Patents

Literature

161results about How to "Has tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

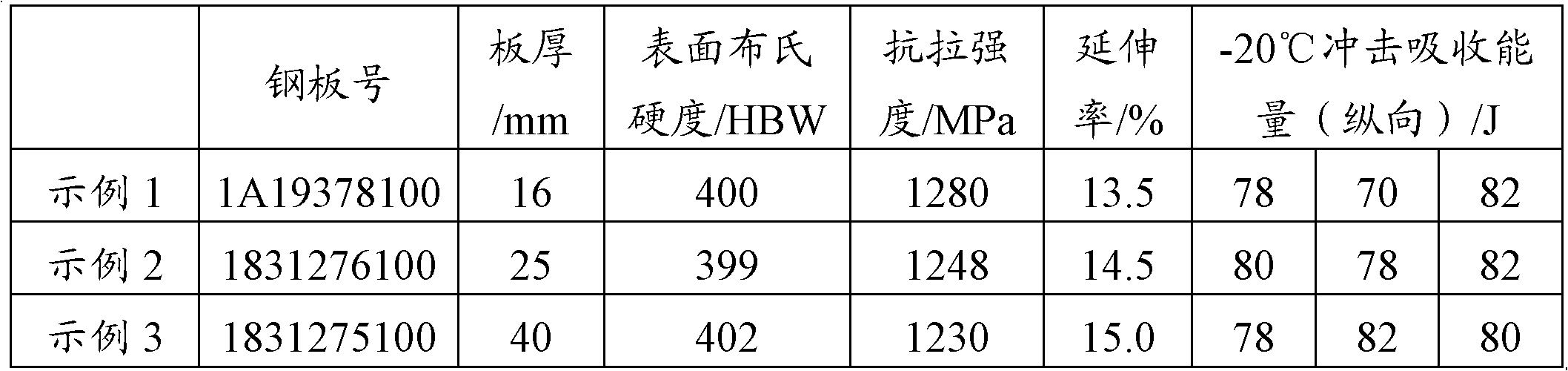

High-strength abrasion-resistant steel for engineering machinery and manufacturing method thereof

InactiveCN102618792ALow costWith superficial Brinell hardnessHigh wear resistanceMechanical products

The invention discloses high-strength abrasion-resistant steel for engineering machinery and a manufacturing method thereof. Components of the steel includes, by weight, 0.05-0.30% of C, 0.20-0.65% of Si, 1.20 to 1.60% of Mn, S<=0.010%, P<=0.020%, 0.0010-0.0040% of B, 0.30-1.00% of Cr, 0.030-0.080% of V, 0.015-0.050% of Al, [N]: 80-(200*10-6), [H]<=2*10-6, [O]<=40*10-6, and the balance Fe and inevitable impurities. The steel has surface brinell hardness no less than 395HBW, tensile strength no less than 1220 MPa, elongation after fracture no less than 13% and -20 DEG C shock absorption energy no less than 70J and is low in cost and capable of being used for manufacturing high-strength and high-abrasion resistance mechanical products in the industries of engineering, mining, building, agriculture, cement production, harbors, electric power and metallurgy. For example, the steel can be used as steel balls and lining plates of a ball grinder, bucket teeth of an excavator, rolling mortar walls, toothed plates and hammers of various crushers, track shoes of a tractor and a tank, scraper knives and relieving teeth for a bulldozer and the like.

Owner:LAIWU IRON & STEEL GRP +1

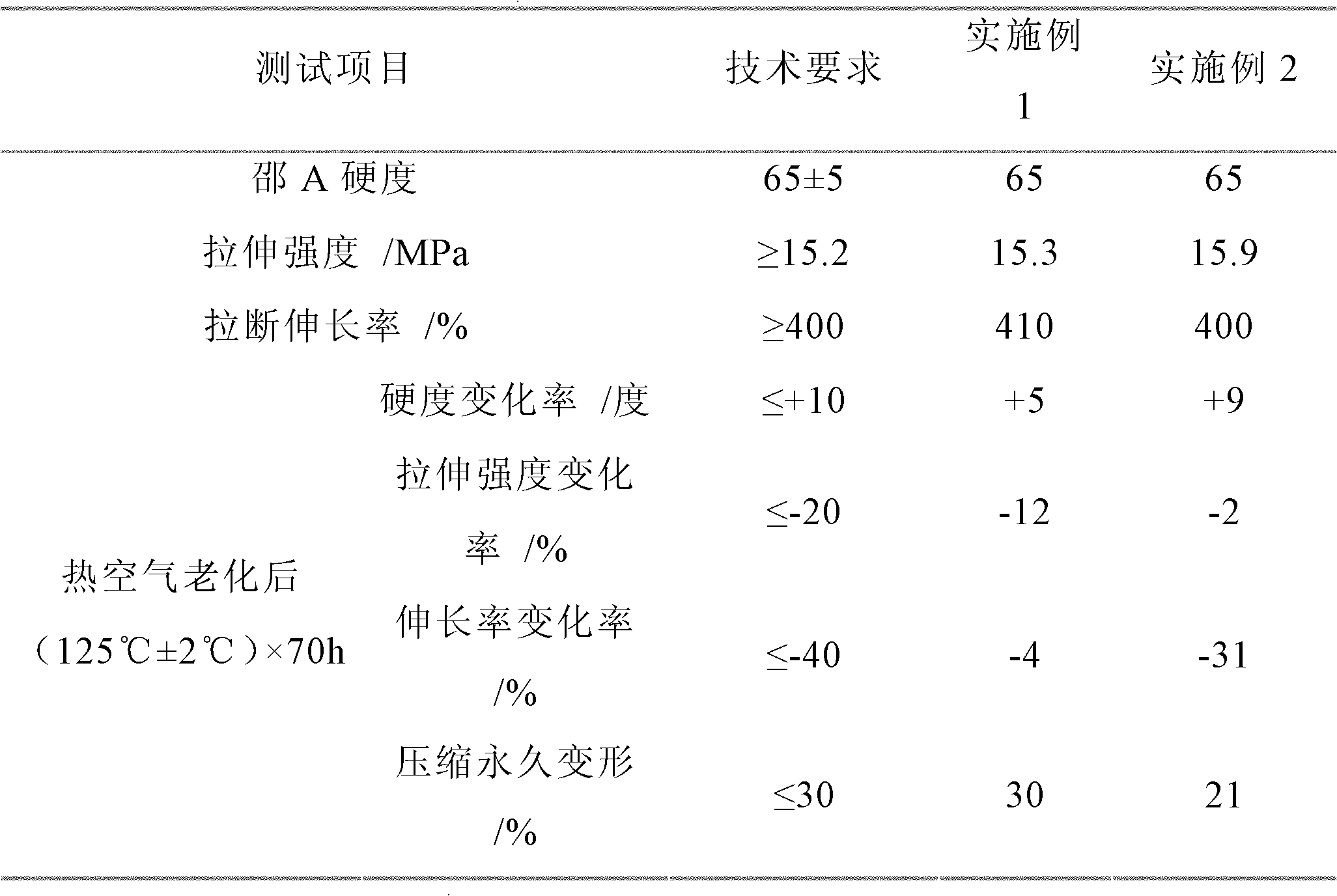

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

Ultrahigh-performance plastic film as well as preparation method and composite material thereof

ActiveCN103724791AHigh tensile strengthReduce material usageSynthetic resin layered productsLaminationChemistryHigh-density polyethylene

The invention relates to an ultrahigh-performance plastic film as well as a preparation method thereof. The film is a one-layer structure of a multilayer structure. At least one layer structure in the film adopts the following formula by weight percent: 0 to 100 percent of metallocene linear low-density polyethylene, 0 to 100 percent of linear low-density polyethylene, 0 to 80 percent of low-density polyethylene, 0 to 60 percent of ultralow-density polyethylene, 0 to 60 percent of high-density polyethylene and 0 to 30 percent of additives. The invention also relates to a composite material which is prepared by compounding the ultrahigh-performance plastic film and a fiber material. When used as operation tablecloth, the composite material has the multiplied performance of the existing operation tablecloth, such as tensile strength, impact resisting strength, tearing resistance and the like.

Owner:SUZHOU ADDISON NONWOVEN PROD CO LTD

Method for producing paper towel

InactiveCN102912676AReduce intensityHigh strengthWater-repelling agents additionReinforcing agents additionFiberPaper towel

The invention relates to a manufacturing method of a crepe paper product. A method for producing a paper towel comprises the following steps of: selecting 70-80 % of bleached softwood pulp and 20-30 % of straw pulp as raw materials; pulping the pulp by using a pulper, after beating the pulp by using a disc mill and adding auxiliary materials of an expanding agent, a softening agent and a wet strength agent to the pulp, molding, dehydrating and squeezing the pulp by using a Harper fourdrinier system; creping a wet paper sheet in a creping cylinder when the dryness of the wet paper sheet is 30-45 %, wherein an angle between a creping knife and the tangential line of a cylinder surface is 20-30 degrees, the cutting edge angle of a scraping knife sticking to the cylinder surface is 60-85 degrees, and the speed ratio of the creping cylinder and a heating cylinder is 1.15-1.18:1; and then drying the wet paper sheet by using the heating cylinder; and winding, rewinding and slicing the paper sheet so as to obtain a finished product. The method for producing the paper towel, provided by the invention, has the advantages as follows: through fiber variety and proportion selection and through the adoption of a wet creping process, the paper towel are produced; and the produced the paper towel has the advantages of tensile strength and proper air permeability; and the strength, wet strength, hydrophobicity, air permeability, flexibility and the like of the paper towel all reach higher standards; therefore, high quality and low cost are achieved.

Owner:QUANZHOU HUAXIANG PAPER IND

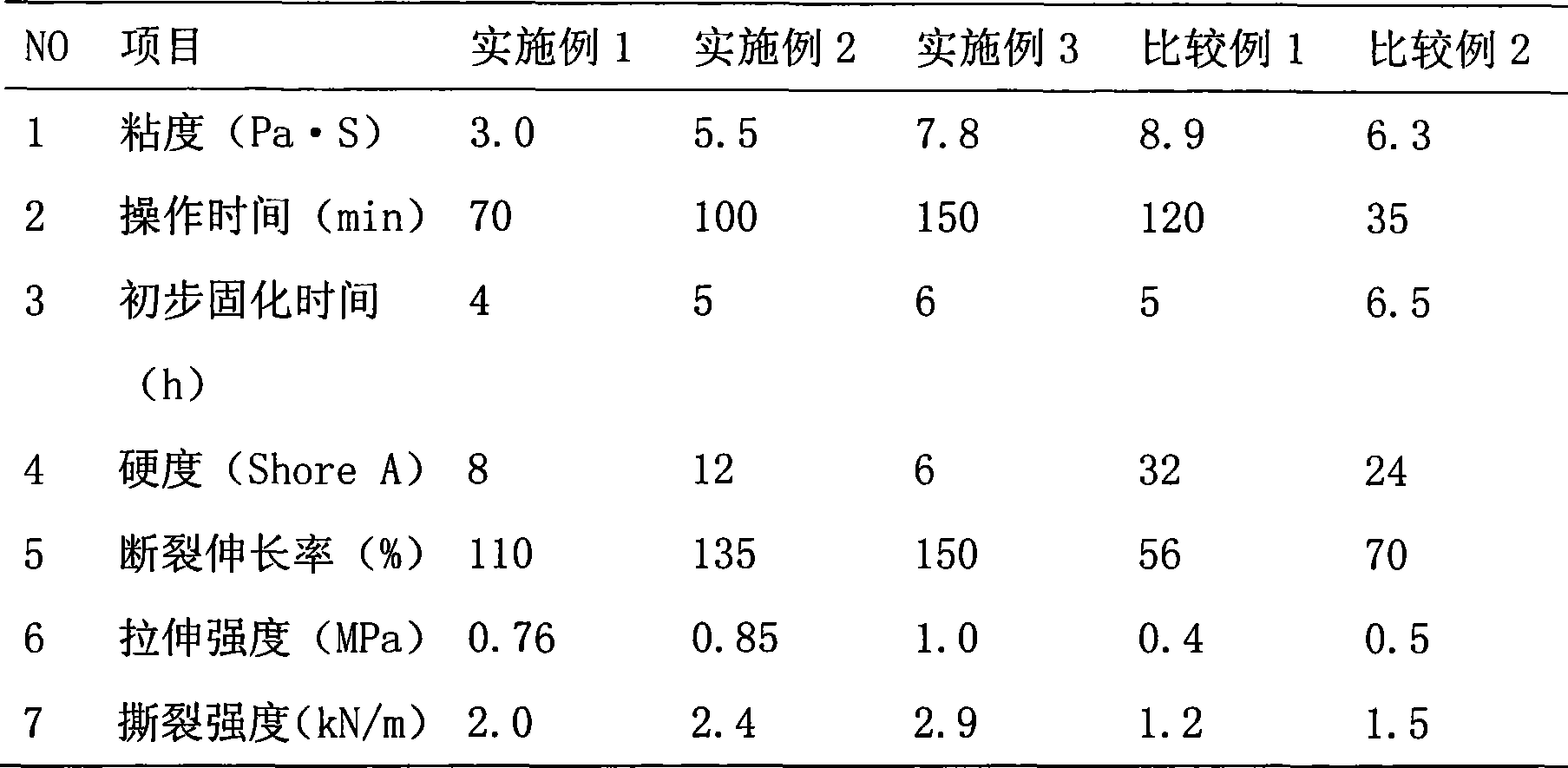

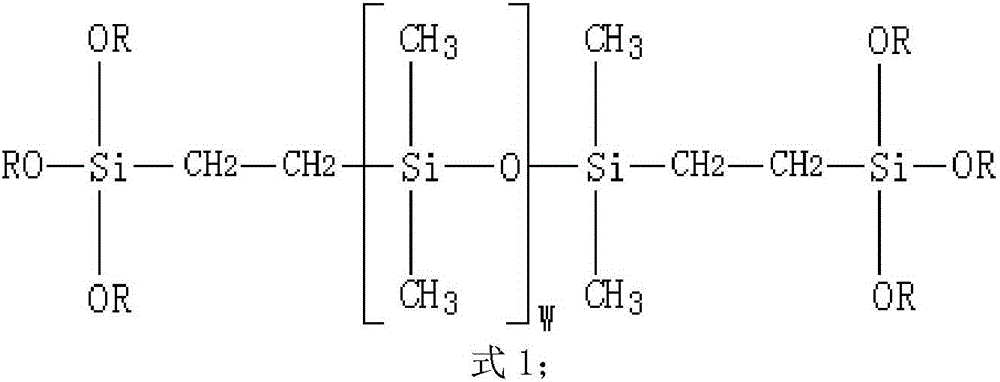

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

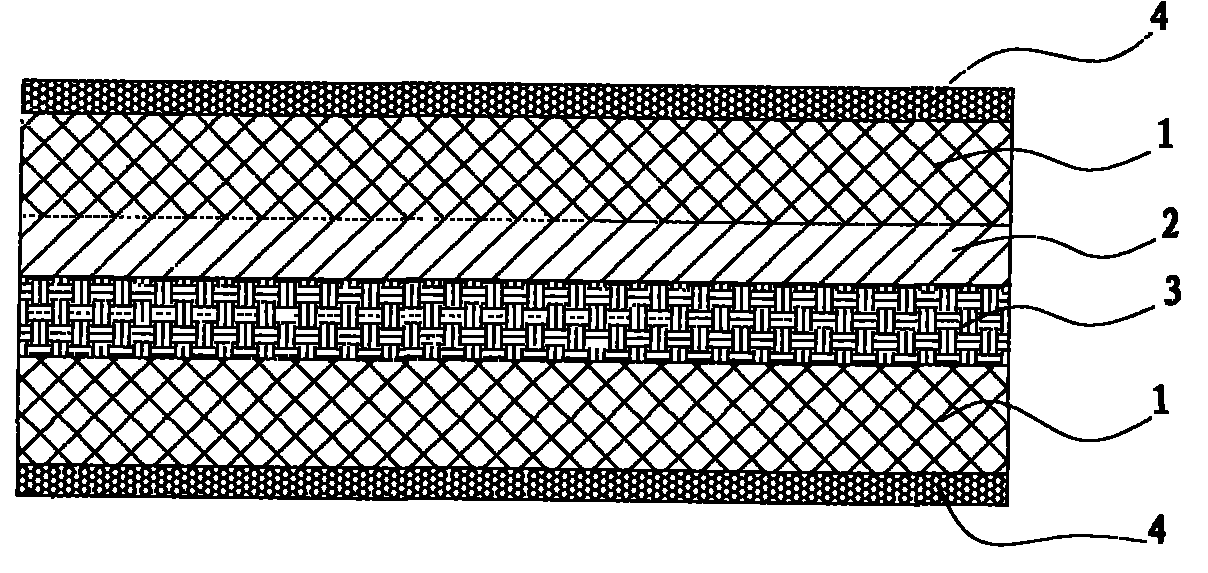

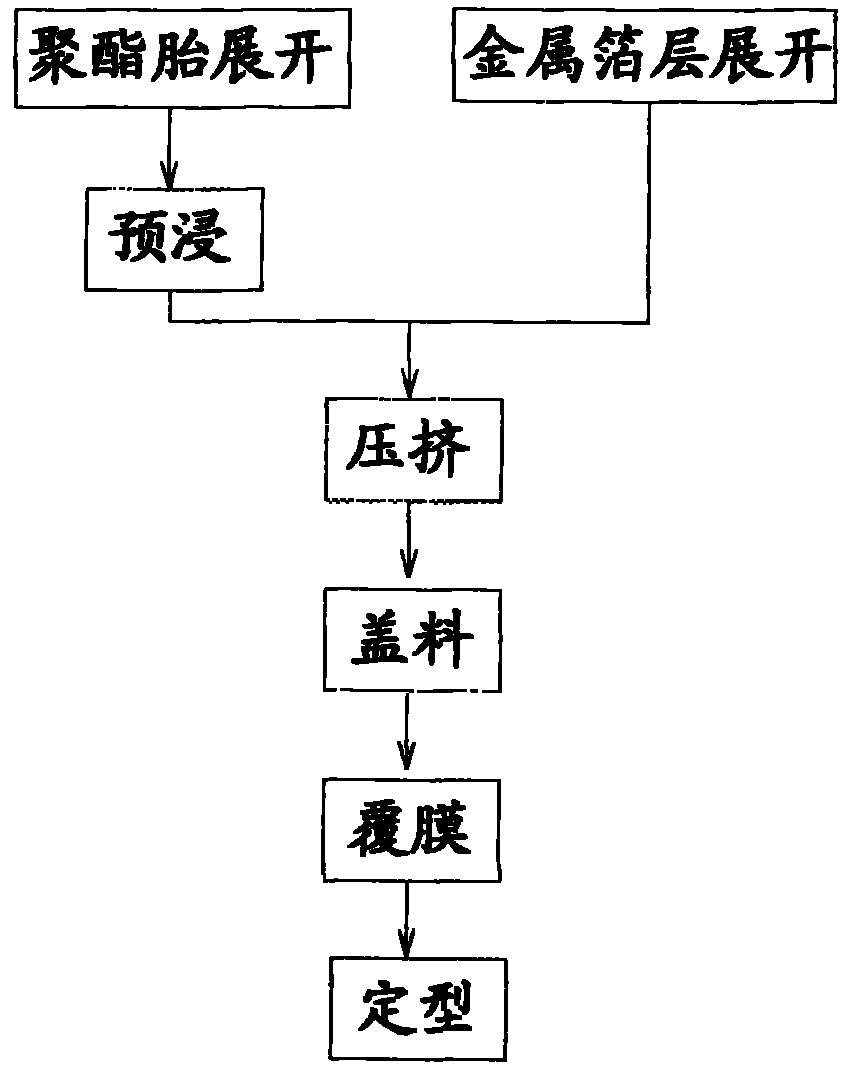

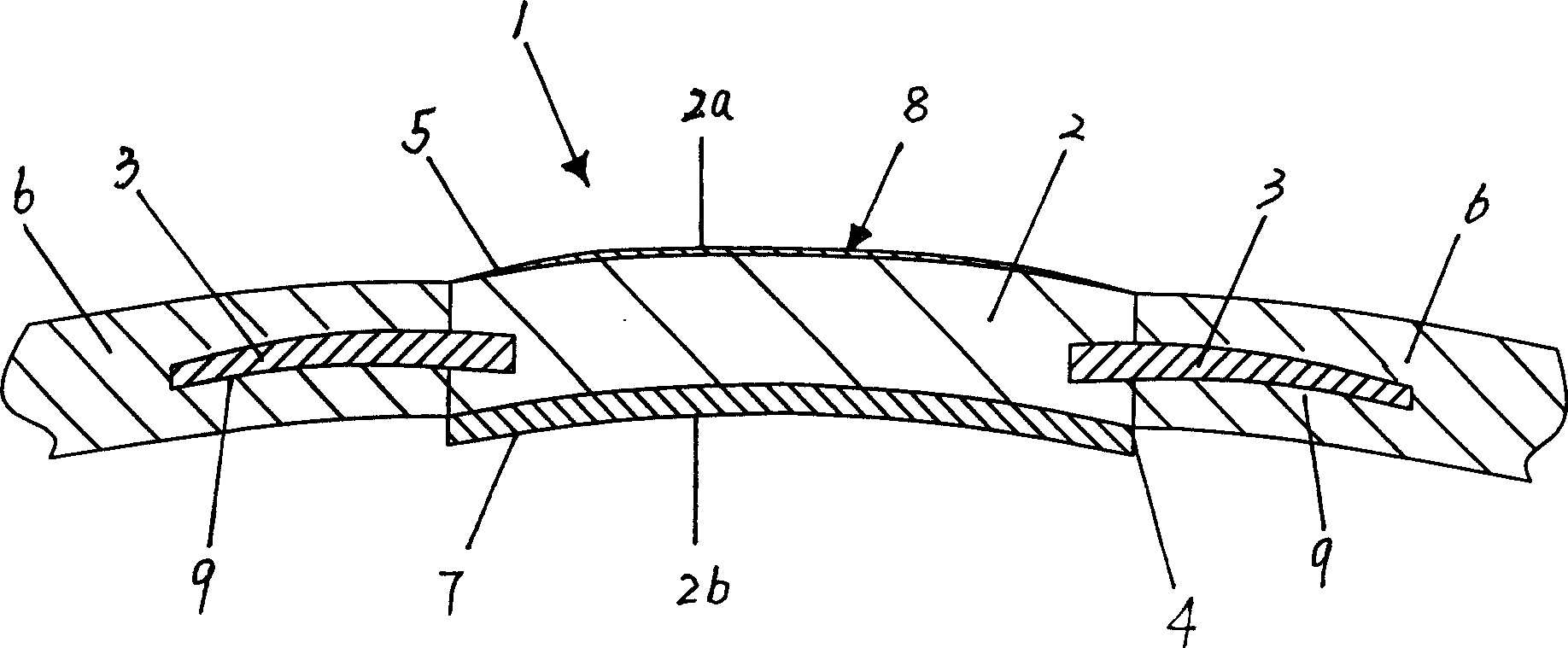

Root thorn-proof and waterproof coiled material and preparation technology

InactiveCN101818548APrevent penetrationDoes not affect growthLamination ancillary operationsRoof covering using flexible materialsPolyesterBituminous waterproofing

The invention provides a root thorn-proof and waterproof coiled material, which comprises a modified asphalt waterproof layer, a metal foil layer and a polyester tire, which are composited together. The polyester tire is presoaked by special modified asphalt. The root thorn-proof and waterproof coiled material is formed by the composite of the modified asphalt waterproof layer, the metal foil layer and the polyester tire, wherein the polyester tire is presoaked by the special modified asphalt, so that the root thorn-proof and waterproof coiled material has double functions of the water resistance and the penetration resistance of plant roots, can prevent from being penetrated by plant root hairs, and keeps the waterproof function for a long time.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

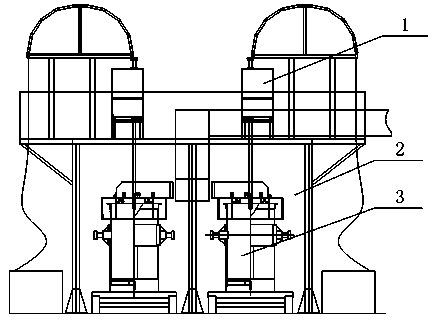

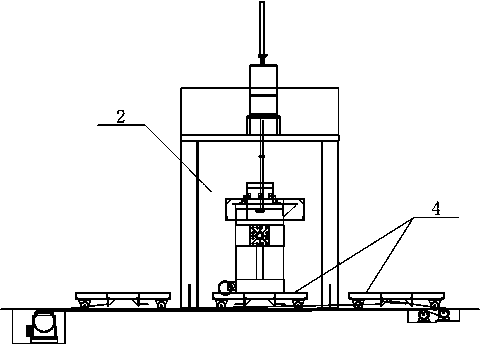

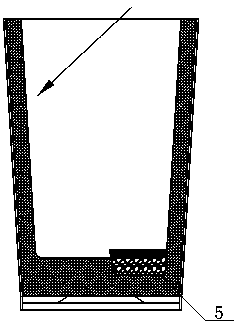

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

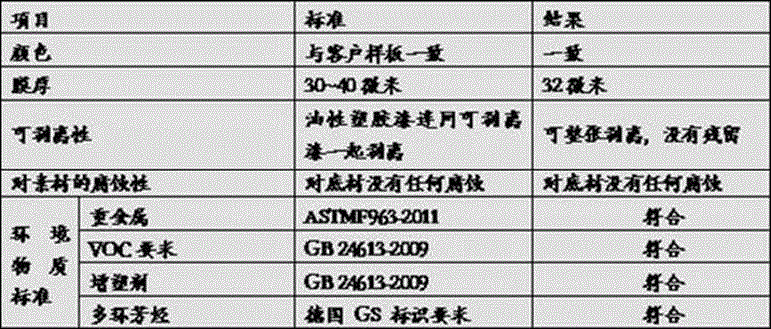

High-water-resistance quick-photocuring pearlescent water-based UV paint, and preparation method and application method thereof

ActiveCN105969161AHigh hardnessImprove wear resistancePretreated surfacesPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to a water-based UV paint, particularly a high-water-resistance quick-photocuring pearlescent water-based UV paint, and a preparation method and application method thereof. The paint is prepared from a water-based polyurethane acrylate resin, a water-based epoxy acrylic resin, a functional monomer, a photoinitiator, a leveling agent, an anti-settling agent, pearl powder and a solvent, wherein the functional monomer comprises at least one of dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate. The number of the functional groups of the dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate is 3 or above. The photocured paint film has the advantages of high crosslinking density, excellent hardness, excellent tensile strength and excellent mechanical properties. The water-based epoxy acrylic resin is introduced on the basis of the water-based polyurethane acrylic resin, thereby enhancing the water resistance of the paint film. By introducing the pearl powder and anti-settling agent, the paint film has gorgeous pearl effects.

Owner:深圳市嘉卓成科技发展有限公司 +1

Ultra-high tension copper wire and method of producing the same

InactiveCN101178958AHas tensile strengthSingle bars/rods/wires/strips conductorsCable/conductor manufactureCopper wireWater cooling

The invention provides an ultra-high tension copper wire and a preparation method thereof. The method comprises the steps of: ① preparing a Cu-Al master alloy rod with an Al content of 0.1-0.63 wt %; ② cold rolling the Cu-Al master alloy rod treatment; ③ drawing Cu-Al master alloy rod to obtain Cu-Al alloy wire with predetermined diameter; ④ internal oxidation treatment on Cu-Al alloy wire to obtain Cu-Al2O3 alloy wire with Al2O3 content of basically 0.2-1.2wt% ; and ⑤ drawing the resulting Cu-Al2O3 alloy wire to obtain an ultra-high tensile copper wire of the desired diameter. The ultra-high tension copper wire thus prepared has good electrical conductivity, high tensile strength and softening temperature, and is suitable for cutting-edge digital communication equipment, high-fidelity wires and voice coil wires, ultra-high magnetic field water-cooled copper wires or connectors. The invention prepares Al2O3 dispersion-strengthened copper alloy high-tensile wires by the overall internal oxidation method of Cu-Al alloy wires, which opens up a new way for the production of high-conductivity high-tensile copper alloy wires in my country.

Owner:HENAN UNIV OF SCI & TECH

Polylactic acid anti-bacterial-activity packaging material and preparation method thereof

InactiveCN104212136AEasy to processAvoid the effects of antimicrobial activityAdditive ingredientAntibacterial activity

The invention discloses a polylactic acid anti-bacterial-activity packaging material and a preparation method thereof and belongs to the technical field of macromolecule. The anti-bacterial-activity packaging material includes, in a blending manner, a matrix resin and natural anti-bacterial plant essential oil, wherein the matrix resin accounts 100 parts by weight and the natural anti-bacterial plant essential oil accounts 2-10 parts by weight. The matrix resin is blended by polylactic acid and polytrimethylenecarbonate with a weight ratio of the polylactic acid to the polytrimethylenecarbonate being (60-90):(40-10). The natural anti-bacterial plant essential oil includes clove essential oil, cinnamon essential oil, fennel essential oil and lemongrass essential oil, thyme essential oil or origanum vulgare essential oil. The ingredients are blended in a double-screw extruder and are prepared into the novel polylactic acid anti-bacterial-activity packaging material through a film blowing machine. The material has a certain tensile strength and a certain elongation at break, can be biologically degraded completely, has an excellent anti-bacterial activity and can be widely applied in the field of packaging.

Owner:KUNMING UNIV OF SCI & TECH

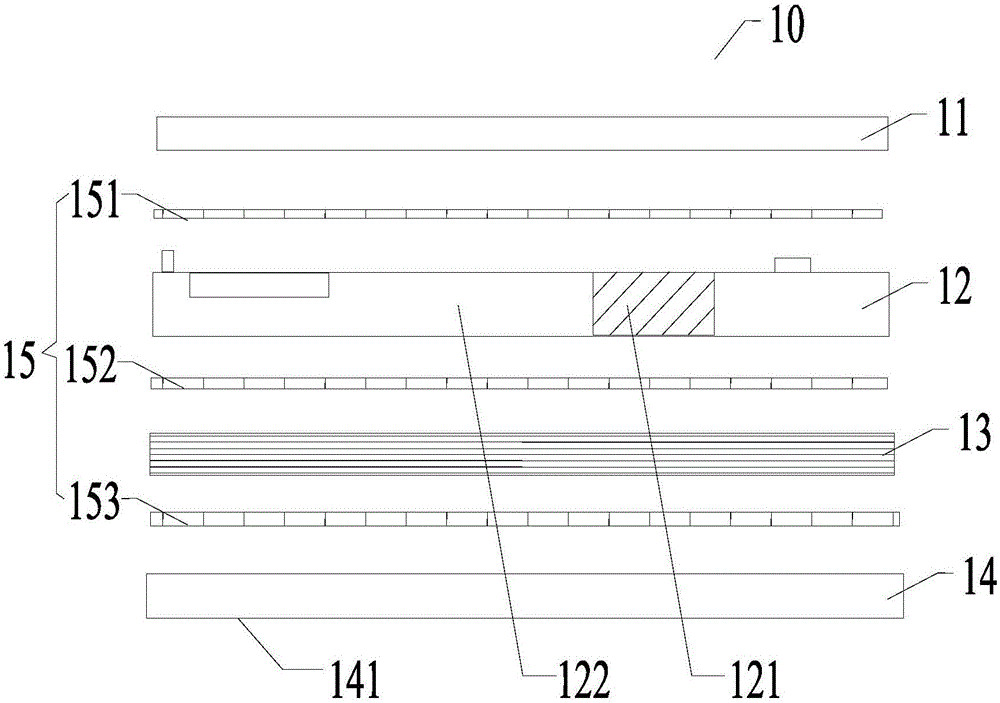

Novel busbar and manufacturing method thereof

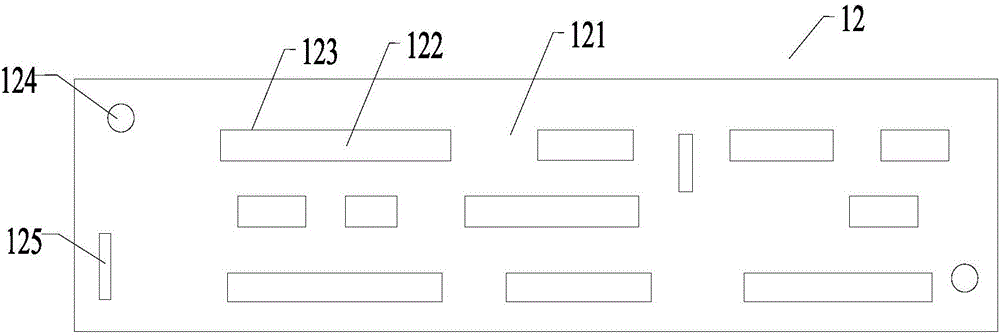

InactiveCN106231810AReduce electromagnetic interferenceGood bonding strengthPrinted circuit assemblingSynthetic resin layered productsBusbarElectricity

The invention discloses a novel busbar, which comprises an insulating layer, a busbar (busbar), an insulating material and a printed board (PCB) which are sequentially laminated into a whole, wherein a bonding sheet is arranged between any two adjacent layers of the insulating layer, the busbar, the insulating material and the PCB; the busbar is formed by inlaying an insulating plate and a copper bar; and the busbar is electrically connected with the PCB through an interlayer conduction structure. The embodiment of the invention further provides a manufacturing method of the novel busbar. The novel busbar disclosed by the technical scheme is of an integrally laminated molded structure; and a plurality of disadvantages due to the fact that the PCB and the busbar are installed together in a bracket fixing manner in the prior art can be overcome.

Owner:深圳众力新能源科技有限公司

A method for preparing bioactivity possessed artificial cornea

The invention relates to a method for preparing biologically active artificial cornea. It takes animal cornea basic material as raw material, promoting cornea growth or / and preventing partial lesion by enzyme slaking, repeated unfreezing, washing, and irradiating with 60Co. It employs physical and chemical method to remove cell component and soluble protein which will cause immune response, and retains external base material construction, adds multifunctional component which is favor for cornea cell growth or / and preventing partial lesion, freeze dries and stores it. The tensile strength and diopter of prepared artificial cornea are similar to that of normal cornea, it can prevent lesion and dissolution after being implanted in, and promote cornea epithelium regeneration and collagen synthesis; the biocompatibility is good, no obvious immune rejection reaction and no toxic to cell, and can be used to treat various eye injury.

Owner:西安组织工程工程技术研究中心

Antibacterial nipple and preparation method thereof

InactiveCN104341779AColor transparentGood water and moisture resistanceTeatsSodium stearateCarrageenan

The invention relates to an antibacterial nipple and a preparation method thereof. The antibacterial nipple is prepared from the raw materials in parts by weight: 100 parts of vinyl raw rubber, 0.5-1.5 parts of potassium chloride, 5-15 parts of konjac glucomannan, 2-5 parts of chitosan, 5-10 parts of carrageenan, 2-4 parts of xanthan gum, 5-9 parts of Gellan gum, 0.5-1 part of starch sodium phosphate, 15-28 parts of gaseous white carbon black, 0.5-1.2 parts of hydrogen containing silicone oil, 2.5-6 parts of hydroxy silicone oil, 0.2-0.5 part of sodium stearate, 0.01-0.05 part of platinum catalyst and 300-450 parts of water, through the steps of cooling and kneading, carrying out high-temperature melted warming, vacuumizing, adding silicone oil, milling, carrying out injection molding, carrying out vulcanization and the like. The antibacterial nipple has the advantages of high transparency and antibacterial property, good biocompatibility, biodegradability, flexibility, retentiveness, tensile strength, pull strength and tear strength, good demolding property and relatively long storage period.

Owner:NINGBO HAPPY BABY

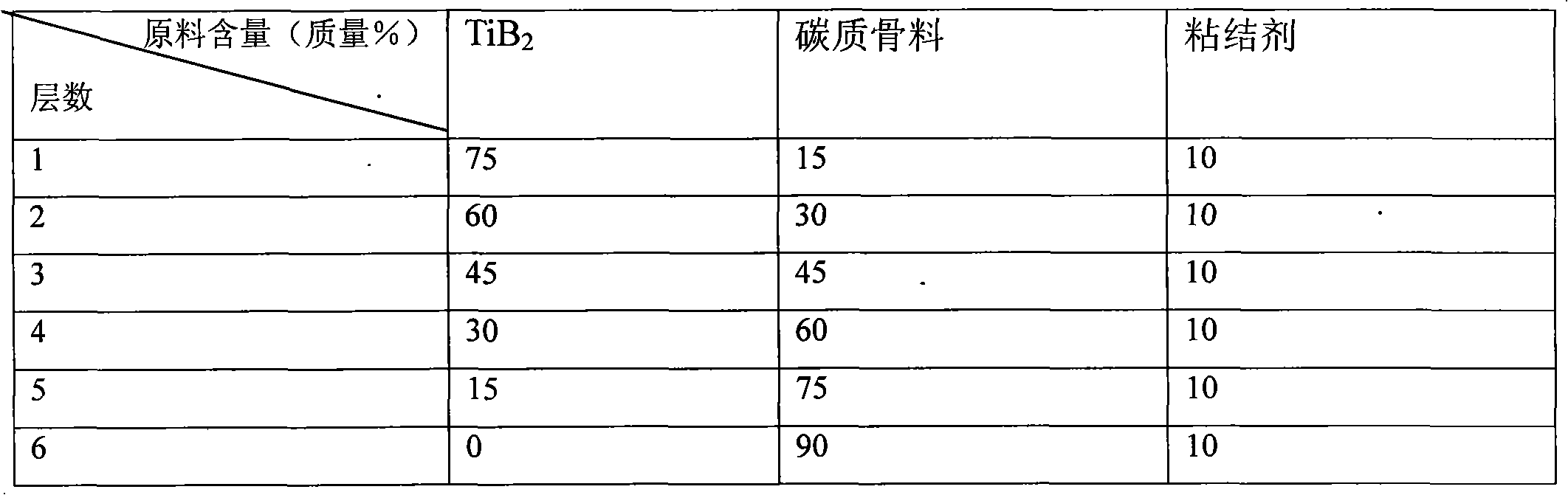

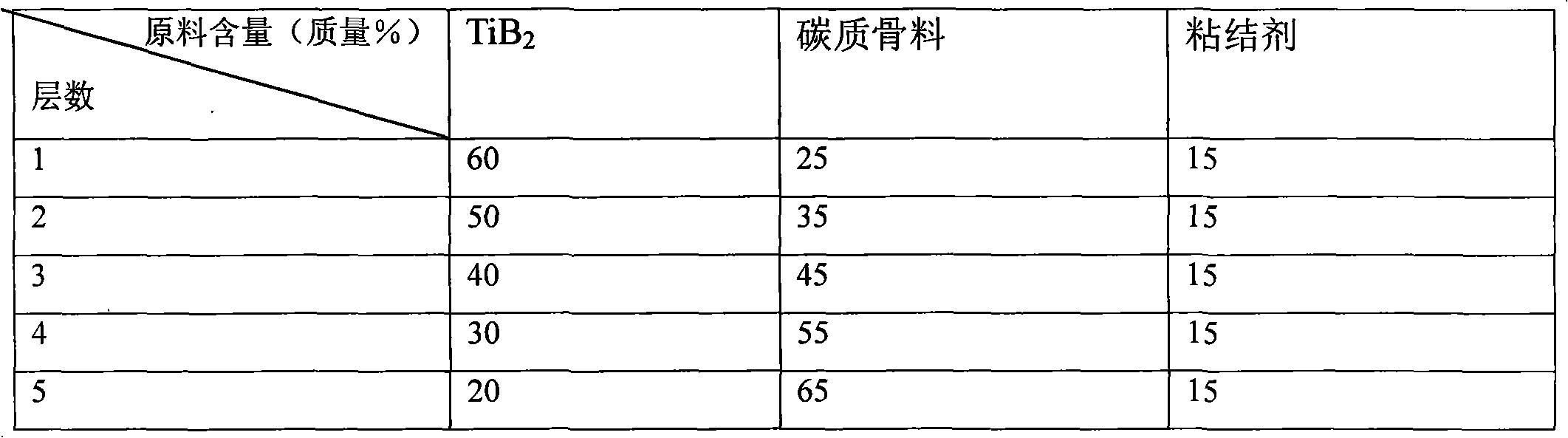

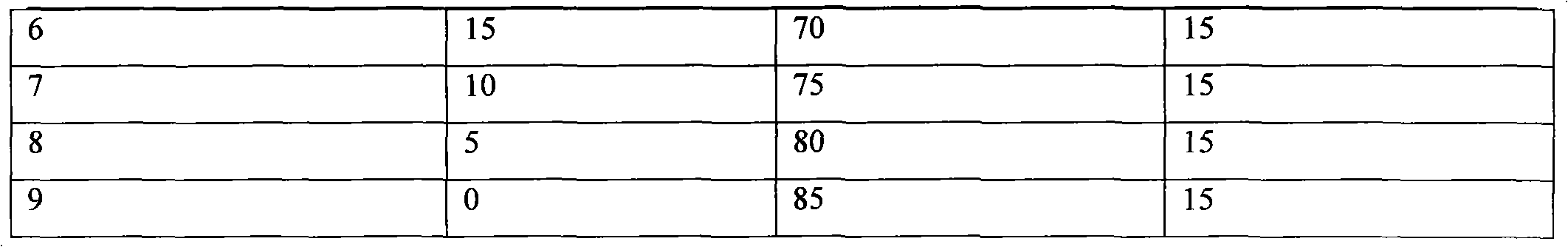

Preparation method of TiB2/C gradient cathode material for aluminum electrolytic bath

InactiveCN101608321AImproved working characteristics of the working faceImprove working characteristicsContinuous mixingMaterials science

The invention relates to a preparation method of TiB2 / C gradient cathode material for an aluminum electrolytic bath, which belongs to the technical field of electrolytic aluminum. The adopted raw materials comprise TiB2, carbon aggregate and cementing agent. The procedure is continuous dosing, continuous mixing and paving and adopts the sequence as follows: the content of the TiB2 in each layer sequentially increases and changes from a bottom layer to a surface layer, and the content of the carbon aggregate sequentially reduces and changes; or the content of the TiB2 sequentially reduces and changes, and the content of the carbon aggregate sequentially increases and changes; the materials paved layer by layer are hot-pressed and sintered, and then are naturally cooled to the room temperature so as to obtain the product. Because micro components of the materials prepared by the invention sequentially change, the invention can better solve the problems of easy coating shedding and the like caused by thermal mismatching of carbon and TiB2; meanwhile, the cathode material has strong sodium corrosion resistance, can remarkably improve the current efficiency of the electrolytic bath, and prolongs the service life of the electrolytic bath.

Owner:NORTHEASTERN UNIV

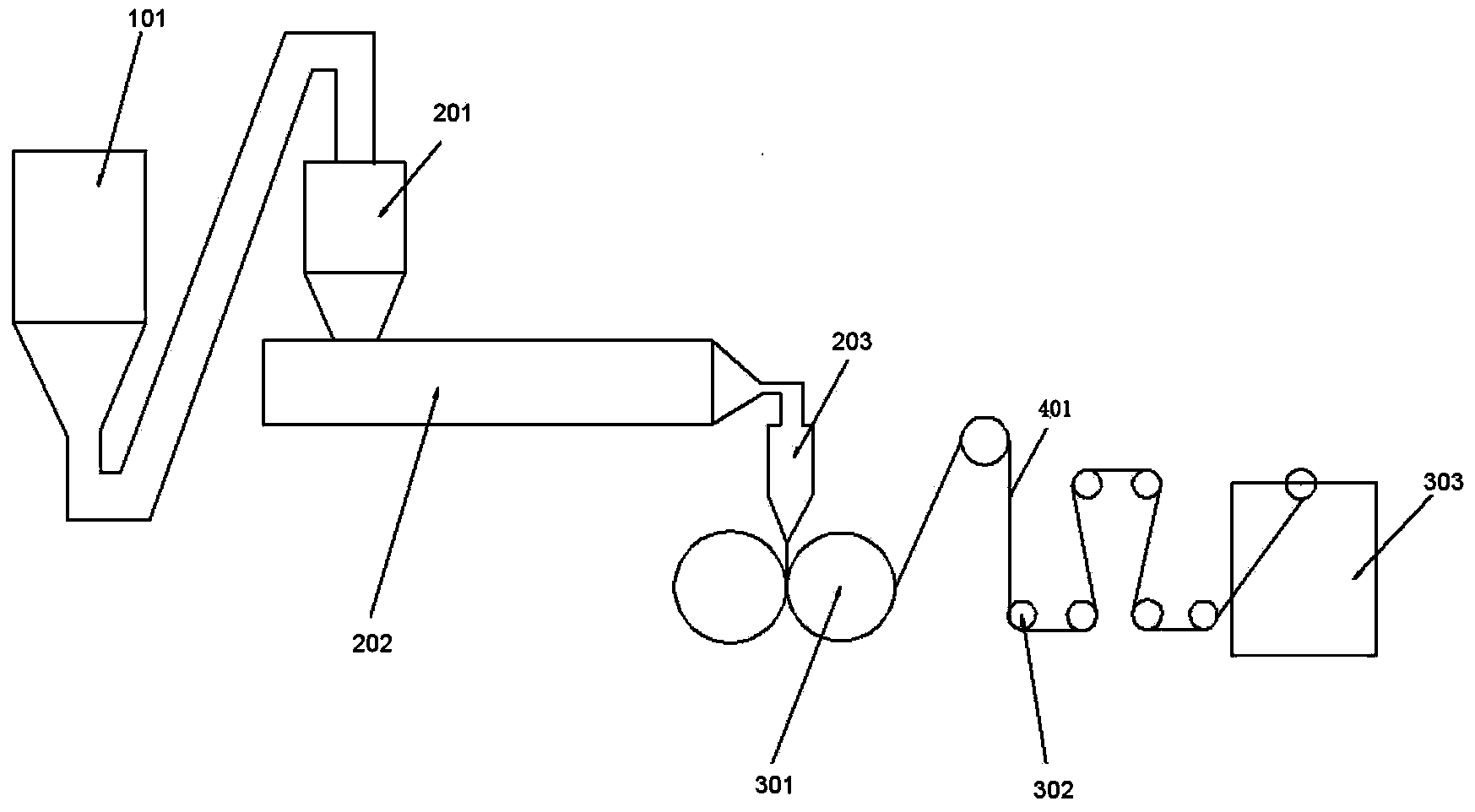

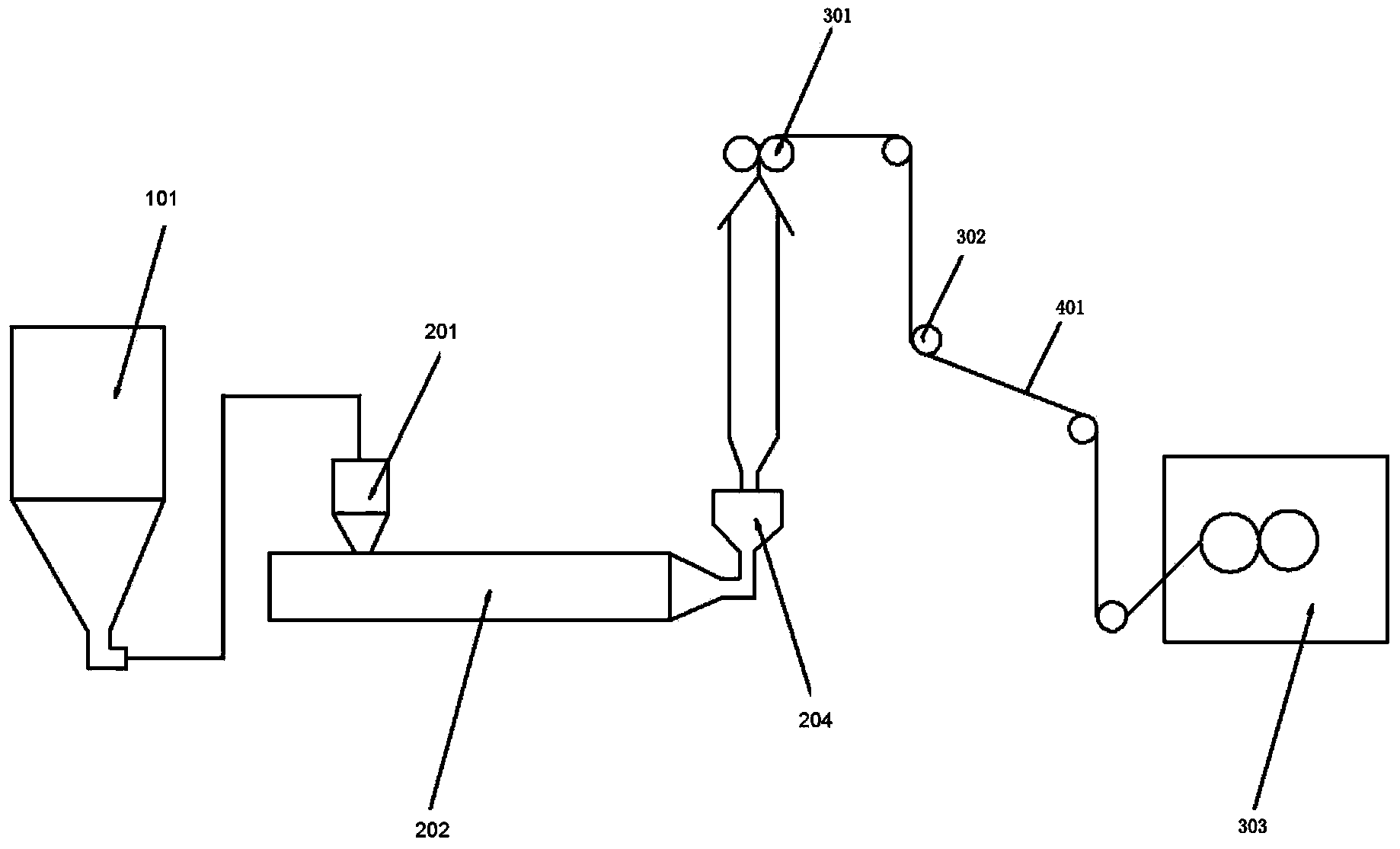

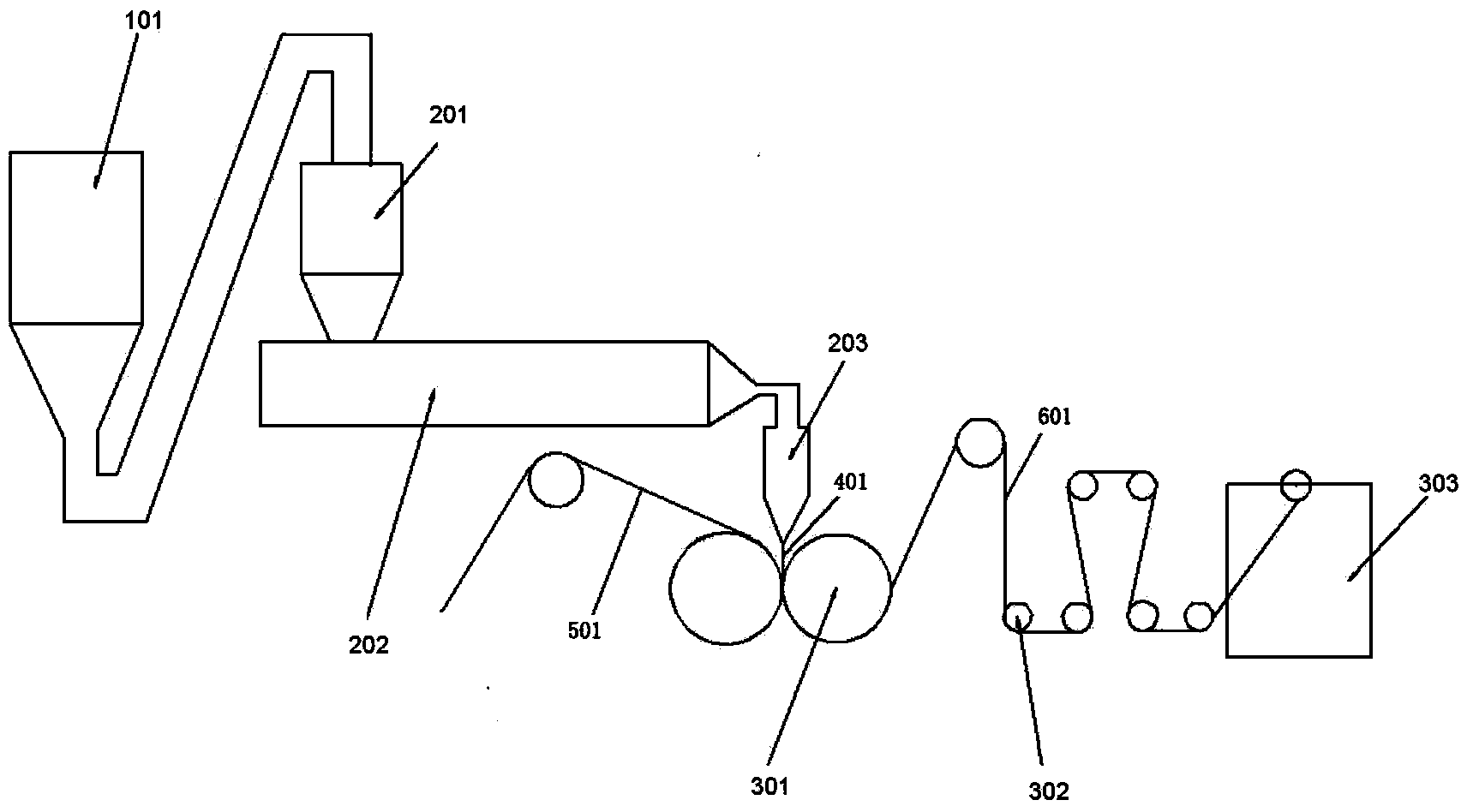

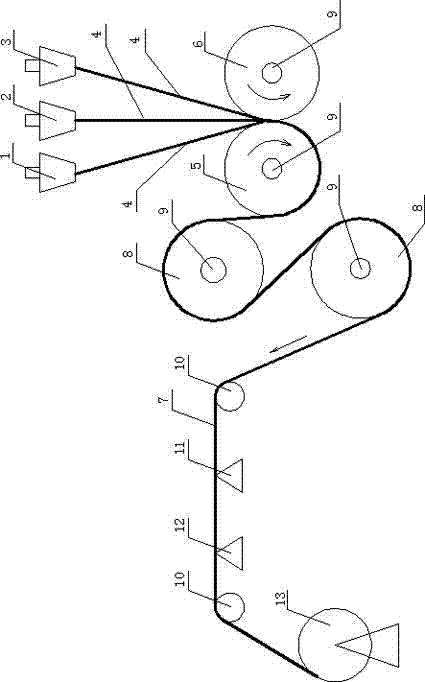

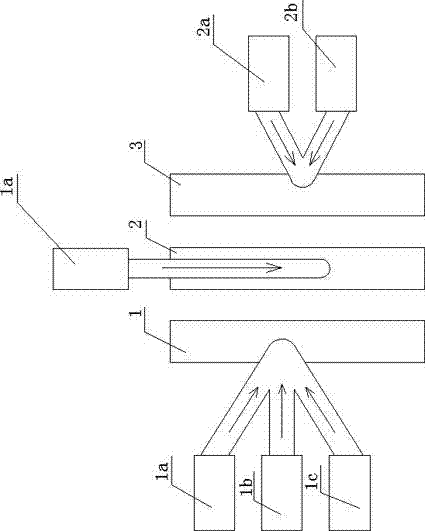

Method for manufacturing reused fresh-keeping isolation layer in rubber tire preparation

InactiveCN103112110AKeep the inherent characteristicsHas tensile strengthCoatingsPolyolefinIsolation layer

The invention discloses a method for manufacturing a reused fresh-keeping isolation layer in rubber tire preparation. According to the method, a linear casting die head is connected with one or more screws, polyolefin materials with different characteristics extruded out by different screws composite in the die head so as to form cast polyolefin cast films of the composite materials casted by the same die head; and the linear casting die head casts melting polyolefin materials with the same or different characteristics at the same time, and the sheet rubber fresh-keeping isolation layer with different characteristics which can be reused can be formed by through hot pressing by two press rolls, cooling by multiple cooling rolls, and one-time hot pressing composite curing. Through the method disclosed by the invention, the fresh-keeping isolation layer can be prepared in once-forming, the multilayer fusion fastness is extremely high, and is integrated into a whole; and the inherent characteristic of the fresh-keeping film is kept, as well as the fresh-keeping isolation layer can be circularly reused.

Owner:卢建忠 +1

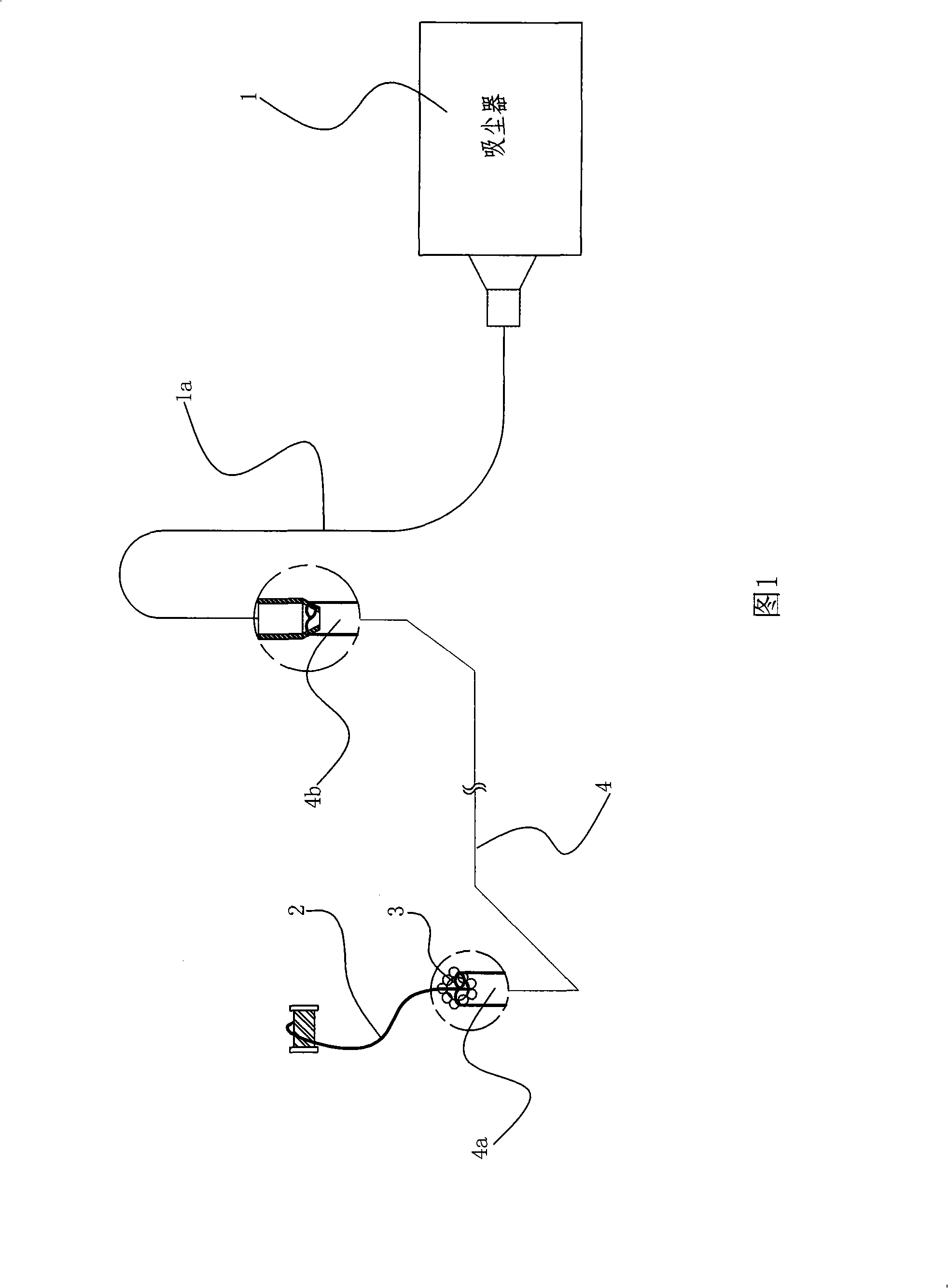

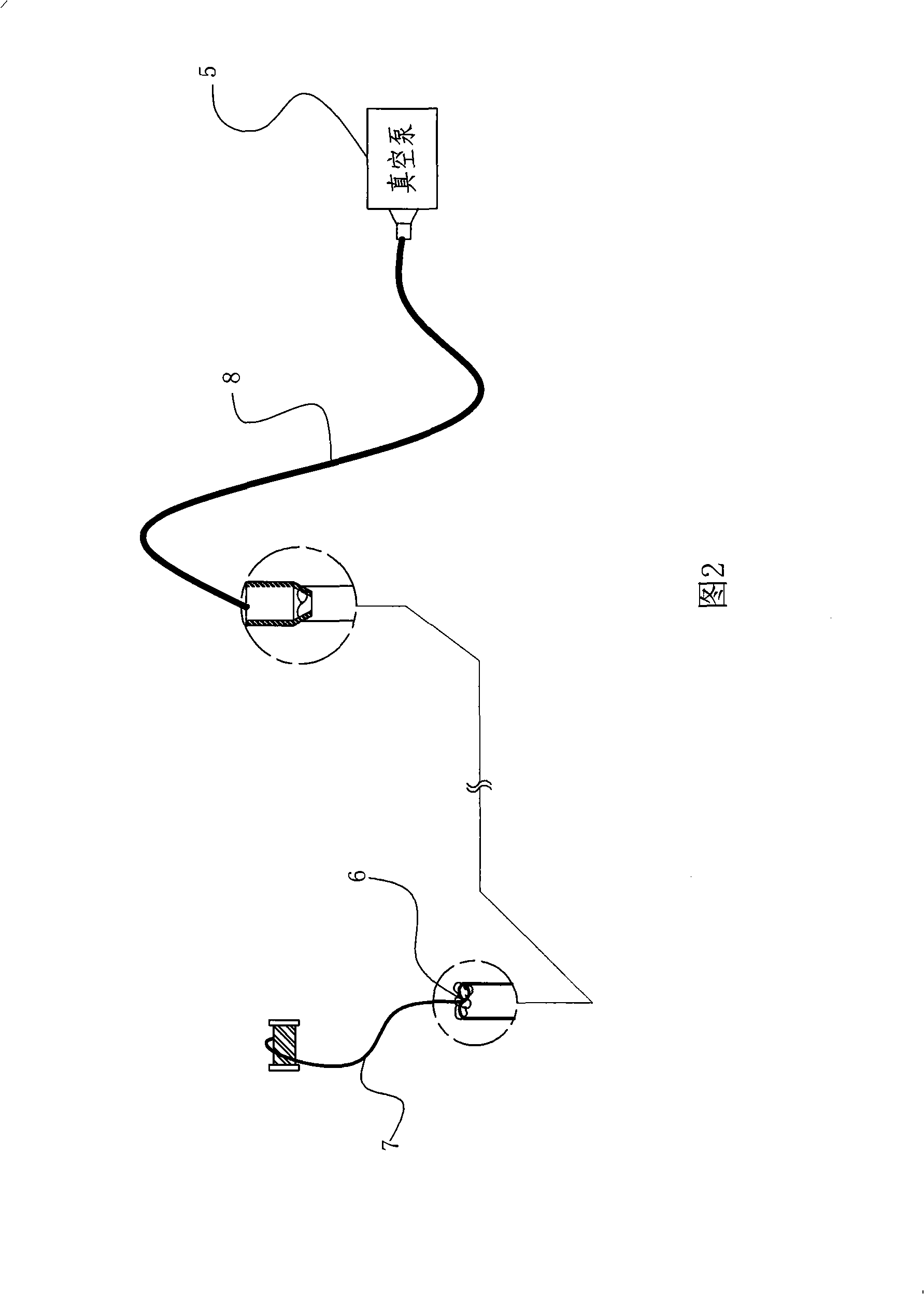

Electric gas tube lead wire penetrating method

InactiveCN101257196AReduce lossLow technical requirementsApparatus for laying cablesVacuum pumpingLine tubing

The invention relates to an electric pipe wire-lead threading method which has characteristic in including steps as follows: a) a flexible wire lead is fixed on a glob flexible material, then the flexible material with fixed flexible wire lead is inserted into initiating terminal and seals the electric pipe initiating terminal; b) the electric pipe terminal is accessed to a vacuum-pumping equipment and is sealed; c) the vacuum-pumping equipment is opened, and the flexible material with fixed flexible wire lead moves forward along the electric pipe under the action of subpressure generated by the vacuum-pumping equipment, until extracting the flexible material from the electric pipe terminal. By comparison with present technique, the method provided by the invention uses the flexible wire lead fixed on the flexible material, and the flexible wire lead is extracted from the electric pipe under the action of subpressure generated by the vacuum-pumping equipment by utilizing vacuum-pumping theory, accordingly, the electric pipe threading is completed. The method needs low technique request, adoptive equipment and material are simple and easy to obtain, is convenient for usage, and increases working efficiency, reduces labour cost and material loss, and has not potential safety hazard. The method is particularly suitable for threading the electric pipe in pre-buried pipe for lighting with a plurality of elbows and long pipe.

Owner:NINGBO CONSTR ENG GROUP

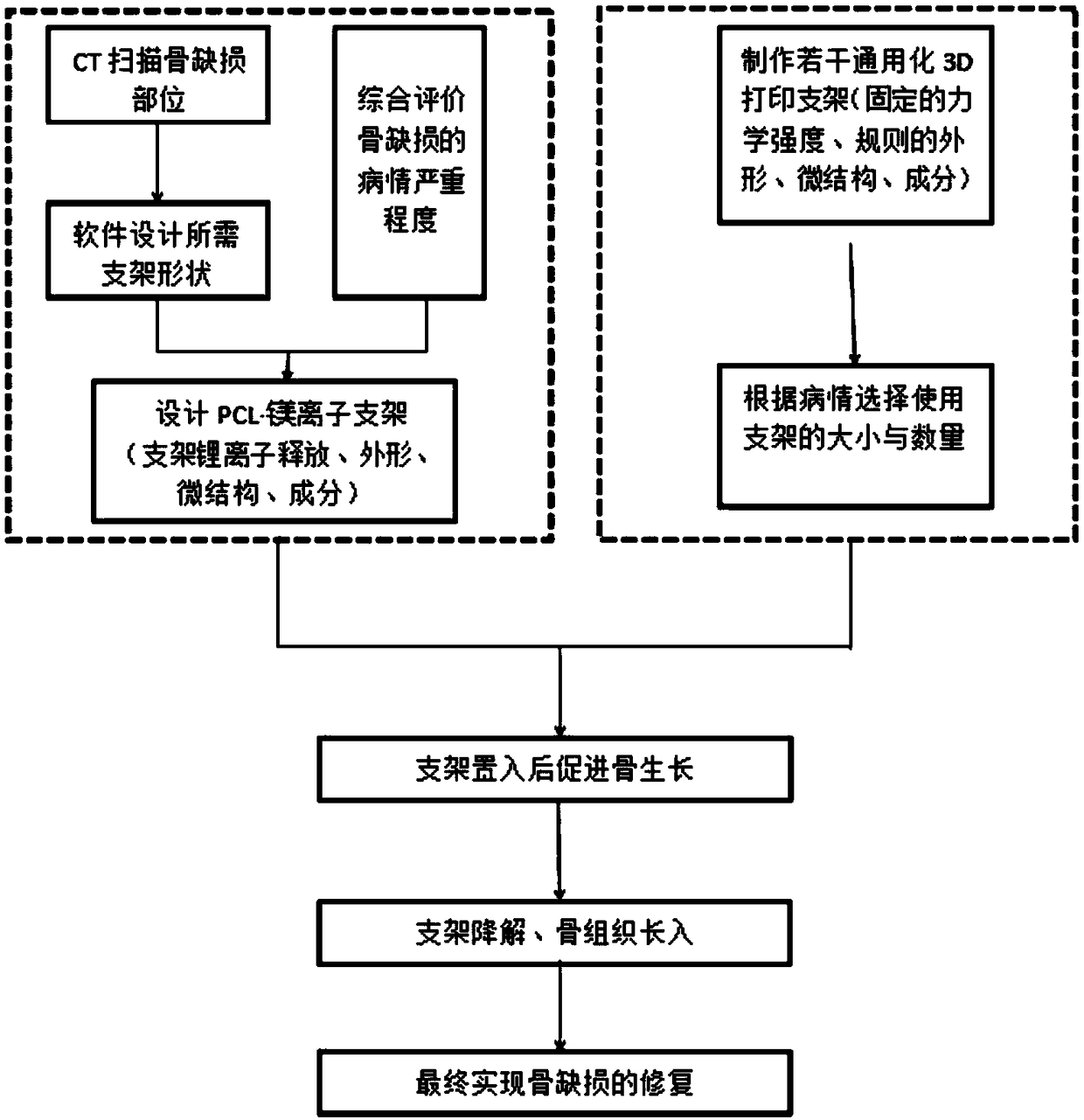

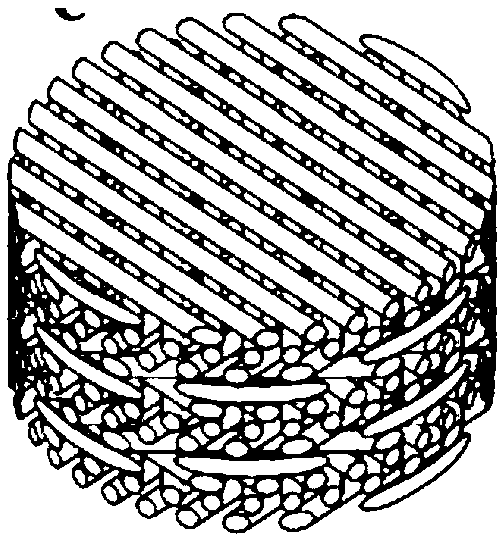

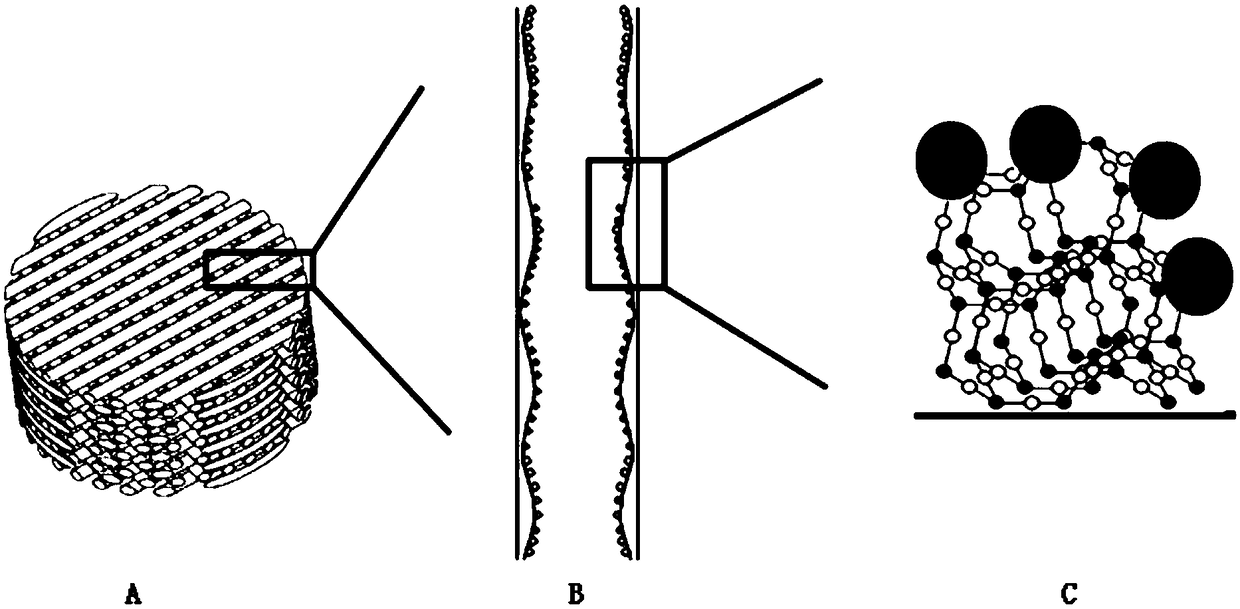

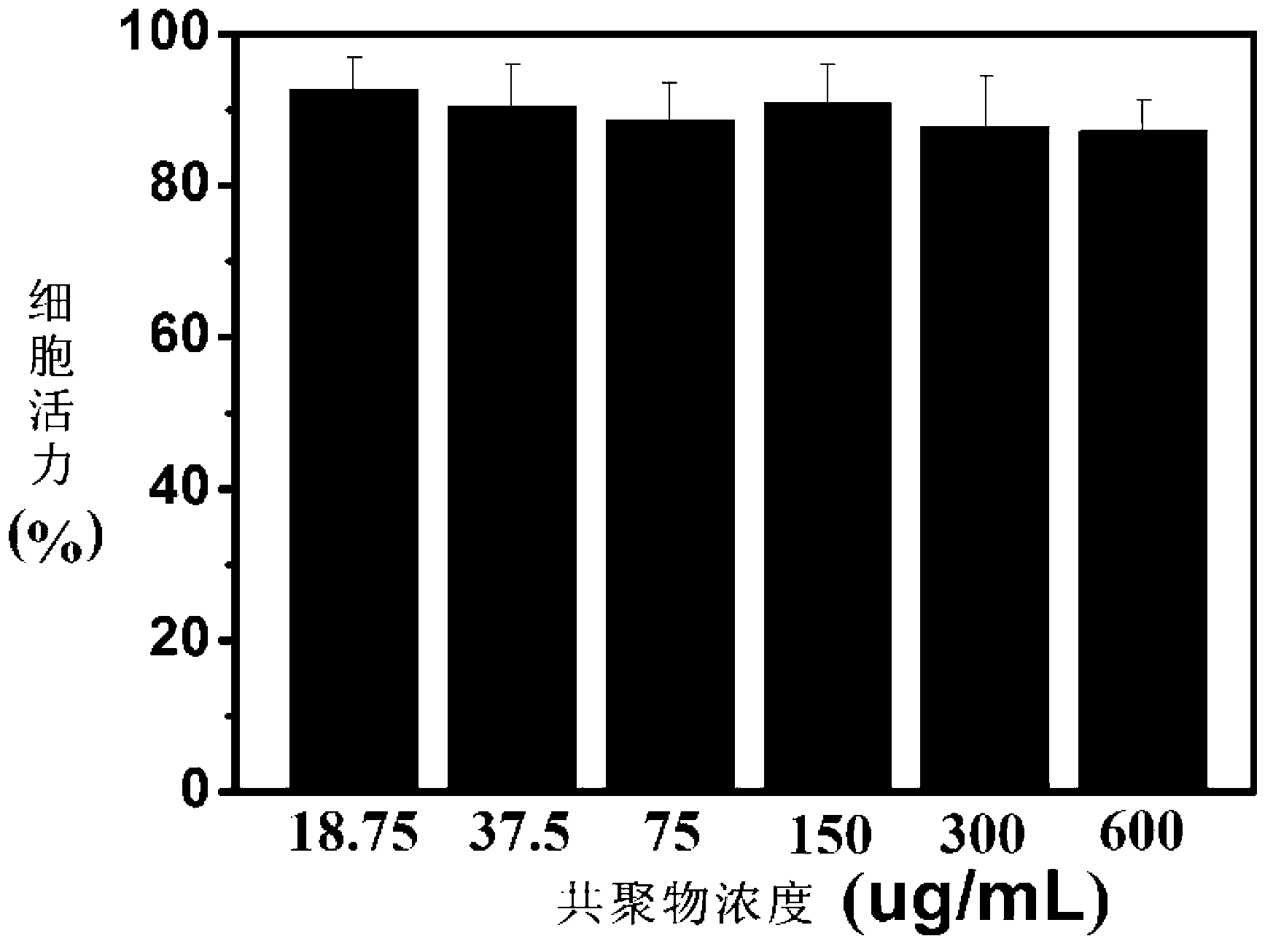

3D printed PCL-Mg bone tissue engineering scaffold and preparation method thereof

InactiveCN108939164AAdjustable loadReasonable strengthAdditive manufacturing apparatusTissue regenerationBone ingrowthMechanical property

The invention discloses a 3D printed PCL-Mg bone tissue engineering scaffold and a preparation method thereof. The 3D printed PCL-Mg bone tissue engineering scaffold is prepared from poly-epsilon-caprolactone PCL and magnesium chloride as raw materials through a 3D printing technology. After being implanted into the human body, PCL as a bioabsorbable material is gradually degraded and releases Mgto promote osteochondral generation. The porous structure of the scaffold can induce bone ingrowth and finally repair bone defects, tumors and bone defects after infection. The 3D printed PCL-Mg bonetissue engineering scaffold has the advantages of simple and reliable structure, controllable shape and microstructure, reliable mechanical property, controllable ion release performance, convenient implantation, small trauma and low cost.

Owner:南京冬尚生物科技有限公司

Biodegradable medical surgery anti-adhesion membrane and preparation method thereof

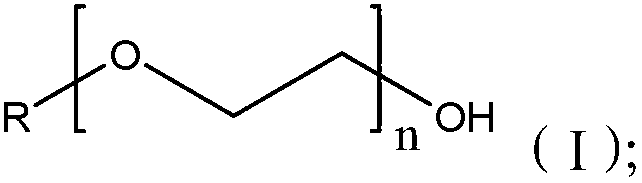

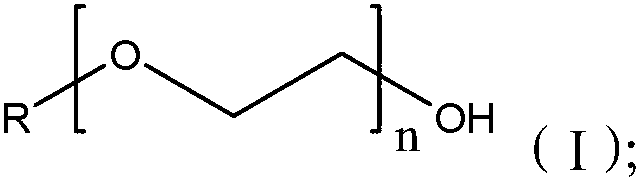

The invention provides a biodegradable medical surgery anti-adhesion membrane and a preparation method thereof. According to the method, polyethylene glycol compound, at least one of lactide and epsilon-caprolactone and glycolide are subjected to copolymerization so as to obtain a polyethylene glycol compound-polyester segmented copolymer of which the number-average molecular weight is 50000 to 150000; and a polymer material containing the polyethylene glycol compound-polyester segmented copolymer is made into a membrane so as to obtain the biodegradable medical surgery anti-adhesion membrane, wherein the polyethylene glycol compound is shown in formula (I) shown in the specification, R is any one selected from hydroxyl, methyl, ethyl, propyl, isopropyl, amino, allyl, propinyl, sulfydryl, carboxyl and azide; and n is the polymerization degree. Through double modulation of the polyethylene glycol compound and glycolid, the anti-adhesion membrane is better in controllability and good in flexibility, has certain tension resistance strength and is beneficial for application.

Owner:CHANGCHUN SINOBIOMATERIALS

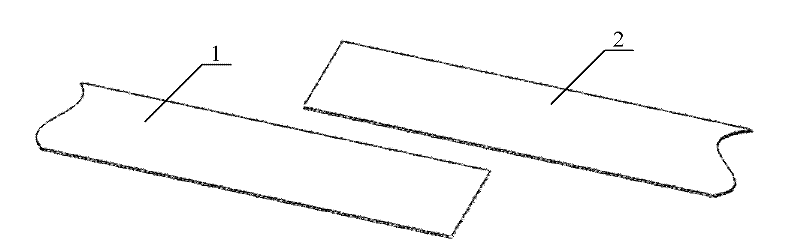

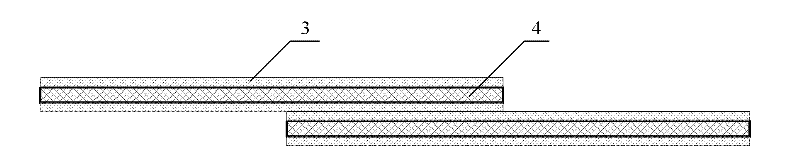

Lapping and tape continuing method for resin-based composite material pre-impregnation adhesive tape

InactiveCN102490361AContinuation RealizationDoes not damage the structureStress concentrationResin matrix

The present invention provides a lapping and tape continuing method for a resin-based composite material pre-impregnation adhesive tape. According to the method, the resin matrix in the pre-impregnation adhesive tape is heated to melt into a viscous fluid; after pressurizing, the resin matrix flows, such that the fiber reinforcing materials in the two sections of the pre-impregnation adhesive tapes are tightly attached; after cooling, the resin matrix is solidified, such that the tight attaching state between the fiber reinforcing materials is maintained; finally the static friction force between the fiber reinforcing materials bears the tensile force to obtain the continuous adhesive tape with the tensile strength so as to achieve the tape continuing of the pre-impregnation adhesive tape during winding. According to the present invention, when the method of the present invention is used, other materials are not required to carry out continuing, and the structure of the pre-impregnation adhesive tape is not damaged, such that the impurities and the stress concentration points are avoided, the composite material pre-impregnation adhesive tape continuing with the characteristics of no impurity and no damage is achieved, and the quality of the winding product is improved, wherein the impurities and the stress concentration points are generated by sewing threads and the pinholes during the manual sewing continuing process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

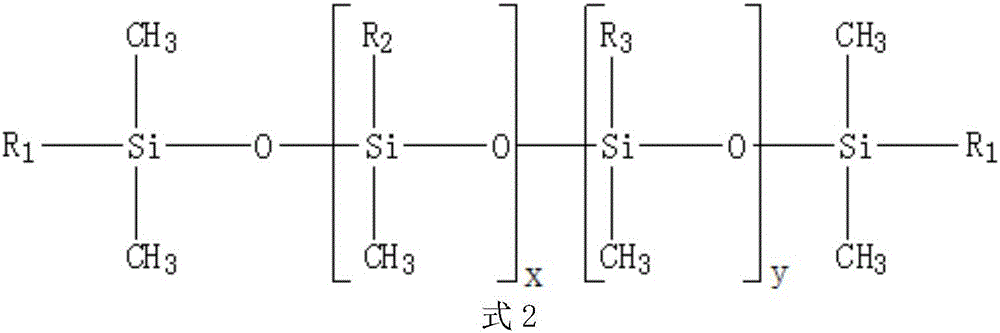

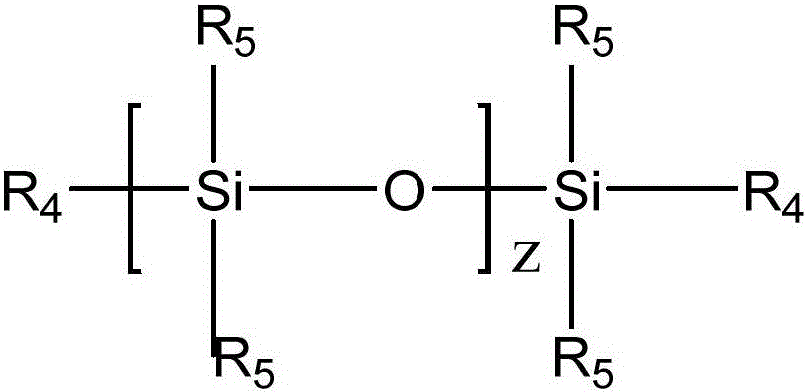

Light-weight heat-conducting organosilicon pouring sealant base sizing material as well as composition and preparation methods thereof

ActiveCN106701012AImprove thermal conductivityReduce product densityNon-macromolecular adhesive additivesSizingOrganosilicon

The invention discloses a light-weight heat-conducting organosilicon pouring sealant base sizing material which comprises unsaturated hydrocarbon terminated polydiorgnosiloxane and light-weight heat-conducting filler with density of 0.1-2.0g / cm<3>. The invention aims at providing a light-weight heat-conducting organosilicon pouring sealant base sizing material and also provides a preparation method of the base sizing material, as well as a composition prepared by using the base sizing material and a preparation method thereof. A pouring sealant prepared by the base sizing material has the advantages of light weight, and good heat-conducting property.

Owner:GUANGZHOU TINCI MATERIALS TECH

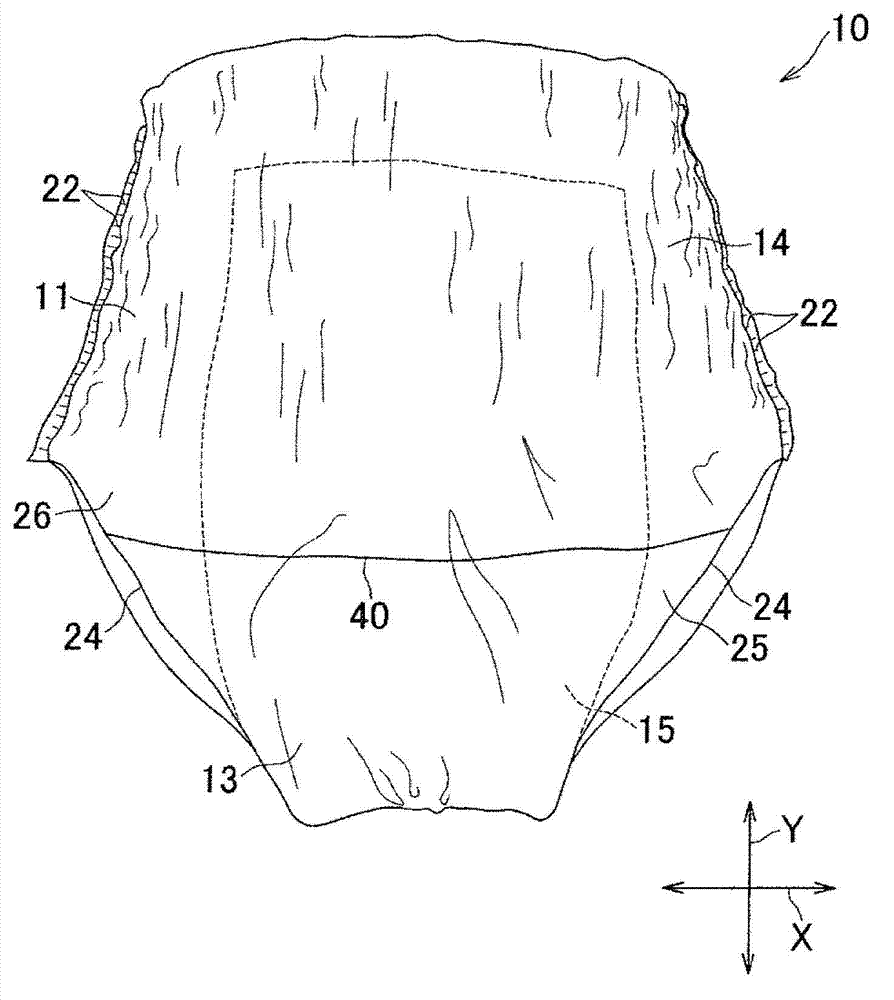

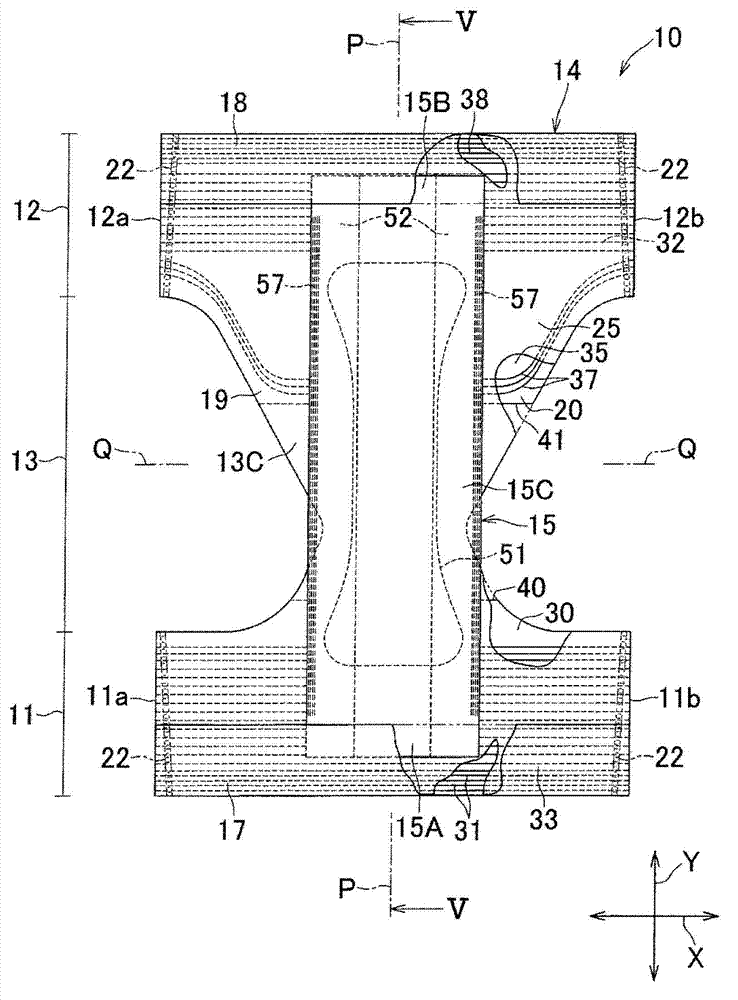

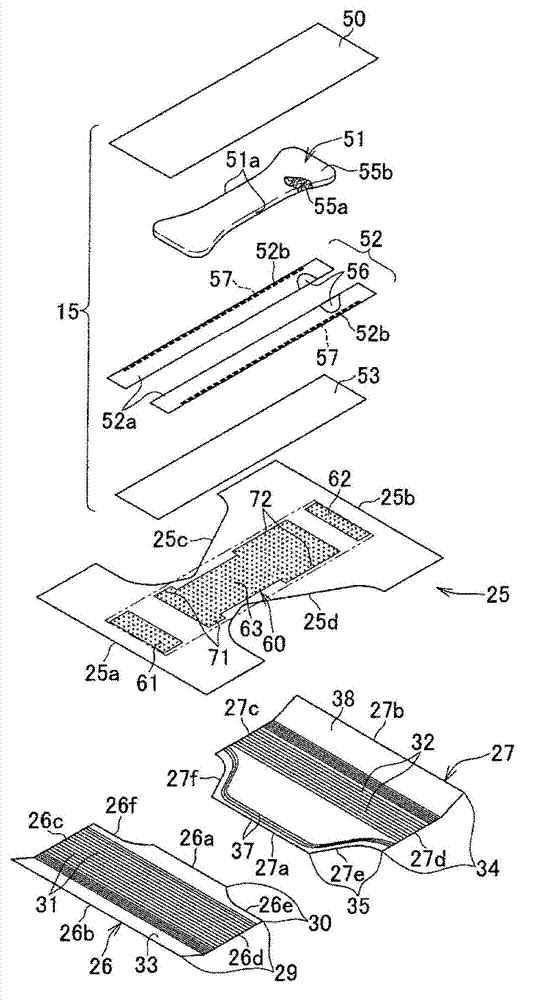

Pants-type apparel artical

The invention provides a pants-type apparel artical, at least a central part is soft, a front waist area side is provided with required tensile strength and at least part of the front waist area (11) side is a multi-layer area (44) passing by a laminated substrate part (25) and a front waist part (26). The central part (13c) of a crotch area (13) is a single-layer area (43) only formed by a substrate part (25); the multi-layer area (44) is provided with a corner part (73) surrounded by a boundary (40), an inner edge (11d) of the front waist area (11), a junction area (60) for connecting an absorption configuration body (15) and a bottom (14) and the above concave-curve shaped side edge (19c) of the crotch area (13); and the boundary (40) of the multi-layer area (44) and the single-layer area (43) passes across the junction area (60).

Owner:UNI CHARM CORP

Artificial multiporous nanometer cornea made of carbon-polyvinyl alcohol hydrogel

InactiveCN1568908AOvercoming complicated proceduresOvercome precisionEye implantsFiberIntra ocular pressure

A porous nanometer carbon-polyvinyl alcohol hydrogel artificial cornea, which is used for patients of cornea diaphaneity descent and cornea blind caused by eye tissue diseases, consisting of an optical part and a supporting part, the optical part being made from transparent polyvinyl alcohol hydrogel, and the supporting part being made from black nanometer carbon materials. The optical part is provided with an upper and a lower surface, the supporting part enwraps the optical part, combines tightly with human cornea tissues, and is embedded in the optical part. The materials of the optical part protrude on the top and the bottom and overtops the supporting part at the joint of the two parts, and forms a trapezoid right-angle structure. The invention overcomes the shortcomings of existing techniques, and is capable of watertightness engomphosis with host cornea, preventing infection, degrowth of corneal epitheliums, antagonizing intra-ocular pressure, and preventing the forming of the back fibrous membrane of cornea. The artificial cornea has advantages of tenderness, good elasticity, certain tensile strength, convenience in surgical operation, and maximum decrease of complicating diseases.

Owner:深圳华明生物科技有限公司

Water-based strippable coating and film forming method thereof

InactiveCN105713499AAdhesiveExcellent peelabilityPolyurea/polyurethane coatingsWater basedPolymer science

The invention discloses a water-based peelable coating, which comprises: main resin; thickener; substrate wetting agent; pigment or filler; wetting and dispersing agent; agent and deionized water; among them: the mass percentage of main resin, thickener, substrate wetting agent, pigment or coating, wetting and dispersing agent, hand feeling aid and deionized water is: main resin 30-70%; Thickener 0.1-0.5%; Substrate wetting agent 0.1-1%; Pigment or coating 10-50%; Wetting and dispersing agent 0.1-1%; Hand feeling aid 0.1-1%; Deionized water 10-25%. The invention also discloses a film forming method using the water-based peelable coating. The water-based peelable coating and the film-forming use method thereof of the present invention have certain adhesion and peelability.

Owner:万辉(广州)高新材料有限公司

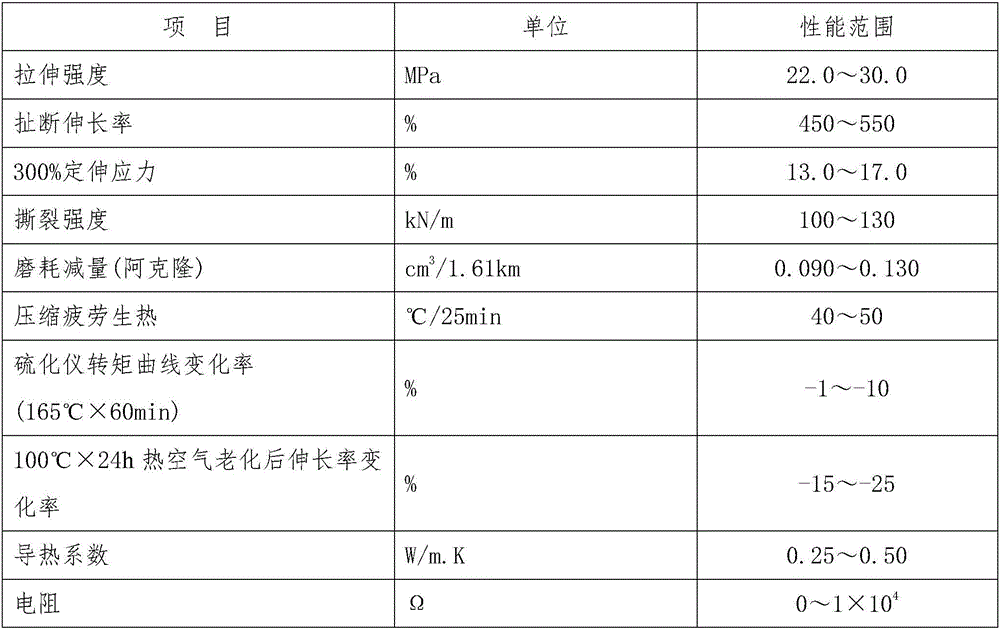

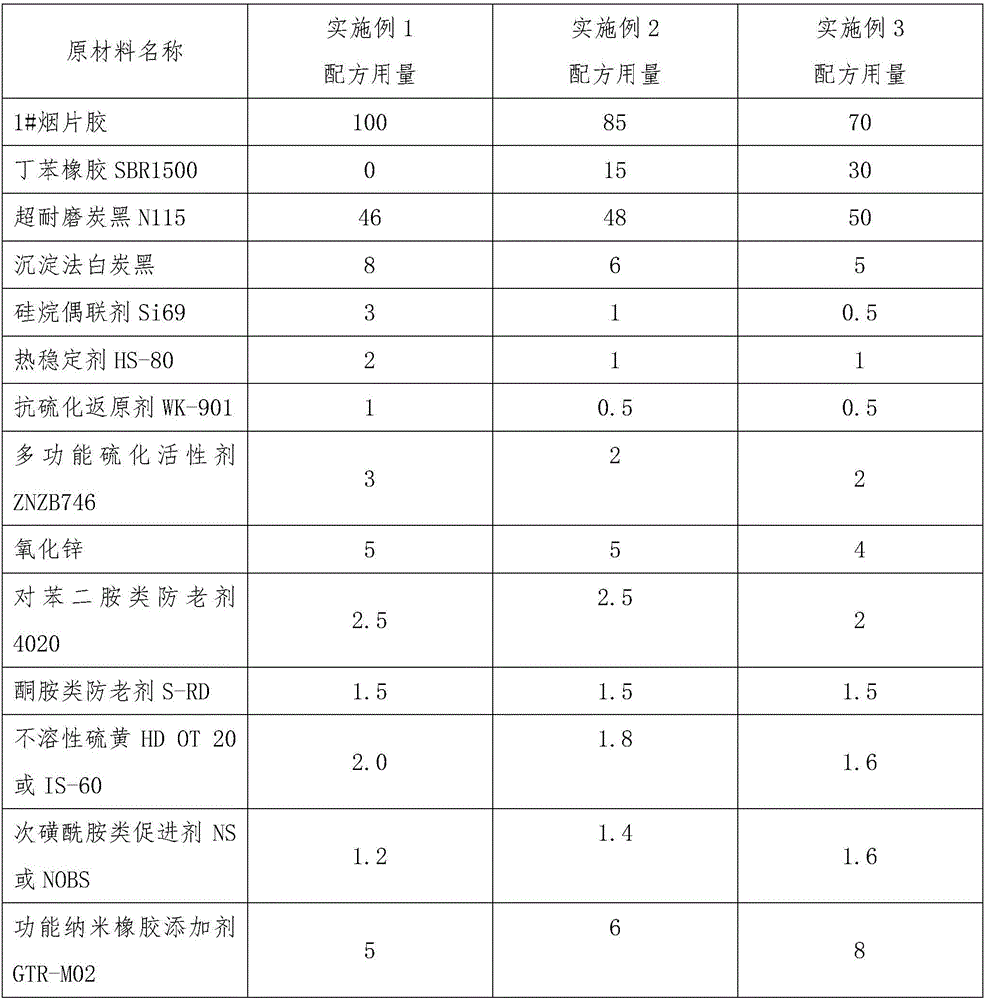

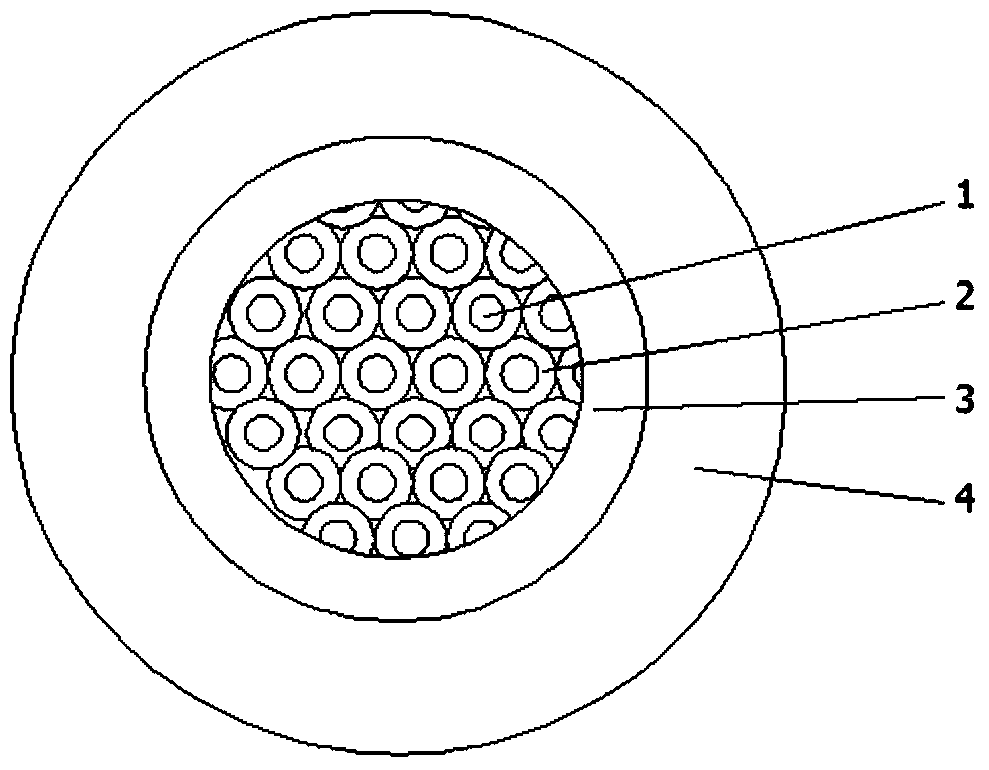

Heat-conducting high-heat-conductivity aircraft tire tread rubber

ActiveCN105713246AGood thermal and electrical conductivityGood wear resistanceSpecial tyresP-PhenylenediamineButadiene-styrene rubber

The invention relates to a heat-conducting high-heat-conductivity aircraft tire tread rubber which is prepared from the following raw materials in parts by weight: 70-100 parts of 1# bacon rubber, 30-0 parts of styrene-butadiene rubber (SBR) 1500, 46-52 parts of super-wear-resistance carbon black N115, 5-8 parts of precipitated white carbon black, 0.5-3 parts of silane coupling agent Si69, 1-2 parts of heat stabilizer HS-80, 0.5-1.0 part of anti-reversion agent WK-901, 1-3 parts of multifunctional vulcanization activator ZNZB746, 3-5 parts of zinc oxide, 1-3 parts of p-phenylenediamine anti-aging agent 4020, 1-2 parts of ketoamine anti-aging agent S-RD, 1.5-2.5 parts of insoluble sulfur HD OT 20 or IS-60, 0.8-2.0 parts of sulfenamide accelerator NS or NOBS and 3-10 parts of functional nano rubber additive GTR-M02. The tread rubber has the characteristics of favorable heat conductivity, favorable electric conductivity, favorable wear resistance and high heat stability, and has the advantages of higher tensile strength, higher elongation at break and higher 300% stress at definite elongation.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Preparation method for steel fiber copper-covered steel wire

The invention relates to a preparation method for a steel fiber copper-covered steel wire. The method comprises the following steps: sleeving a steel fiber into a copper tube and drawing for three times continuously; heating and annealing the drawn copper-covered steel fiber; sleeving the annealed copper-covered steel fiber into another copper tube, and drawing for three times continuously; heating the drawn copper-covered steel fiber and quickly putting the heated drawn copper-covered steel fiber into saline water for performing quenching treatment; integrating treated copper-covered steel fibers into a copper-covered fiber bundle; putting the copper-covered fiber bundle into an Ag-Ni-Nb alloy tube for drawing; putting an alloy composite body into the copper tube for drawing to obtain the steel fiber copper-covered steel wire. The steel fiber copper-covered steel wire prepared by the invention has the electric conductivity of 38 percent of IACS (international annealed copper standard) to 43 percent of IACS, and the tensile strength of over 1,200 Mpa.

Owner:JINZHONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

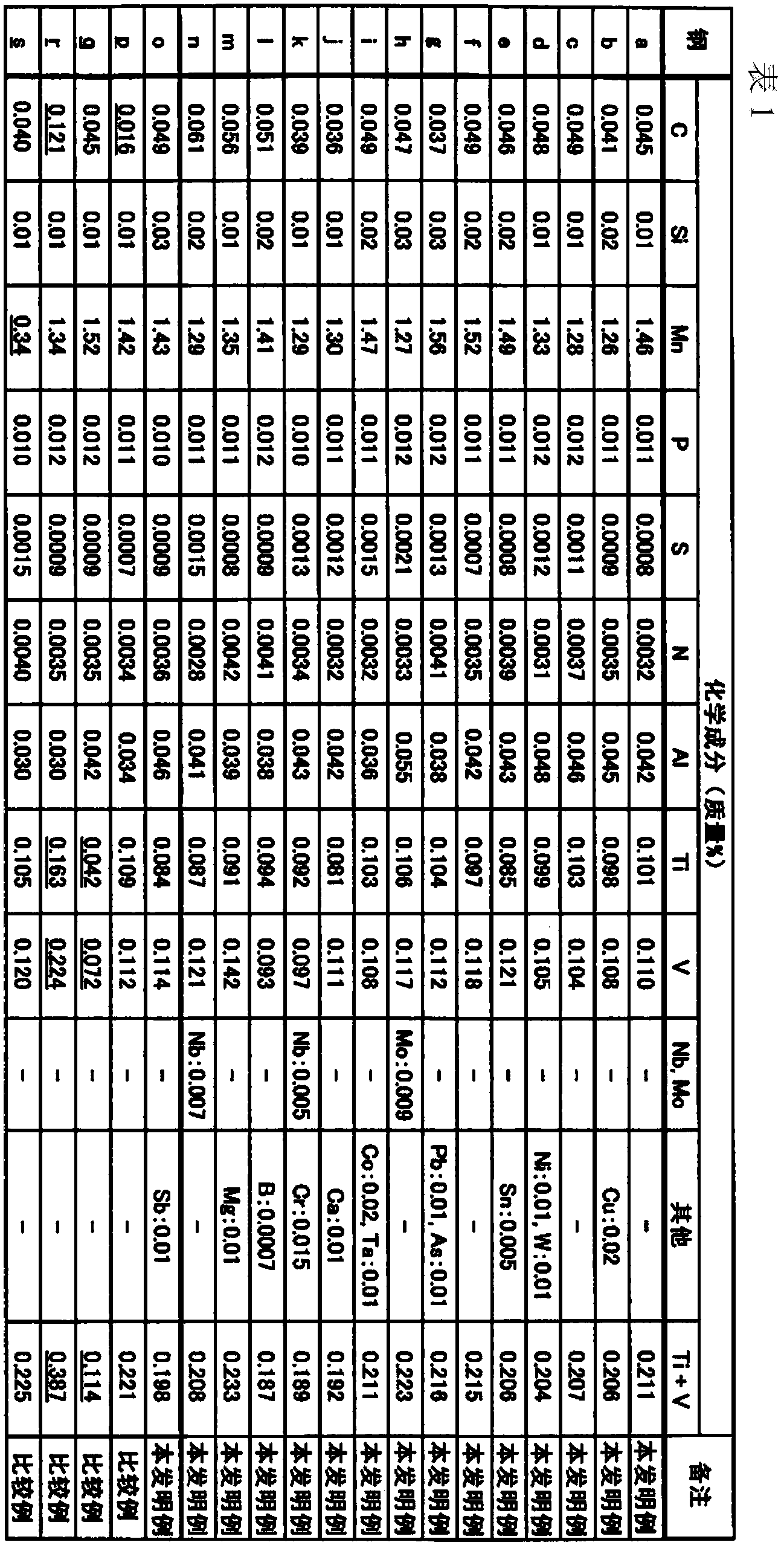

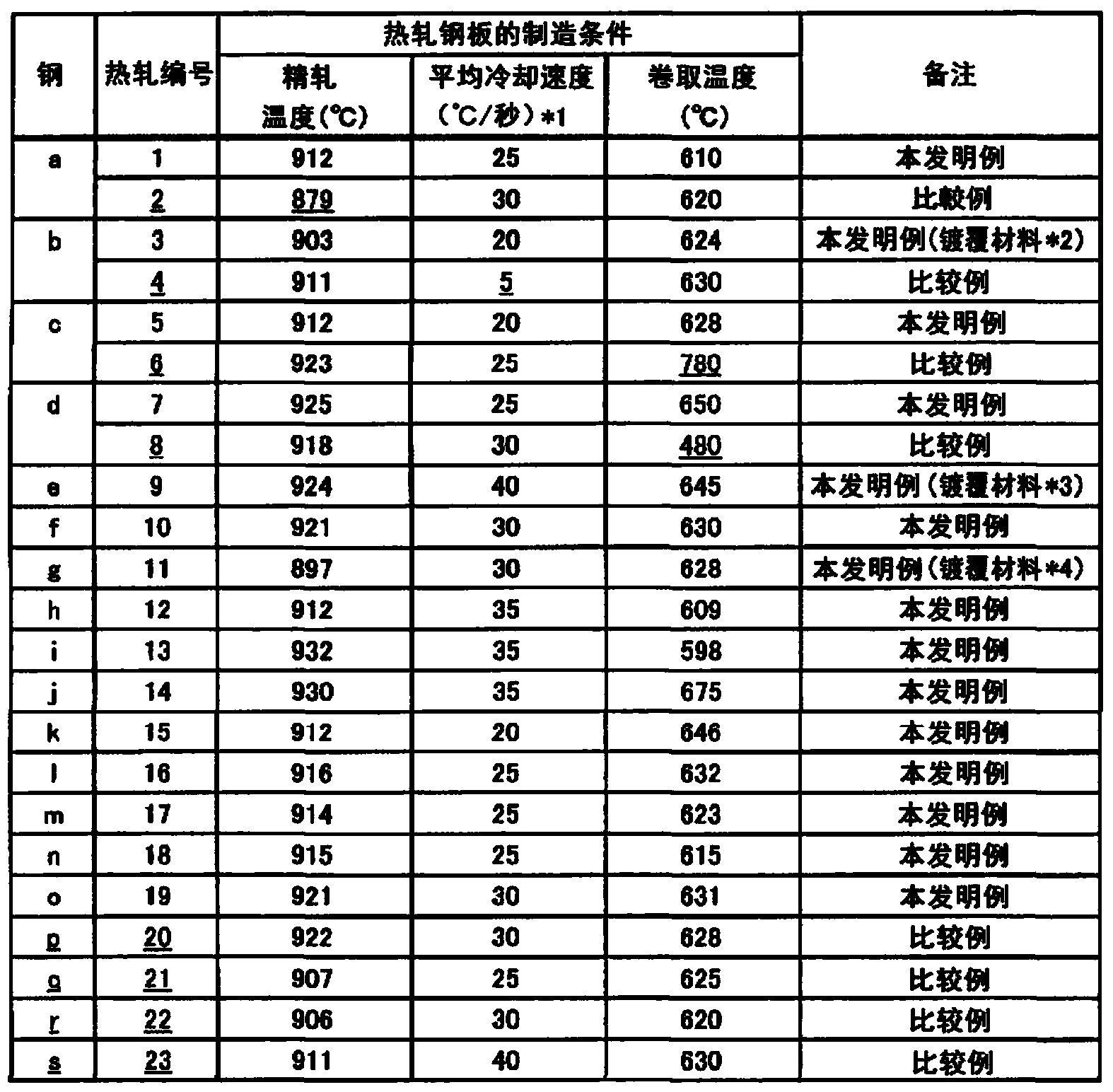

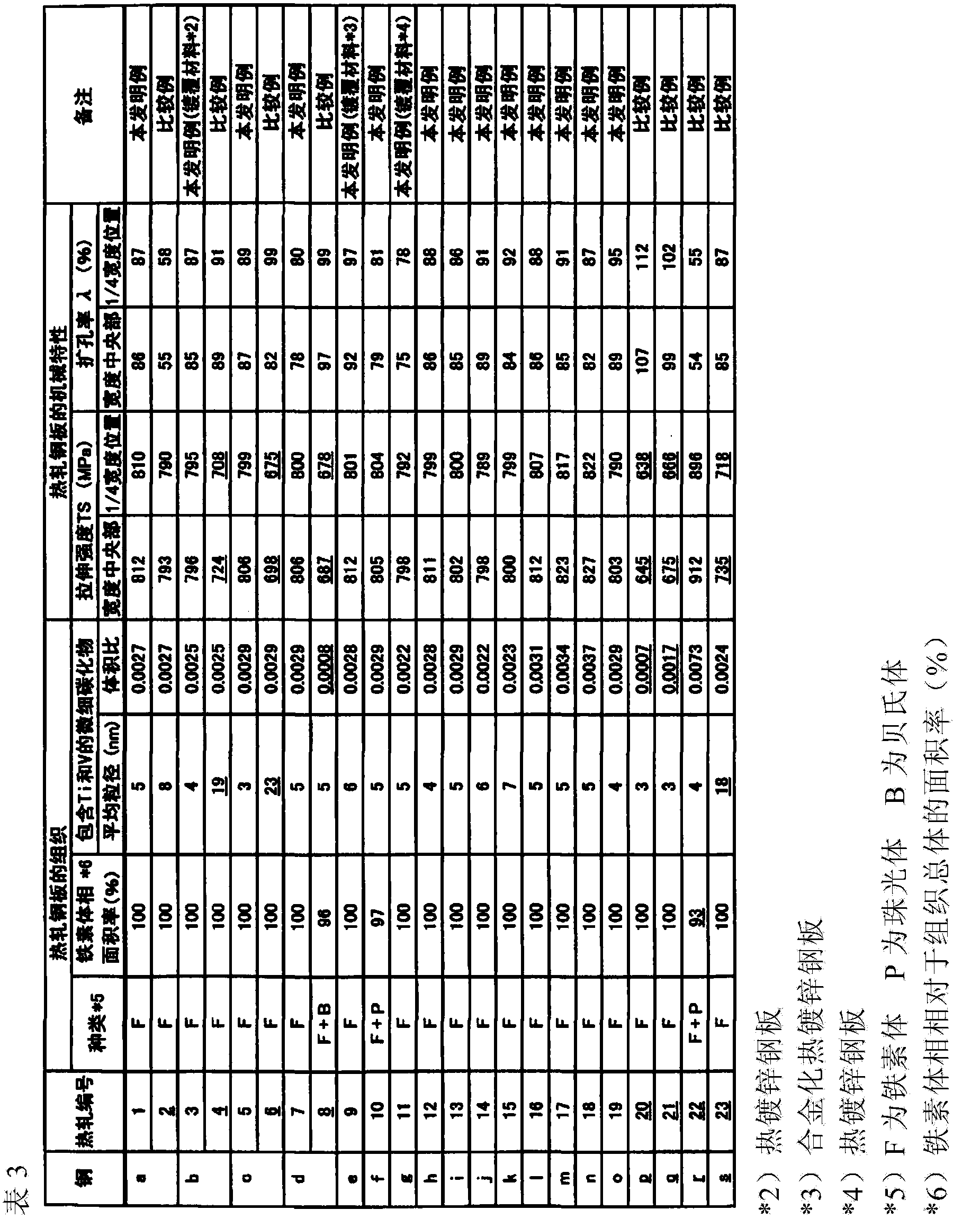

High-tensile-strength hot-rolled steel sheet and method for producing same

ActiveCN103930582AStable production processabilityImprove production and processing effectsHot-dipping/immersion processesFurnace typesCarbideUltimate tensile strength

Provided are: a high-tensile-strength hot-rolled steel sheet provided with both high strength and favorable workability (stretch flangeability), and moreover has superior material uniformity; and a method for producing same. The hot-rolled steel sheet has a tensile strength of at least 780 MPa, and has: a composition containing, by mass%, at least 0.03% and less than 0.07% of C, no greater than 0.3% of Si, 0.5-2.0% inclusive of Mn, no greater than 0.025% of P, no greater than 0.005% of S, no greater than 0.0060% of N, no greater than 0.1% of Al, 0.07-0.11% inclusive of Ti, and at least 0.08% and less than 0.15% of V in a manner such that Ti and V satisfy 0.18 <= Ti + V <= 0.24 (Ti and V being the amount contained (mass%) of the respective elements), the remainder comprising Fe and unavoidable impurities; a matrix such that the area ratio of ferrite phase with respect to the total structure is at least 95%; and a structure such that minute carbides containing Ti and V and having an average grain size of less than 10 nm are dispersed / precipitated, and the volume ratio of the minute carbides with respect to the total structure is at least 0.0020.

Owner:JFE STEEL CORP

Medical acellular dermal matrix and preparation method thereof

InactiveCN107029298ASimple processIncrease productivityTissue regenerationProsthesisAcellular DermisChemistry

The invention relates to the field of medical biomaterials, and concretely relates to a medical acellular dermal matrix and a preparation method thereof. The preparation method comprises the following steps: fleshing animal skins, sequentially carrying out disinfecting, cleaning and hypertonic saline treatment, and immersing the treated animal skins in an alkali liquid and hydrogen peroxide mixed solution; and carrying out enzyme digestion treatment on the animal skins in a trypsin solution, and crosslinking collagens by using a crosslinking agent. The treatment of a hypertonic saline treated dermal sheet with the alkali liquid and hydrogen peroxide mixed solution makes protein molecules in the dermal sheet expanded and loosened and hair directly removed, so the manual hair removal process is omitted, the process flow is simplified, the production efficiency is increased, the protection cost is saved, and the used reagents are nontoxic and do not cause environment pollution. The crosslinking treatment is carried out after the enzyme digestion, so destroys of excess digestion the structure and the arrangement mode of the collagens are avoided, and the toughness, the elasticity and the flexibility of the product are improved.

Owner:HENAN HUIBO MEDICAL CO LTD

Preparation method of low-modulus high-elastic beta-type titanium alloy dental arch wire

The invention provides a preparation method of a low-modulus high-elastic beta-type titanium alloy dental arch wire. The method conducts annealing treatment, low temperature rotary forging, multi-modedrawing, corresponding solution treatment and surface brightening treatment on titanium alloy bars to prepare the low-modulus high-elastic beta-type titanium alloy dental arch wire. The method fullyutilizes the characteristics of low strength and good elongation of a beta-type titanium alloy at a certain temperature, the deformation is increased and the number of pass is reduced by low temperature rotary forging, a clad layer is prepared on the surface of the dental arch wire, the color of the titanium alloy dental arch wire can be changed, and the use requirements of people can be met; anti-corrosion treatment is conducted on the titanium alloy dental arch wire, and the service life of the dental arch wire clad layer is prolonged. The preparation method of the titanium alloy dental archwire has the advantages of simple process, high manufacturing efficiency and good product effect, the prepared beta-type titanium alloy dental arch wire has good biocompatibility, low elastic modulusand high elasticity, and stable and mild corrective force and long-term moderate displacement can be obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

ActiveCN107237259AHigh compressive strengthHas tensile strengthBridge structural detailsBridge deckHigh pressure

The invention provides a composite steel fiber-concrete steel bridge deck based on cohesive cotter groups. The preparation method comprises the following steps that 1, cleaning and shot blasting are conducted on the cover plate of the steel bridge deck by means of a high-pressure air gun; 2, cotter connecting components are arranged on the cover plate of the steel bridge deck in a bonding mode; 3, a fiber-concrete pavement layer is casted on the cover plate of the steel bridge deck with the cohesive cotter groups and the cotter connecting components in situ. By means of the composite steel fiber-concrete steel bridge deck based on the cohesive cotter groups, the structure stiffness can be improved, the stress amplitude of a fatigue detail place is reduced, and long service life design of an orthotropic steel bridge deck is achieved.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com