Prefabricated component for residenter house, prefabricated component house and its construction method

A technology of houses and prefabricated walls, which is applied in the direction of residential buildings, buildings, building materials, etc., can solve the problems of no earthquake resistance, no heat insulation, high construction costs, etc., to save construction period and labor costs, construction The effect of short time and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

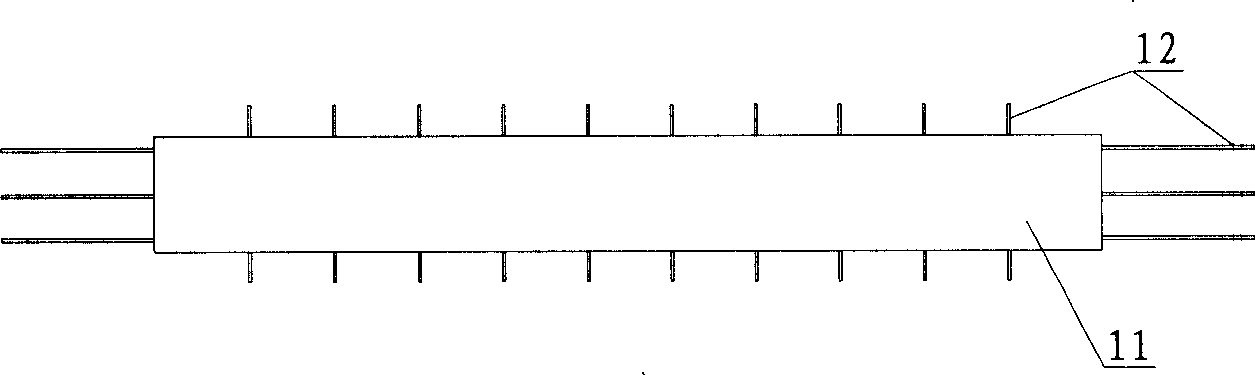

[0031] As shown in Figures 1-1 and 1-2, the prefabricated beam includes a reinforced keel and a concrete structure 11. The reinforced keel is arranged in the transverse and longitudinal directions of the beam, and two rows of reinforcement heads 12 are reserved on the upper and lower sides of the concrete structure. , Reserve several rows of rebar heads at the left and right ends, and the reserved rebar heads are used for welding with other connectors. The upper floor room uses prefabricated beams and no steel heads are reserved.

[0032] As shown in Figures 2-1 and 2-2, the prefabricated wall slab includes a reinforced keel and a concrete structure 21. The reinforced keel is arranged in the longitudinal and transverse directions of the wall slab, and steel bars 22 are reserved on the edges of the concrete structure. . The top floor room uses prefabricated wall panels without reserved steel heads. Such as Figure 7 As shown, the prefabricated wall panels can be prefabricated into ...

Embodiment 2

[0037] The same as the first embodiment, the difference is, such as Picture 9 As shown, the process of laying the floor on the beam is as follows: a steel tile 8 is placed on the beam 1, and the steel tile 8 is drilled at the position of the steel head of the beam 1 for the reinforcement head 12 to pass through, the beam 1, the steel tile 8 and Concrete is poured over the gaps between the pillars and the steel tiles to form the floor 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com