Silica sol modified coating for precision casting

A technology of silica sol and coating, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problem of high manufacturing cost of castings, and achieve the effect of low manufacturing cost and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

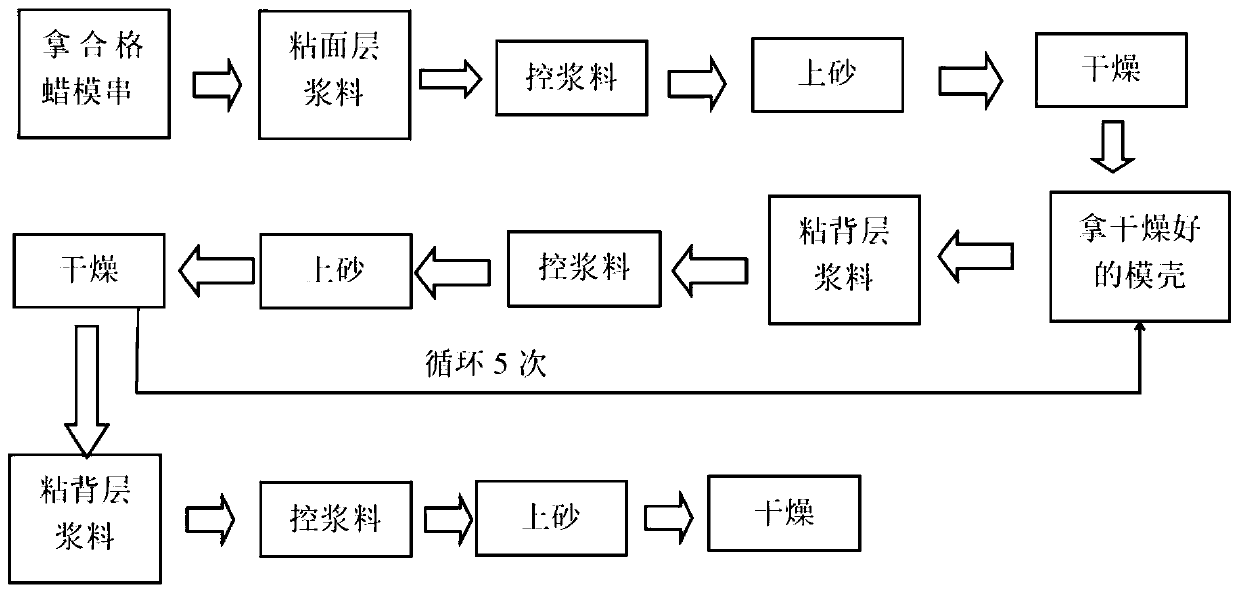

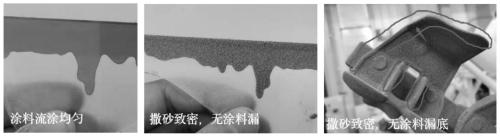

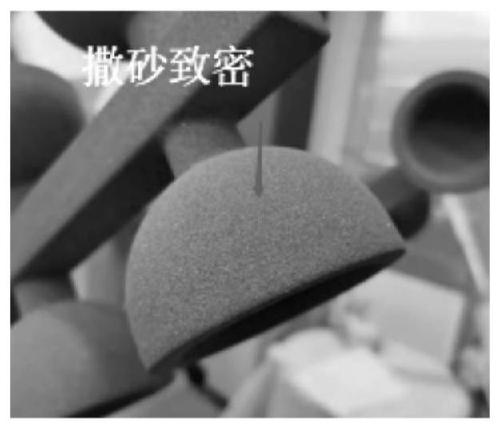

Method used

Image

Examples

Embodiment 1

[0028] The coating formula and coating thickness of the shell making process are shown in Table 1.

[0029] Table 1

[0030]

[0031] The formulation of the coating in the shell making process:

[0032] The preparation method of the surface coating is: according to the mass percentage, add 19.8% silica sol, 5% cobalt aluminate, 75% zirconium powder, 0.1% PVA, 0.1% magnesium aluminum silicate into the mixing tank, and start the mixing tank at the same time Stir the bar, rotate and stir at 30r / min, and stir for 12h to get the surface coating.

[0033] The preparation method of the back layer coating is as follows: according to the mass percentage, add 15% silica sol, 84.8% fused silica powder, 0.1% PVA, 0.1% magnesium aluminum silicate into the mixing tank, start the stirring bar at the same time, 30r / Min rotation and stirring, stirring for 12h, that is, the back coating.

Embodiment 2

[0035] See Table 2 for details of coating formula and coating thickness for shell making process.

[0036] Table 2

[0037]

[0038]

[0039] The formulation of the coating in the shell making process:

[0040] The preparation method of the surface coating is: according to the mass percentage, add 15% silica sol, 6% cobalt aluminate, 78.9% zirconium powder, 0.05% PVA, 0.05% magnesium aluminum silicate into the mixing tank, and start the mixing tank at the same time Stir the bar, rotate and stir at 20r / min, stir for 36h, and then get the surface coating.

[0041] The preparation method of the back layer coating is as follows: according to the mass percentage, add 18% silica sol, 81.9% fused silica powder, 0.05% PVA, 0.05% magnesium aluminum silicate into the mixing tank, start the stirring bar while adding the mixing tank, 20r / Min rotation and stirring, stirring for 36h, that is, the back coating.

Embodiment 3

[0043] See Table 3 for details of coating formula and coating thickness for shell making process.

[0044] table 3

[0045]

[0046] The formulation of the coating in the shell making process:

[0047] The preparation method of the surface coating is: according to the mass percentage, add 18% silica sol, 4.96% cobalt aluminate, 77% zirconium powder, 0.02% PVA, 0.02% magnesium aluminum silicate into the mixing tank, and start the mixing tank at the same time Stir the bar, rotate and stir at 25r / min, stir for 20h, and then get the surface coating.

[0048] The preparation method of the back layer coating is as follows: according to the mass percentage, add 19.6% silica sol, 80% fused silica powder, 0.02% PVA, 0.02% magnesium aluminum silicate into the mixing tank, start the stirring bar while adding the mixing tank, 25r / Min rotation and stirring, stirring for 20h, that is, the back coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com