High-flame-retardant low-smoke halogen-free TPU cable material and preparation method thereof

A high flame retardant, cable material technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of agglomeration into small particles or powder packets, affecting the mechanical properties of cable materials, and difficult to disperse evenly by mixing machines. problems, to achieve the effect of low exudation, good cation exchangeability, and reduction of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

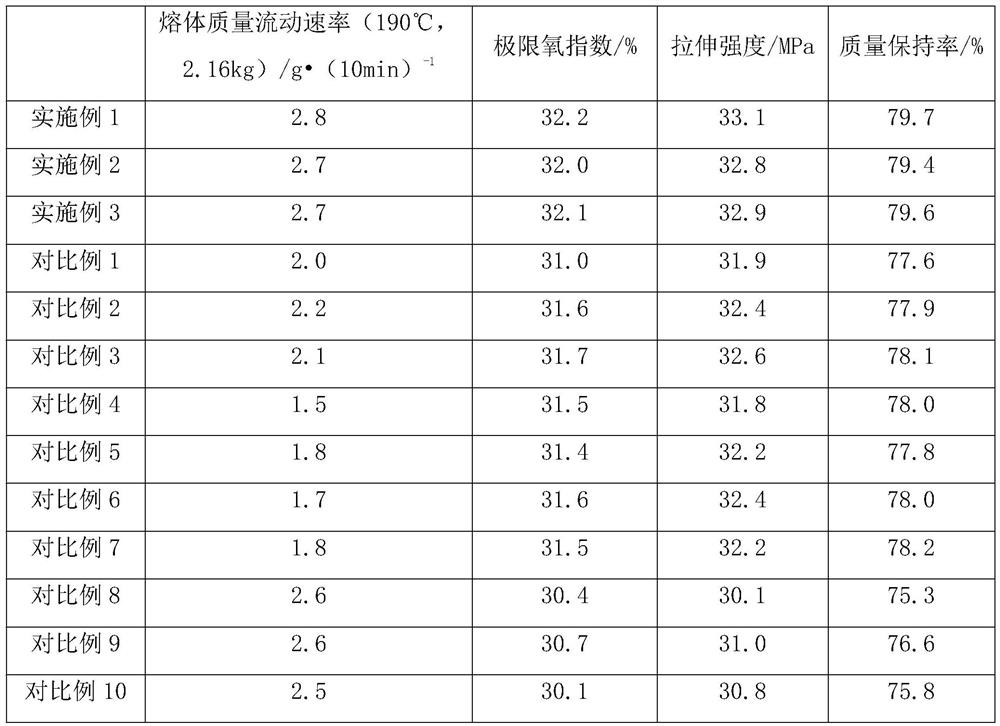

Examples

Embodiment 1

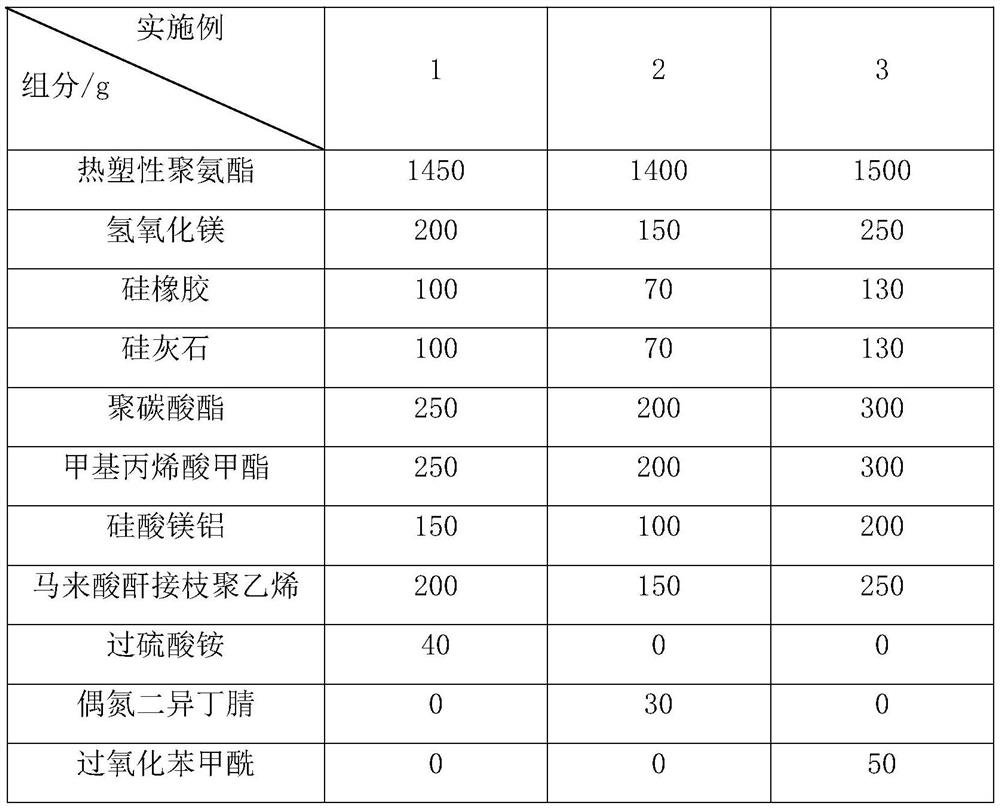

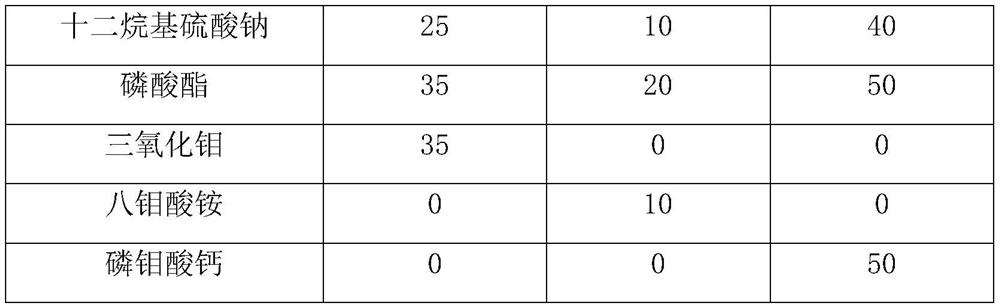

[0035] A high flame-retardant low-smoke halogen-free TPU cable material, its raw material ratio is shown in Table 1, the preparation method of the high flame-retardant low-smoke halogen-free TPU cable material includes the following steps:

[0036] (1) Weigh magnesium hydroxide in proportion, dry it at 102.5°C for 3.5h, add the weighed methyl methacrylate, surfactant and 1900g deionized water, and carry out under ultrasonic conditions with a frequency of 1525Hz Ultrasonic disperse for 17.5 minutes, then add the initiator, and pass through nitrogen to react for 2.5 hours, after cooling to room temperature, carry out vacuum filtration, vacuum drying, and grinding through a 95 mesh sieve to obtain modified magnesium hydroxide particles;

[0037] (2) Weigh thermoplastic polyurethane and polycarbonate in proportion, mix them evenly, and dry them in a vacuum oven at 76.5°C for 3 hours, and set them aside;

[0038] (3) Weigh silicone rubber, wollastonite, magnesium aluminum silicate,...

Embodiment 2

[0040] A high flame-retardant low-smoke halogen-free TPU cable material, its raw material ratio is shown in Table 1, the preparation method of the high flame-retardant low-smoke halogen-free TPU cable material includes the following steps:

[0041] (1) Weigh magnesium hydroxide in proportion, dry it at 100°C for 3 hours, add the weighed methyl methacrylate, surfactant and 1800g deionized water, and perform ultrasonication under ultrasonic conditions with a frequency of 1500Hz Disperse for 15 minutes, then add the initiator, and pass through nitrogen to react for 2 hours, after cooling to room temperature, perform vacuum filtration, vacuum drying, and grinding through a 90-mesh sieve to obtain modified magnesium hydroxide particles;

[0042] (2) Take thermoplastic polyurethane and polycarbonate in proportion, after mixing evenly, place in a vacuum oven at 75°C to dry for 2.5 hours, and set aside;

[0043] (3) Weigh silicone rubber, wollastonite, magnesium aluminum silicate, com...

Embodiment 3

[0045] A high flame-retardant low-smoke halogen-free TPU cable material, its raw material ratio is shown in Table 1, the preparation method of the high flame-retardant low-smoke halogen-free TPU cable material includes the following steps:

[0046] (1) Weigh magnesium hydroxide in proportion, dry it at 105°C for 4 hours, add the weighed methyl methacrylate, surfactant and 2000g deionized water, and perform ultrasonication under ultrasonic conditions with a frequency of 1550Hz Disperse for 20 minutes, then add the initiator, and pass through nitrogen to react for 3 hours, after cooling to room temperature, carry out vacuum filtration, vacuum drying, and grinding through a 100-mesh sieve to obtain modified magnesium hydroxide particles;

[0047] (2) Take thermoplastic polyurethane and polycarbonate in proportion, mix them evenly, place them in a vacuum oven at 78°C and dry them for 3.5 hours, and set them aside;

[0048] (3) Weigh silicone rubber, wollastonite, magnesium aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com