Lapping and tape continuing method for resin-based composite material pre-impregnation adhesive tape

A composite material and resin-based technology, which is applied in the field of lay-up molding and composite material winding, can solve the problems of complex process, low efficiency of prepreg tape, and doping materials, so as to improve the quality of winding products and avoid impurities and stress concentration point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, two sections of composite material prepreg tapes are lapped together by means of heating and pressure to form a continuous prepreg tape.

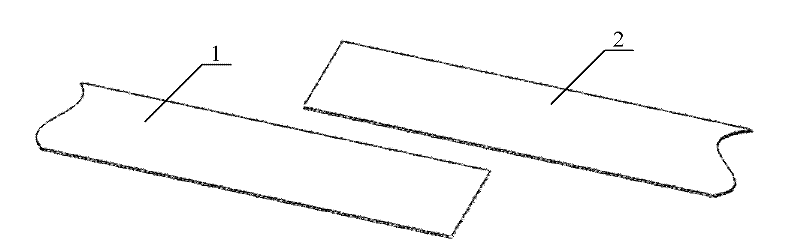

[0025] Step 1: Horizontally overlap the joint part of the resin-based composite material prepreg tape 1 with the joint part of the resin-based composite material prepreg tape 2 by 100 mm, and align the sides of the two prepreg tapes. figure 2 shown.

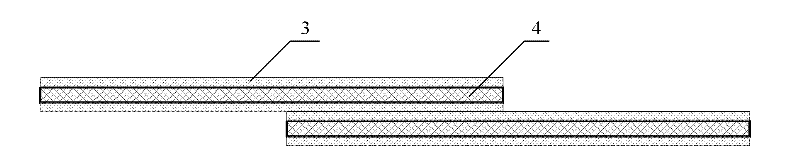

[0026] Step 2: Heat the overlapping part of the two prepreg tapes to 40°C, so that the resin matrix 3 on the surface of the overlapping part melts into a viscous fluid with a certain viscosity. Since the resin matrix materials of the two prepreg tapes to be overlapped are the same , so the resin matrix on the surface of the two prepreg tapes is integrated, such as image 3 shown.

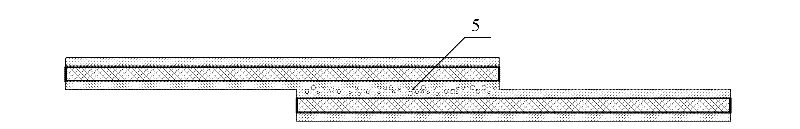

[0027] Step 3: Apply 10Kg / cm to the overlapping part of the two prepreg tapes in the direction perpendicular to the overlapping surface 2 pressure, and keep it for 8 seconds, so that the ...

Embodiment 2

[0030] In this example, two sections of composite material prepreg tapes are lapped together by means of heating and pressure to form a continuous prepreg tape.

[0031] Step 1: Horizontally overlap the joint part of the resin-based composite material prepreg tape 1 with the joint part of the resin-based composite material prepreg tape 2 by 200mm, and align the sides of the two prepreg tapes.

[0032] Step 2: Heat the overlapping part of the two prepreg tapes to 60°C, so that the resin matrix 3 on the surface of the overlapping part melts into a viscous fluid with a certain viscosity, because the resin matrix materials of the two prepreg tapes to be overlapped are the same , so the resin matrix on the surface of the two prepreg tapes is integrated.

[0033] Step 3: Apply 5Kg / cm to the overlapping part of the two prepreg tapes in the direction perpendicular to the overlapping surface 2 pressure, and keep it for 10 seconds, so that the fiber reinforcements 4 inside the two sect...

Embodiment 3

[0036] In this example, two sections of composite material prepreg tapes are lapped together by means of heating and pressure to form a continuous prepreg tape.

[0037] Step 1: Horizontally overlap the joint part of the resin-based composite material prepreg tape 1 with the joint part of the resin-based composite material prepreg tape 2 by 150mm, and align the sides of the two prepreg tapes.

[0038] Step 2: Heat the overlapping part of the two prepreg tapes to 50°C, so that the resin matrix 3 on the surface of the overlapping part melts into a viscous fluid with a certain viscosity. Since the resin matrix materials of the two prepreg tapes to be overlapped are the same , so the resin matrix on the surface of the two prepreg tapes is integrated.

[0039] Step 3: Apply 7Kg / cm to the overlapping part of the two prepreg tapes in the direction perpendicular to the overlapping surface 2 pressure, and keep it for 10 seconds, so that the fiber reinforcements 4 inside the two sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com