Overhead cast-in-place box beam pressure-bearing strut and construction technology thereof

A box girder, cast-in-place technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of difficult to control the erection accuracy of the support platform, long construction time, low cost performance, etc., to achieve easy control of erection accuracy, short construction time, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

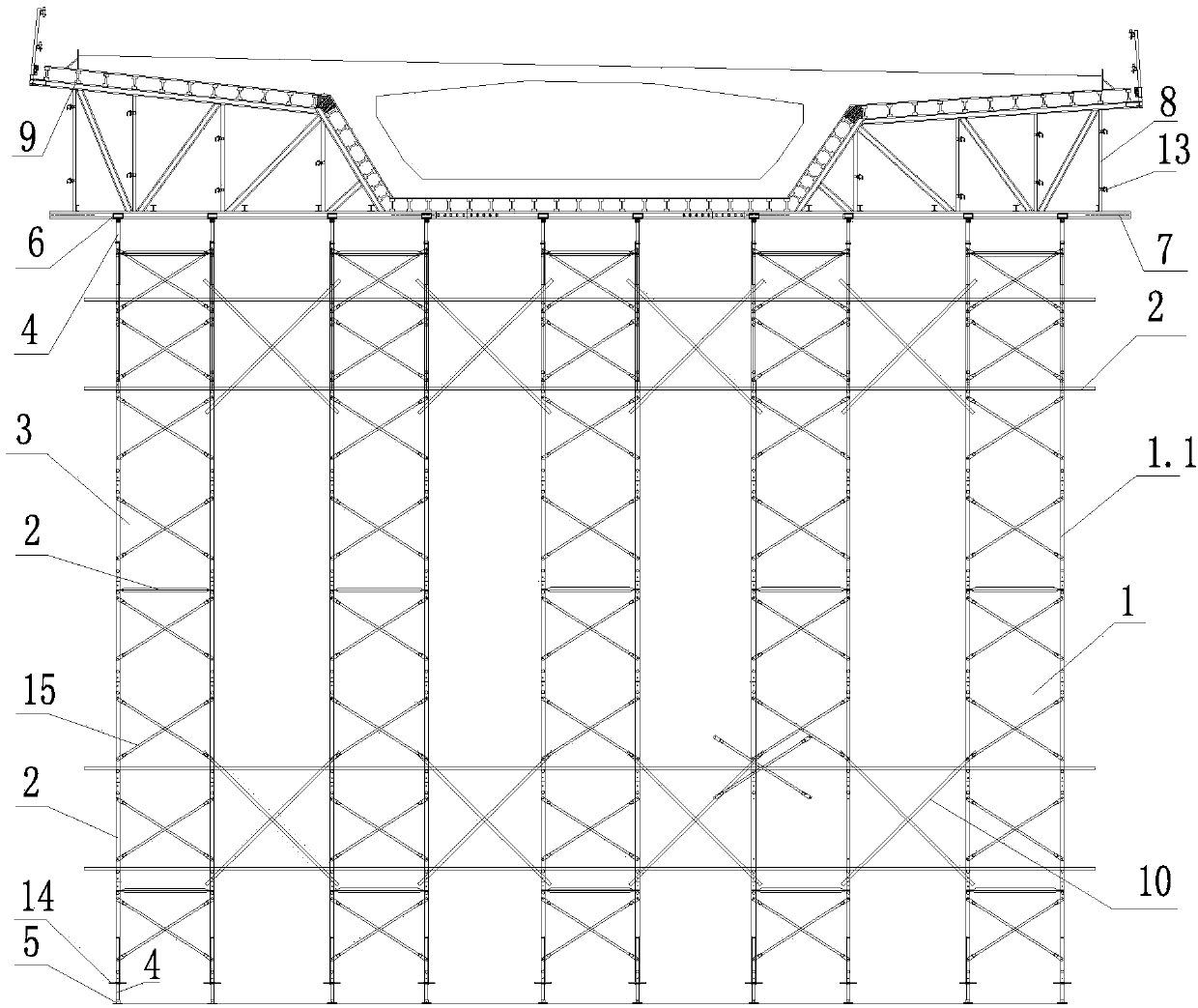

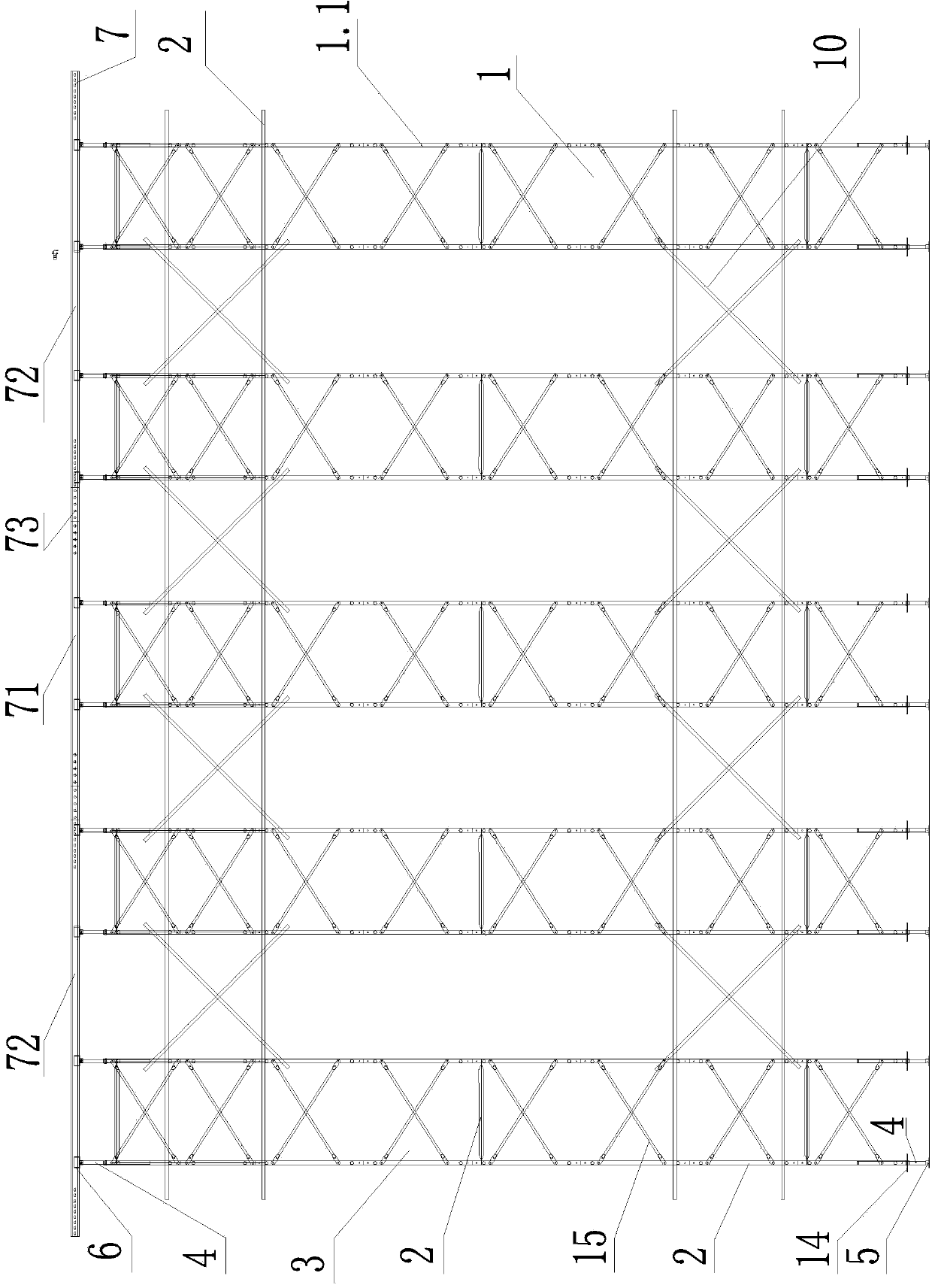

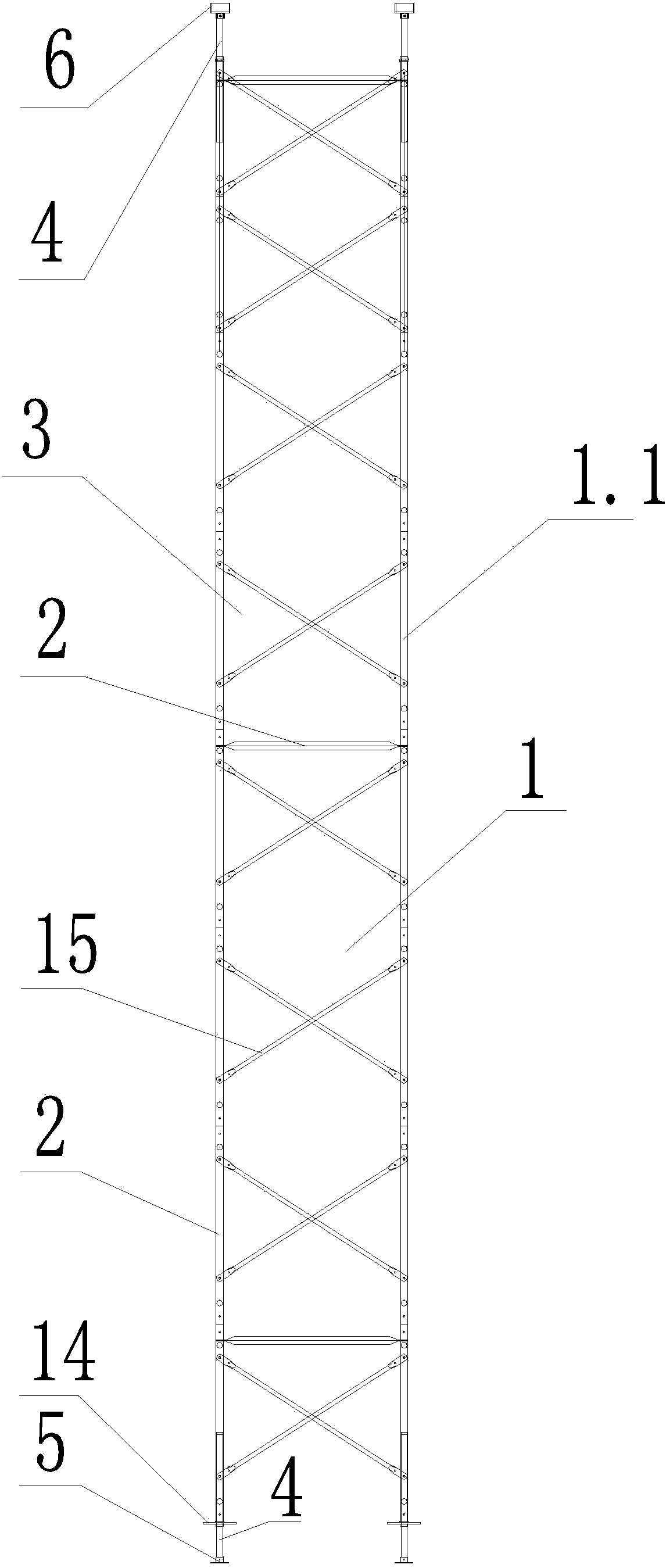

[0035] Referring to the accompanying drawings, it can be seen that the high-altitude cast-in-place box girder pressure-bearing pillars include several bracket bodies 1 with vertical support rods 1.1, and also include transverse stiffening brackets 2 connected to the side walls of the bracket body 1. The bracket body 1 is composed of multiple Two scaffolds 3 arranged up and down are composed, and cross brackets 10 are connected between adjacent bracket main bodies 1; the top and bottom ends of the vertical support bar 1.1 are respectively equipped with a support 5 and a bracket 6, and the support 5 The middle part of the bracket and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com