Prepn of mesoporous spherical nano Sio2 particle

A technology of mesoporous silica and nanoparticles, which is applied in the preparation of mesoporous silica spherical nanoparticles and the field of mesoporous silica spherical nanoparticles prepared by hydrothermal method, which can solve the problem of irregular and uniform product morphology. problem, to achieve the effect of low reaction temperature, cheap reaction raw materials and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①In a 50ml Erlenmeyer flask, mix 0.35ml of 2 mol / L sodium hydroxide aqueous solution, 8ml of ethanol, 0.05g of cetyltrimethylammonium bromide, 0.25ml of tetraethyl orthosilicate and 40ml Mix with deionized water. Stir at room temperature for 30 minutes.

[0019] ②Synthesis process: Pour the above-mentioned mixed solution into a polytetrafluoroethylene reactor of about 50 ml, put the reactor into a stainless steel protective shell, and tighten the cover. As for the blast oven, raise the temperature to 100°C and keep the temperature constant for 24 hours.

[0020] ③Post-treatment: After the reaction is completed, filter and wash the solution in the reactor, place the resulting filter cake in an oven at 50°C to dry to obtain a powder, place the powder in a muffle furnace, raise the temperature to 550°C and keep the temperature constant for 6 hours , the resulting powder is spherical mesoporous silica nanoparticles.

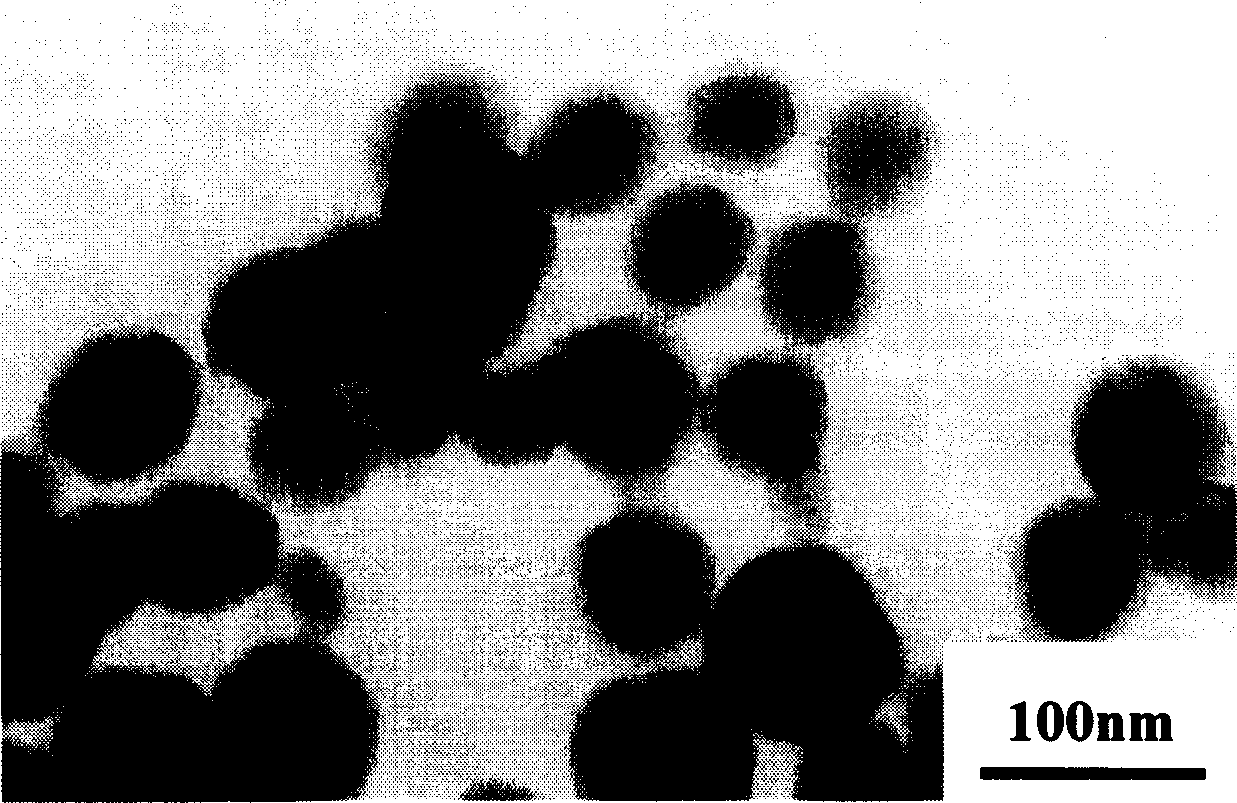

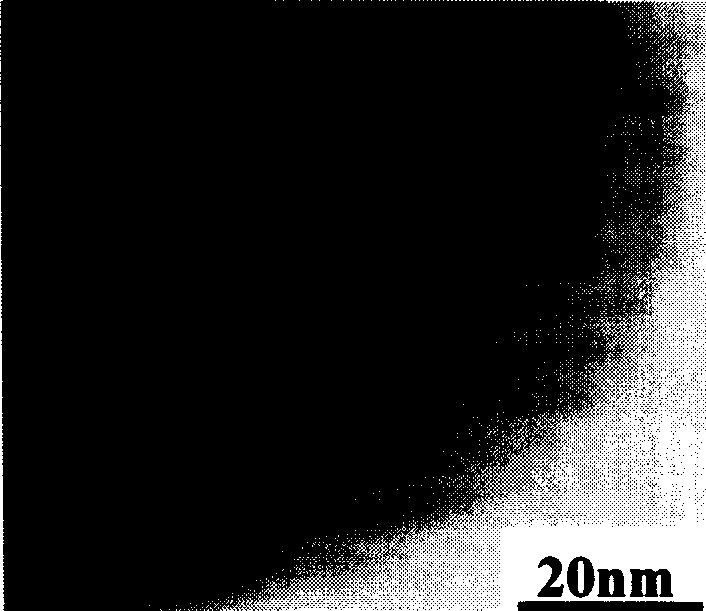

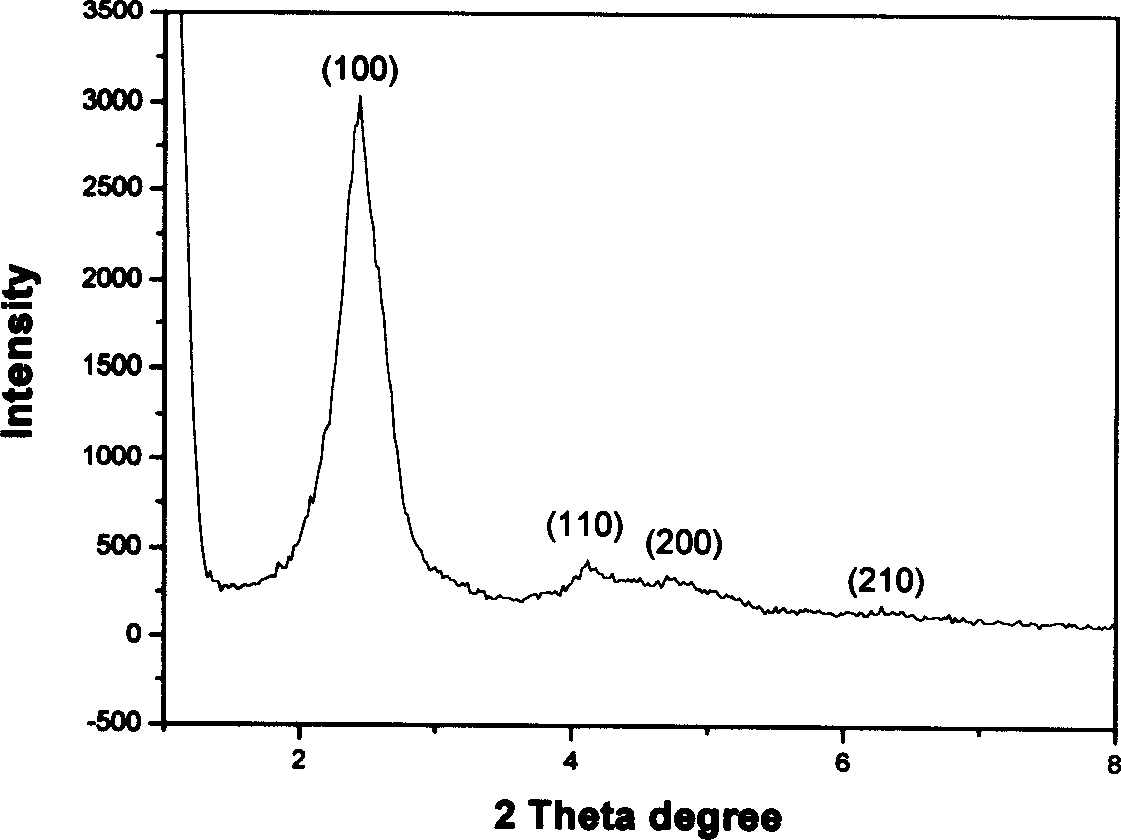

[0021] The transmission electron microscope pictures ...

Embodiment 2

[0023] ①In a 50ml Erlenmeyer flask, mix 0.35ml of 2 mol / liter sodium hydroxide aqueous solution, 0.05g of cetyltrimethylammonium bromide, 0.25ml of tetraethyl orthosilicate and 50ml of deionized water mix. Stir at room temperature for 30 minutes.

[0024] ②Synthesis process: Pour the above mixed solution into a polytetrafluoroethylene reactor, put the reactor into a stainless steel protective shell, and tighten the cover. As for the blast oven, the temperature was raised to 120° C., and the temperature was kept constant for 12 hours.

[0025] ③Post-treatment: After the reaction is completed, filter and wash the solution in the reactor, place the resulting filter cake in an oven at 50°C to dry to obtain a powder, place the powder in a muffle furnace, raise the temperature to 550°C and keep the temperature constant for 6 hours , the resulting powder is spherical mesoporous silica nanoparticles.

Embodiment 3

[0027] ①In a 50ml Erlenmeyer flask, mix 0.14g of sodium hydroxide powder, 8ml of n-butanol, 0.05g of cetyltrimethylammonium bromide and 0.25ml of tetraethyl orthosilicate with 40ml of deionized water to mix. Stir at room temperature for 30 minutes.

[0028] ②Synthesis process: Pour the above mixed solution into a polytetrafluoroethylene reactor, put the reactor into a stainless steel protective shell, and tighten the cover. As for the blast oven, raise the temperature to 120°C and keep the temperature constant for 24 hours.

[0029] ③Post-treatment: After the reaction is completed, filter and wash the solution in the reactor, place the resulting filter cake in an oven at 50°C to dry to obtain a powder, place the powder in a muffle furnace, raise the temperature to 550°C and keep the temperature constant for 6 hours , the resulting powder is spherical mesoporous silica nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com