Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

A technology of steel fiber concrete and steel bridge deck, which is applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of improved mechanical performance, convenient maintenance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

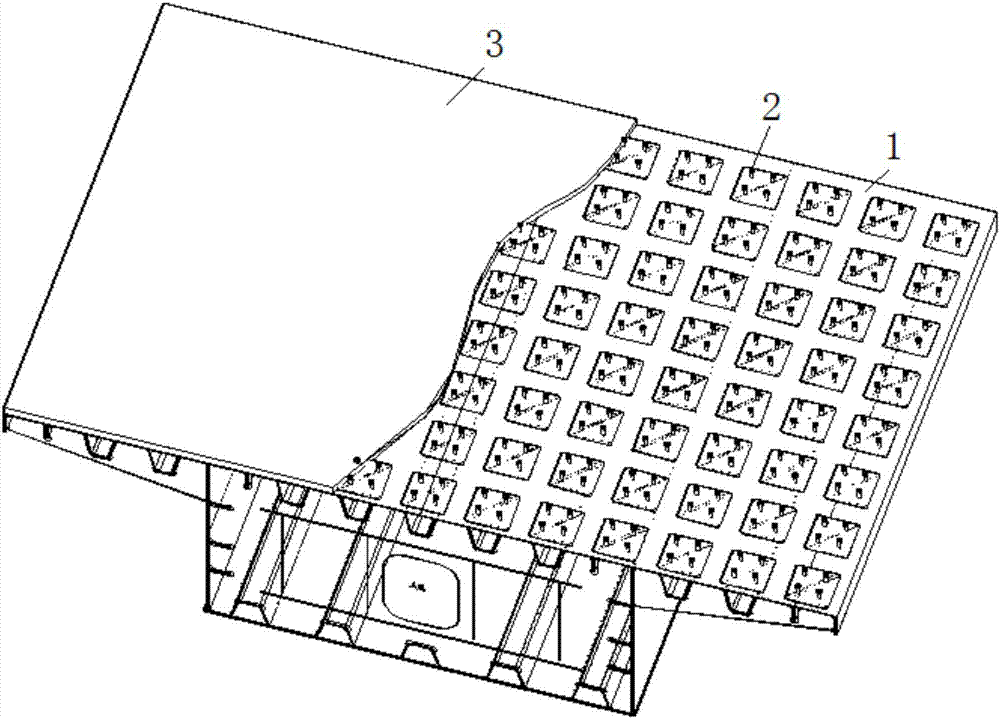

[0040] exist figure 1 , 2 , 3, the present invention is based on the steel fiber concrete composite steel bridge deck of bonded stud group, has the following steps:

[0041] S1, the steel bridge deck cover plate 1 is cleaned and shot blasted with a high-pressure air gun;

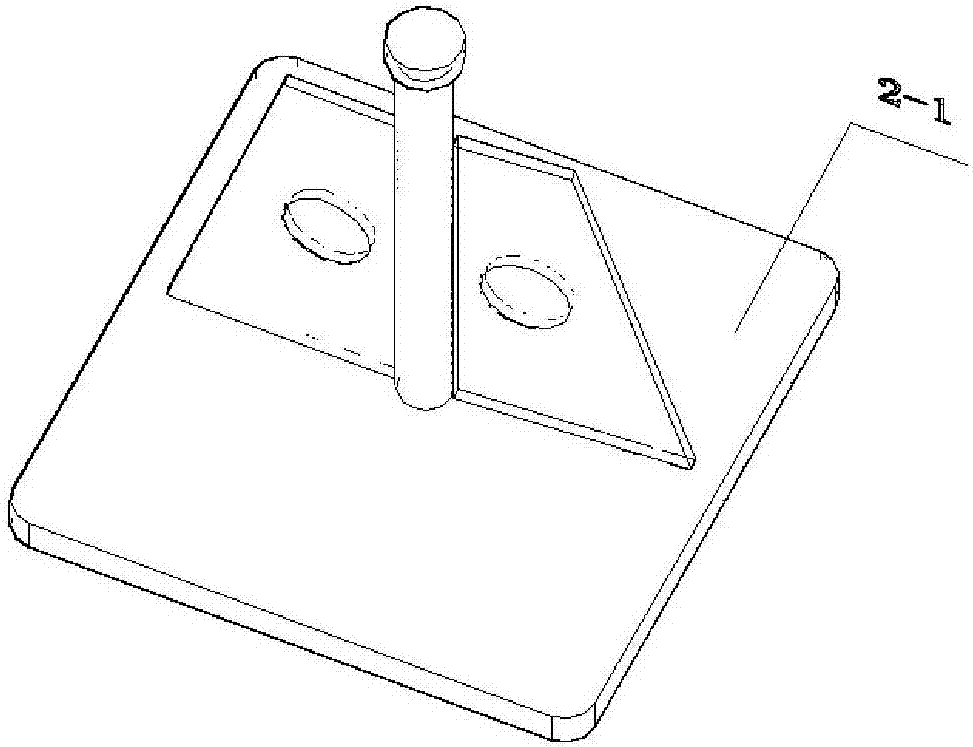

[0042]S2. Bond the stud connection assembly 2 on the steel bridge deck cover plate 1; in this embodiment, epoxy resin glue is used to paste the stud connection assembly 2 on the steel bridge deck cover plate 1, and the epoxy resin glue The thickness is 2-4mm. Further, this embodiment uses Sika 30 to bond the stud connection components. In terms of strength, the bonded combination layer can not only meet the force requirements of the structure, but also has high wear resistance and vibration resistance; in terms of durability , the epoxy resin glue has no shrinkage after curing, has good temperature resistance, and has high creep resistance under long-term load; in terms of construction feasibility, the ep...

Embodiment 2

[0055] exist Figure 6 In the stud connection assembly 2 of this embodiment, two stud connectors 2-2 are vertically arranged on the bottom plate 2-1, and the distance between adjacent stud connectors 2-2 is 150 mm to 250 mm. All the other components and the connections of the components are the same as those in Embodiment 1.

Embodiment 3

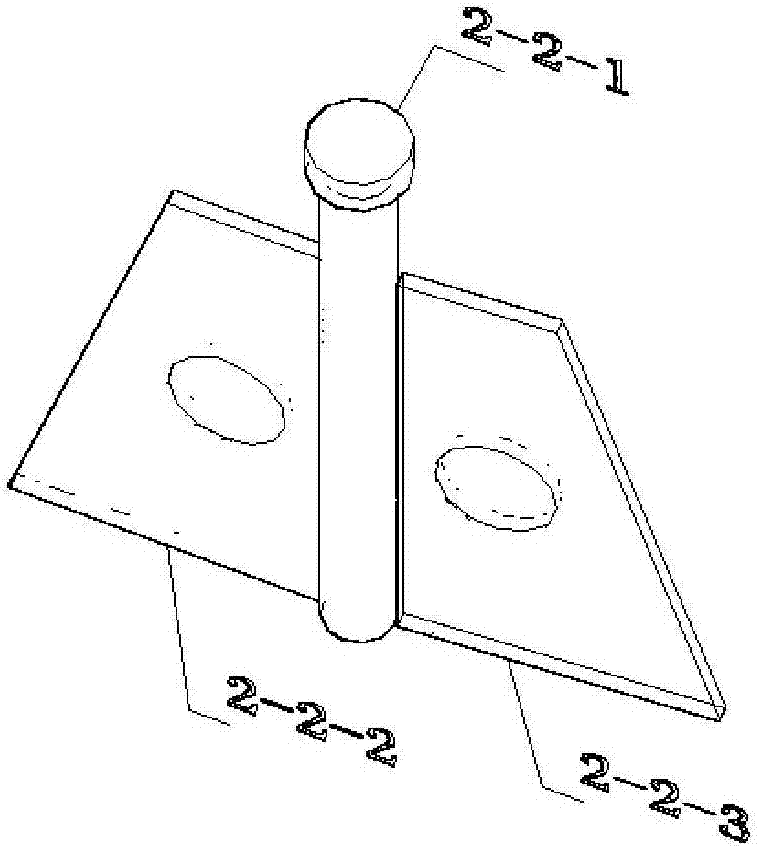

[0057] exist Figure 7 Among them, the stud connection assembly 2 of this embodiment is vertically provided with four stud connectors 2-2 on the bottom plate 2-1, and the connecting line of the center lines of the four stud connectors 2-2 is a square. The distance between the adjacent peg connectors 2-2 is 150 mm to 250 mm, and the other components and their connection relationship are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com