Hollow cast iron tubular product and vertical continuous casting method and special equipment thereof

A technology of vertical continuous casting and special equipment, applied in the field of hollow cast iron pipes, vertical continuous casting methods and special equipment, can solve the problems of dimensional error, deterioration of uniformity of structure and performance, deterioration of fluidity of molten iron, etc. The ratio of the equiaxed crystal region, the effect of improving the mechanical properties, and improving the dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

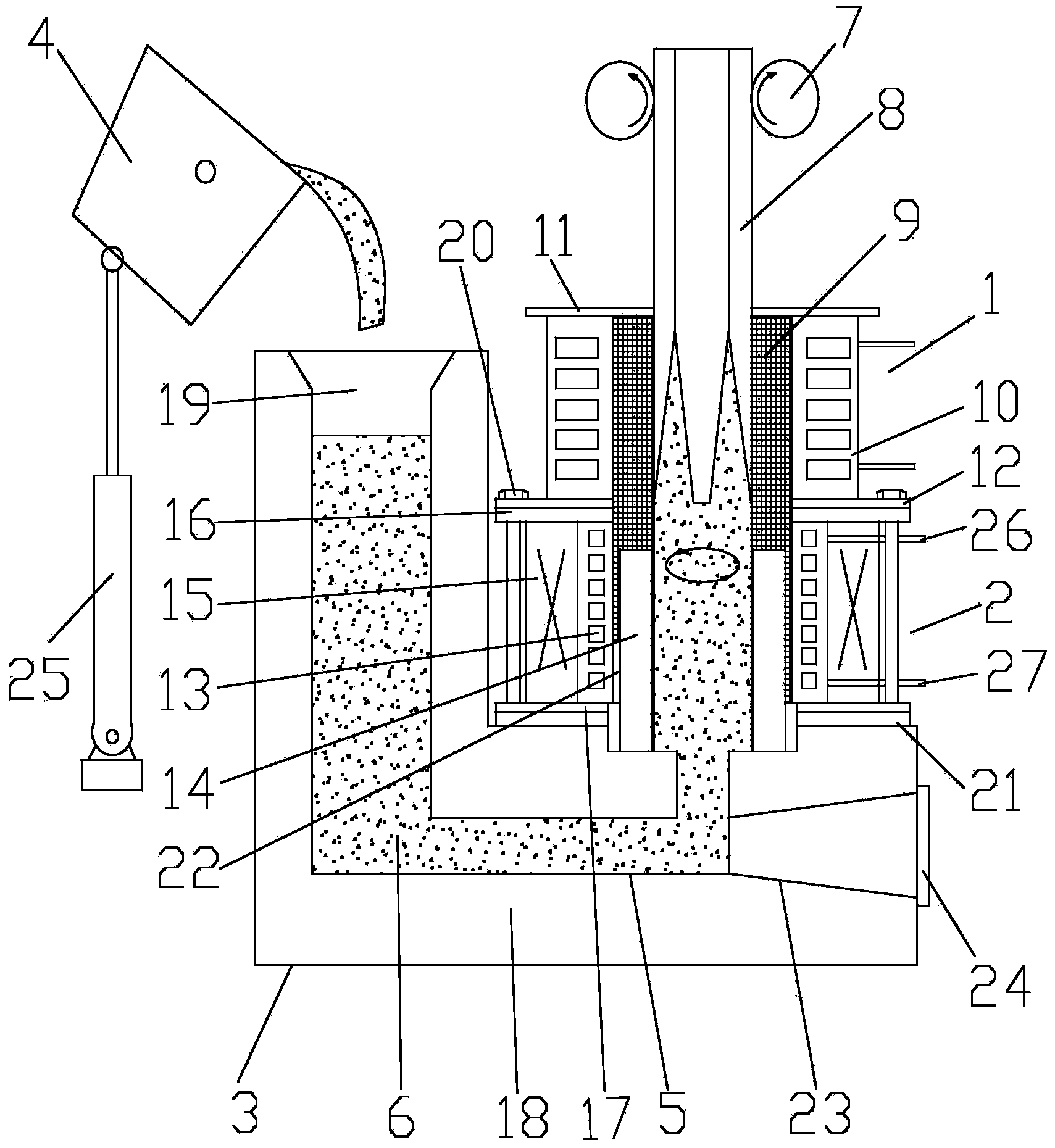

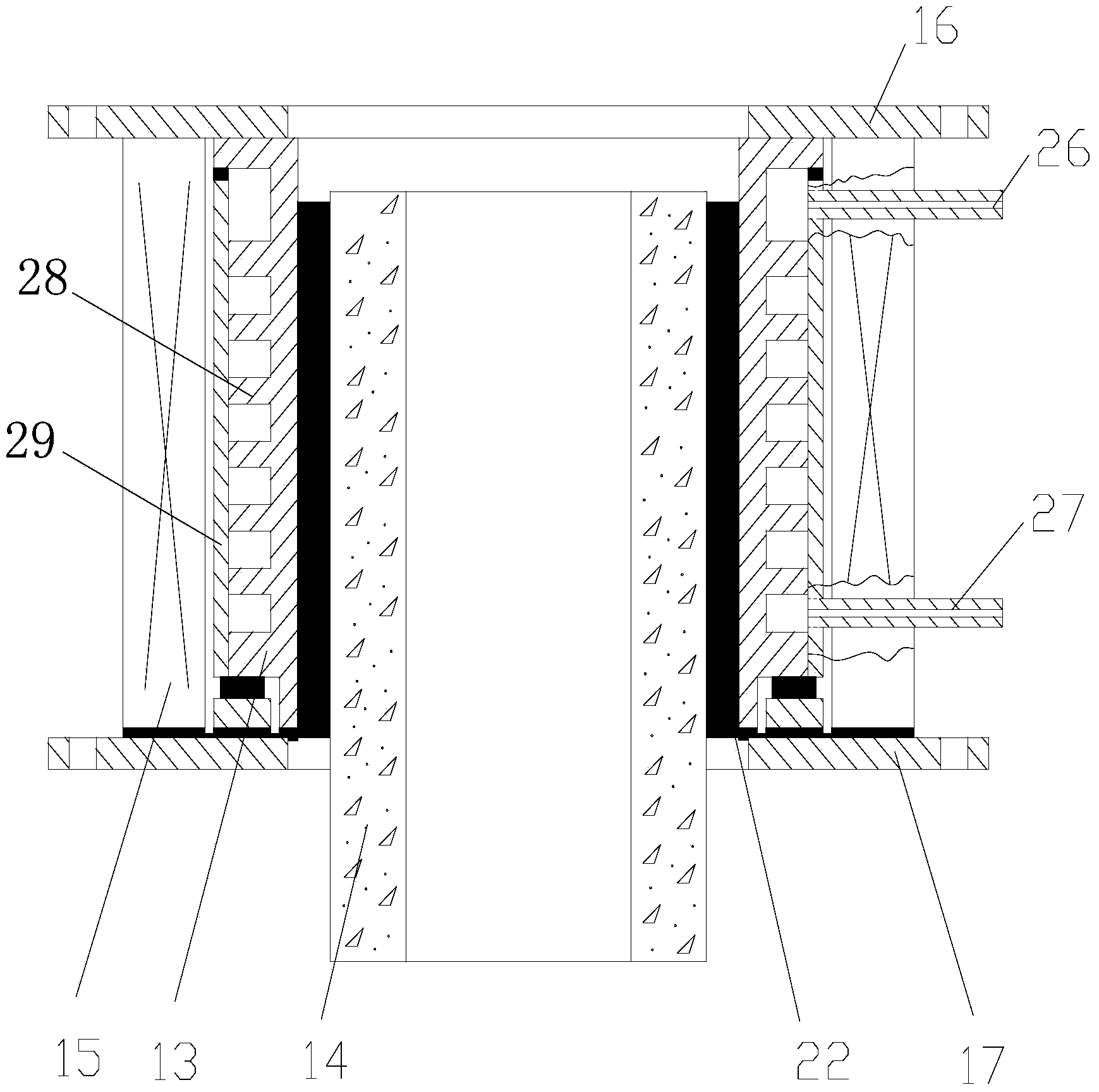

[0025] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0026] The vertical continuous casting method of the hollow cast iron pipe adopts the L-shaped continuous casting holding furnace 3, the rotating magnetic field generator 2 and the crystallizer 1 to jointly form a U-shaped channel 5 for the circulation of the molten iron 6, and the molten iron 6 in the molten iron pouring ladle 4 flows from the L-shaped Continuous injection is made at the entrance of the left end of the U-shaped channel 5 of the continuous casting holding furnace 3, flows through the rotating magnetic field generator 2 and then enters the crystallizer 1, and the rotating magnetic field generated by the rotating magnetic field generator 2 drives the molten iron 6 surrounded by the magnetic field to rotate at a high speed, driving crystallization The molten iron 6 in the mold 1 rotates, and the high-speed rotating molten iron 6 is condensed from the outside to the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com