Patents

Literature

37results about How to "Guarantee joint force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

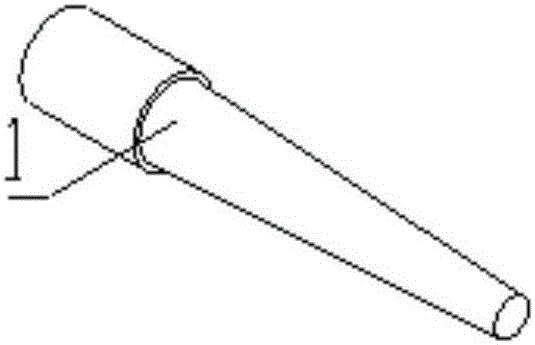

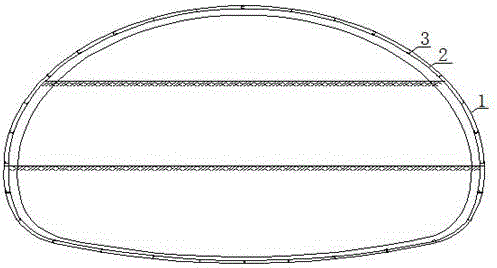

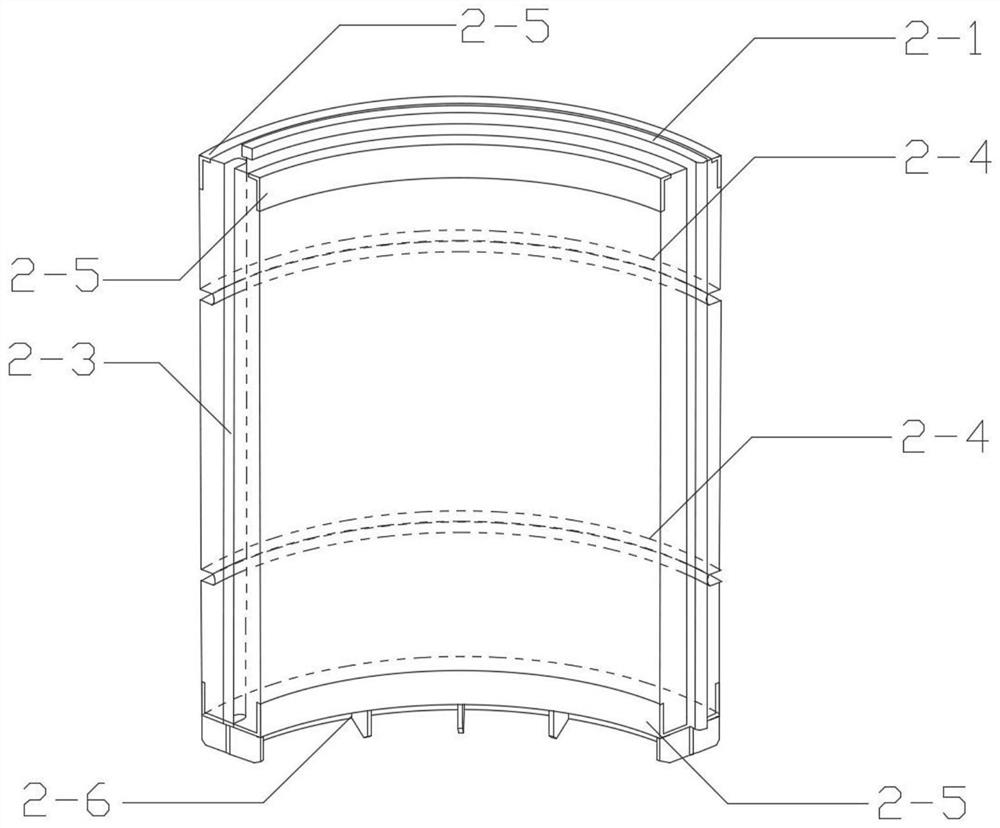

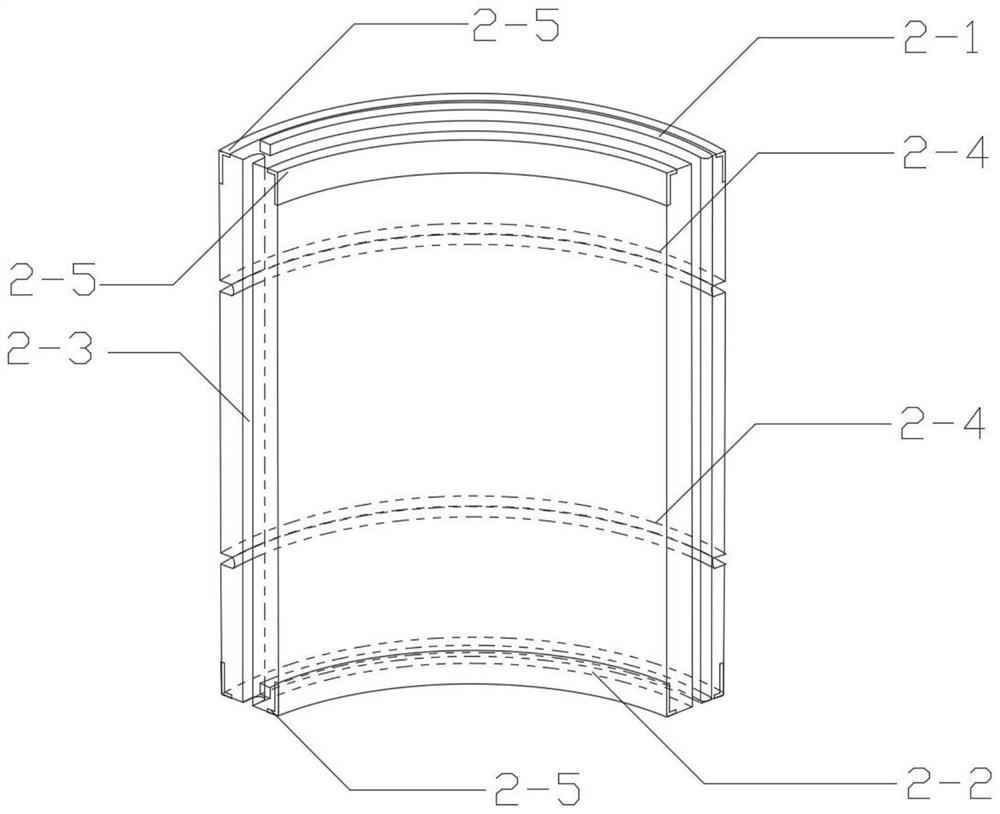

Waterproof type single-layer lining structure applicable to fourth level surrounding rock double-line track and manufacturing method thereof

ActiveCN110359915AEven by forceSimple construction processUnderground chambersTunnel liningFiberRock bolt

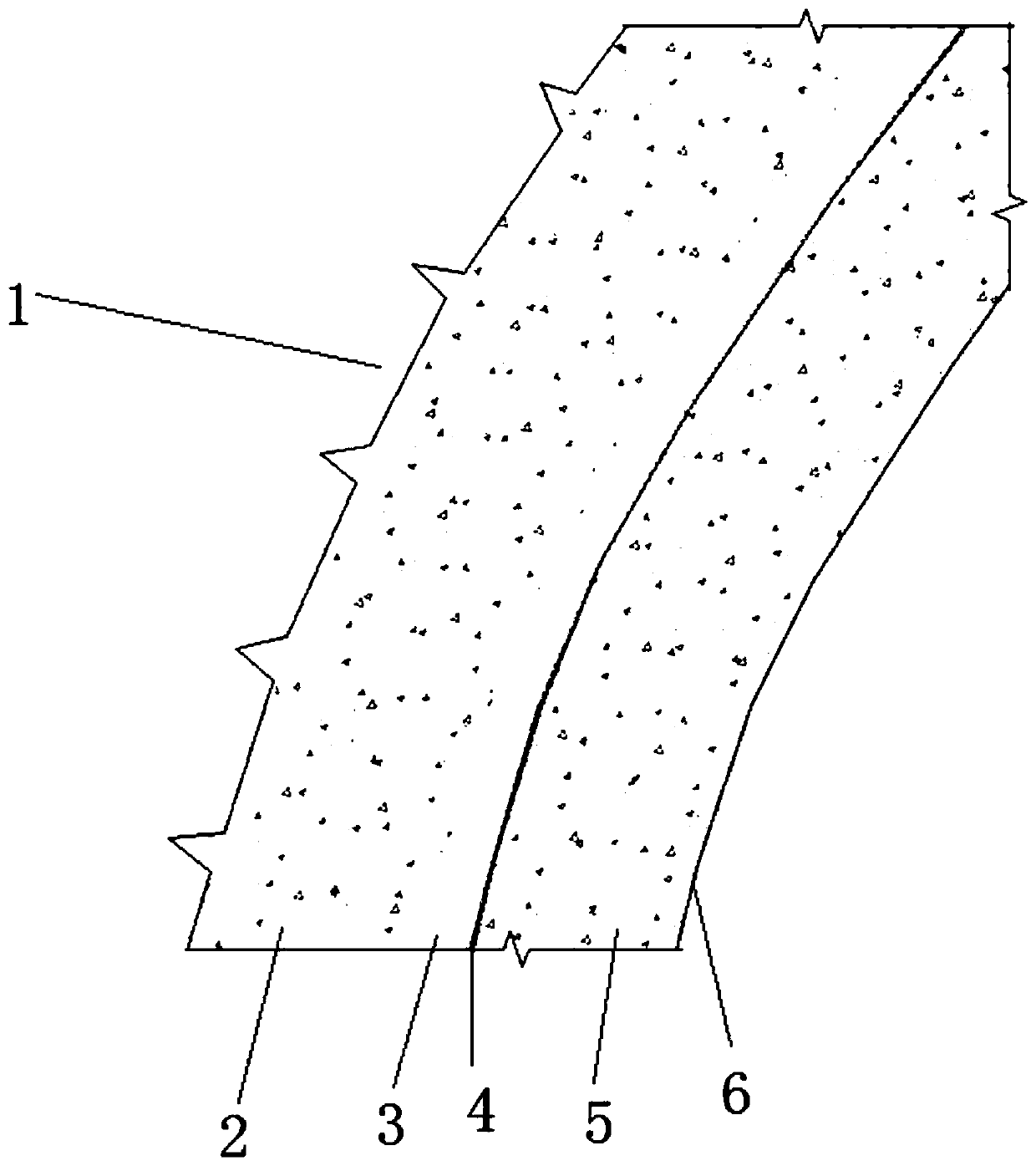

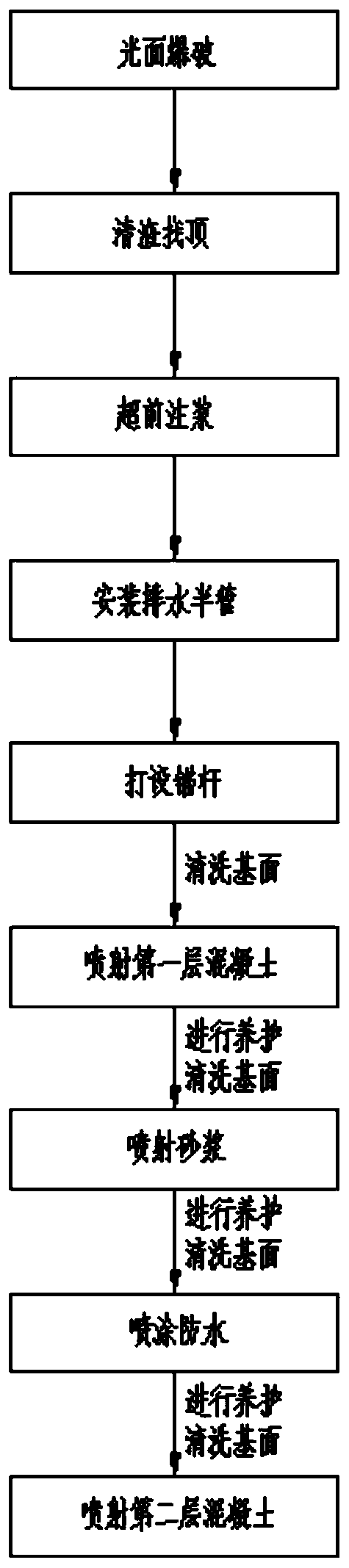

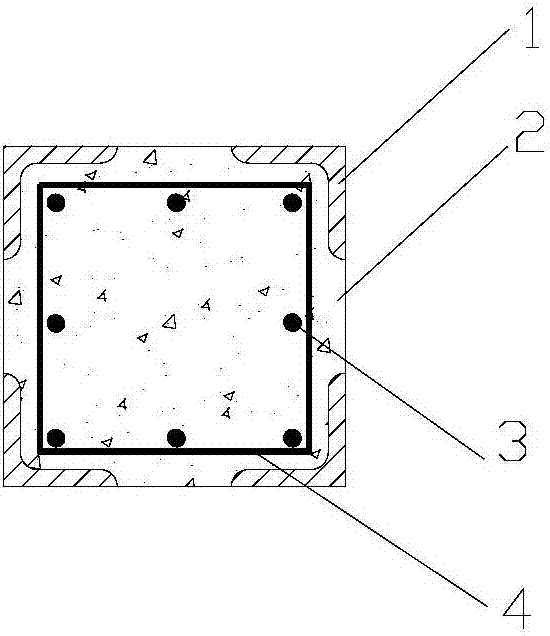

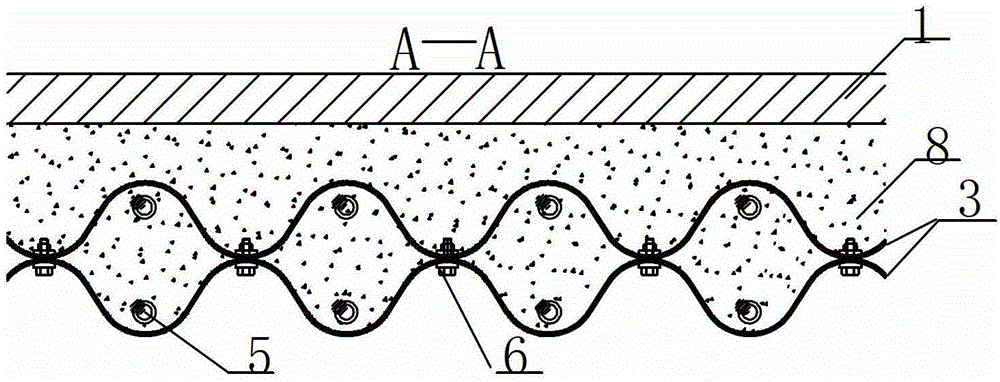

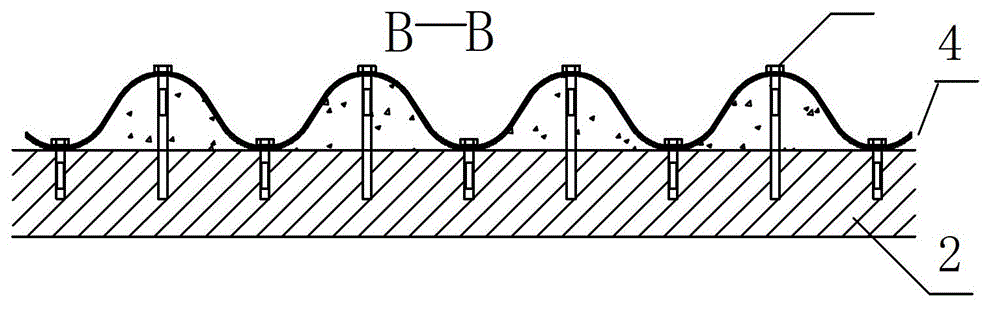

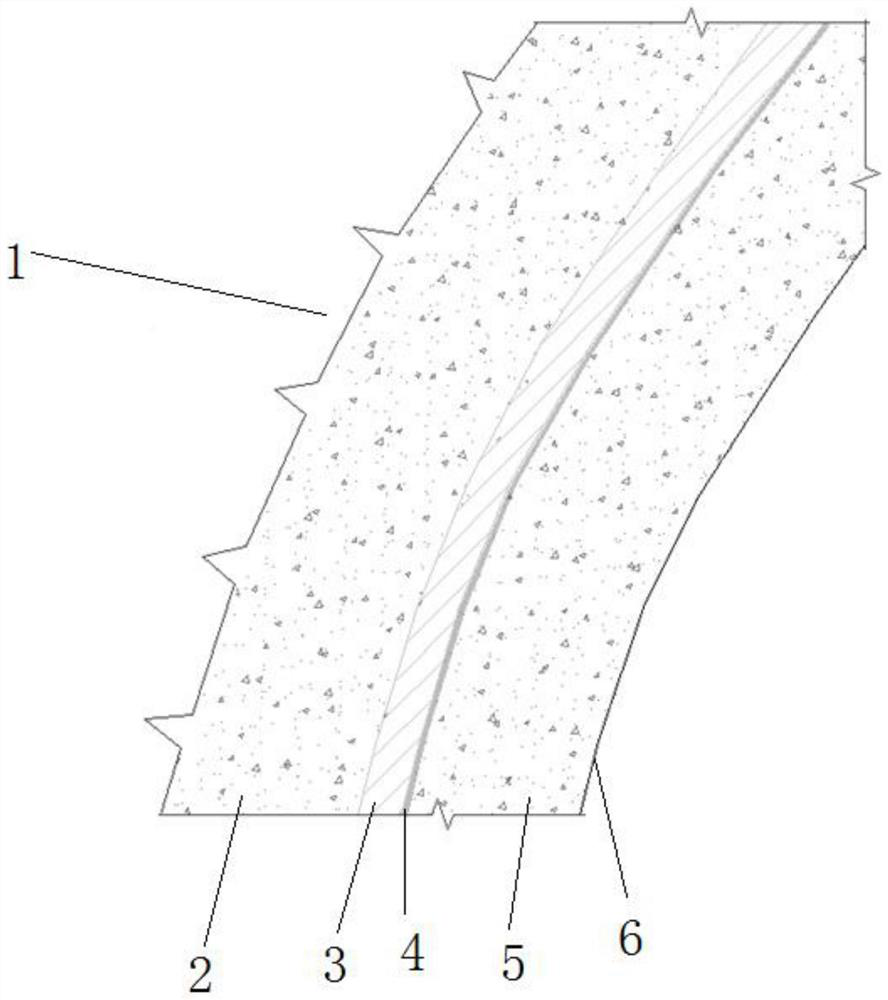

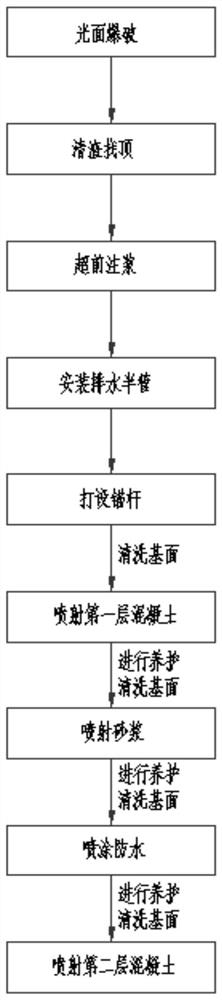

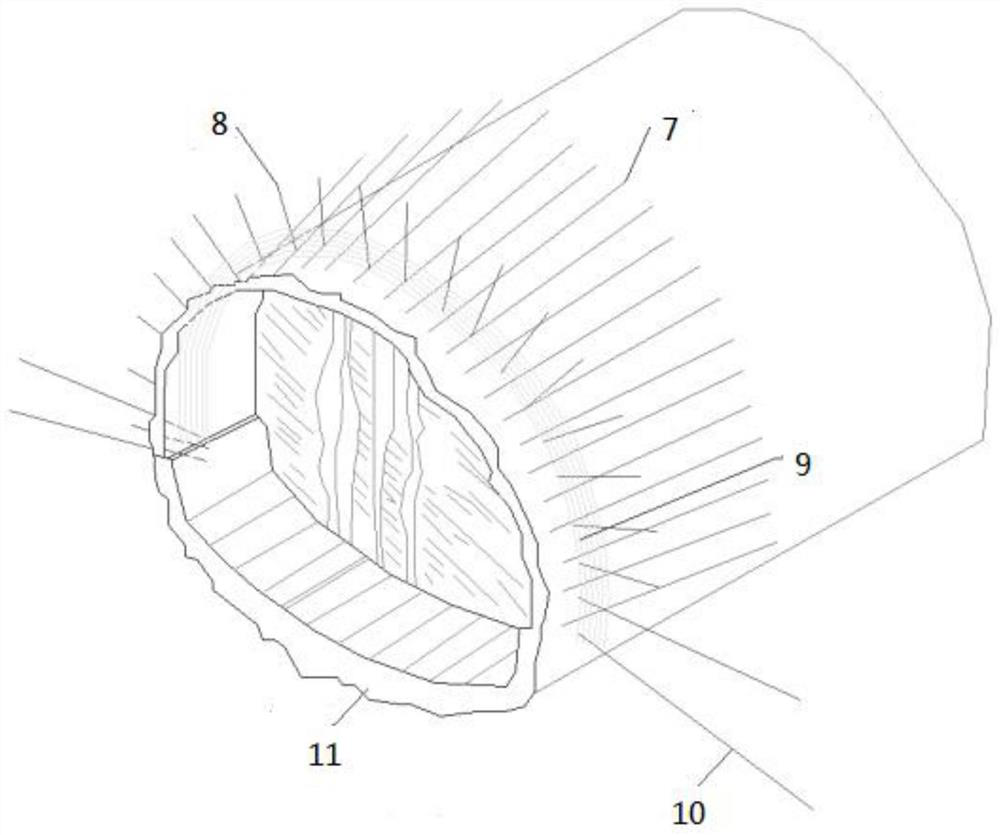

The invention discloses a waterproof type single-layer lining structure applicable to a fourth level surrounding rock double-line track. The waterproof type single-layer lining structure applicable tothe fourth level surrounding rock double-line track comprises fourth-level surrounding rocks subjected to smooth blasting treatment and further comprises omega-shaped spring drainage half pipes and anchored rods arranged in the fourth-level surrounding rocks in a struck manner. The anchored rods are perpendicular to the rock surfaces of the fourth-level surrounding rocks. The rock surfaces of thefourth-level surrounding rocks are further subjected to washing, injection of a first layer crude fiber concrete and curing, injection of mortar and curing, spraying of a waterproof material and curing, ejection of a second layer fine fiber concrete and curing in sequence. According to the waterproof type single-layer lining structure applicable to the fourth level surrounding rock double-track tunnel involved, force bearing of the single-layer lining structure formed by the technology is uniform; the structure has certain deformation resistant capacity; the construction technology is simple;the construction period is short; construction pollution is reduced; the structure is low-carbon and environment-friendly and widely applied to projects of fourth-level surrounding rock double-tracktunnel lining structures.

Owner:中铁科学研究院有限公司

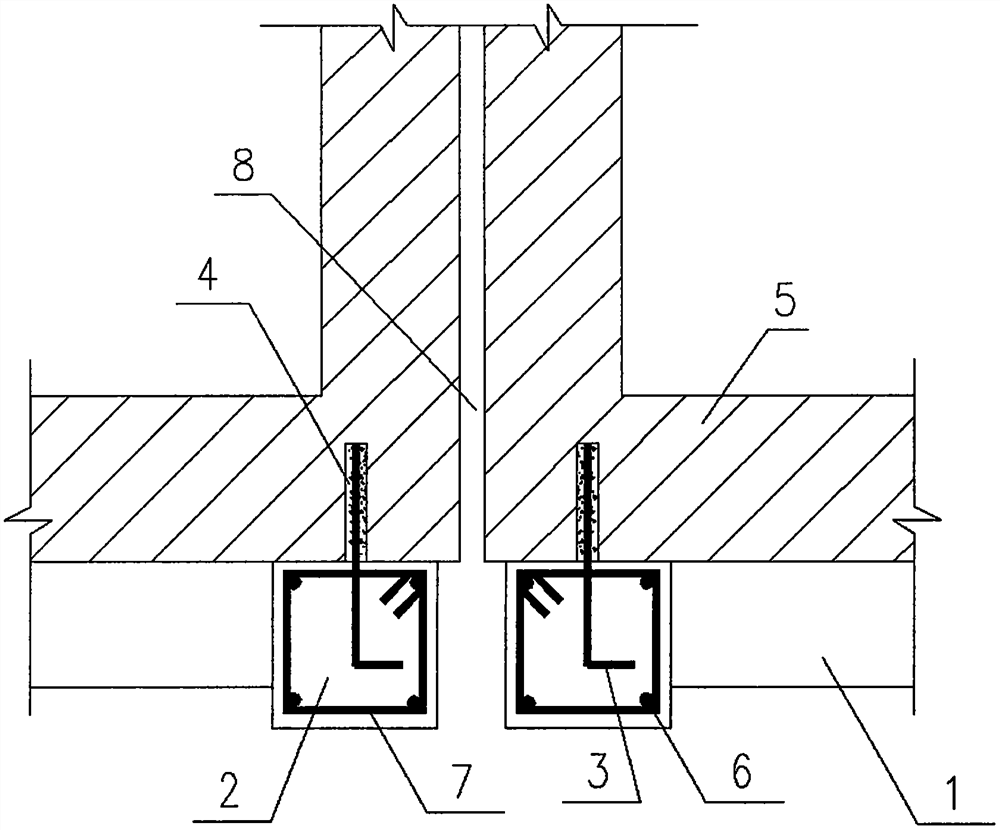

Method suitable for underground storey adding of frame-structure independent foundation building

ActiveCN107035159AImprove stabilityExtended service lifeArtificial islandsBuilding repairsBasementJoint stress

The invention discloses a method suitable for underground storey adding of a frame-structure independent foundation building. The method solves the problem that basement storey adding in the prior art is severe in waste, and has the beneficial effects that waste of dismounting of pressed piles is reduced, and a new though is provided for underground storey adding of an existing building. The method includes the specific steps that earthwork above and around an independent foundation of the frame-structure building is excavated, and the independent foundation is exposed; a reaction frame and a jack are arranged on the top face of the independent foundation, and a precast pile is planted into the independent foundation through the reaction frame; the precast piles under all frame columns are connected in a pulling mode through rigid connecting parts to form a joint stress body; and a basement structure is constructed with the precast piles used as supporting columns of the basement structure.

Owner:SHANDONG JIANZHU UNIV +2

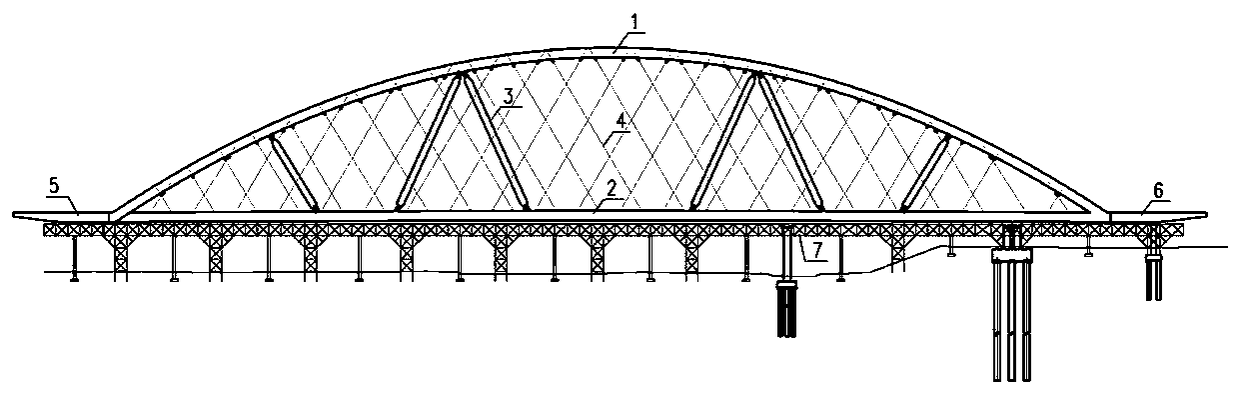

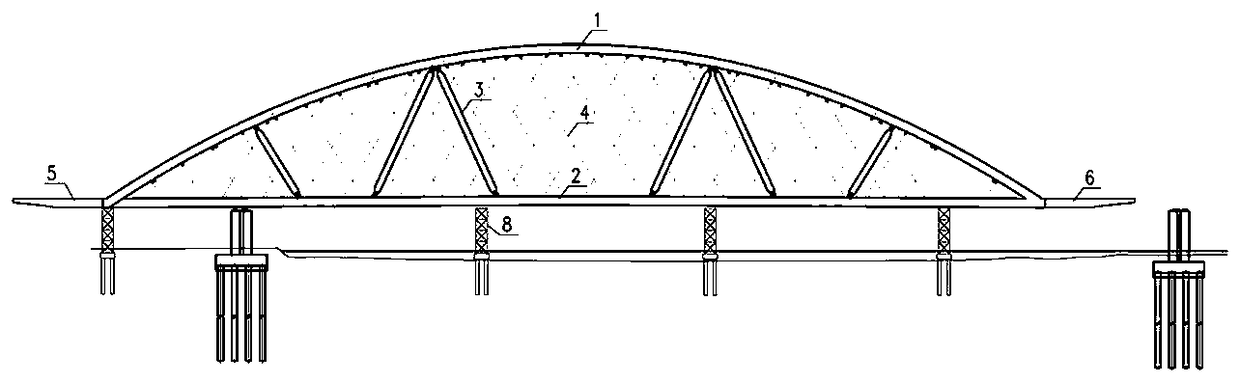

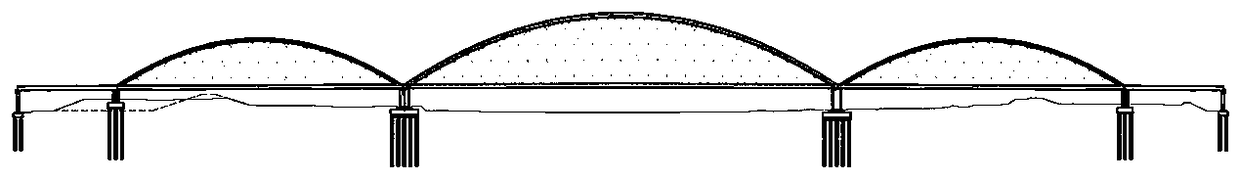

Pushing construction method for a large-span composite arch bridge with adjustable construction state

PendingCN109252454AGuarantee joint forceReduce in quantityBridge erection/assemblyArch-type bridgeEngineeringStressed state

The invention relates to a pushing construction method for a large-span composite arch bridge with adjustable construction state, which is characterized in that a steel arch, a steel beam, a hanger and a connecting steel arch, a temporary strut of a steel beam are assembled into a beam-arch composite system on the shore in advance, and the suspension rods are pretensioned. In the process of pushing the composite arch bridge with suspension rods and temporary struts as a whole, the construction state is adjusted by optimizing the tension of suspension rods based on the structural function of component stress limits. The construction method adjusts the stress state of the composite arch bridge in real time by adjusting the tension of the suspension bar, to some extent, it ensures the cooperation of arch and beam, improves the mechanical performance of the structure, reduces the number of temporary piers and arch beam temporary struts in water, reduces the complexity of the structure construction, and has high popularization value in applicability, economy, construction quality, construction period and other aspects, which is of pioneering significance for similar projects in the future.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

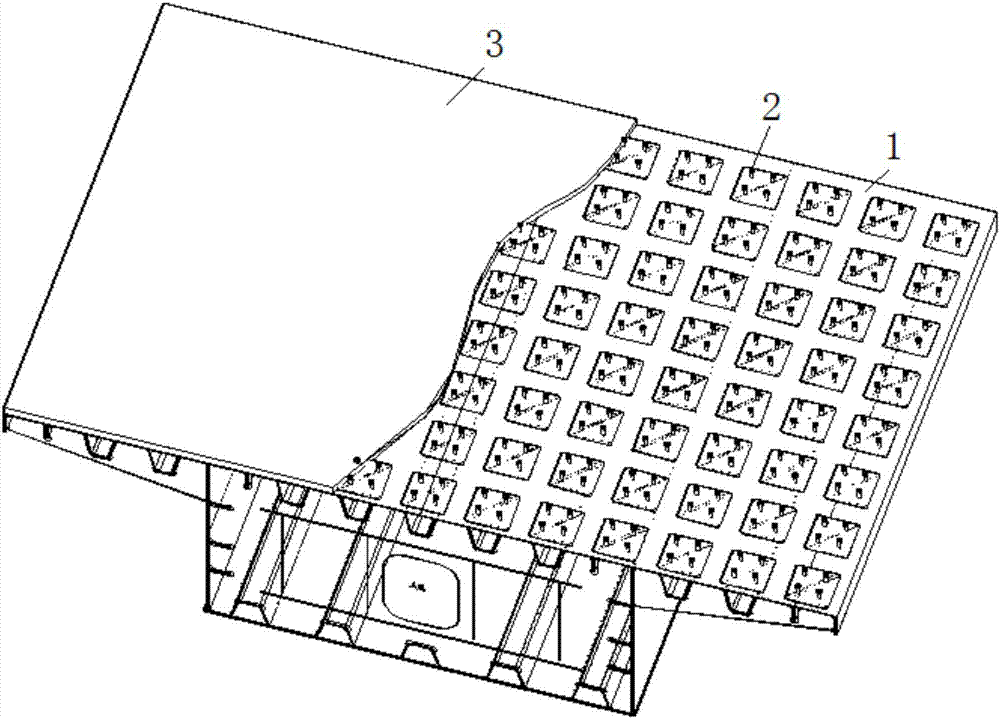

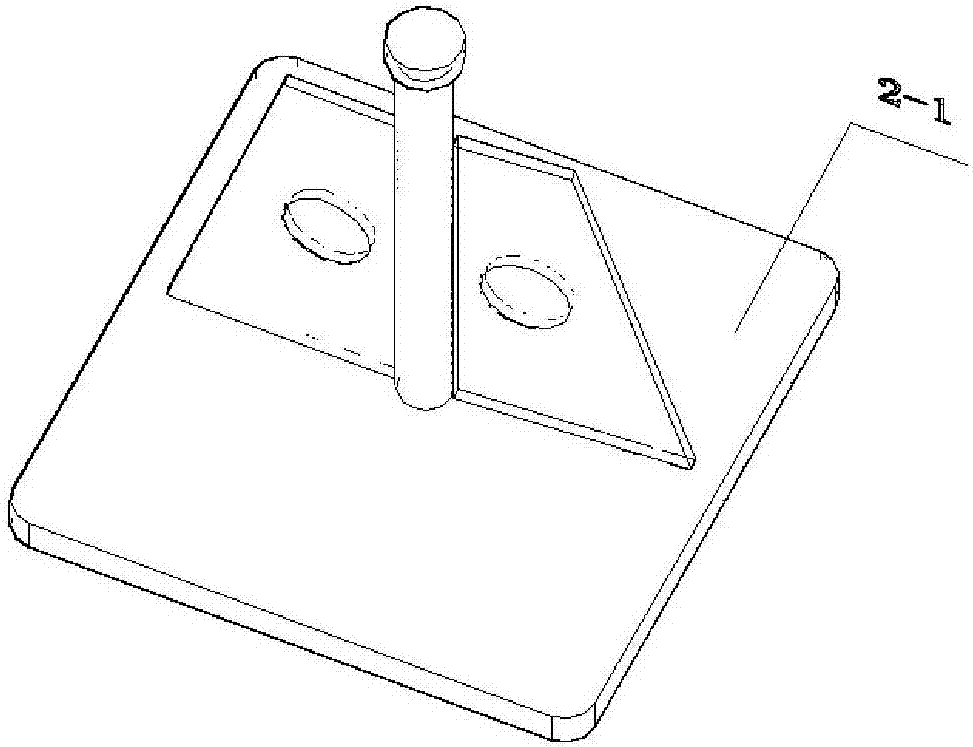

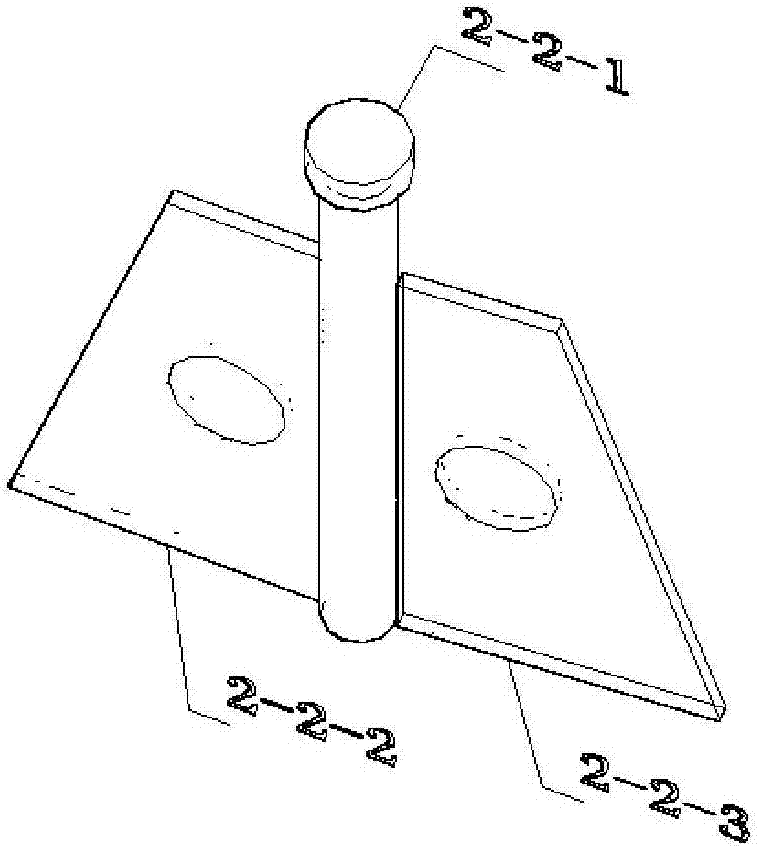

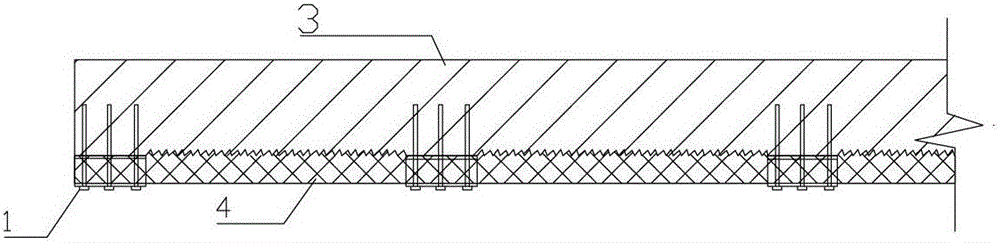

Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

ActiveCN107237259AHigh compressive strengthHas tensile strengthBridge structural detailsBridge deckHigh pressure

The invention provides a composite steel fiber-concrete steel bridge deck based on cohesive cotter groups. The preparation method comprises the following steps that 1, cleaning and shot blasting are conducted on the cover plate of the steel bridge deck by means of a high-pressure air gun; 2, cotter connecting components are arranged on the cover plate of the steel bridge deck in a bonding mode; 3, a fiber-concrete pavement layer is casted on the cover plate of the steel bridge deck with the cohesive cotter groups and the cotter connecting components in situ. By means of the composite steel fiber-concrete steel bridge deck based on the cohesive cotter groups, the structure stiffness can be improved, the stress amplitude of a fatigue detail place is reduced, and long service life design of an orthotropic steel bridge deck is achieved.

Owner:CHANGAN UNIV

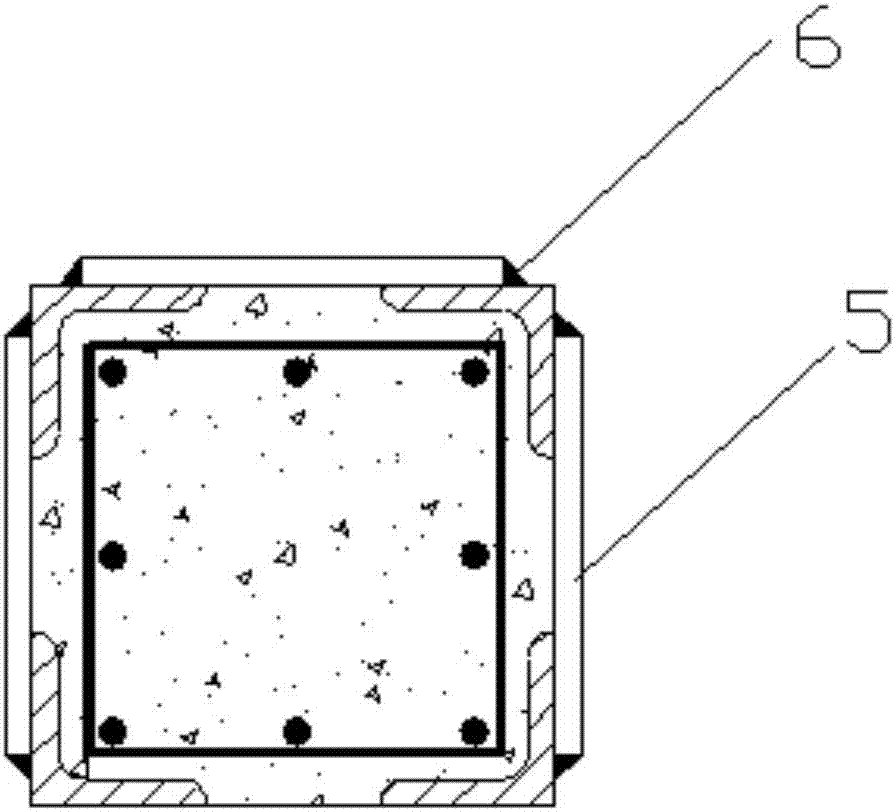

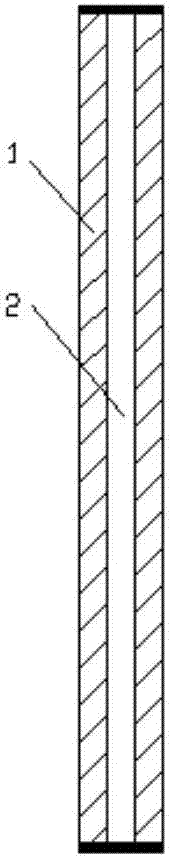

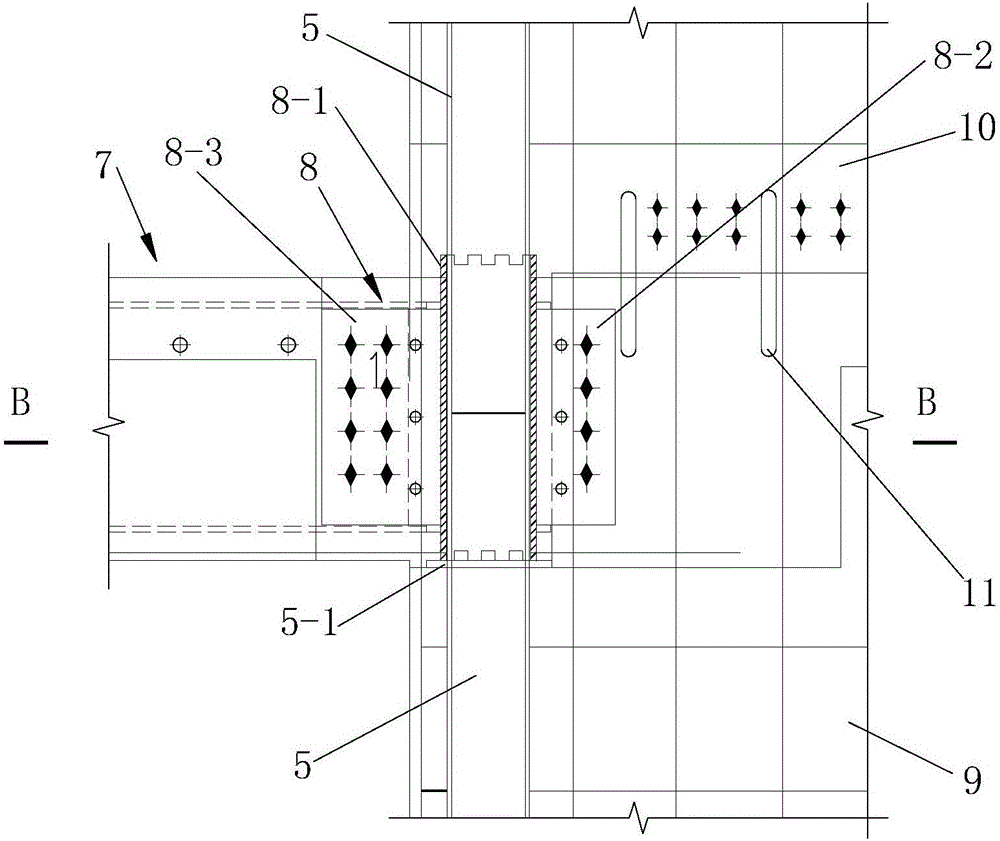

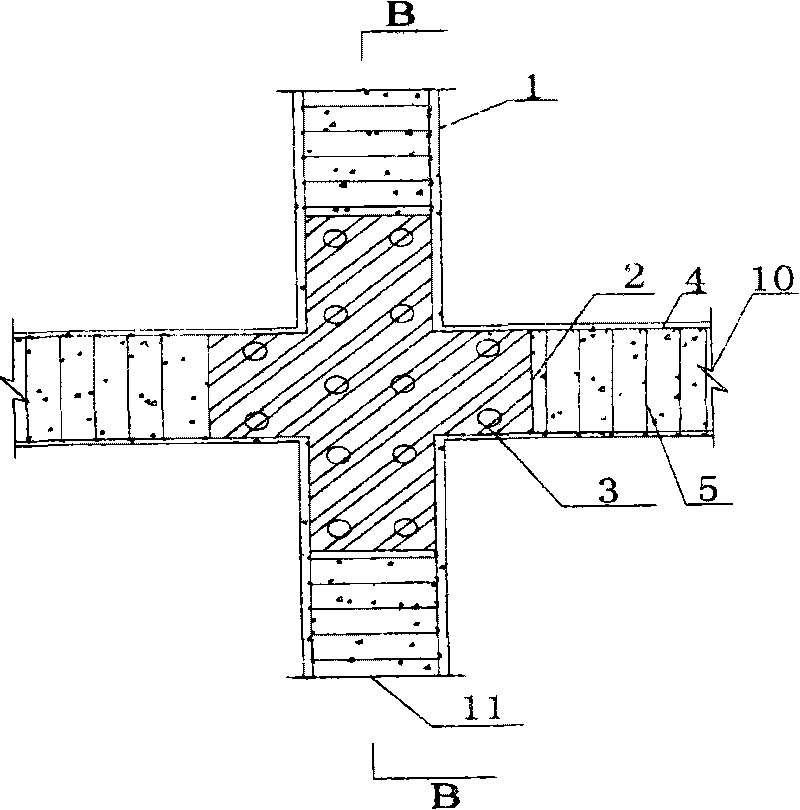

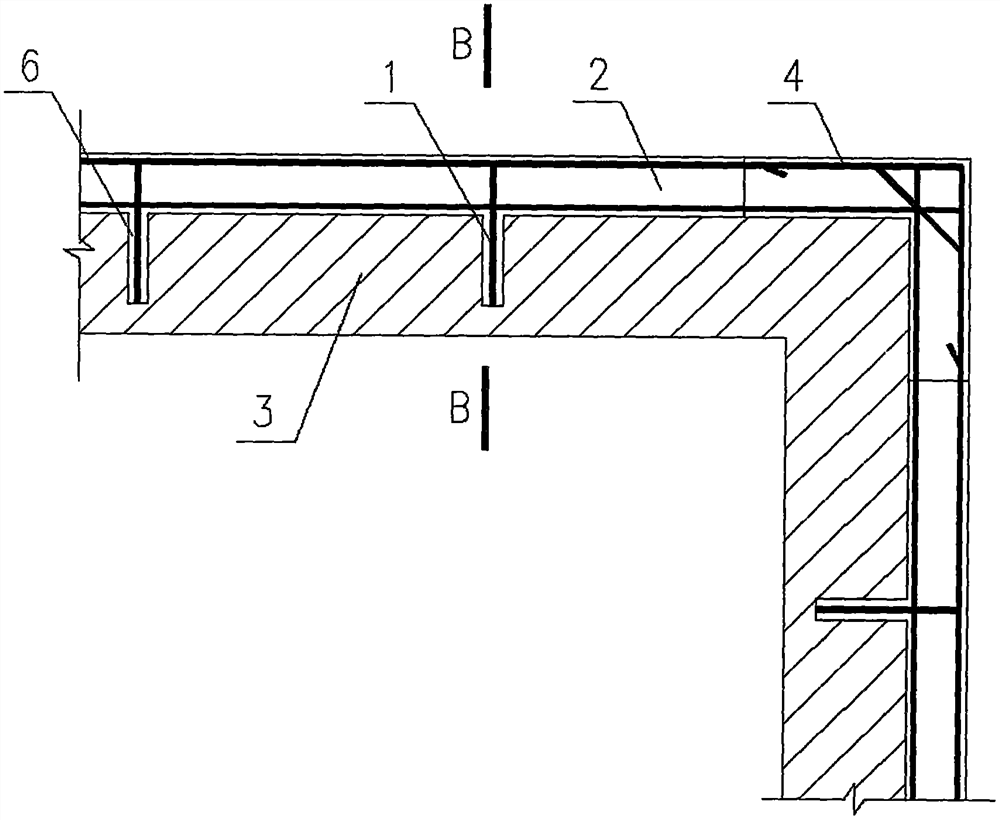

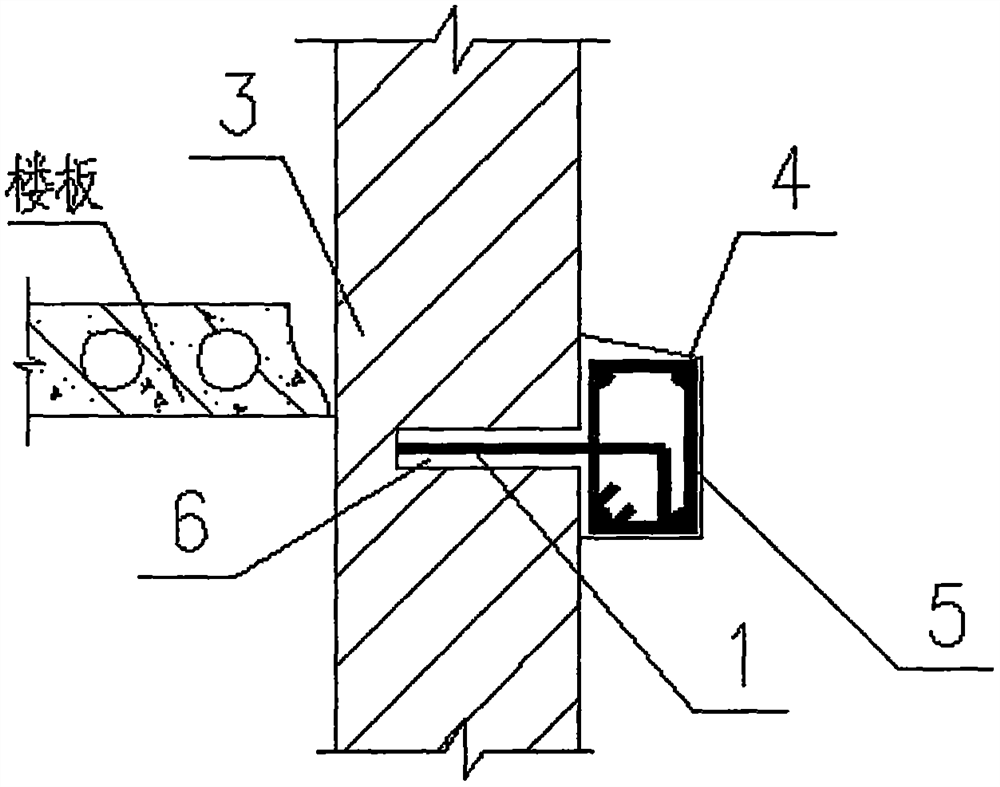

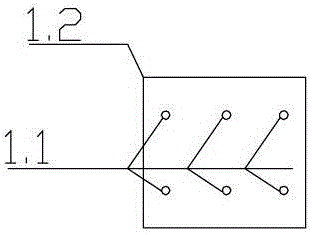

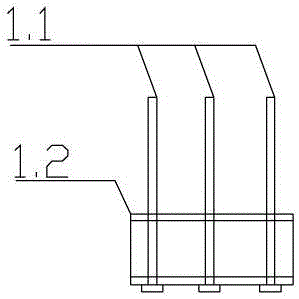

Fabricated structural system of steel plate reinforced concrete shear walls and construction method of fabricated structural system

ActiveCN106639052AReduce section loss rateOvercome the technical difficulty of being unable to fix on the vertical steel plateWallsLoad-supporting elementsFloor slabSheet steel

The invention discloses a fabricated structural system of steel plate reinforced concrete shear walls. The fabricated structural system comprises a beam member, the steel plate reinforced concrete shear walls, a floor and a sleeve connecting piece. Each steel plate reinforced concrete shear wall comprises vertical steel plates and continuous spiral stirrups. The structural system is high in assembling rate. The invention further discloses a construction method of the fabricated structural system of the steel plate reinforced concrete shear walls. The construction method comprises the steps that firstly, one prefabricated steel plate reinforced concrete shear wall is manufactured; secondly, the steel plate reinforced concrete shear wall on the lower layer is assembled; thirdly, the sleeve connecting piece is assembled on the steel plate reinforced concrete shear wall on the lower layer; fourthly, the beam member is assembled, and the floor is installed; fifthly, the floor and the beam member as well as the floor and the steel plate reinforced concrete shear wall on the lower layer are connected by pouring concrete, and concrete is poured to the junction of the beam member and the steel plate reinforced concrete shear wall on the lower layer; and sixthly, the steel plate reinforced concrete shear wall on the upper layer is hoisted, and finally concrete is poured to the junction of the steel plate reinforced concrete shear walls on the upper layer and the lower layer in situ. By adoption of the fabricated structural system of steel plate reinforced concrete shear walls and the construction method of the fabricated structural system, construction can be completed with the high assembling rate.

Owner:陕西省建筑设计研究院(集团)有限公司

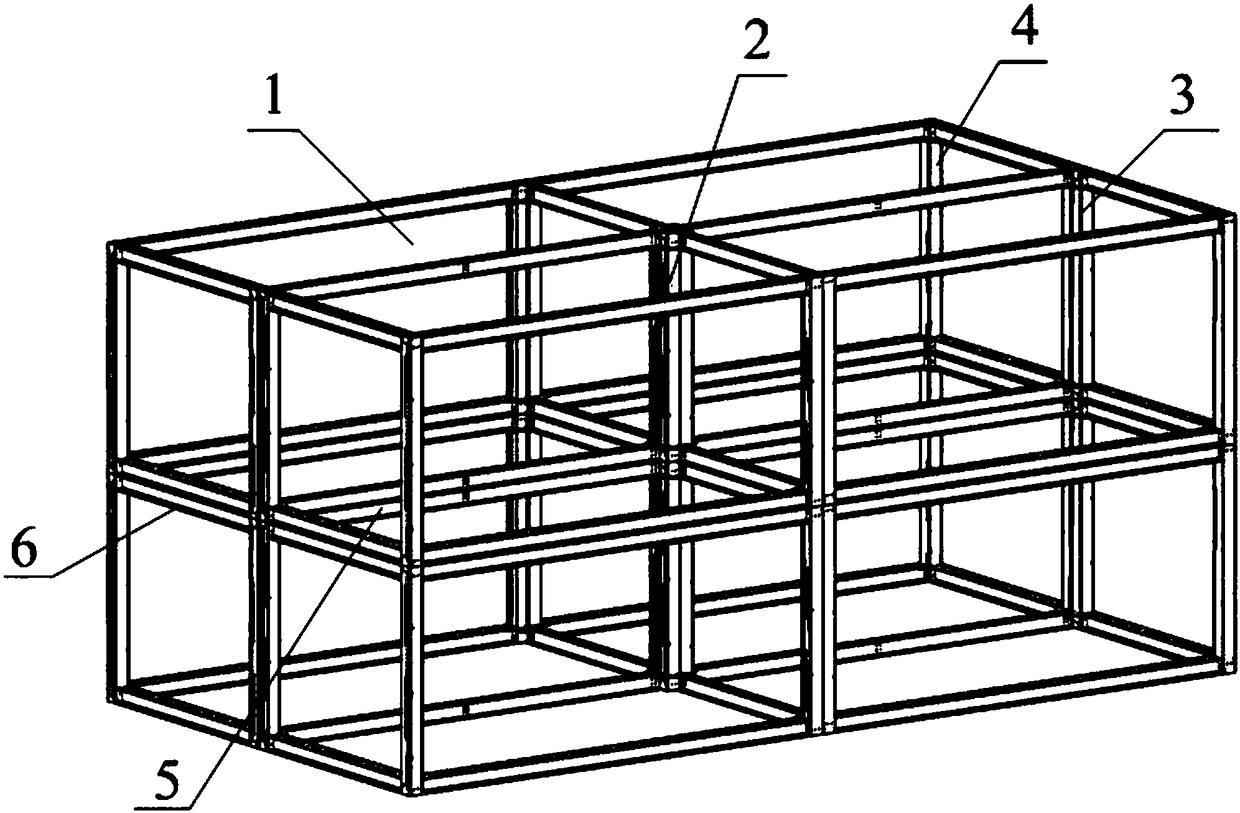

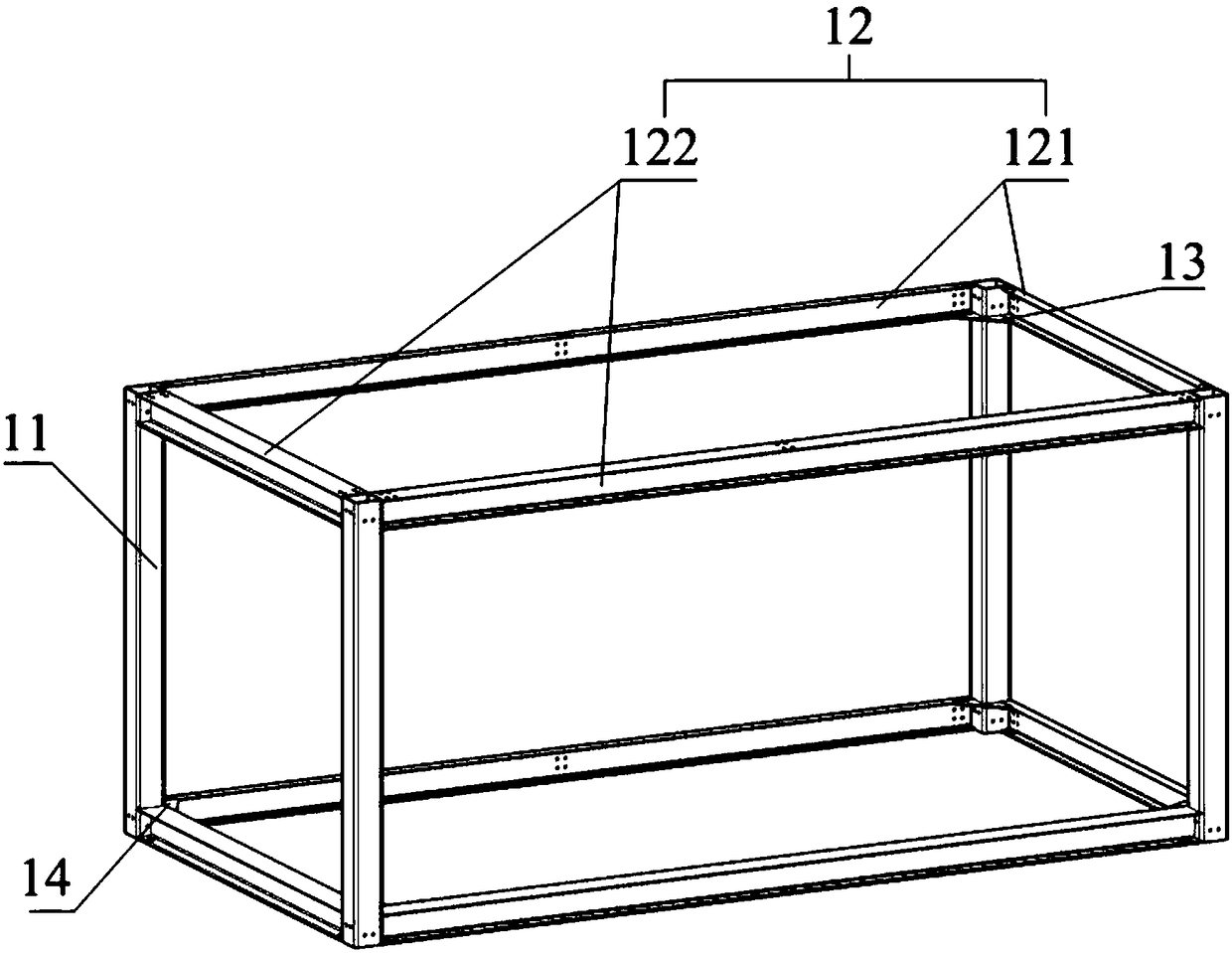

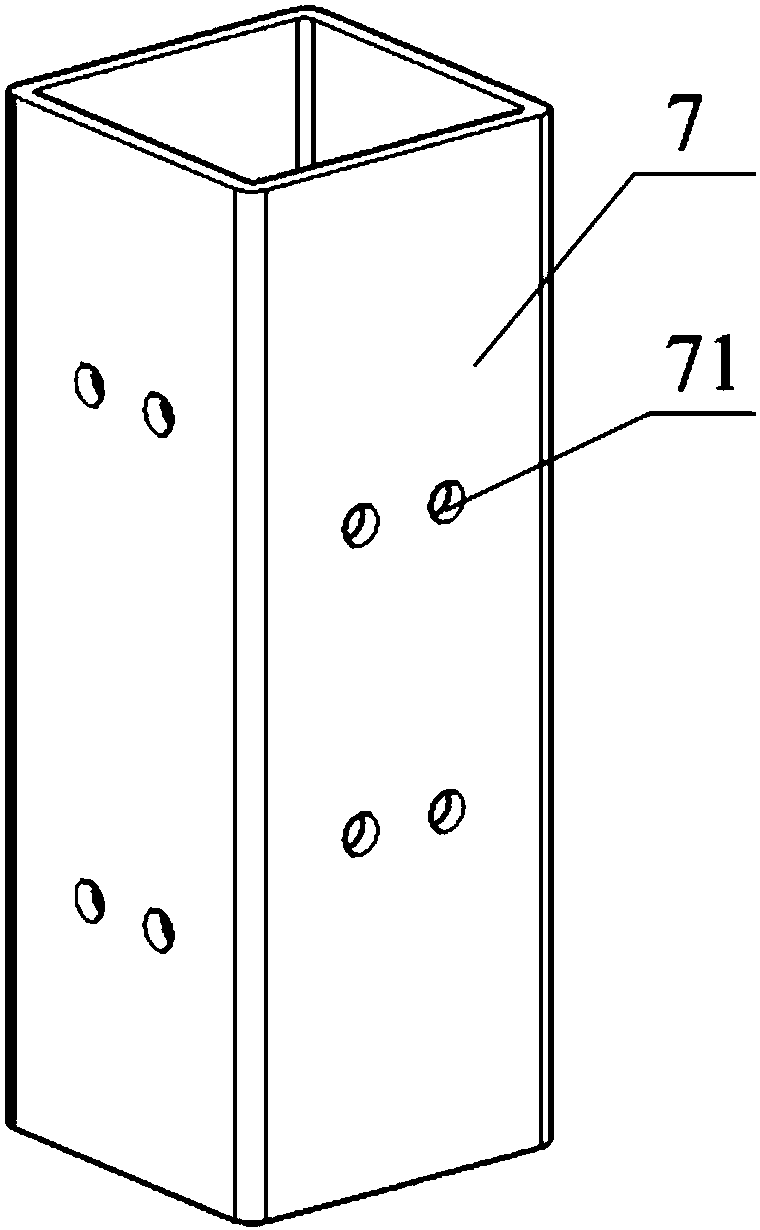

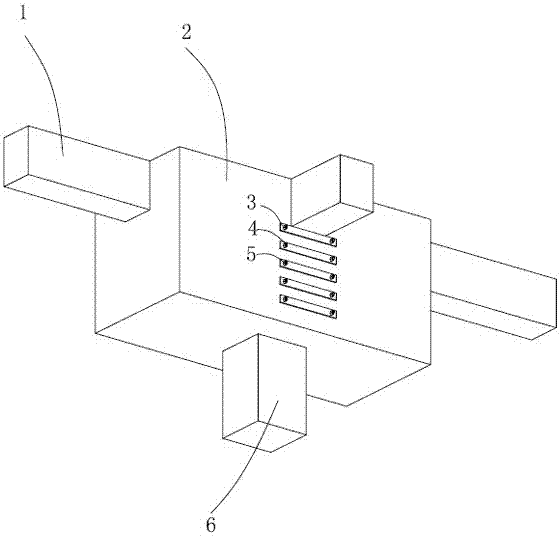

Modular steel frame

PendingCN108487455AGive full play to the combination effectReduce distortionStrutsGirdersModular unitModularity

The invention provides a modular steel frame and belongs to the technical field of structural engineering. According to the modular steel frame, the double-column and double-beam combined effect can be brought into full play. The modular steel frame comprises a plurality of same modular unit layers. Each modular unit layer comprises a plurality of modular units, and each modular unit is a box-typeframe formed by a frame column and a frame beam which are connected. The modular steel frame further comprises a connecting assembly which comprises inner sleeves, column connecting bolts and beam connecting bolts. In the same modular unit layer, the four frame columns in the middle are connected into a combined middle column through the corresponding column connecting bolts, the two frame columns on the outer side face are connected into a combined side column through the corresponding column connecting bolts, and the frame columns at the corners are corner columns. In every two adjacent modular unit layers, the vertically-adjacent two combined middle columns, two combined side columns and two corner columns are connected through the inner sleeves correspondingly. In every two adjacent modular unit layers, the four frame beams in the middle are connected into a combined middle beam through the corresponding beam connecting bolts, and the two frame beams on the outer side faces are connected into a combined edge beam through the corresponding beam connecting bolts.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

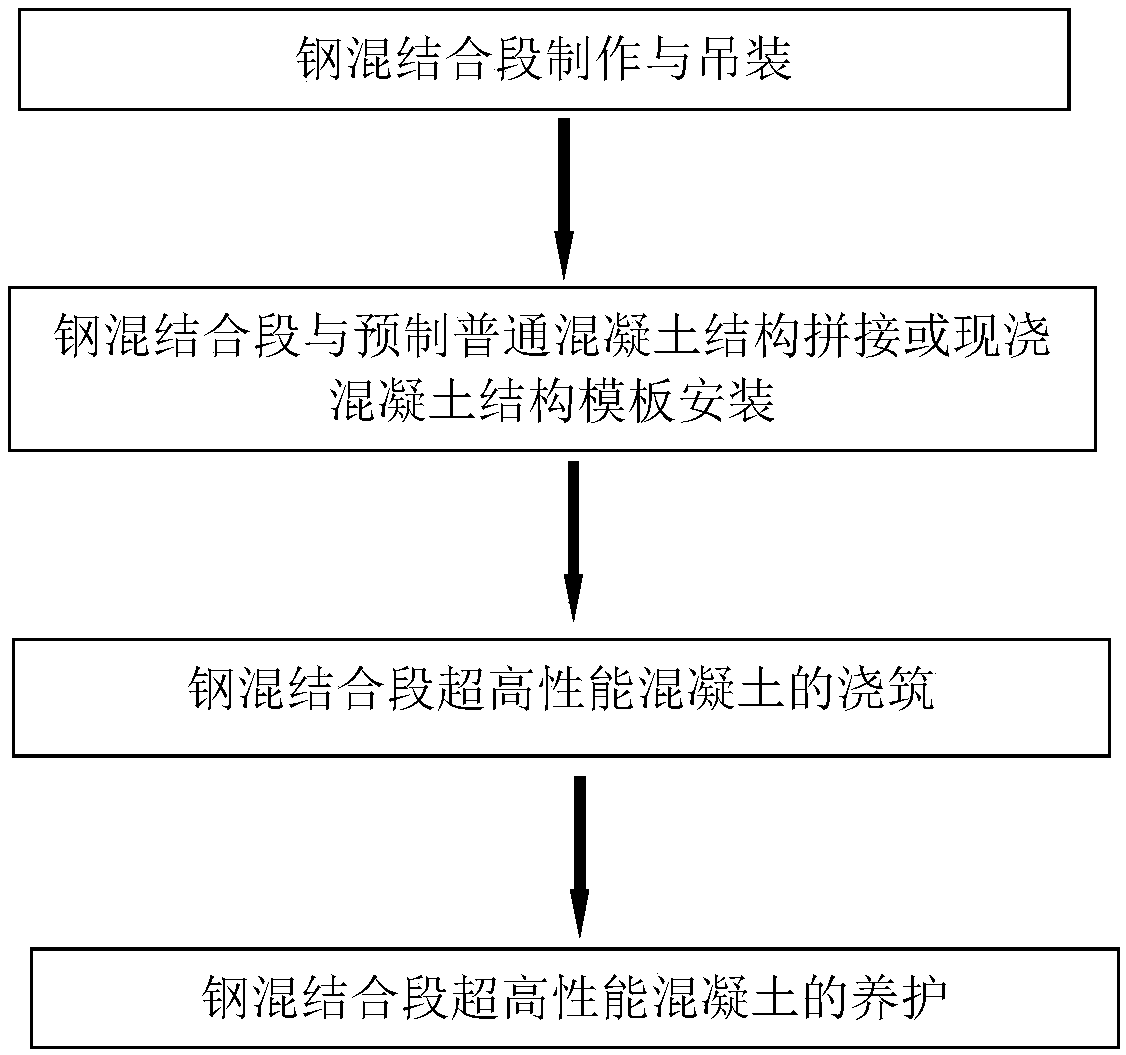

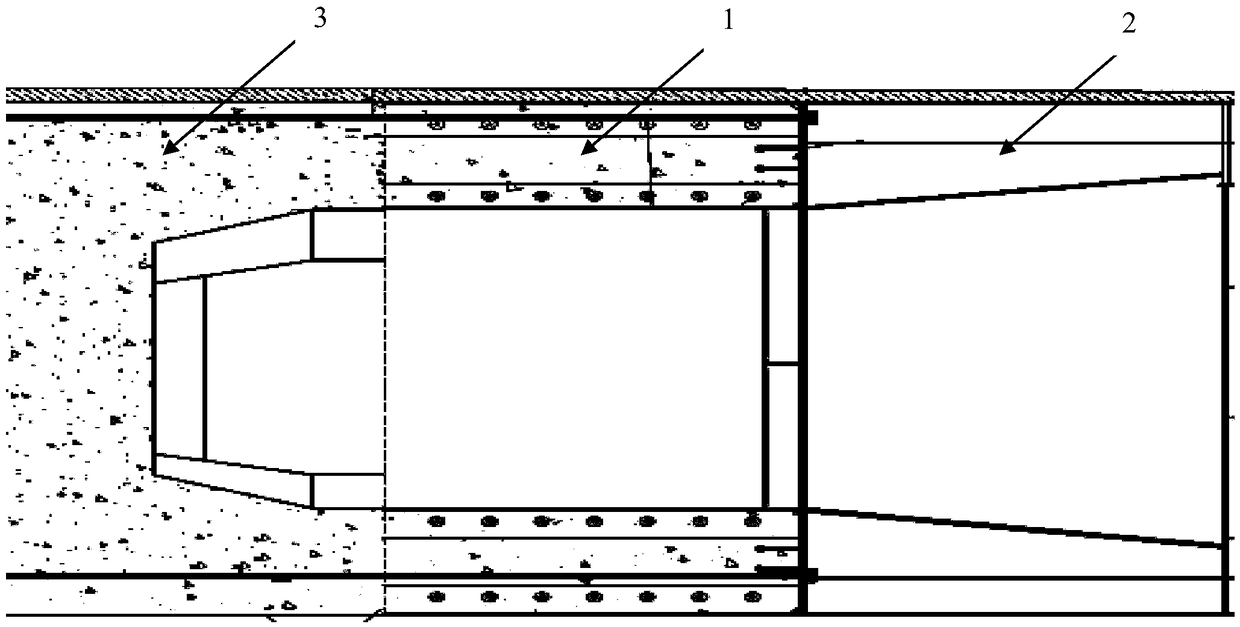

Construction method of steel-concrete joint section

The invention provides a construction method of a steel-concrete joint section, which relates to the field of bridge construction and is carried out according to the following steps: 1) manufacturingand hoisting of the steel-concrete joint section; 2) splice that steel-concrete joint section with the precast ordinary concrete structure or installing the cast-in-situ concrete structure formwork; 3) pour the ultra high performance concrete of the steel-concrete joint section; 4) curing the ultra high performance concrete of the steel-concrete joint section. The invention is fast, convenient, reliable, suitable for the construction of the long-span mixed bridge, greatly shortens the construction period and improves the construction quality.

Owner:HUNAN UNIV +1

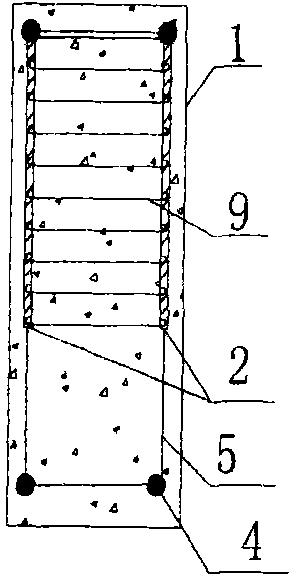

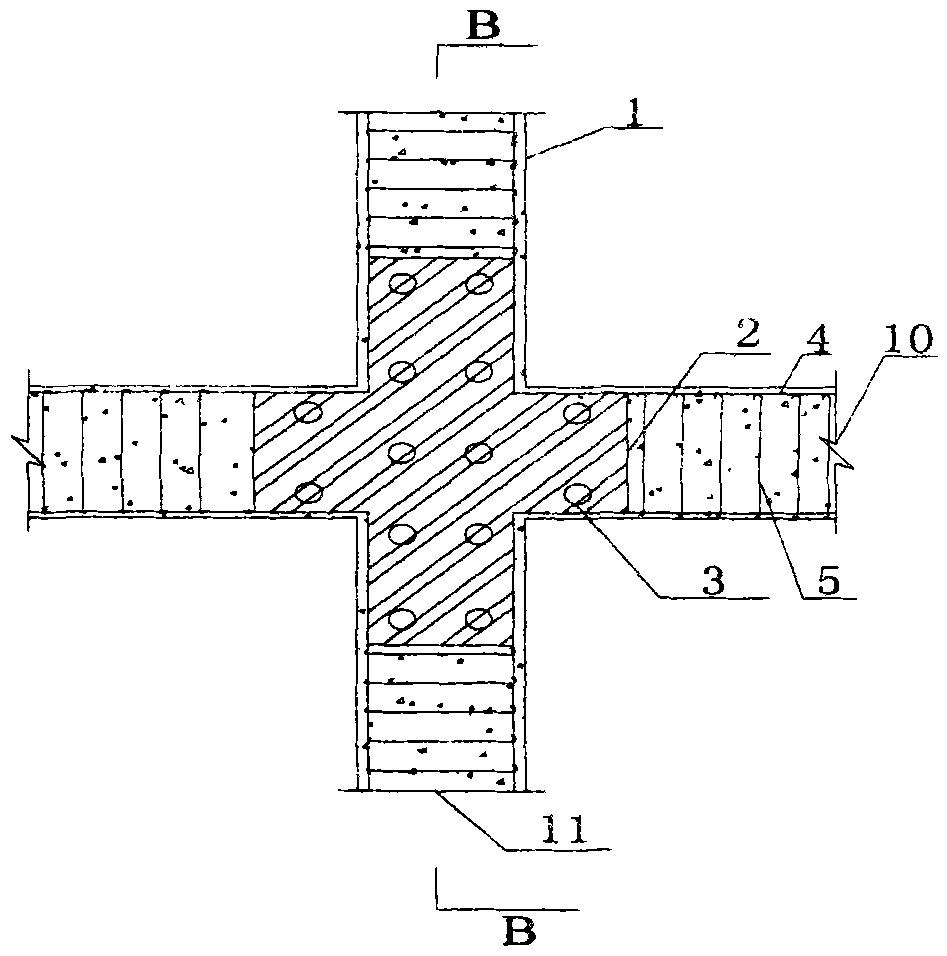

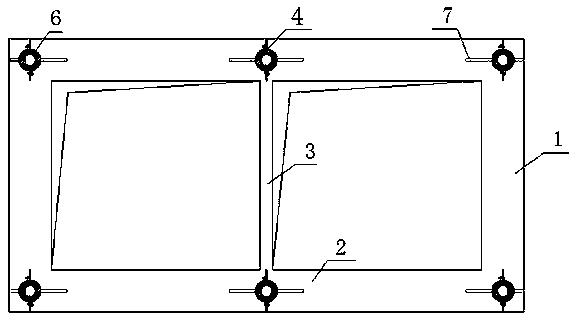

Node crack prevention and reinforced structure of reinforced concrete and manufacture method thereof

InactiveCN101705750BHigh strengthSolve crackingBuilding repairsBridge erection/assemblyStress conditionsReinforced concrete

The invention discloses a node crack prevention and reinforced structure of reinforced concrete and a manufacture method thereof. In the structure, an embedded heterotype steel plate, which has the same shape as that of a node and the edge size of 2.5-3cm less than the node edge size, is arranged on a node reinforcement longitudinal section. Round holes with the diameter of 5cm are processed on the steel plate, and the amount of the round holes ensures the hollowing ratio of the steel plate to be 30-35 percent; the thickness of the heterotype steel plate is 5mm to 10mm; and a Q235 type steel plate is selected for the steel plate. An arrangement mode is determined according to the thickness and the stress condition of a concrete component at the node part. The invention prevents cracking of the concrete node at root, completely solves the problem of node cracking which troubles engineering departments including road, industrial civil construction, bridge and water conservancy for many years on the premise of not obviously increasing the engineering cost, ensures the safe use of a newly constructed reinforced concrete structure, stops troubles in the bud and greatly saves the maintenance fund of the concrete structure.

Owner:SHANDONG UNIV OF SCI & TECH

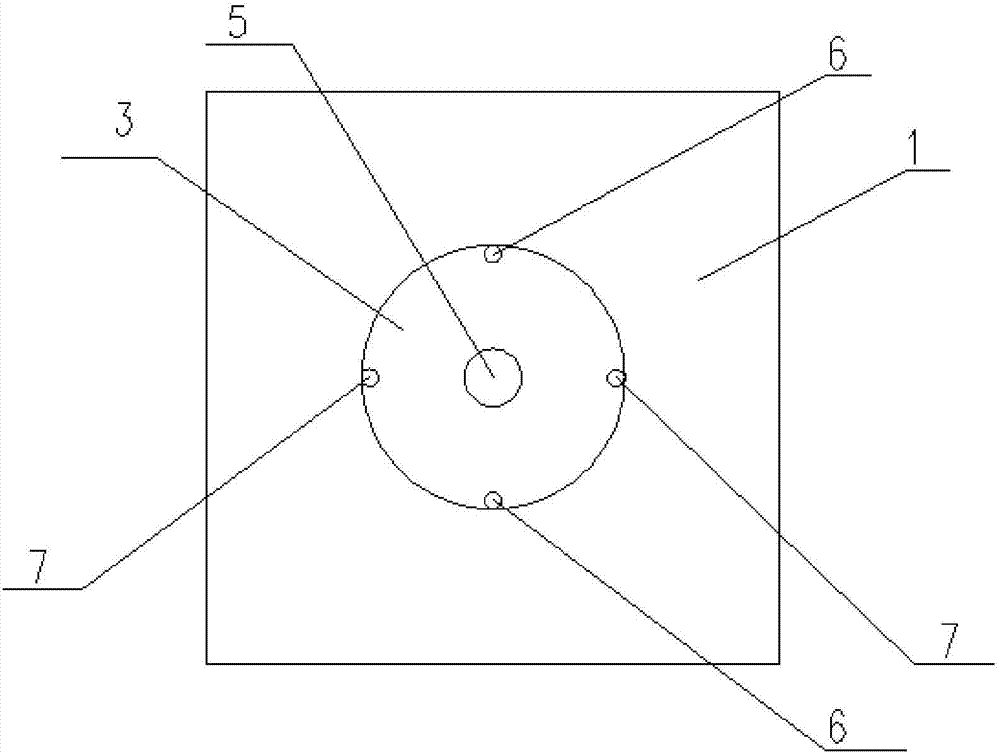

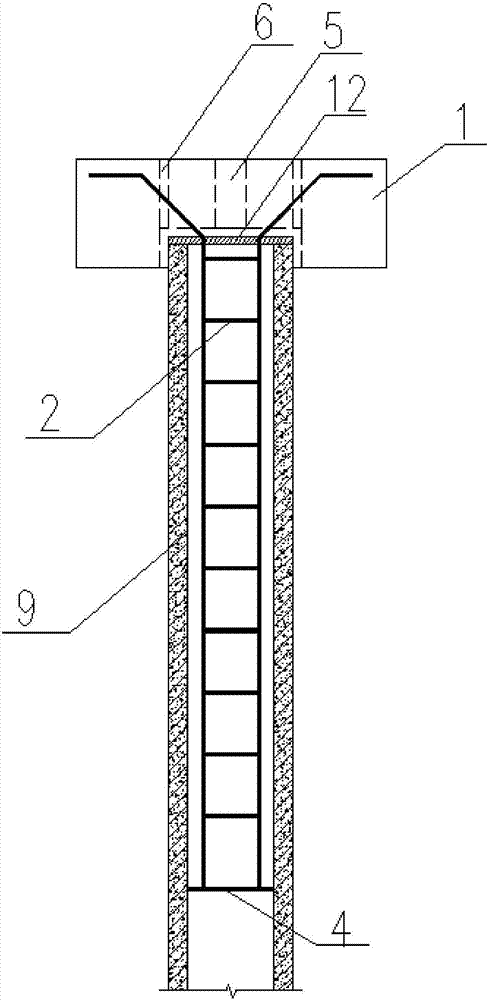

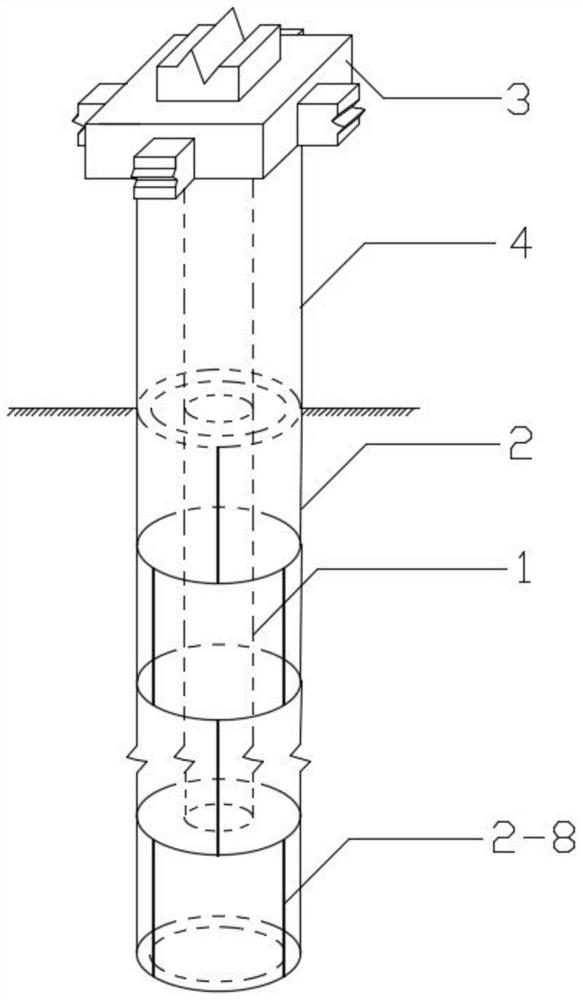

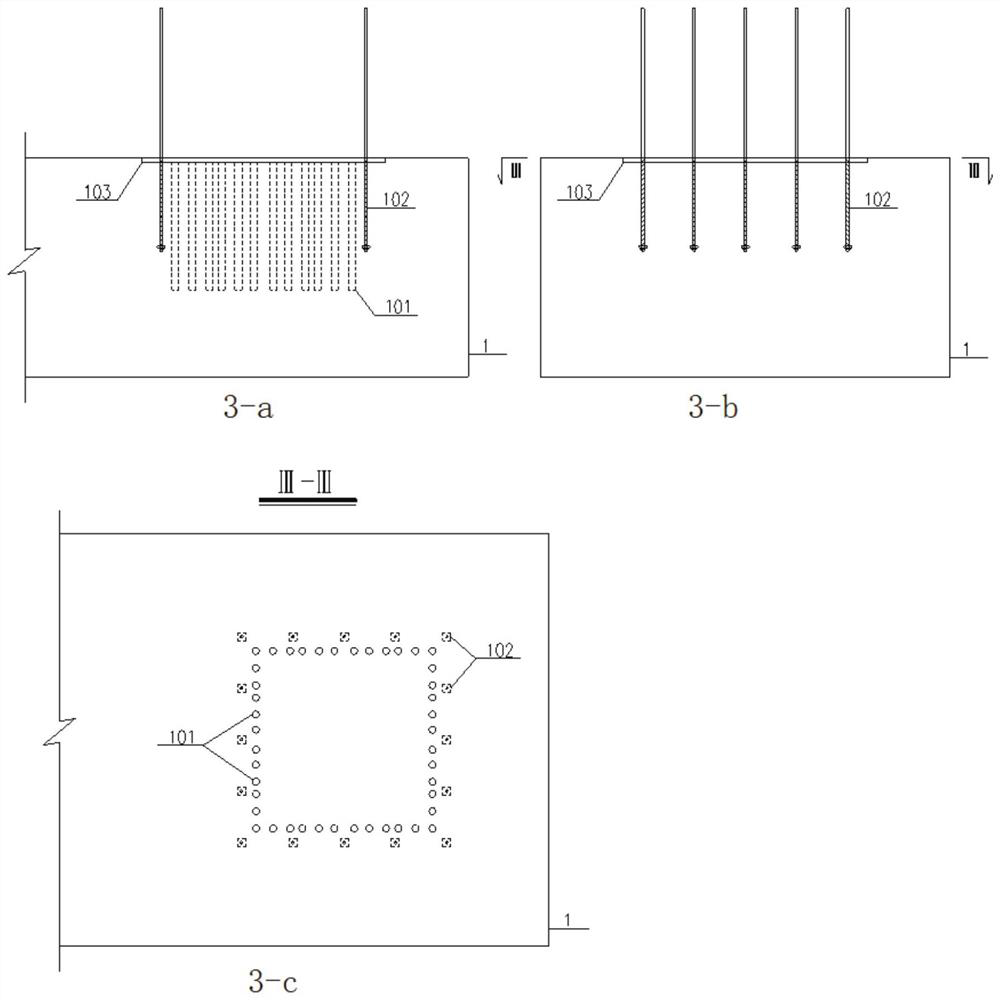

Prefabricated bearing platform with joint bar grouted core and construction process of prefabricated bearing platform

PendingCN106988333AGuarantee the construction qualityAvoid connectionFoundation engineeringArchitectural engineeringEngineering

The invention discloses a prefabricated bearing platform with a joint bar grouted core and a construction process of the prefabricated bearing platform. The bearing platform comprises a bearing platform body and a core insertion rebar. The bearing platform body is provided with a groove structure with the inner diameter being greater than the outer diameter of a hollow pile or a stiff body. The core insertion rebar with a supporting plate is coaxially formed to the bottom face of the groove structure of the bearing platform body. The core insertion rebar and the supporting plate can be arranged in the hollow part of the hollow pile or in the hollow part of the stiff body. An injection hole which can communicate with the interior of the hollow pile or the interior of the stiff body and a grouting which can communicate with a gap between the outer side of the hollow pile or the stiff body and the side wall of het groove structure are formed in the bottom face of the groove structure of the bearing platform body. According to the construction process, the prefabricated bearing platform is manufactured at first, then an end plate of the constructed hollow pile or the stiff body is levelled, a cushion layer at the prefabricated bearing platform is constructed, the prefabricated bearing platform is hoisted, core grouting is conducted through the injection hole, and finally the gap between the prefabricated bearing platform and the hollow pile or the stiff body is grouted. The construction quality of the bearing platform is ensured, the construction progress is accelerated, and the utilization rate of turnover materials is increased.

Owner:江苏九如建设有限公司

Connecting node for trusses made of composite materials

ActiveCN105756200APrevent pulling outImprove tensile propertiesBuilding constructionsAdhesiveEngineering

The invention provides a connecting node for trusses made of composite materials. The connecting node comprises a conical connector and a conical connecting barrel. The shape of an inner barrel of the conical connecting barrel is consistent with the external profile of the conical connector, through holes are formed in barrel walls of the conical connecting barrel, sealing adhesive hoses are arranged on the barrel walls of the conical connecting barrel and are filled with adhesive, the conical connector is embedded in a truss pipe made of composite materials, a large-diameter end of the conical connector is integrated with the inner wall of the truss pipe, and the conical connecting barrel is fixedly connected to the other end of another truss pipe made of composite materials. The connecting node has the advantages that various accessories of the connecting node can be prefabricated and machined in a factory in advance, accordingly, truss structures can be modularly produced and can be transported to fields in a sectioned manner, the connecting node can be quickly assembled, the construction time can be effectively saved, the work efficiency can be improved, and nodes for the trusses can be assuredly reliably connected with one another, and reasonable stress on the nodes can be guaranteed.

Owner:HARBIN ENG UNIV

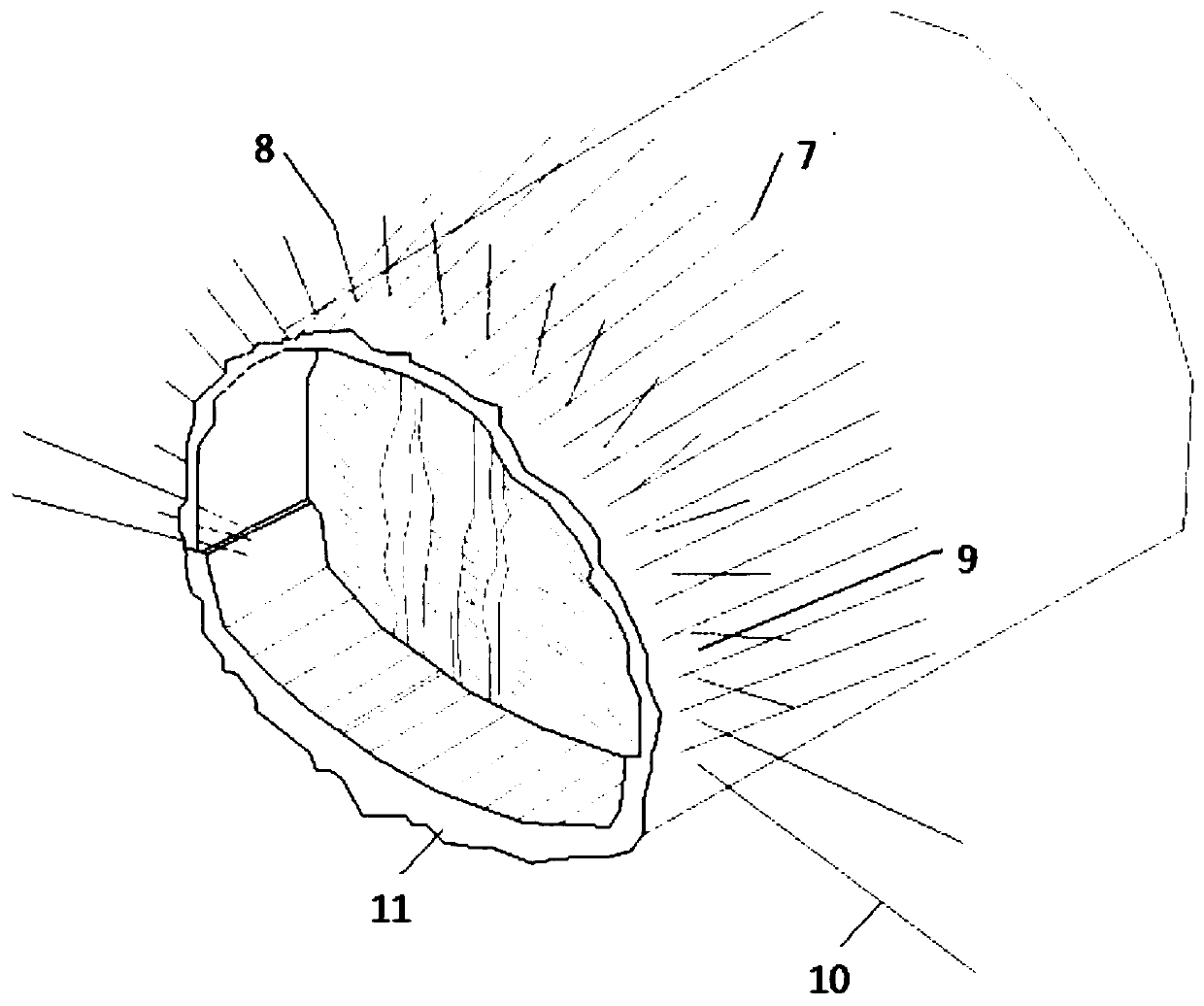

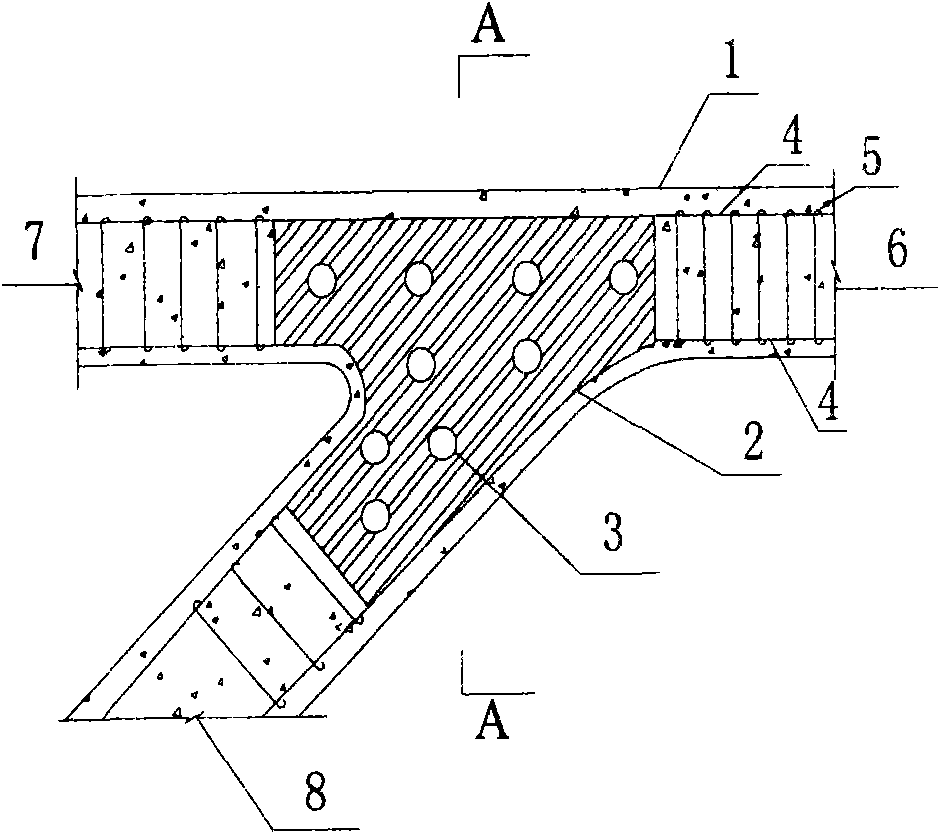

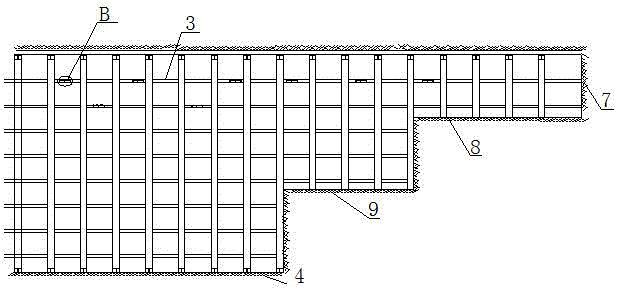

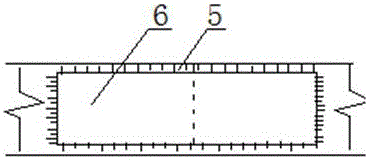

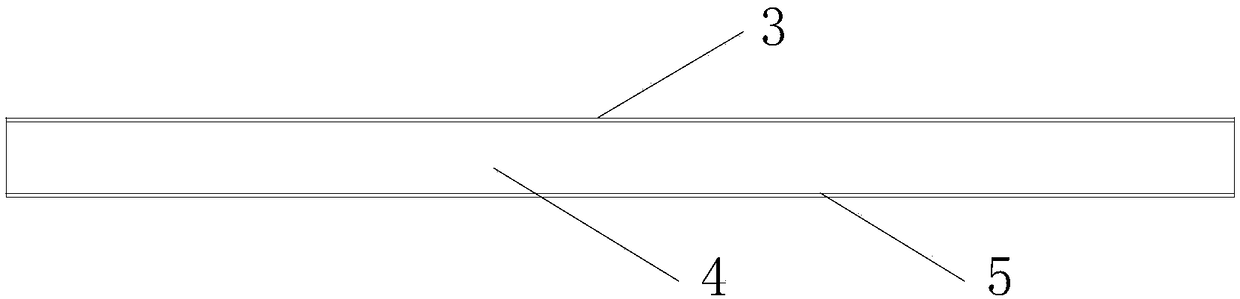

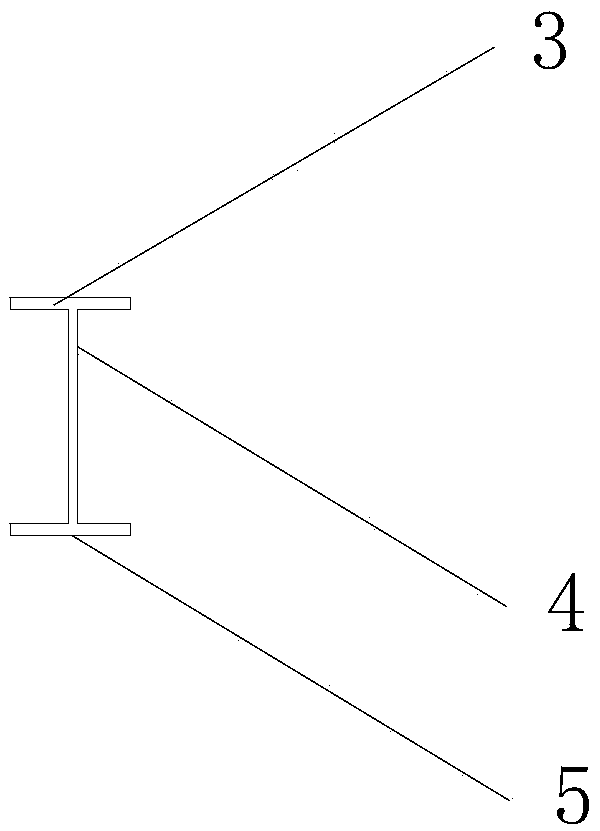

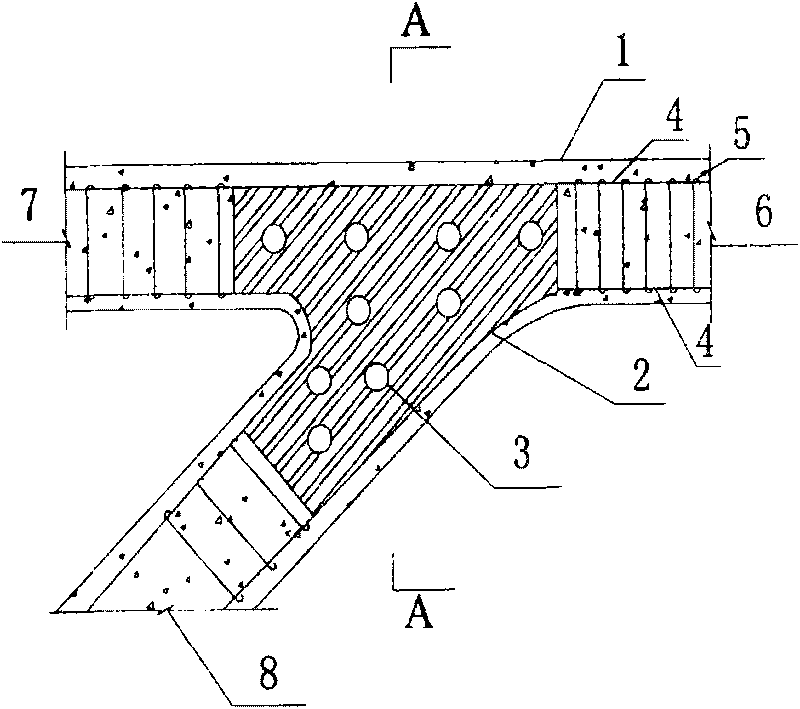

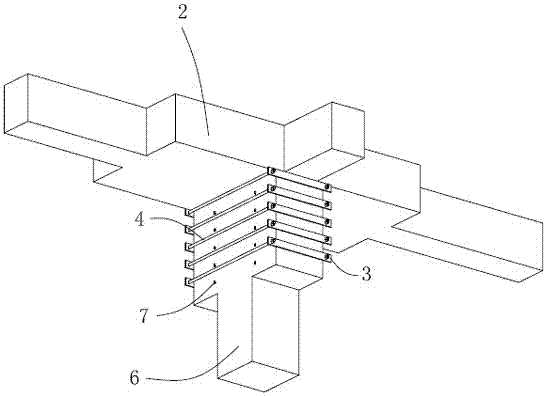

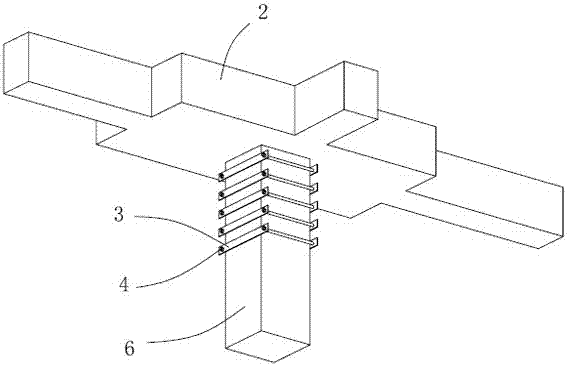

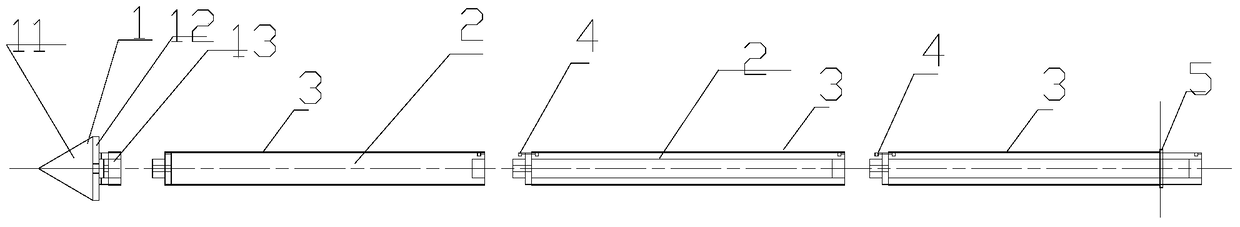

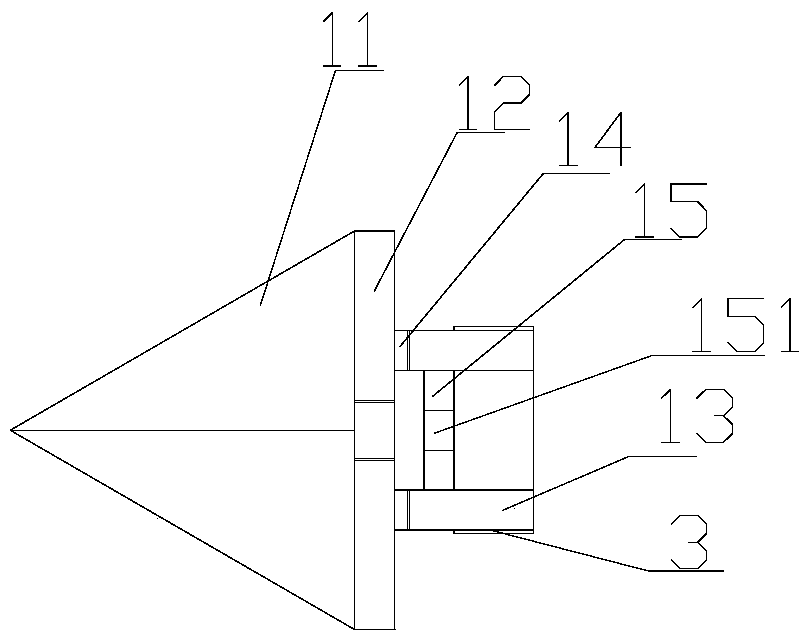

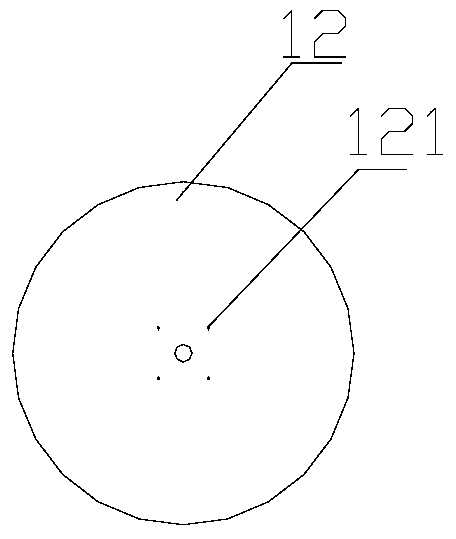

Bent-frame preliminary supporting structure for weak surrounding rock tunnel and supporting method

InactiveCN106223986AGuarantee joint forceAvoid destructionUnderground chambersTunnel liningRock tunnelEngineering

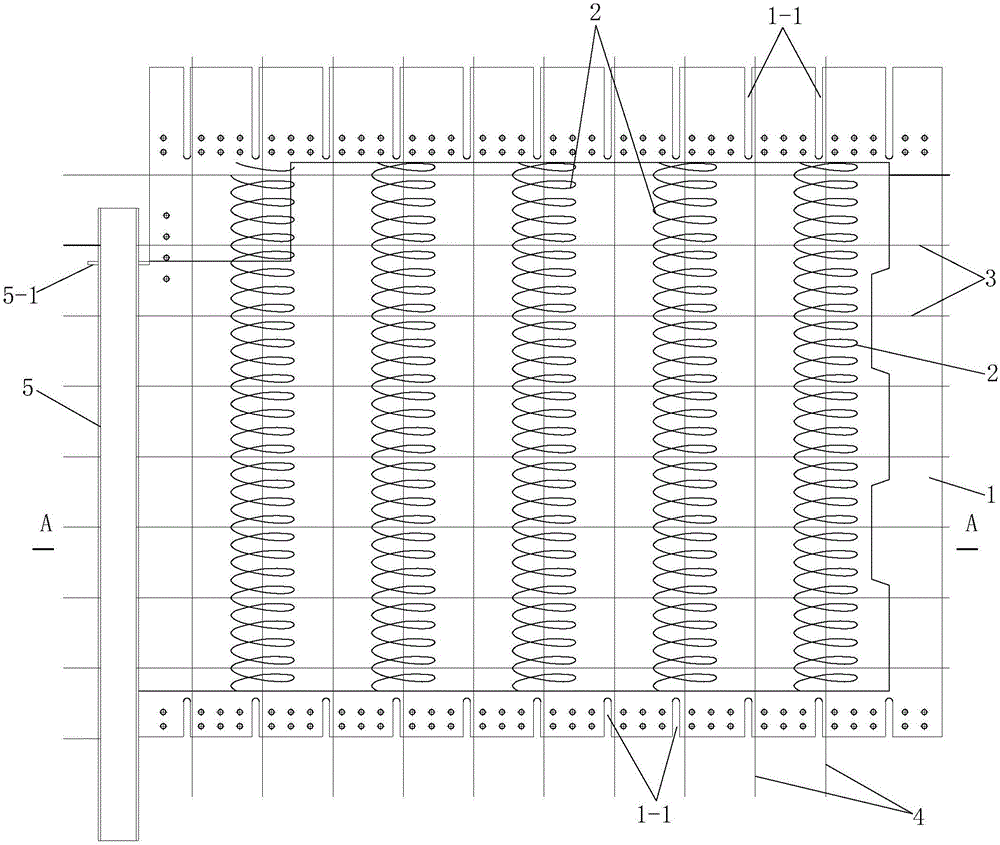

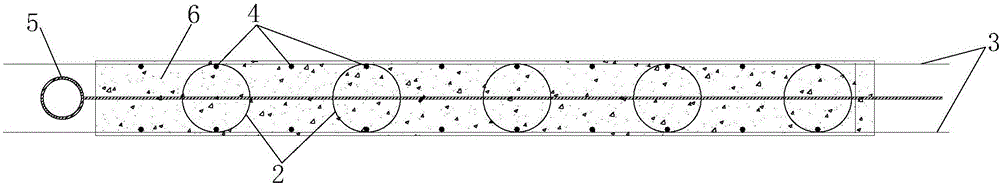

The invention provides a bent-frame preliminary supporting structure for a weak surrounding rock tunnel and a supporting method. The supporting structure comprises an H-shaped steel arching (2), wherein multiple sections of longitudinal distribution beams (3) are arranged outside the H-shaped steel arching (2) along a tunnel outline line. The supporting method comprises the steps that multi-step divided excavation is conducted; a spacing and specifications of the H-shaped steel arching (2), as well as the spacing between the longitudinal distribution beams (3) are determined, so that the H-shaped steel arching (2) can be connected with the longitudinal distribution beams (3), and a bent-frame support can be formed; and binding protection is conducted to connection heads of the longitudinal distribution beams (3), and then concrete jetting is carried out. Collapse risks are reduced when lower steps are excavated and upper arch feet are suspended.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

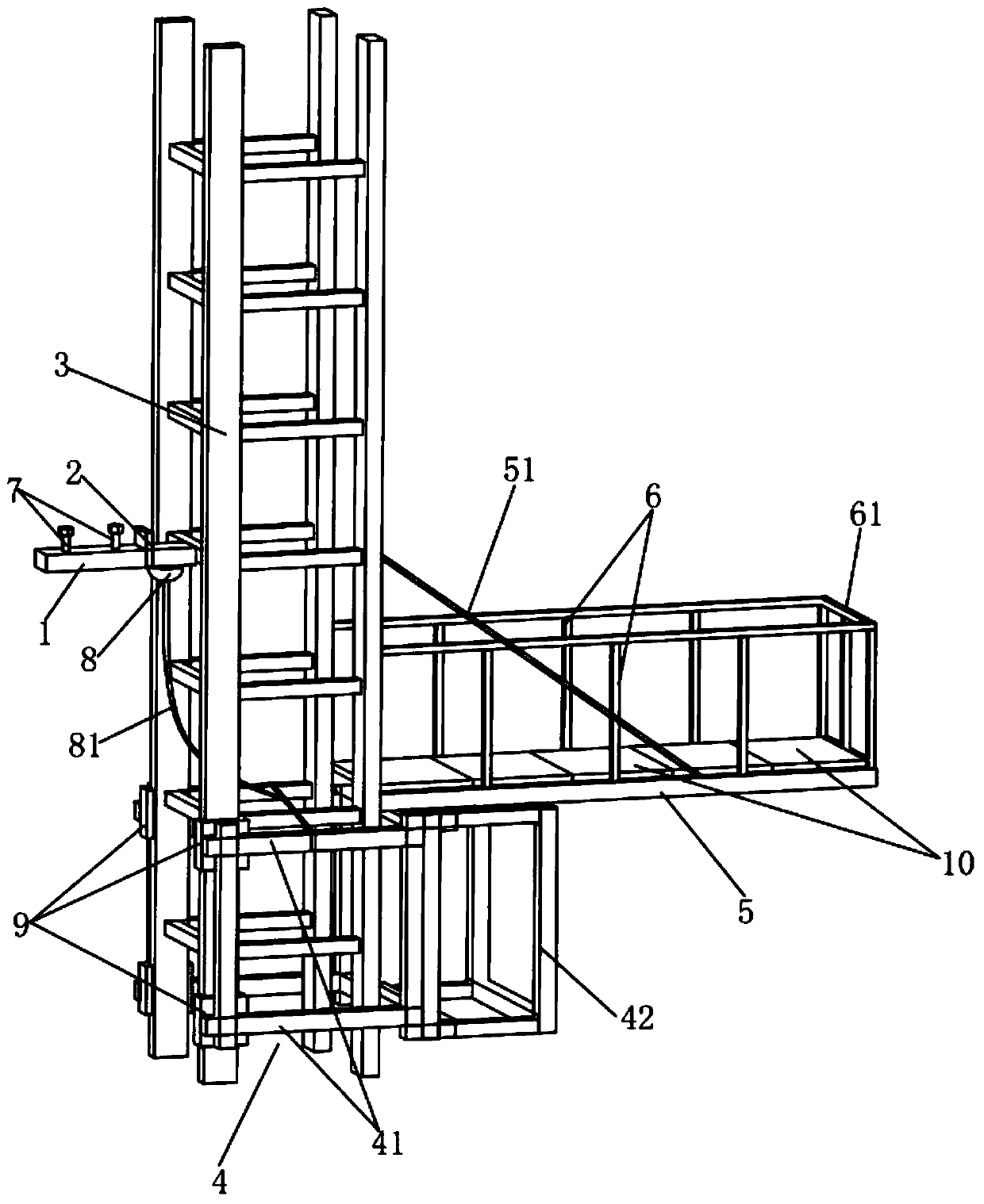

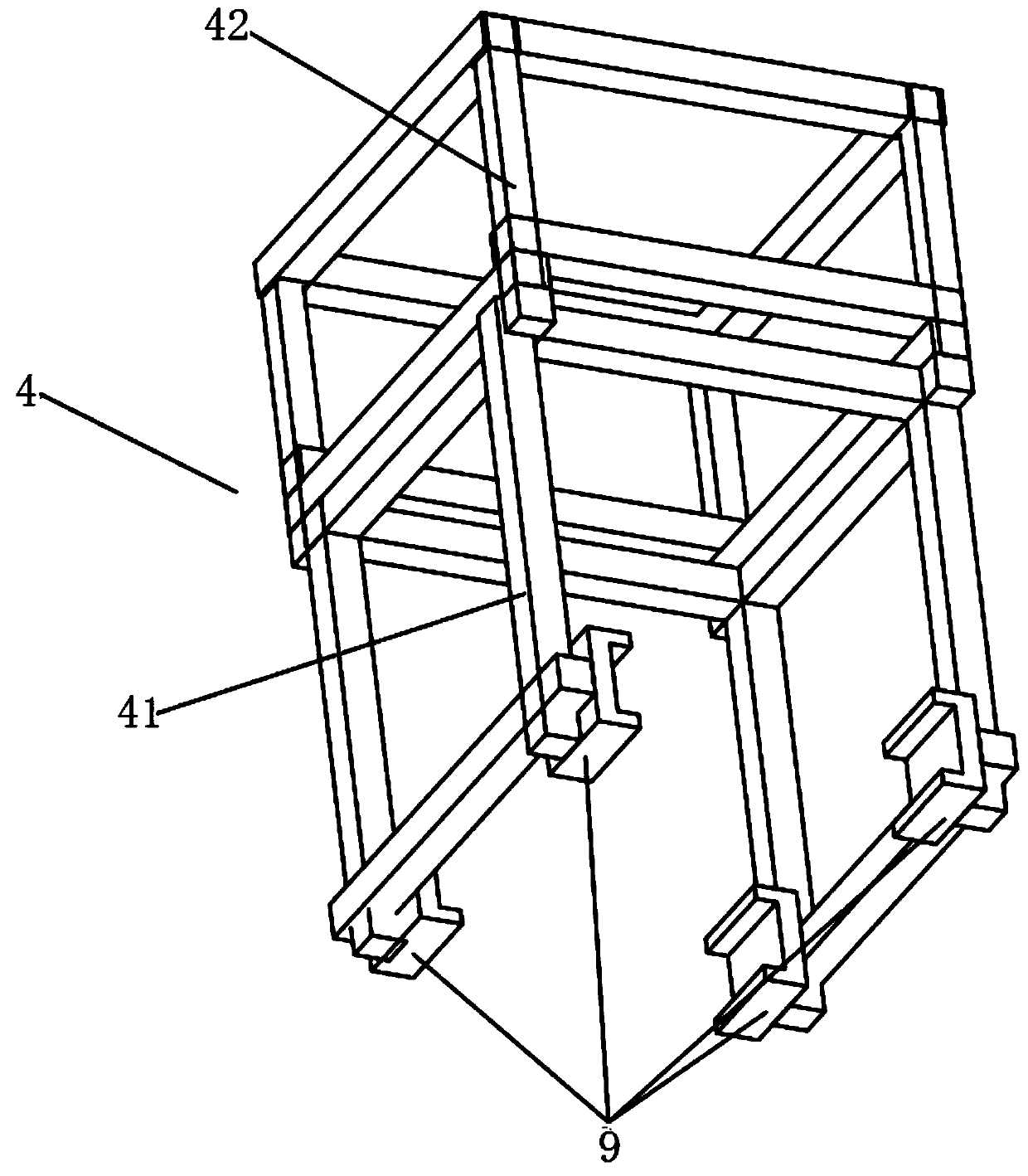

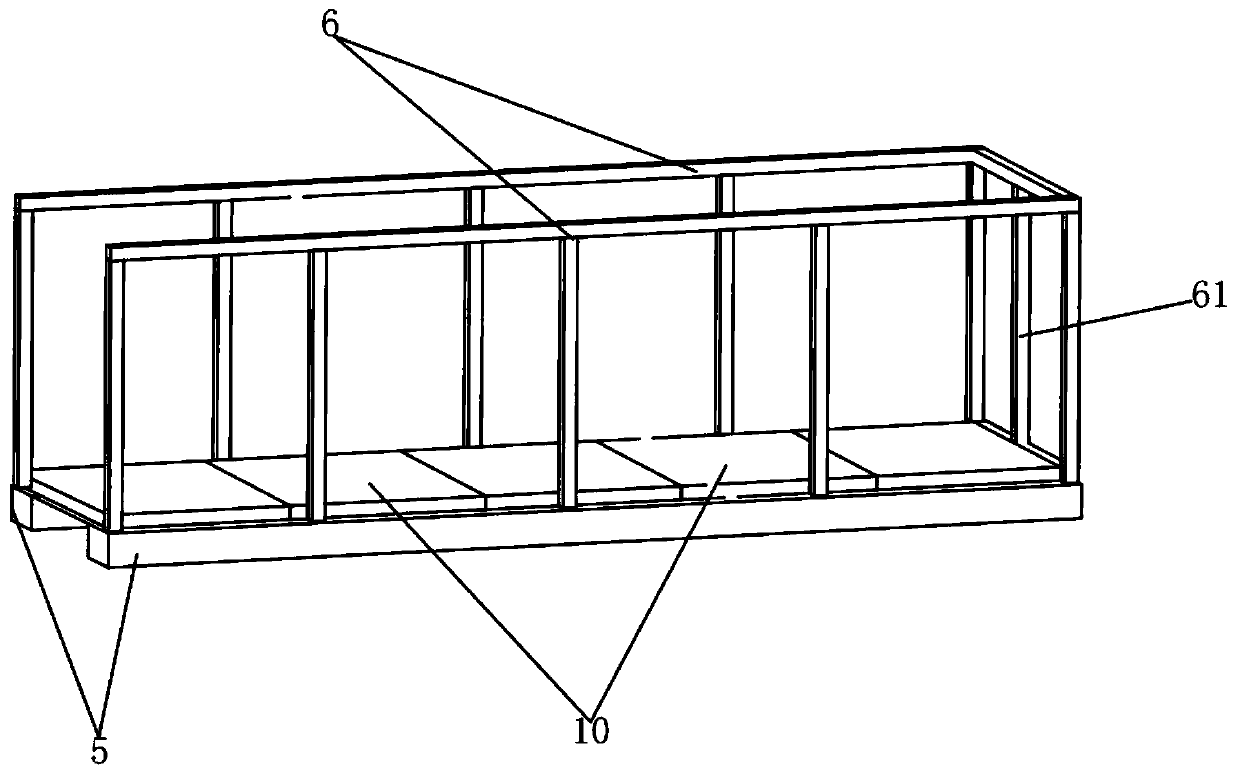

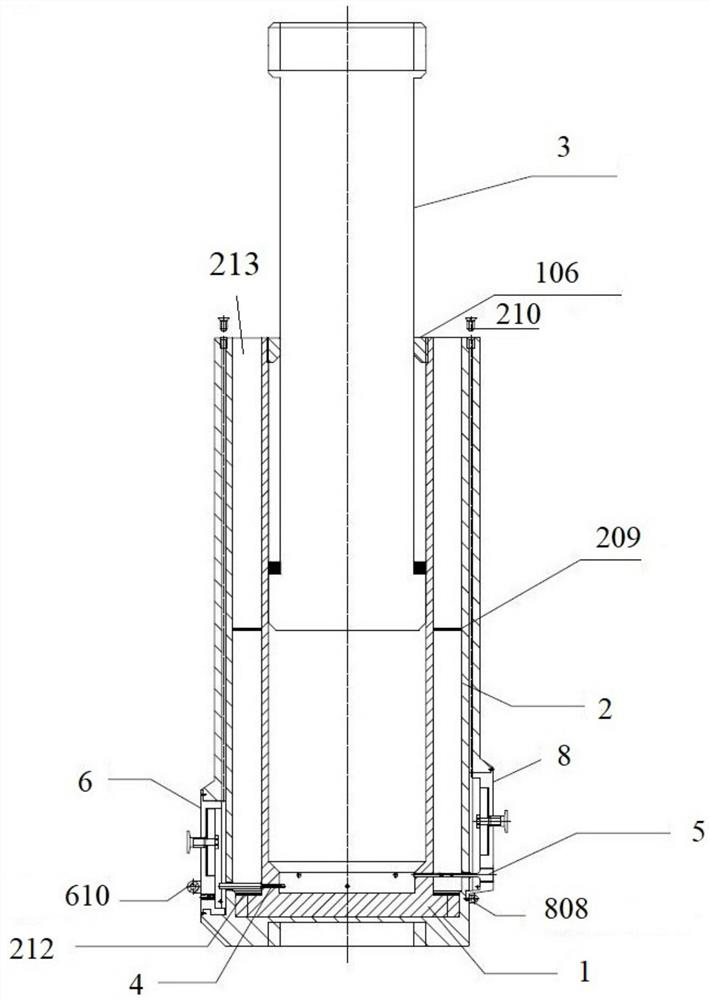

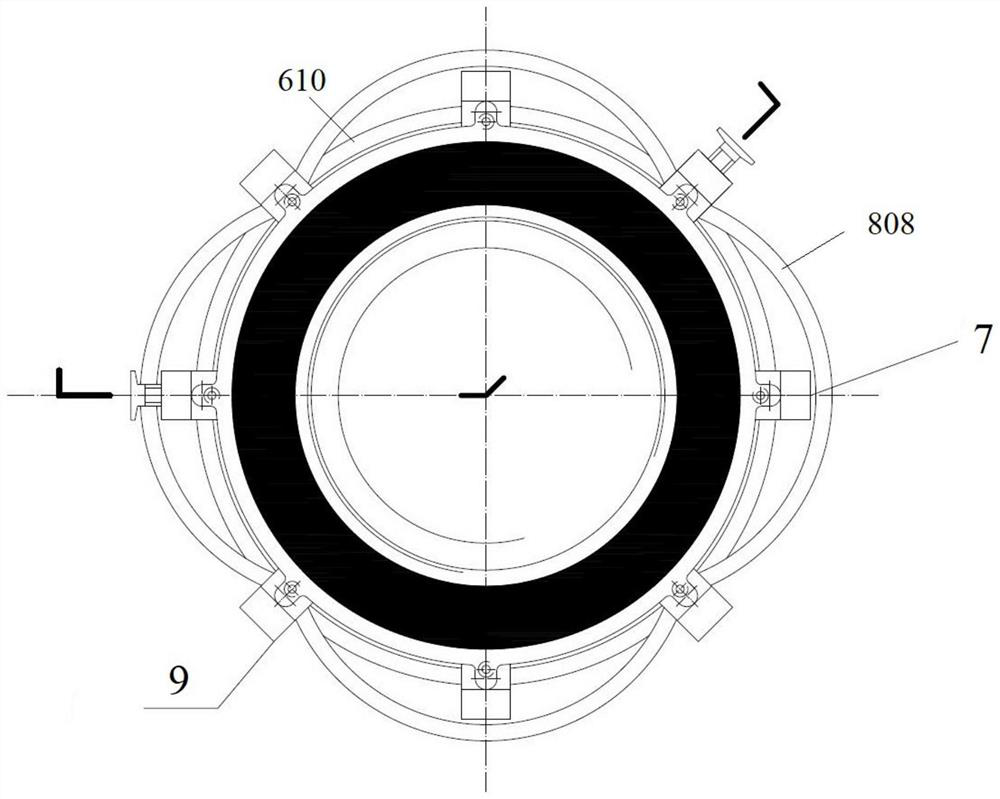

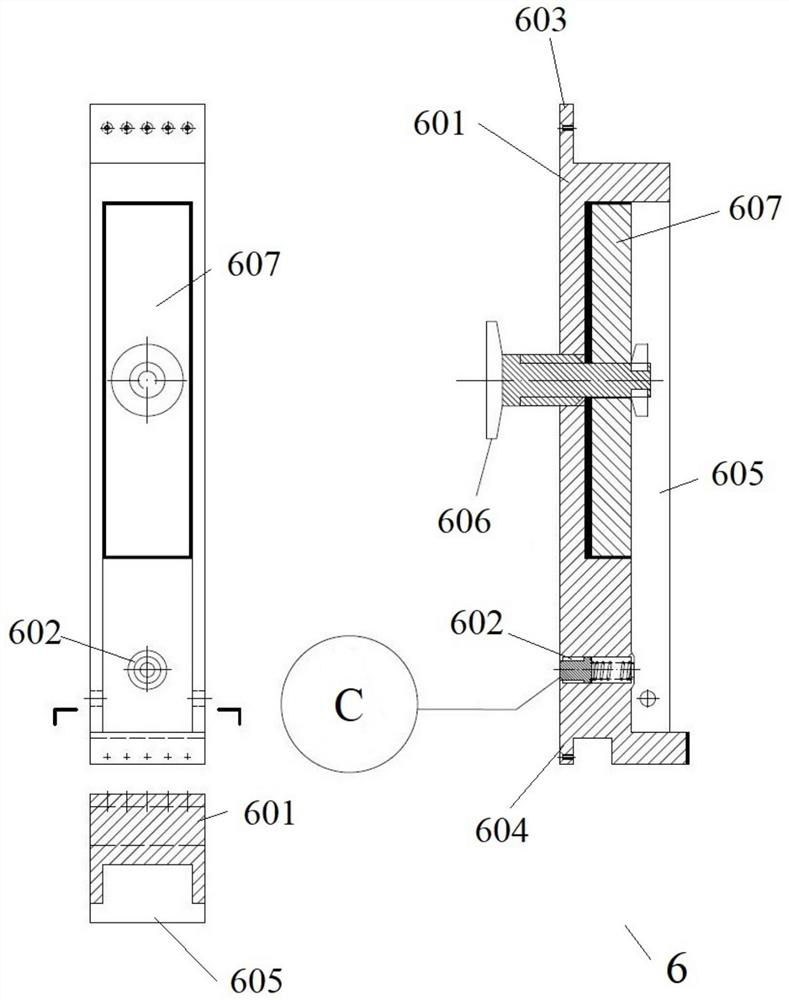

Integrated climbing frame

InactiveCN110629997ASimple structureAdaptableScaffold accessoriesBuilding support scaffoldsEngineeringFolded structure

The invention discloses an integrated climbing frame, and relates to the field of building construction. The integrated climbing frame comprises an attached support structure connected with a wall body, a lifting structure connected with the attached support structure, and a folding structure arranged on the lifting structure, wherein the attached support structure comprises a connection beam anda connection seat, one end of the connection beam is fixedly connected with the connection seat, and the other end of the connection beam is connected with the wall body; the lifting structure comprises a lifting frame body and a guide rail frame body, one side of the lifting frame body is fixed to the connection seat, the guide rail frame body is arranged on the lifting frame body, and the guiderail frame body is capable of sliding on the lifting frame body; and the folding structure comprises a folding guard railing and two cross beams, the two cross beams are fixed to the two ends of the top of the guide rail frame body separately, and the folding guard railing is arranged on the two cross beams. The integrated climbing frame is capable of independently climbing, simple in structure, high in adaptation to a construction place, convenient to install and detach, further capable of being repeatedly used, and economic and efficient.

Owner:浙江华铁应急设备科技股份有限公司

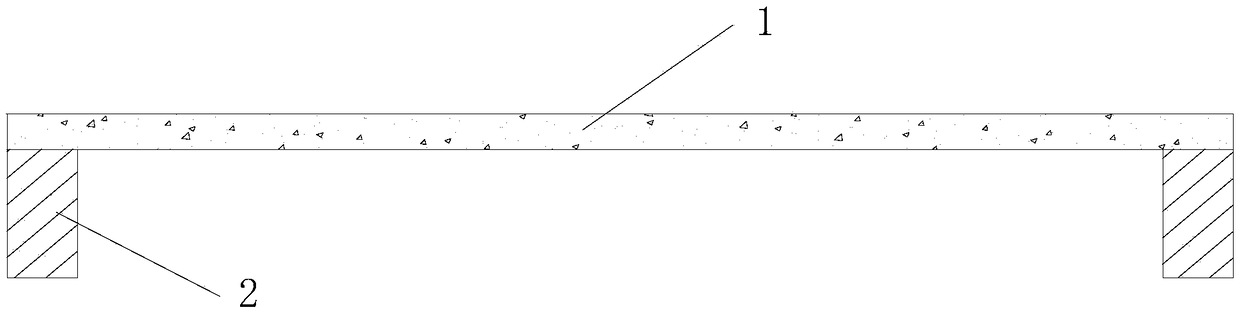

Method for reinforcing concrete floor by H-shaped steel

InactiveCN109505421AImprove mechanical performanceImprove securityBuilding repairsConcrete beamsMechanical property

The invention relates to a method for reinforcing a concrete floor by H-shaped steel and belongs to the technical field of civil engineering. The method is a reinforcing method for improving the mechanical property of the floor by improving measures of connecting the floor and an H-shaped steel beam, and according to a bolt fixing method of connecting the floor and the H-shaped steel beam, the method is divided into a floor penetrating bolt fixing method and a plate bottom bolt fixing method. The H-shaped steel beam and the concrete floor are connected to be a whole through a bolt, common stress of the two can be ensured, the bearing capacity of the reinforced floor is obviously improved, and compared with a cast-in-place concrete beam construction method, the construction method is simplein process, fast in speed and more suitable for applications in reinforcement engineering.

Owner:SHANDONG JIANZHU UNIV

Node crack prevention and reinforced structure of reinforced concrete and manufacture method thereof

InactiveCN101705750APrevent cracking at jointsImprove concrete strengthBuilding repairsBridge erection/assemblySteel platesRebar

The invention discloses a node crack prevention and reinforced structure of reinforced concrete and a manufacture method thereof. In the structure, an embedded heterotype steel plate, which has the same shape as that of a node and the edge size of 2.5-3cm less than the node edge size, is arranged on a node reinforcement longitudinal section. Round holes with the diameter of 5cm are processed on the steel plate, and the amount of the round holes ensures the hollowing ratio of the steel plate to be 30-35 percent; the thickness of the heterotype steel plate is 5mm to 10mm; and a Q235 type steel plate is selected for the steel plate. An arrangement mode is determined according to the thickness and the stress condition of a concrete component at the node part. The invention prevents cracking of the concrete node at root, completely solves the problem of node cracking which troubles engineering departments including road, industrial civil construction, bridge and water conservancy for many years on the premise of not obviously increasing the engineering cost, ensures the safe use of a newly constructed reinforced concrete structure, stops troubles in the bud and greatly saves the maintenance fund of the concrete structure.

Owner:SHANDONG UNIV OF SCI & TECH

A combined structure with hollow piles on the periphery of existing piles and its construction method

ActiveCN110284723BImprove carrying capacityConsolidate stabilityBuilding repairsFoundation repairArchitectural engineeringHollow core

Owner:HEBEI UNIV OF TECH

Connecting structure and method for foundation piles and bearing platform in pile foundation underpinning

InactiveCN106703092AMeet the actual engineering needsResolve connectionFoundation repairAnchor boltUnderpinning

The invention relates to improvement in the pile foundation underpinning field, in particular to a connecting structure and method for foundation piles and a bearing platform in pile foundation underpinning. The connecting structure comprises an original pile foundation, the bearing platform, concrete, steel sleeves and anchor bolts, wherein the one or more underpinning foundation piles are arranged on one side of the original pile foundation, and underpinning foundation pile reserved main reinforcements stretch out from the underpinning foundation piles; the bearing platform is connected with the original pile foundation, and bearing platform reserved main reinforcements stretch out from the lower side of the bearing platform; the underpinning foundation pile reserved main reinforcements and the bearing platform reserved main reinforcements are wrapped by the concrete; the concrete is wrapped by the steel sleeves; and the steel sleeves and the concrete are fixed through the anchor bolts. The problem of new connection in pile foundation underpinning is solved successfully, and smooth proceeding of a reconstruction project of a bridge in a certain place is guaranteed.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST

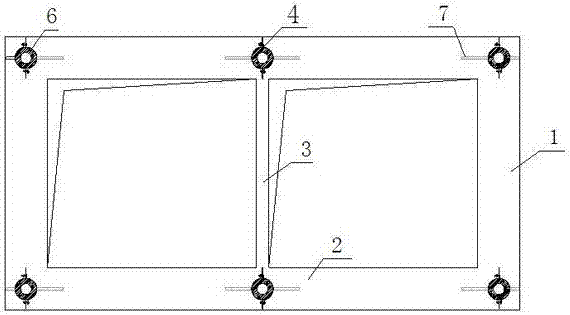

Reinforced culvert

The invention discloses a reinforced culvert. The reinforced culvert comprises a culvert top and side walls. A prestress top plate which is composed of a symmetrically fastened double-layer corrugated steel is arranged at the bottom of the culvert top, single-layer corrugated steels are arranged on the inner sides of left and right side walls, the top plate is installed on the single-layer corrugated steels of the side walls, reinforcing steel bars are arranged in a cavity cylinder formed by the double-layer corrugated steel, the cavity cylinder is filled with concrete, and simultaneously, concrete is filled between the culvert top and the prestress top plate as well as between left and right side walls and the single-layer corrugated steels. The reinforced culvert has the advantages that a corrugated steel rigid support is added on the basis of the original culvert structure, and further expansion of cracks is prevented, so that the internal force and deformation of the original culvert structure are reduced greatly, simultaneously, the original structure is fully utilized, and shared force bearing of new and old structures is guaranteed with the using function of the original culvert unchanged.

Owner:NANJING LIANZHONG CONSTR ENG TECH

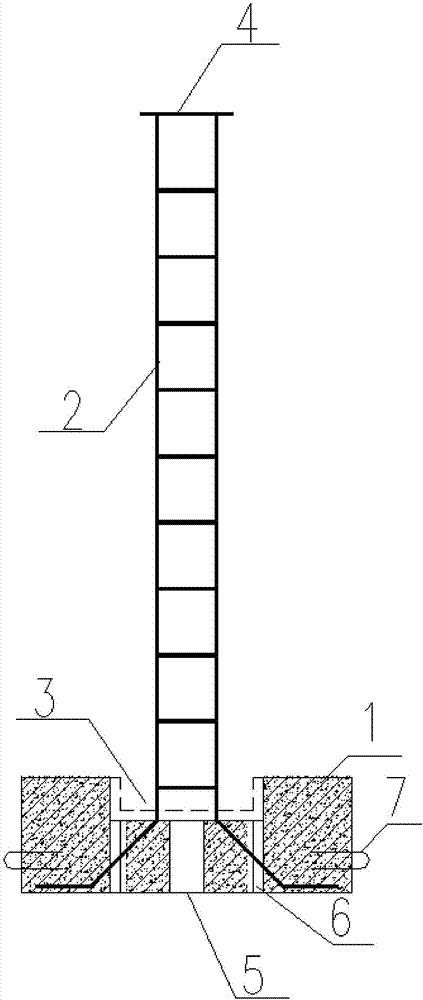

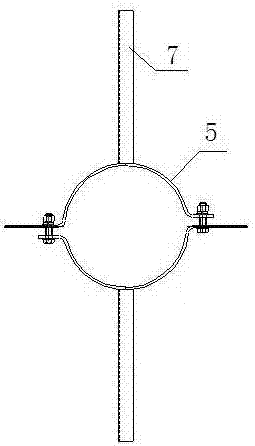

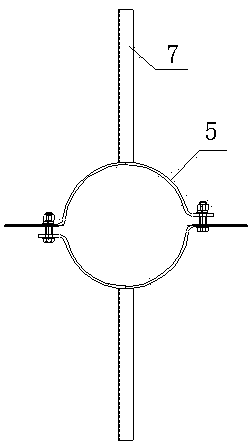

Pile foundation reinforcement method for inverter box transformer platform

ActiveCN106930339AGuarantee joint forceActive connectionArtificial islandsFoundation repairPull forceReinforced concrete

The invention discloses a pile foundation reinforcement method for an inverter box transformer platform. According to the method, a plurality of tubular piles connected through ring beams are included; after hoops connected with the ring beams are wrapped outside the tubular piles, the ring beams, the hoops and the tubular piles are poured into a whole through concrete. The reinforced concrete ring beams are additionally arranged on the ground where the inverter box transformer platform tubular piles are located. The tubular piles are connected into a whole under the tying action of the ring beams. The tubular piles and the ring beams are effectively connected through the hoops of which steel angles are welded to the two sides. When local settlement occurs to some tubular pile due to low bearing capacity caused by defects of a pile body, downward pull force can be transmitted to the ring beams nearby through the hoops and the steel angles and then transmitted to adjacent pile foundations. Finally, the pile foundations of the whole platform share the force to be stressed uniformly. Adverse effects caused by uneven settlement of individual pile foundations are avoided. It is guaranteed that all the pile foundations of the whole platform are stressed jointly. The integrality is enhanced. Accordingly, inverters, box inverters and other electronic equipment on the platform can operate normally. The pile foundation reinforcement method has high practicality and extensive applicability.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

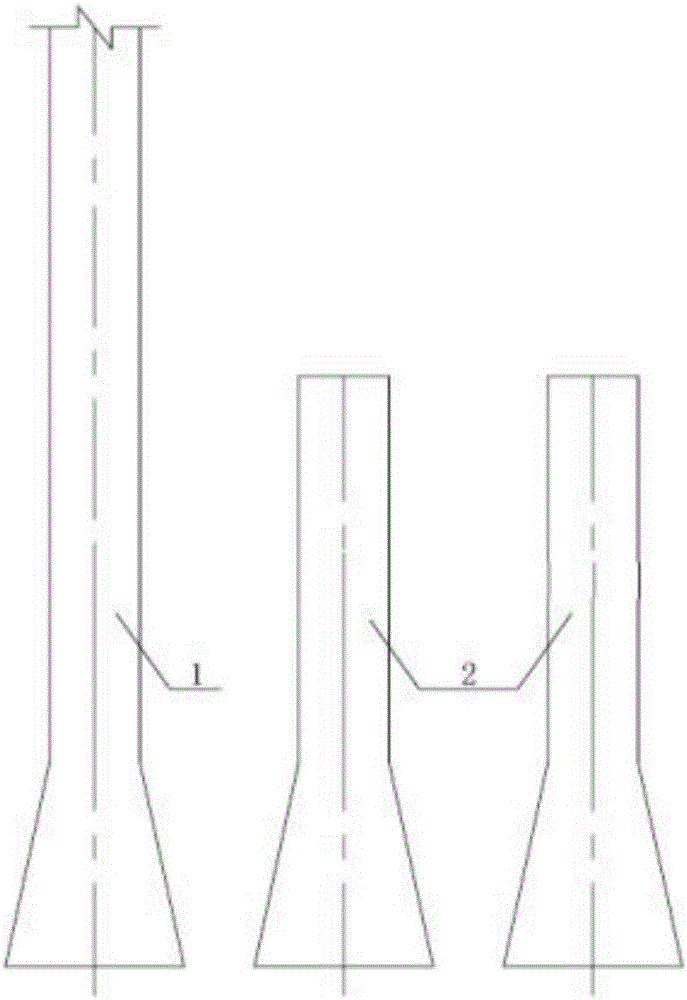

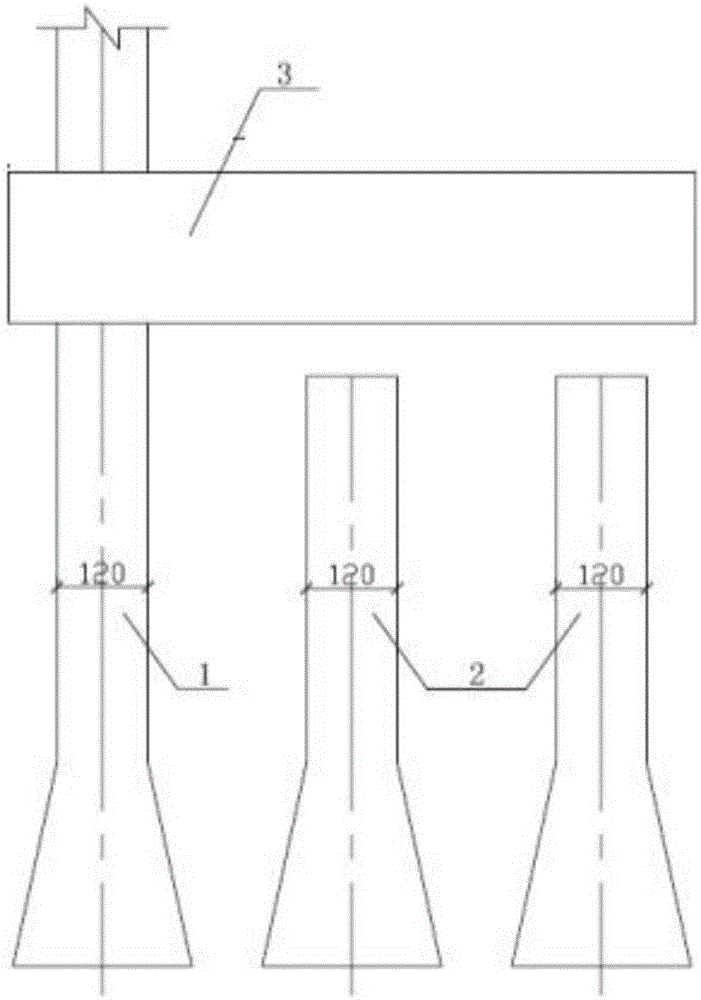

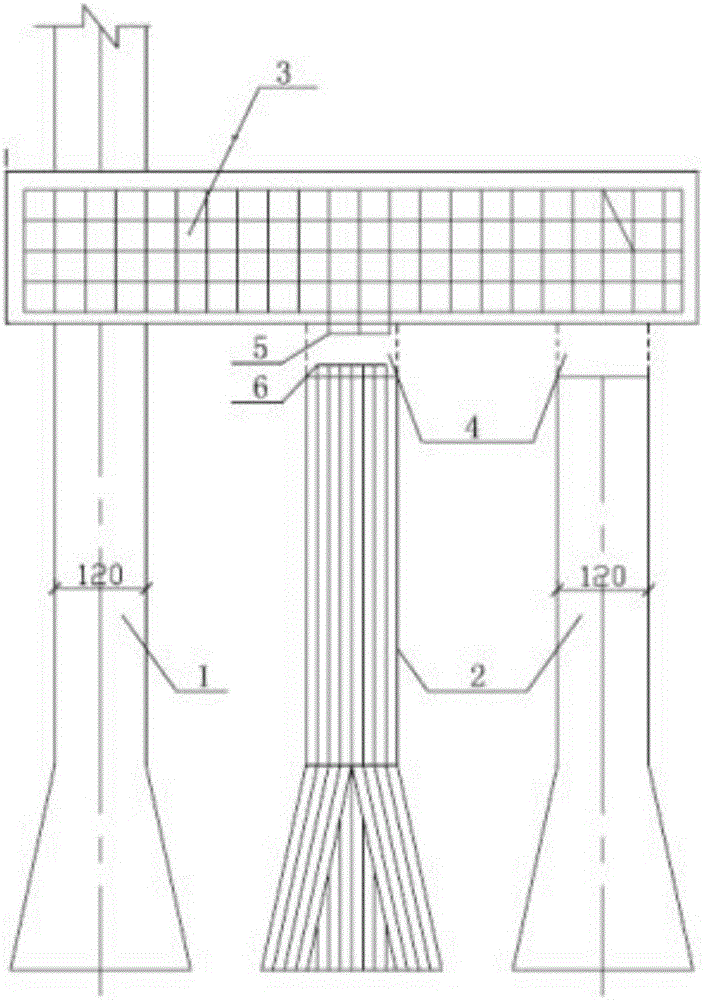

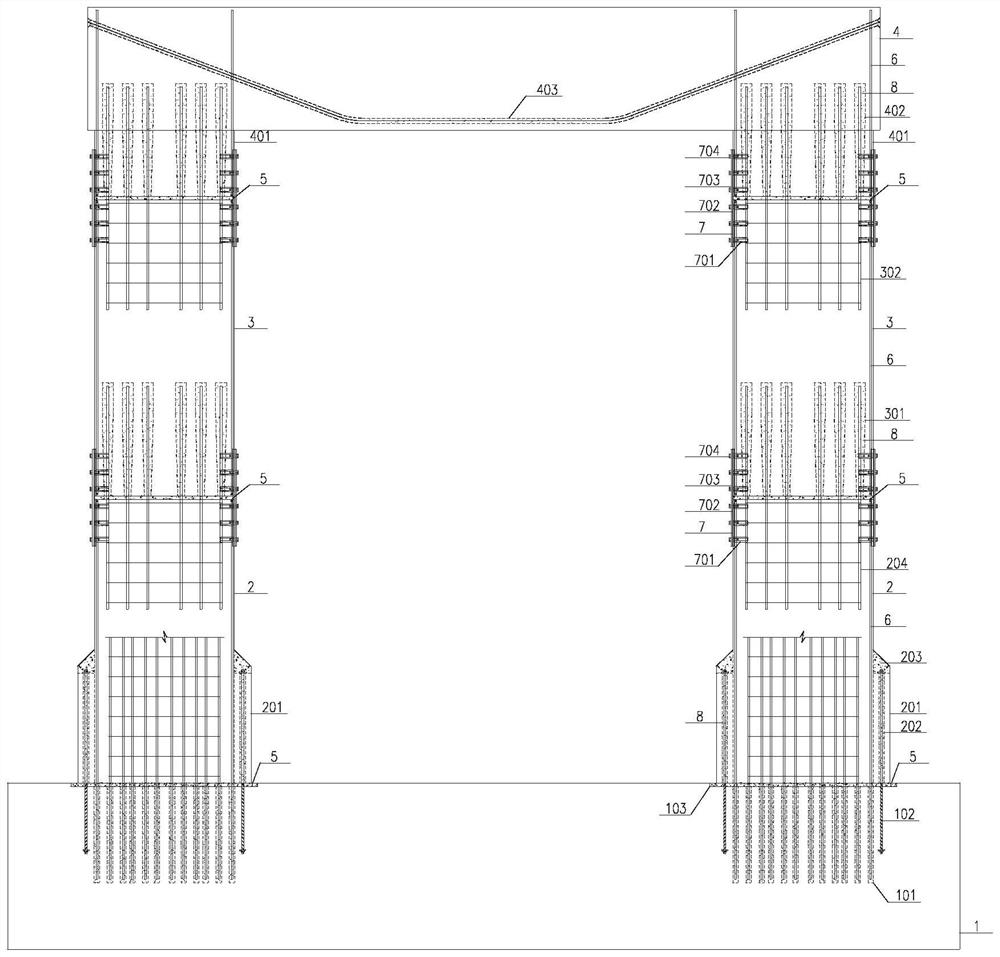

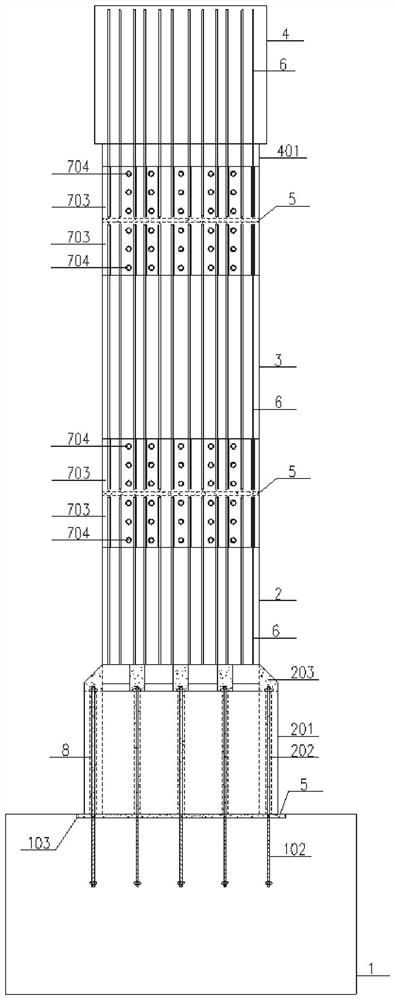

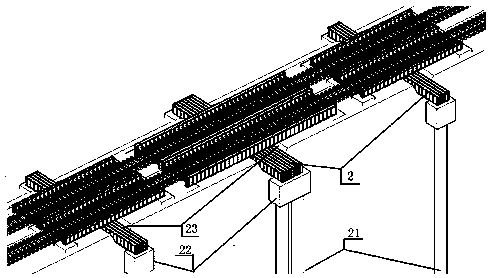

Prefabricated and assembled frame pier with large cross beams and high stand columns and construction method

PendingCN113123214AImprove tensile propertiesImprove shear resistanceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention provides a prefabricated and assembled frame pier with large cross beams and high stand columns and a construction method. The frame pier comprises a foundation, a bottom section pier column, a middle section pier column and a cross beam; when the foundation is constructed, steel bar embedded pipes and embedded thick steel bars are arranged, and joint notches are formed; a transition section is arranged below the bottom section pier column during prefabrication, thick steel bar reserved hole channels and sealing anchors are arranged in the transition section, connecting steel bars extend out of the bottom face of the bottom section pier column, and steel plate connecting pieces are embedded in the top face of the bottom section pier column. During prefabrication of the middle-section pier column, steel bar embedded pipes are arranged at the bottom, connecting steel bars are arranged at the top, and steel plate connecting pieces are embedded; when the cross beam is prefabricated, extending columns are arranged at the positions corresponding to pier columns, steel bar embedded pipes are embedded, and steel plate connecting pieces are embedded. The foundation is connected with the bottom-section pier column through thick steel bars and main bars, the bottom-section pier column is connected with the middle-section pier column through connecting steel bars and steel plate connecting pieces, and the middle-section pier column is connected with the cross beam through the connecting steel bars and steel plate connecting pieces. The structure effectively ensures the strength and durability of each joint, and is suitable for the prefabricated assembled frame pier adopting large cross beams and high stand columns.

Owner:CHINA RAILWAYS CORPORATION +1

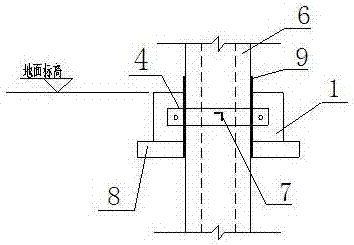

Adjusting device suitable for building differential settlement

ActiveCN112324737ARelief forceGuarantee joint forceFluid-pressure actuatorsFoundation engineeringStructural engineeringMechanical engineering

Owner:TONGJI UNIV

A waterproof single-layer lining structure suitable for four-level surrounding rock double-track track and its manufacturing method

ActiveCN110359915BEven by forceSimple construction processUnderground chambersTunnel liningFiberCrude fibre

The invention discloses a waterproof single-layer lining structure suitable for a four-level surrounding rock double-track track. The bolt on the Ⅳ-level surrounding rock, the bolt is perpendicular to the rock surface of the Ⅳ-level surrounding rock; wherein, the rock surface of the Ⅳ-level surrounding rock is also washed, sprayed with the first layer of coarse fiber concrete and Curing, spray mortar and curing, spray waterproofing and curing, spray the second layer of fine fiber concrete and curing. The invention relates to a waterproof single-layer lining structure suitable for grade IV surrounding rock double-track tunnels. The single-layer lining structure formed by this technology is uniformly stressed, has a certain ability to resist deformation, and has simple construction technology and construction period. Short, reduce construction pollution, low-carbon and environmental protection, widely used in the lining structure of grade IV surrounding rock double-track tunnel engineering.

Owner:中铁科学研究院有限公司

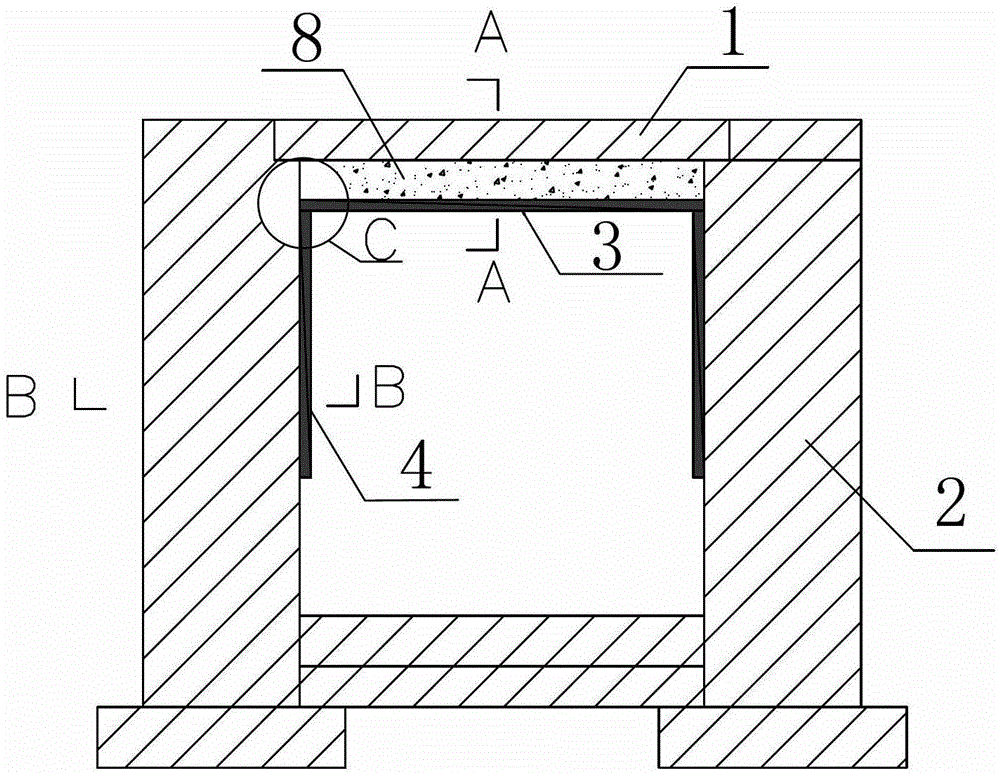

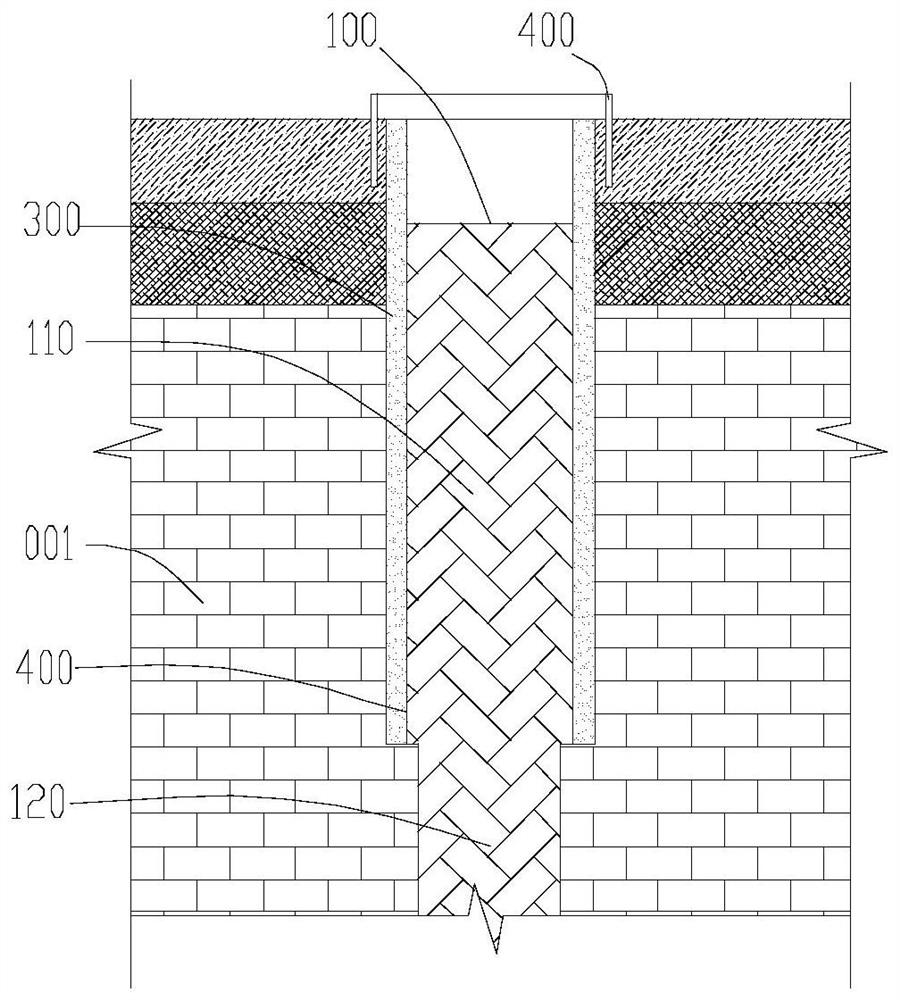

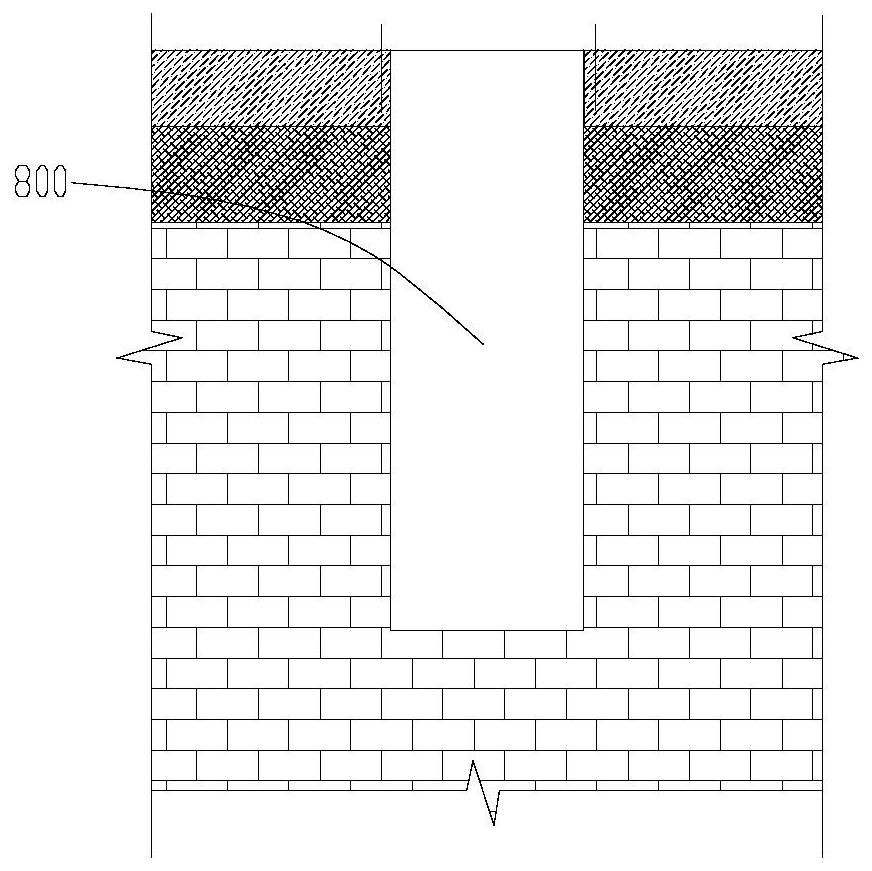

External ring beam and original structure wall body connected through L-shaped anchor bars and construction method

The invention relates to an external ring beam and an original structure wall body connected through L-shaped anchor bars and a construction method. The L-shaped anchor bar, the external ring beam, a ring beam stirrup, a longitudinal steel bar and an anchor hole are included. The external ring beam forms a closed whole along the periphery of a building; the L-shaped anchor bars and the external ring beam are integrally cast; the anchoring depth of the L-shaped anchor bar in the original structure wall body is 150 to 200 mm; the anchor slurry of the L-shaped anchor bars in the anchor holes of the wall body is grouted by cement-based antirust mortar; the L-shaped anchor bars are suitable for being arranged on two sides of a door and window opening of an original structure wall, and the horizontal distance between the L-shaped anchor bars ranges from 1000 mm to 2000 mm. The L-shaped anchor bars, the external ring beam longitudinal steel bars and the ring beam stirrups are bound and poured together. The new structure and the old structure are reliably connected in a pulling mode, so that common stress is guaranteed, and stiffness mutation of each layer is prevented.

Owner:北京筑福国际抗震技术有限责任公司

External ring beam constructional column expansion joint structure and construction method thereof

PendingCN113737972AGuarantee joint forceAvoid sudden changes in stiffnessStrutsBuilding repairsAdhesiveExpansion joint

The invention relates to an external ring beam constructional column expansion joint structure and a construction method thereof. The external ring beam constructional column expansion joint structure comprises an external ring beam, external constructional columns and L-shaped anchor bars, wherein the external constructional columns are arranged on the two sides of an expansion joint, the external constructional columns on each side and the external ring beam are integrally poured to form a closed whole along the periphery of the building, the external constructional columns are connected with the original structure wall body through the L-shaped anchor bars, the anchor slurry of the L-shaped anchor bars in the anchor holes of the wall body is grouted by adopting A-grade structural adhesive, and the L-shaped anchor bars, constructional column main bars and constructional column stirrups are bound and poured together.

Owner:北京筑福国际抗震技术有限责任公司

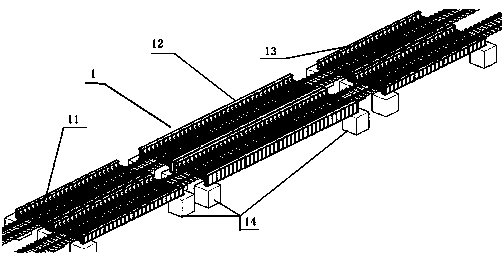

Combined type steel large cross beam erection multi-span make-shift beam line reinforcing method

ActiveCN110374018ADoes not affect normal driving operationImprove construction efficiencyBridge erection/assemblyBridge strengtheningPhysicsBeamline

The invention discloses a combined type steel large cross beam erection multi-span make-shift beam line reinforcing method. The combined type steel large cross beam erection multi-span make-shift beamline reinforcing method comprises five steps of transition type D construction make-shift beam erection, steel large cross beam installation, distribution beam installation, formal type D construction make-shift beam backward-moving erection and limiting device installation. According to the method, the operation of normal traffic of a serving line is not influenced during the whole constructionprocess, and meanwhile, the traffic safety of the serving line (a railway ) is strengthened; two or more lines can be simultaneously reinforced at the same time through adoption of the steel large cross beams with different lengths, when two or more-hole frame box bridges are jacked, a multi-span type D construction make-shift beam can be erected, meanwhile, the multi-span type D construction make-shift beam is jacked, so that time and labor are saved, and the construction efficiency is at least improved by 50%; and the steel large cross beam, the distribution beam and the limiting device arein a combined connection mode and can be repeatedly used, split, spliced and repeatedly utilized, so that the labor cost and the material cost are greatly reduced.

Owner:HOHHOT RAILWAY CONSTR OF THE SIXTH ENG BUREAU CREC +1

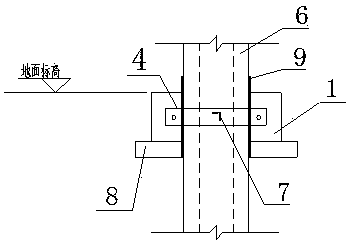

Construction method of cap-beam-column joint replacement for advance reinforcement of hoop structure

ActiveCN105257015BPrecise control of forceGuarantee joint forceBuilding repairsFoundation engineeringBasementEngineering

The invention relates to a construction method of a bearing platform-beam column joint replacement advance reinforcement hoop structure. Shortcomings that the existing bearing platform becomes a joint weak region in a basement storey adding project, and large potential safety hazards of the project are easily caused are overcome. The construction method comprises the following steps of A, manufacturing a first-stage hoop structure; B, manufacturing a second-stage hoop structure; and C, dismounting the first-stage hoop structure and chiseling off bearing platform concrete on the outer side of an anchor rod of the second-stage hoop structure. Through stretching of the anchor rods and slip casing by pressure, mechanical performance of the hoop structures is controlled accurately, and joint load carrying of concrete of original core regions of the closed hoop structures and a bearing platform is guaranteed. In whole construction, safety and adaptation are high, bearing platform-beam column core region structure replacement can be finished under the condition that functions of an upper structure are not affected, and various detailing requirements on beam column joints and actual stress requirements in a basement storey-adding projection in Chinese standards can be met.

Owner:ZHEJIANG SCI-TECH UNIV

A Pile Foundation Reinforcement Method for Inverter Box Transformer Platform

ActiveCN106930339BGuarantee joint forceActive connectionArtificial islandsFoundation repairReinforced concreteTransformer

The invention discloses a pile foundation reinforcement method for an inverter box transformer platform. According to the method, a plurality of tubular piles connected through ring beams are included; after hoops connected with the ring beams are wrapped outside the tubular piles, the ring beams, the hoops and the tubular piles are poured into a whole through concrete. The reinforced concrete ring beams are additionally arranged on the ground where the inverter box transformer platform tubular piles are located. The tubular piles are connected into a whole under the tying action of the ring beams. The tubular piles and the ring beams are effectively connected through the hoops of which steel angles are welded to the two sides. When local settlement occurs to some tubular pile due to low bearing capacity caused by defects of a pile body, downward pull force can be transmitted to the ring beams nearby through the hoops and the steel angles and then transmitted to adjacent pile foundations. Finally, the pile foundations of the whole platform share the force to be stressed uniformly. Adverse effects caused by uneven settlement of individual pile foundations are avoided. It is guaranteed that all the pile foundations of the whole platform are stressed jointly. The integrality is enhanced. Accordingly, inverters, box inverters and other electronic equipment on the platform can operate normally. The pile foundation reinforcement method has high practicality and extensive applicability.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST CO LTD

Bridge support structure and bridge pile foundation construction technology for increasing pile foundation flexibility

The invention provides a bridge support structure and a bridge pile foundation construction process for increasing the flexibility of the pile foundation, which is suitable for bridge support in areas with shallow coverage of complete rock formations, which includes a pile basic body, an expansion casing and a filling layer. The basic body has a first support section and a second support section along the central axis direction, the first support section is inserted into the reaming casing, and the outer peripheral wall of the first support section is in contact with the reaming casing The inner cylinder wall of the cylinder is in contact, the second support section protrudes from one end of the reaming casing, and the second support section is in contact with the rock formation; the filling layer is wrapped in the outer cylinder of the reaming casing on the wall. The pile foundation structure is simple and reasonable, and the settlement of the pile foundation is uniform, which effectively ensures the joint force of the pile foundation and the adjacent pier pile foundation on the horizontal impact, and strengthens the durability of the pile foundation.

Owner:CCFEB CIVIL ENG

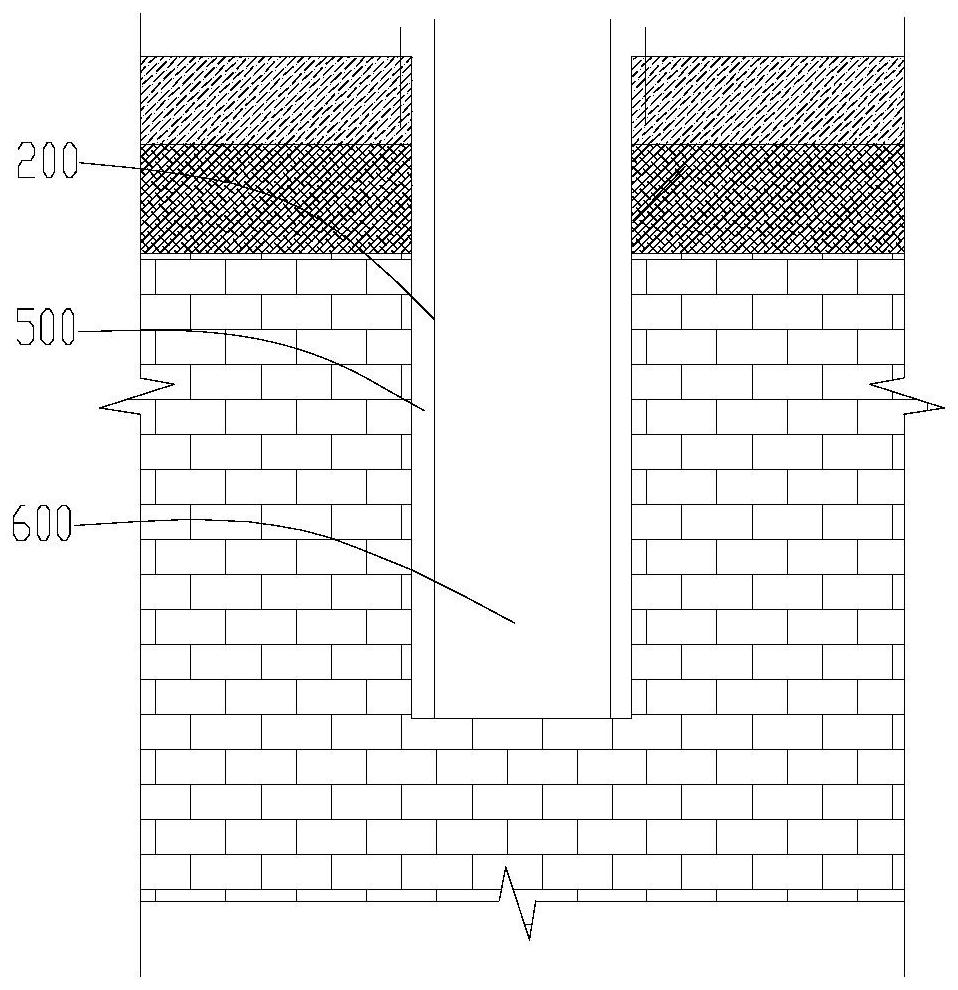

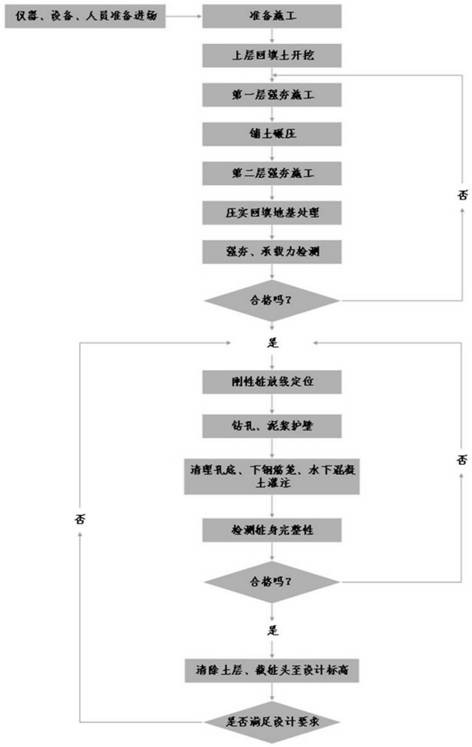

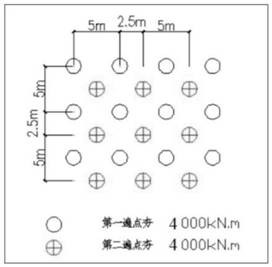

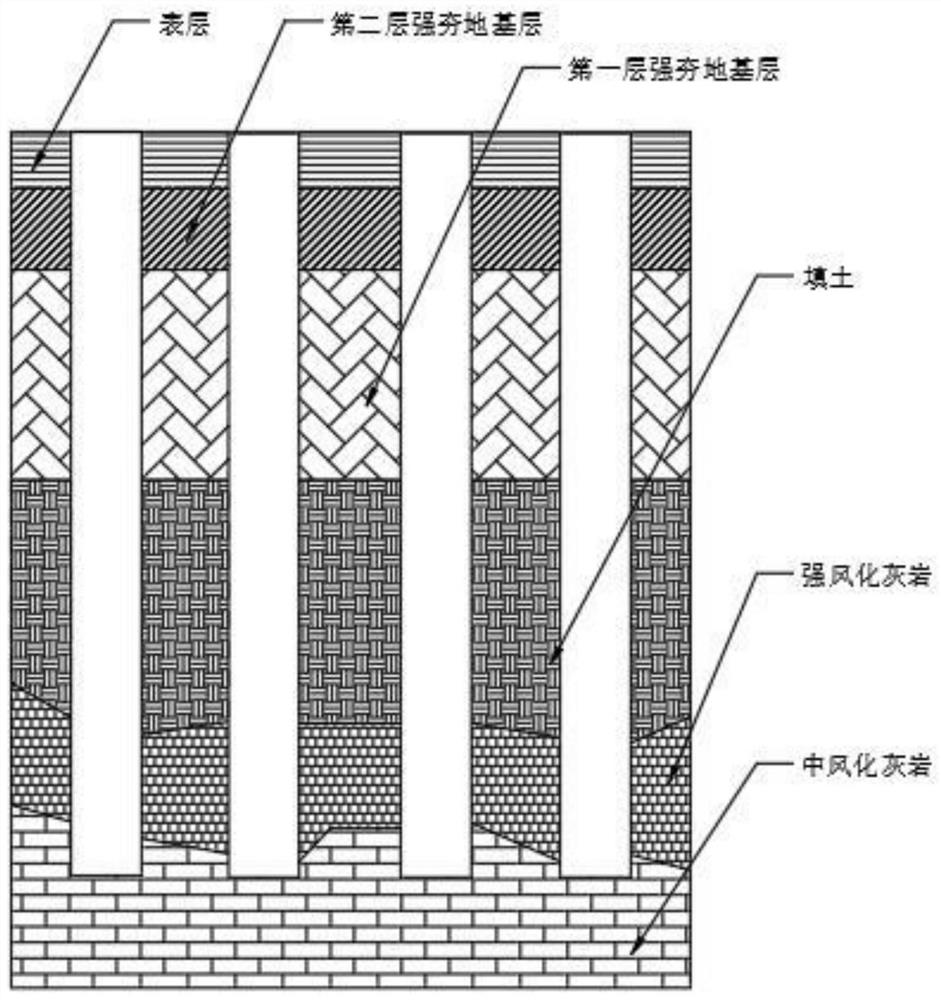

High fill area end bearing pile foundation construction method

PendingCN114232593AHigh hole-forming value retention rateReduce negative frictionBulkheads/pilesSoil preservationDynamic compactionArchitectural engineering

The invention relates to the technical field of civil engineering, in particular to a high fill area end bearing pile foundation construction method which comprises the steps of construction preparation, surface layer backfill soil excavation, first layer dynamic compaction foundation layer construction, soil paving and rolling compaction, second layer dynamic compaction foundation layer construction, compaction backfill foundation treatment, bearing capacity detection, rigid pile paying-off positioning and drilling. According to the construction method for the end bearing pile foundation of the high fill area, the negative friction resistance of backfill soil on the pile side is reduced, it is guaranteed that the pile and the soil are jointly stressed, and the construction efficiency of the end bearing pile foundation of the high fill area is improved. After the foundation which is not suitable for building a high-rise building originally is treated, the requirement for the bearing capacity of the designed foundation can be met, the land utilization rate is greatly increased, the land cost is saved, and compared with an existing replacement filling method for compacting the foundation, construction is fast, economical efficiency is good, and social and economic benefits are remarkable.

Owner:重庆建工第七建筑工程有限责任公司

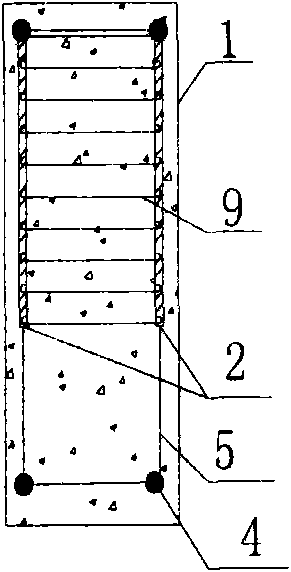

A kind of reinforced structure and its construction method to ensure the common stress of new and old concrete structures

ActiveCN103195260BGuarantee joint forceGuaranteed carrying capacityBuilding repairsSteel barBuilding construction

The invention discloses a reinforcing structure capable of ensuring new and old concrete structures to be stressed together. The reinforcing structure comprises a plurality of connection members, an adhesion agent, newly-added reinforcing steel bars and new concrete, wherein the connection members are longitudinally arranged along the old concrete structure at intervals, the adhesion agent is coated on the surface of the old concrete structure between adjacent I-shaped steel members after the surface of the old concrete structure is roughened, the newly-added reinforcing steel bars are longitudinally arranged along the I-shaped steel members, the new concrete is formed by pouring concrete on the surface of the old concrete structure, and the surface of the new concrete is parallel and level to the surfaces of the joist steel members. The invention also discloses a reinforcing construction method with the above reinforcing structure. According to the reinforcing structure and the reinforcing construction method, the plurality of connection members are arranged on the contact surfaces of the new concrete structure and the old concrete structure, and the anti-slip capability in the horizontal and the vertical directions and the separation resistance in the longitudinal direction of the contact surfaces of the new concrete structure and the old concrete structure can be improved, so that the new concrete structure and the old concrete structure can be stressed together and perfectly connected to achieve coordinate deformation, and the bearing capability and the long-term using performance of the reinforcing structure are guaranteed.

Owner:CCCC FOURTH HARBOR ENG INST +3

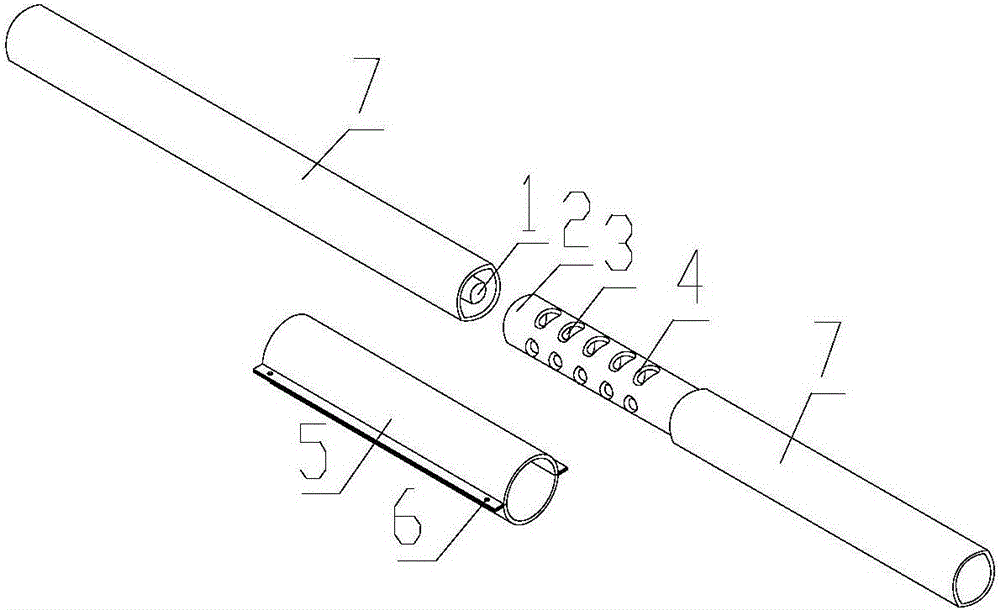

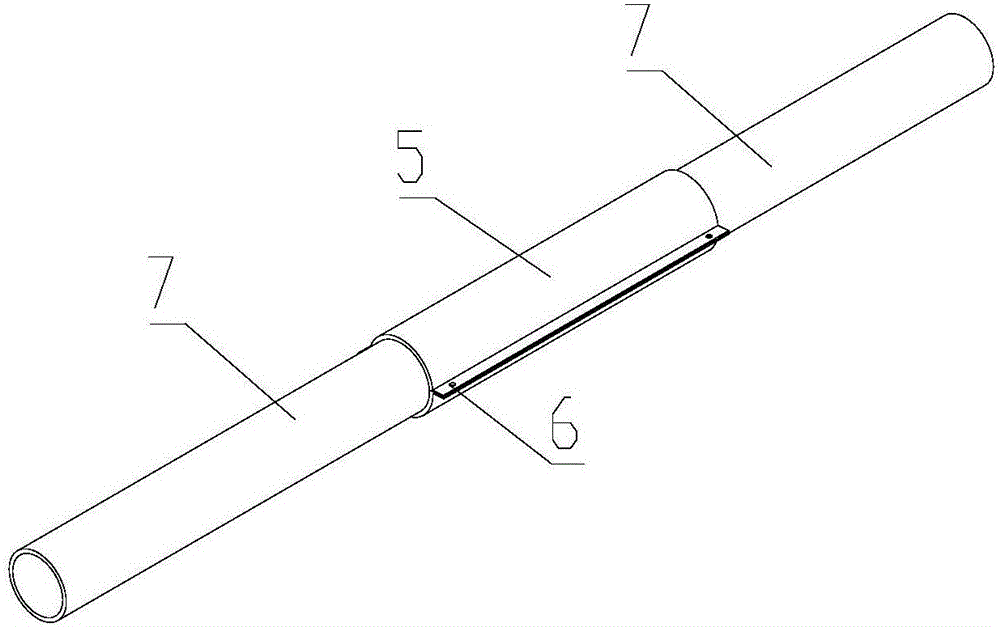

Recyclable soil nail and construction method using recyclable soil nail

ActiveCN106480880BAchieve recyclingAchieve recyclabilityExcavationsBulkheads/pilesSoil scienceScrew thread

The invention provides a recoverable soil nail and a method for construction with the recoverable soil nail. The recoverable soil nail comprises a soil nail end, a tubular soil nail body, a grouting pipe and an outer sleeve. The soil nail end comprises a nail point, an end plate and a connection pipe, the nail point, the end plate and the connection pipe are welded sequentially, a sealing partition provided with a via hole is arranged in the connection pipe, and the outer wall of the connection pipe is provided with an external thread. The soil nail body is formed by sequential threaded connection of at least two soil nail sections, adjacent soil nail sections are positioned through anti-rotating pins, the soil nail section at one end is in threaded connection with the connection pipe, and the outer wall of each soil nail section is provided with an external thread. One end of the grouting pipe is penetratingly arranged in the via hole of the sealing partition, and the other end of the grouting pipe penetrates out of the whole soil nail body. The inner wall of the outer sleeve is provided with an internal thread, and the outer sleeve sleeves the connection pipe and the soil nail body through the thread. By the sectional structure, soil nail recovery in a narrow space is realized.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com