Porcelain white highlight PVC tube and preparation method thereof

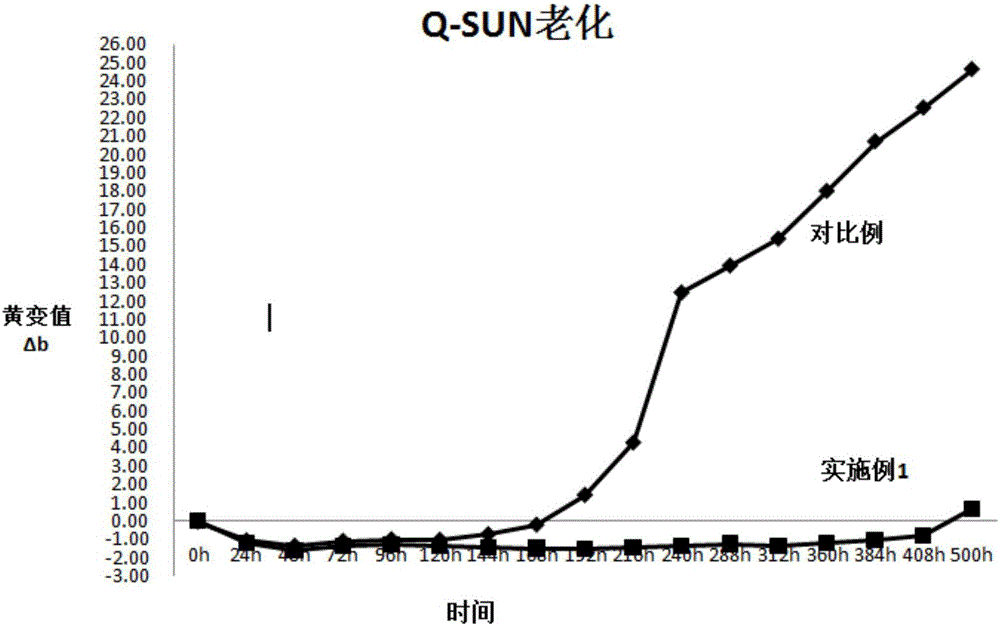

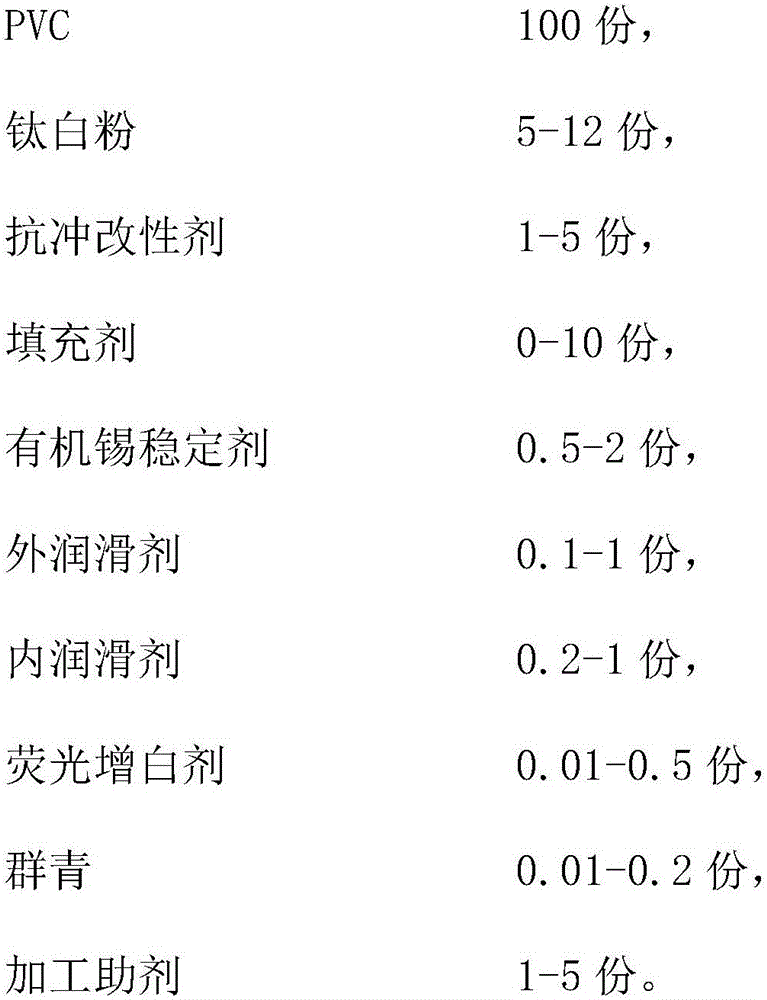

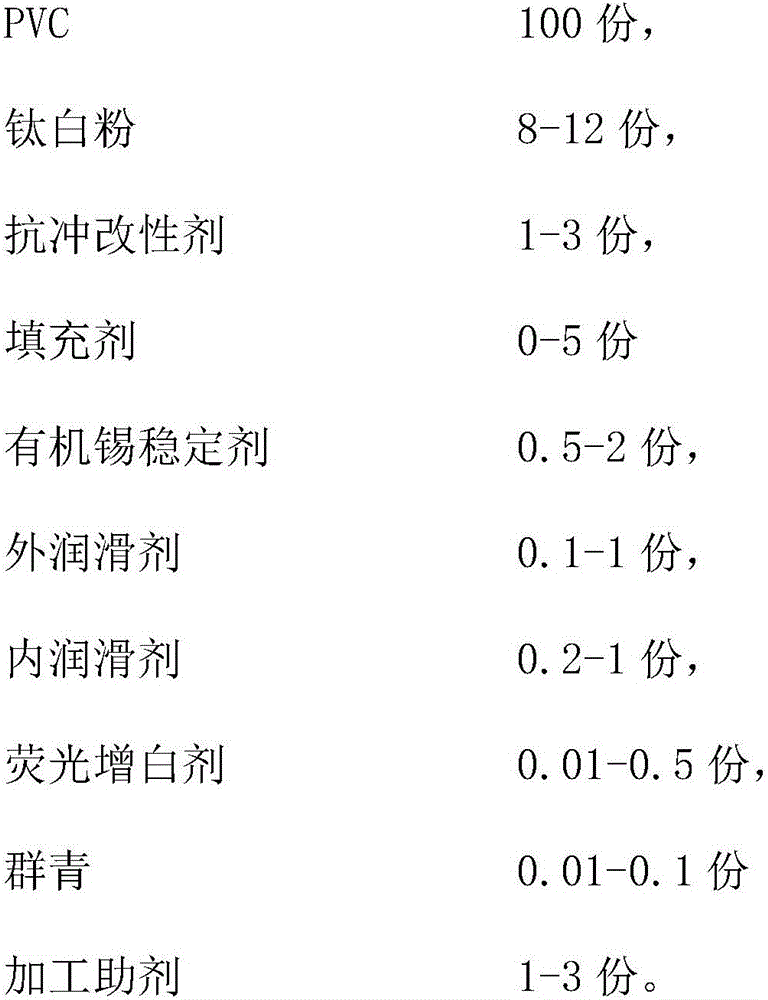

A PVC pipe, porcelain white technology, applied in the field of porcelain white high-gloss PVC pipe and its preparation, can solve the problems of local corrosion of steel pipes, poor toughness, high price of ABS pipes, etc., achieve high gloss, high mechanical strength, and improve aesthetic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A porcelain white high-gloss PVC pipe, which is made of the following raw materials in parts by weight: 100 parts of PVC, 8 parts of titanium dioxide, 1 part of MBS, 0.5 part of methyl tin SAK-MT-9001, 0.5 part of calcium stearate, 0.2 parts of stearic acid, 0.5 parts of polyethylene wax, 0.3 parts of oxidized polyethylene, 0.01 parts of OB-1, 0.03 parts of Holliday 5008, 2 parts of ACR (K-120).

[0046] The preparation method of the described porcelain white high-gloss PVC pipe comprises the following steps:

[0047] (1) Add each raw material in the high-speed mixer, and after the mixing is completed, the temperature of the mixed material is reduced to 40° C. through the cold mixer to obtain PVC clinker for extrusion production;

[0048] (2) Add the PVC clinker into the hopper of the extruder, adjust the feeding speed, so that the extrusion amount can match the feeding amount, the PVC clinker is compacted, melted, mixed and homogenized, and then extruded Strip tube bla...

Embodiment 2

[0051] A porcelain white high-gloss PVC pipe, which is made of the following raw materials in parts by weight: 100 parts of PVC, 10 parts of titanium dioxide, 2 parts of POE, 1 part of activated calcium carbonate, 1 part of dibutyltin laurate, and 0.8 parts of calcium stearate 0.1 part of stearic acid, 0.5 part of polyethylene wax, 0.1 part of oxidized polyethylene, 10.3 parts of OB-10.3 part, 0.1 part of Holliday 5008, 3 parts of Rohm and Haas K125P.

[0052] The preparation method of the described porcelain white high-gloss PVC pipe comprises the following steps:

[0053] (1) Add each raw material in the high-speed mixer, and after the mixing is completed, the temperature of the mixed material is reduced to 40° C. through the cold mixer to obtain PVC clinker for extrusion production;

[0054] (2) Add the PVC clinker into the hopper of the extruder, adjust the feeding speed, so that the extrusion amount can match the feeding amount, the PVC clinker is compacted, melted, mixed...

Embodiment 3

[0057] A porcelain white high-gloss PVC pipe, which is made of the following raw materials in parts by weight: 100 parts of PVC, 12 parts of titanium dioxide, 3 parts of acrylate impact modifier 606P, 2 parts of activated calcium carbonate, and 2 parts of dibutyltin sulfate 0.2 parts of calcium stearate, 0.05 parts of stearic acid, 0.1 parts of polyethylene wax, 0.05 parts of oxidized polyethylene, 0.5 parts of OB-1, 0.2 parts of Holliday 5008, 5 parts of Rohm and Haas K125P.

[0058] The preparation method of the described porcelain white high-gloss PVC pipe comprises the following steps:

[0059] (1) Add each raw material in the high-speed mixer, and after the mixing is completed, the temperature of the mixed material is reduced to 40° C. through the cold mixer to obtain PVC clinker for extrusion production;

[0060] (2) Add the PVC clinker into the hopper of the extruder, adjust the feeding speed, so that the extrusion amount can match the feeding amount, the PVC clinker is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com