Interior wall thermal insulation putty and preparation method

A thermal insulation putty and interior wall technology, which is applied in the direction of filling slurry, etc., can solve the problems of low strength and hardness of putty powder, failure to meet construction requirements, poor thermal insulation performance, etc., achieve low water absorption and satisfy decorative properties , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

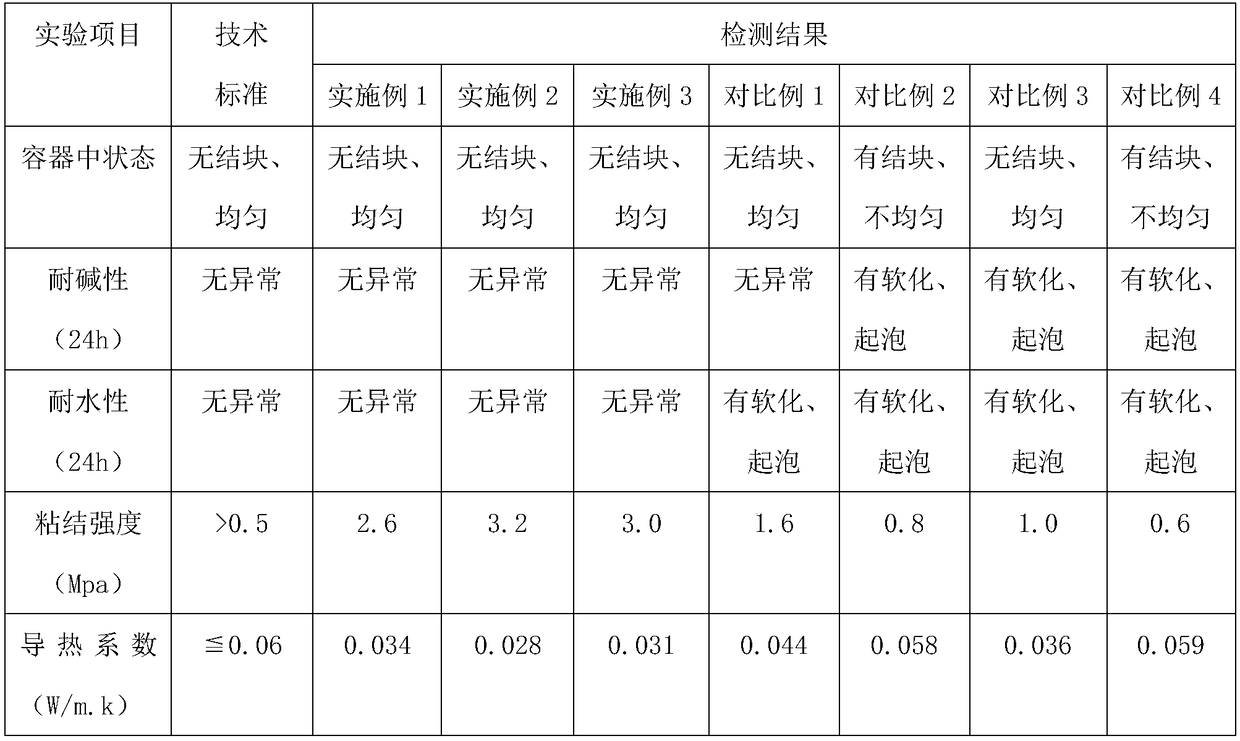

Examples

Embodiment 1

[0041] Add 20% of light calcium carbonate powder, 27% of shell powder, 1.5% of N-methyltrimethylacetamide, 1.5% of 4-methylcatechol, and 20% of floating beads under stirring at 20-30r / min. %, nano thermal insulation powder 5%, titanium dioxide 12.7%, thixotropic agent magnesium aluminum silicate 2%, bentonite 1%, redispersible latex powder 5%, polyvinyl alcohol 2488 3%, alum powder 0.5%, carboxylate 0.2% of methyl cellulose, 0.3% of lignocellulose, and 0.3% of pregelatinized starch. After the addition, continue to stir for 10-30 minutes, and after mixing evenly, the inner wall thermal insulation putty powder is obtained. Under stirring at 20-30r / min, mix tap water and interior wall thermal insulation putty powder according to the mass ratio of 1:1, and mix well to obtain interior wall thermal insulation putty paste.

Embodiment 2

[0043] Under stirring at 20-30r / min, add 24% of light calcium carbonate powder, 25% of shell powder, 1% of N-methyltrimethylacetamide, 2% of 4-methylcatechol, and 18% of floating beads. %, nano heat insulation powder 4%, titanium dioxide 15%, thixotropic agent magnesium aluminum silicate 1.5%, bentonite 1.5%, redispersible latex powder 3%, polyvinyl alcohol 2488 4%, alum powder 0.3%, carboxylate 0.3% of methyl cellulose, 0.2% of lignocellulose, 0.2% of pregelatinized starch, after adding, continue to stir for 10-30min, after mixing evenly, get the inner wall thermal insulation putty powder. Under stirring at 20-30r / min, mix tap water and interior wall thermal insulation putty powder according to the mass ratio of 1:1, and mix well to obtain interior wall thermal insulation putty paste.

Embodiment 3

[0045] Add 30% of light calcium carbonate powder, 30% of shell powder, 2% of N-methyltrimethylacetamide, 1% of 4-methylcatechol, and 15% of floating beads under stirring at 20-30r / min. %, nano thermal insulation powder 3%, titanium dioxide 10%, thixotropic agent magnesium aluminum silicate 1%, bentonite 2%, redispersible latex powder 3%, polyvinyl alcohol 2488 2%, alum powder 0.3%, carboxylate 0.2% of methyl cellulose, 0.2% of lignocellulose, 0.3% of pregelatinized starch, after adding, continue to stir for 10-30min, after mixing evenly, the inner wall thermal insulation putty powder is obtained. Under stirring at 20-30r / min, mix tap water and interior wall thermal insulation putty powder according to the mass ratio of 1:1, and mix well to obtain interior wall thermal insulation putty paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com