Combined type steel large cross beam erection multi-span make-shift beam line reinforcing method

A large beam, combined technology, used in bridge reinforcement, erection/assembly of bridges, bridge construction, etc., can solve the problems of long construction period, limitations, and small scope of application, so as to improve construction efficiency, strengthen load capacity, and strengthen traffic. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

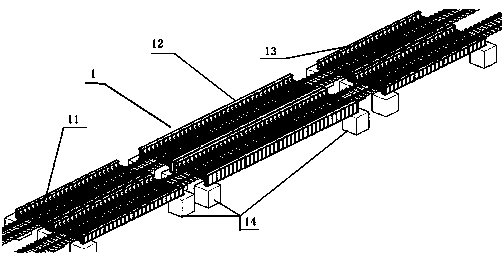

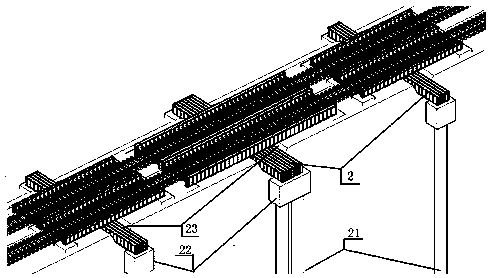

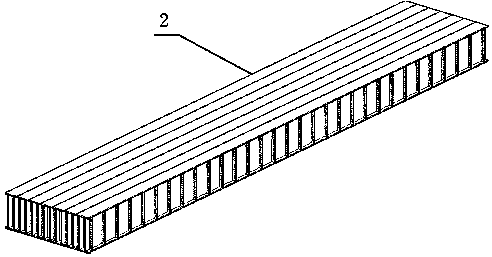

[0054] A combined steel large beam erection multi-span convenience beam line reinforcement method, such as Figure 1-13 As shown, five steps including the erection of the transitional D-type construction beam 1, the installation of the steel large beam 2, the installation of the distribution beam 3, the reverse erection of the formal D-type construction beam 4 and the installation of the limit device 5;

[0055] The first step: if figure 1 As shown, the erection of the transitional D-type construction beam 1 specifically includes the following steps:

[0056] The transitional D-shaped construction beam 1 is divided into a front D-shaped beam 11, a middle D-shaped beam 12, and a rear D-shaped beam 13 according to different installation positions;

[0057] Temporary pier 14 is poured at both ends of the pre-installed transitional D-shaped construction beam 1, and the front D-shaped beam 11, the middle D-shaped beam 12, and the rear D-shaped beam 13 are erected on the temporary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com