A drill pipe and casing storage system

A storage system and casing technology, applied in drill pipe, casing, drill pipe, etc., can solve the problems of shortened connection time and more time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

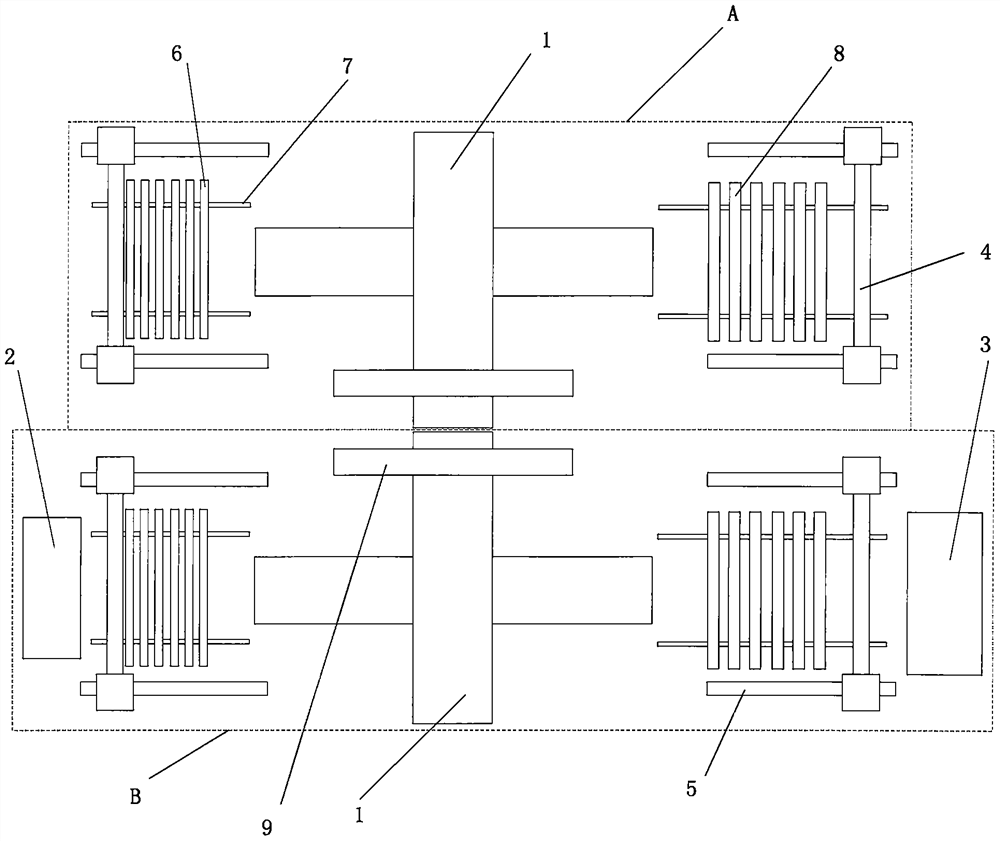

[0021] The step of continuing drill pipe 6 is:

[0022] 1. The gantry crane 4 lifts a drill pipe 6 from the drill pipe box 2 , the gantry crane 4 slides along the track 5 to the vicinity of the auxiliary support 7 , and places the drill pipe 6 on the auxiliary support 7 .

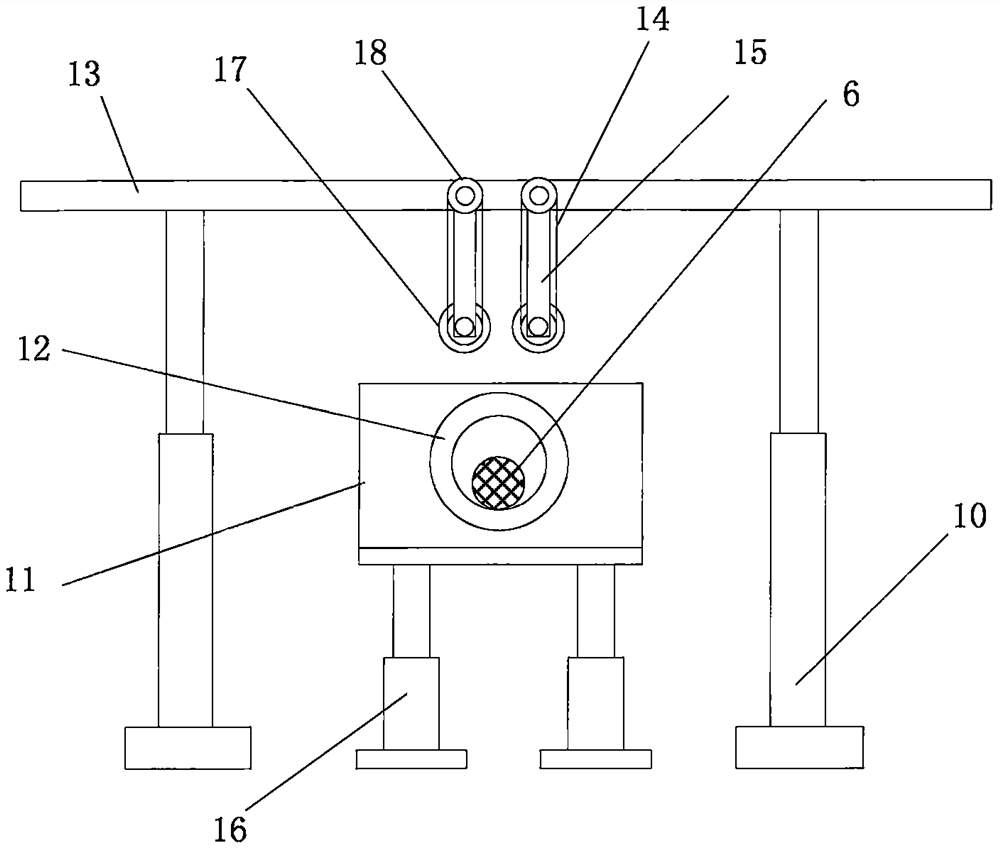

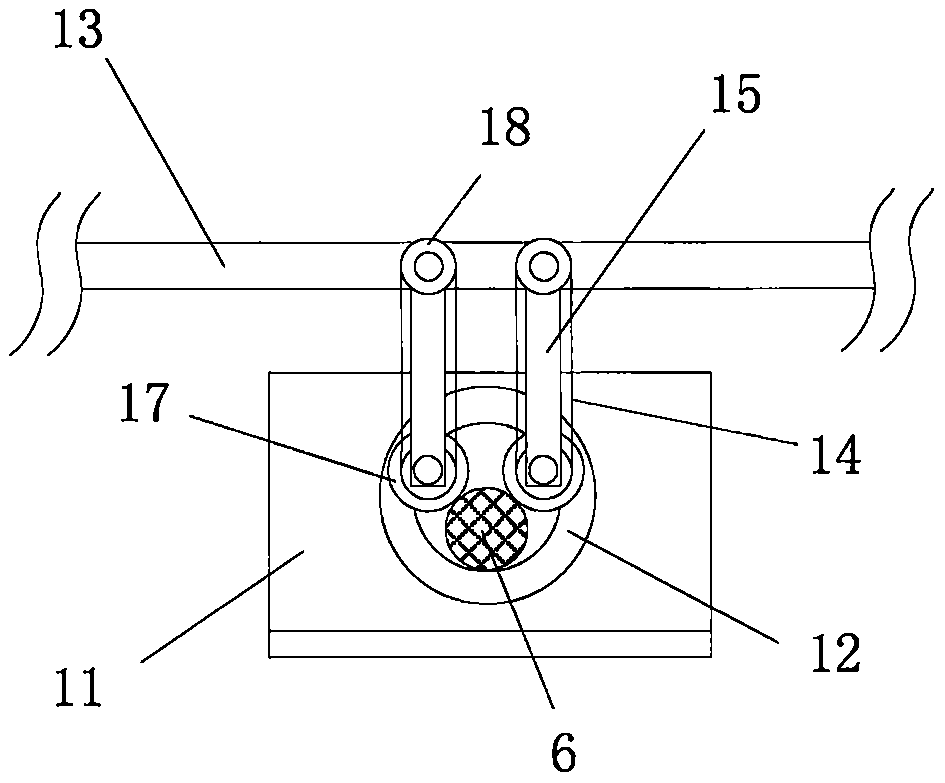

[0023] 2. The second support rod 16 pushes the frame 11 to move up, so that the lower surface of the inner hole of the bearing 12 is flush with the upper surface of the power catwalk 1, and the second support rod 16 stops and locks.

[0024] 3. The drill pipe 6 rolls onto the power catwalk 1 along the auxiliary bracket 7, and advances along the power catwalk 1 under the push of the pushing mechanism, passing through two bearings 12 in turn.

[0025] 4. When the pushing distance of the drill pipe 6 is about 1.2 times the length of the drill pipe, stop pushing, and the pushing mechanism reversely moves to the initial position.

[0026] 5. Repeat step 1, place a new drill pipe 6 on the power catwalk 1, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com