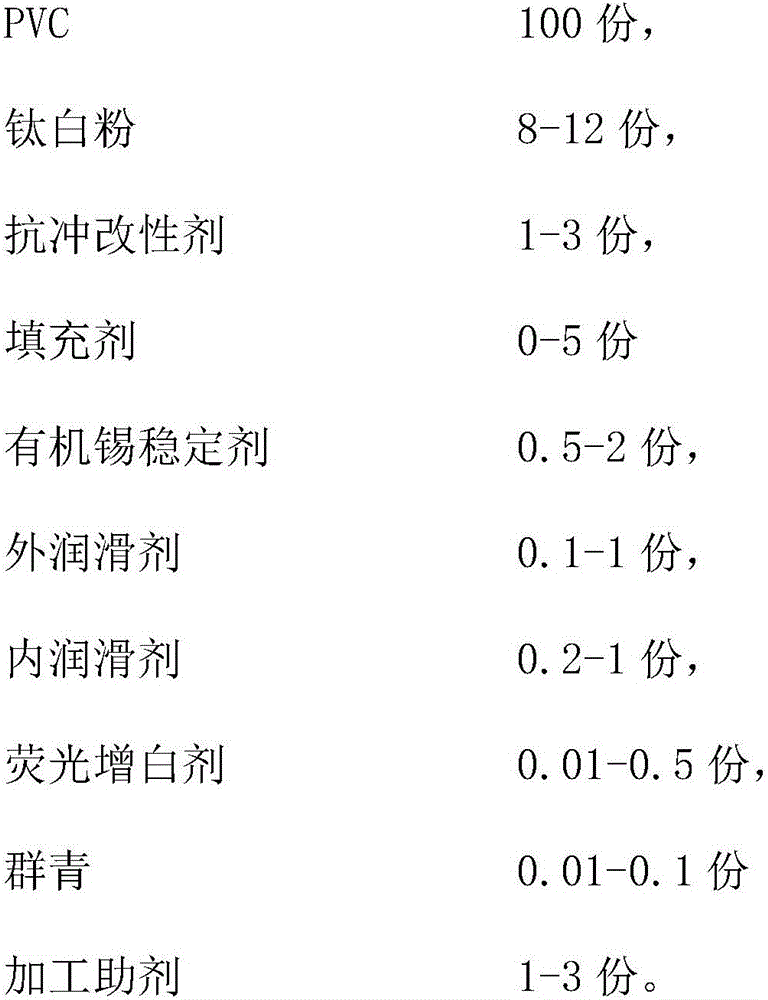

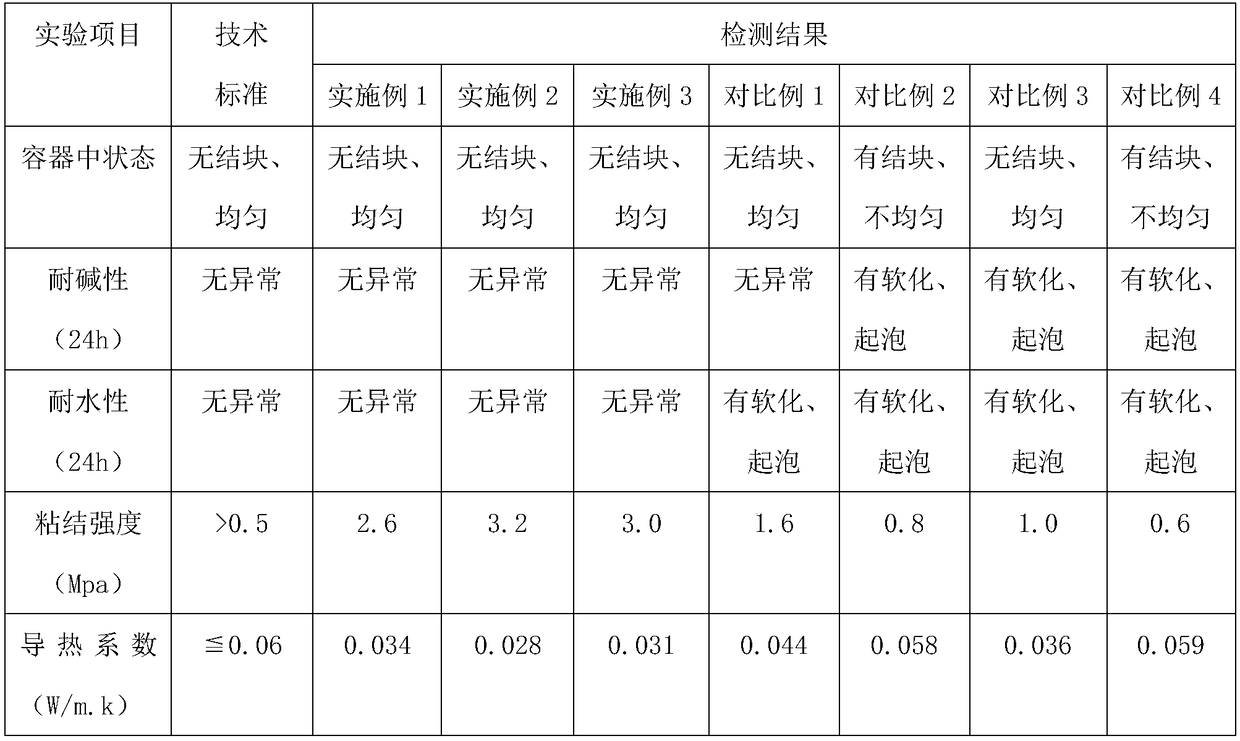

Porcelain white highlight PVC tube and preparation method thereof

The invention provides a porcelain white highlight PVC tube. The tube is prepared from, by weight, 100 parts of PVC, 5-12 parts of titanium dioxide, 1-5 parts of impact modifier, 0-10 parts of filler, 0.5-2 parts of organic tin stabilizer, 0.1-1 part of external lubricating agent, 0.2-1 part of internal lubricating agent, 0.01-0.5 part of flourescent brightener, 0.01-0.2 part of ultramarine and 1-5 parts of processing aid. The porcelain white highlight PVC tube is smooth in surface and small in fluid resistance, and the coarse crude coefficient of the tube is only 0.009; mechanical strength is large, and the tube is good in water pressure resisting strength, external pressure resisting strength, impact resisting strength and the like and suitable for various conditions.

Owner:TIANJIN ZHONGCAI PROFILES

Interior wall thermal insulation putty and preparation method

InactiveCN108410245AHas a dispelling effectUnique three-dimensional space chain structureFilling pastesCelluloseAluminum magnesium silicate

The invention discloses interior wall thermal insulation putty and a preparation method. The interior wall thermal insulation putty is prepared from, by mass, 20-30% of light calcium carbonate powder,15-20% of floating beads, 10-15% of titanium dioxide, 25-30% of shell powder, 3-5% of nano thermal insulation powder, 0.2-0.3% of lignocelluloses, 0.3-0.5% of alum powder, 1-2% of bentonite, 2-4% ofpolyvinyl alcohol 2488, 1-2% of N-methyl trimethylacetamide, 1-2% of 4-methyl catechol, 0.2-0.3% of carboxymethyl cellulose, 3-5% of redispersible latex powder, 0.2-0.3% of pre-gelatinized starch and1-2% of thixotropic agent aluminum-magnesium silicate. By adoption of the raw materials and the adding sequence, the putty gives full play to advantages of the floating beads, and water resistance, alkali resistance, base material bonding strength and thermal insulation performance of the putty are remarkably improved.

Owner:常德市万福达环保节能建材有限公司

Treatment method for decorative construction wall space of building exterior wall

InactiveCN111283884ASmooth wallEasy constructionGrinding drivesBuilding repairsElectric machineryEngineering

The invention relates to the field of building decoration, in particular to a treatment method for a decorative construction wall space of a building exterior wall, and the treatment method uses a wall space treatment device. The wall space treatment device comprises a main body, an inner container and a rotary module, wherein the outer side of one end, away from a rotary motor I, of the rotary module is symmetrically fixedly connected with a plurality of blades; a rotary shaft I and a rotary shaft II are symmetrically inserted into the rotary module; one end of the rotary shaft I and one endof the rotary shaft II are fixedly connected with transmission gears which are engaged with each other; one end of the rotary shaft I is fixedly connected to a bevel gear I; a bevel gear II is inserted into the inner wall of the rotary module; the bevel gear II is engaged with the bevel gear I; a tooth slot is formed in the inner wall of the inner container; one side, away from the bevel gear I, of the bevel gear II penetrates through the rotary module and is engaged with the tooth slot; and grinding rollers are inserted into the rotary shaft I and the rotary shaft II. The treatment method canquickly and efficiently perform flattening treatment on a building wall space, and is suitable for being popularized.

Owner:储小燕

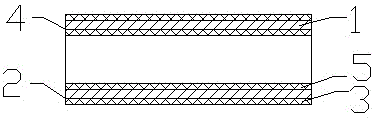

Plastic-coated composite steel tube

A plastic-coated composite steel tube comprises a steel tube body (1), wherein an external epoxy resin layer (3) is arranged on the outer wall (2) of the steel tube body (1); and an internal epoxy resin layer (5) is arranged on the inner wall (4) of the steel tube body (1). By the structure, the plastic-coated composite steel tube has the advantages of high mechanical strength, corrosion resistance, low friction coefficient, long service life and the like. Moreover, the plastic-coated composite steel tube is high in corrosion resistance, high in flame retardancy, high in antistatic property and high in weather resistance.

Owner:丁春英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com