Method for manufacturing reused fresh-keeping isolation layer in rubber tire preparation

A technology of rubber tires and manufacturing methods, applied in the direction of coating, etc., can solve the problem of high manufacturing cost of fresh-keeping isolation layers, and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

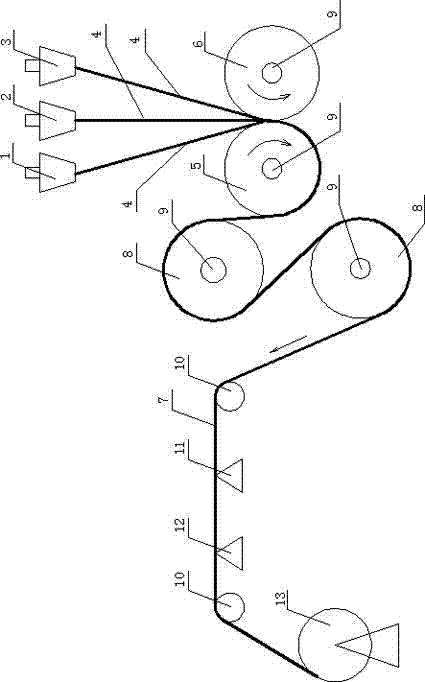

[0014] An example such as figure 1 Place three salivating dies 1, 2 and 3 above the pressure rollers 5 and 6, and the salivating dies 1 and 3 simultaneously drool and melt the polyolefin fresh-keeping isolation layer layer 4, and the salivating die 2 drools out the ratio of the fabric layer 4 Middle layer 2 with high tensile strength and low elongation. Under the rolling of two pressure rollers 5 and 6 with the same rotating speed, opposite rotation and substantially parallel axis centers, the fresh-keeping isolation layer 7 is hot-pressed and compounded and cooled and leveled by a plurality of cooling rollers 8 .

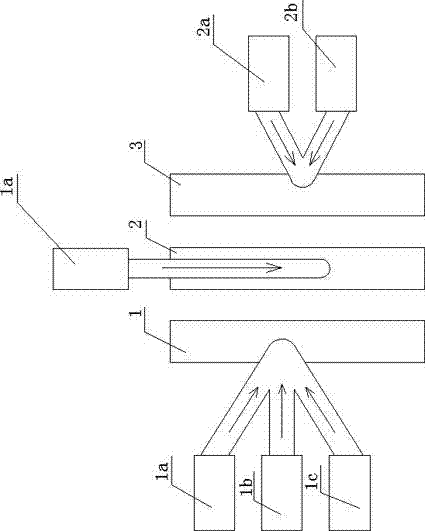

[0015] The salivating die heads 1, 2, and 3 can be connected with one or more screws respectively. The structure is as follows: figure 2 , The drooling die head 1 is connected with the screws 1a, 1b, 1c, the die head 3 is connected with the screw rod 3a, and the die head 2 is connected with the screws 2a, 2b.

[0016] Another kind of embodiment, place two saliva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com