A Pile Foundation Reinforcement Method for Inverter Box Transformer Platform

An inverter box and platform technology, which is applied in infrastructure engineering, infrastructure repair, construction, etc., can solve problems such as weak connection integrity, avoid adverse effects, simple structure, and ensure normal power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

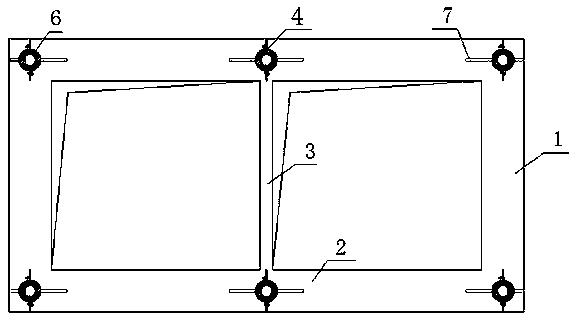

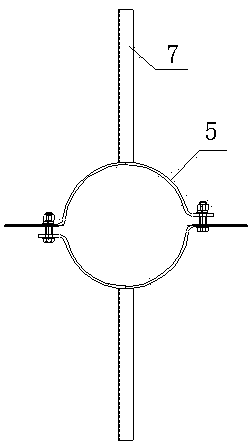

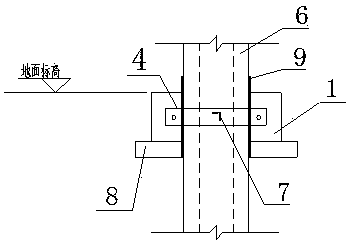

[0023] A pile foundation reinforcement method for an inverter box transformer platform, on a plain concrete cushion 8, a plurality of pipe piles 6 are connected through a ring beam 1 on the ground consisting of a number of transverse ring beams 2 and a longitudinal ring beam 3, After the pipe pile 6 is wrapped by the hoop 4 connected with the ring beam 1, which is composed of several single-piece hoops 5 and has several pairs of mutually symmetrical angle steels 7 on the outer surface, the ring beam 1, hoop 4, The angle steel 7 and the pipe pile 6 are poured into one body.

[0024] The outer surface of the pipe pile 6 in contact with the ring beam 1 and the hoop 4 is coated with an anti-corrosion paint 9 .

[0025] During actual construction, the plain concrete cushion 8 is first poured near the ground, and then the hoop 4 is set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com