Thermal desorption method for contaminated soil

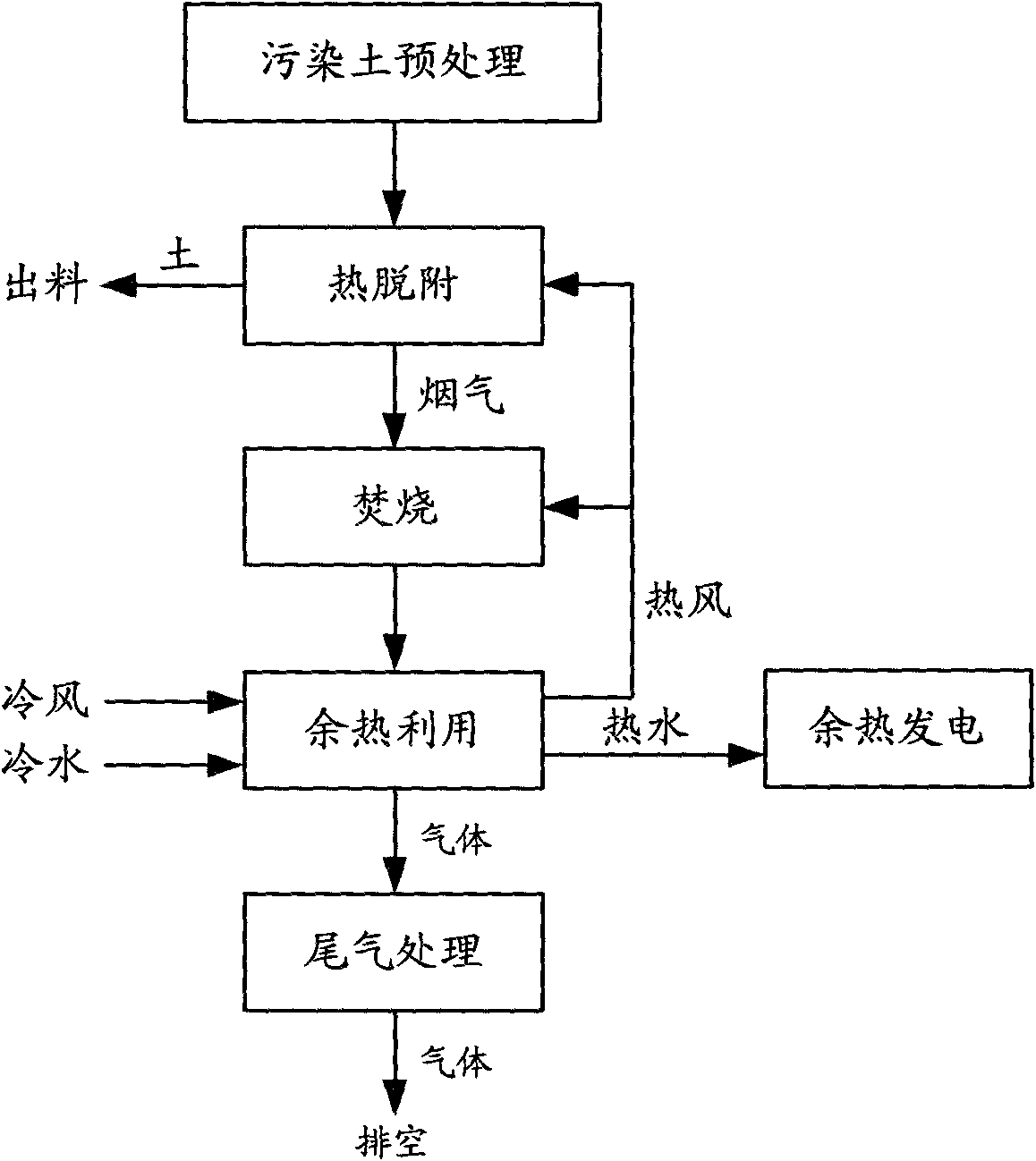

A technology for thermal desorption and polluted soil, which is applied in the field of incineration to treat flue gas containing gasification pollutants and purify polluted soil. It can solve the problems of secondary pollution, long biological treatment cycle, expensive landfill and incineration, etc., and achieve Maintain the inherent characteristics and eliminate the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Contaminated soil sieved by a 50mm screen is conveyed to the feed inlet of the desorption chamber of the horizontal rotary kiln by a grab bucket, and then pushed into the desorption chamber by a hydraulic push rod device at a feed rate of 1 ton / hour. The temperature of the desorption chamber is 450°C-600°C, the rotation speed is 0.6-1.5r / min, the desorption time is 40-17 minutes, and the negative pressure in the kiln is -15Pa. During operation, natural gas (natural gas is used as combustion-supporting fuel to prevent secondary pollution to the soil) and primary air are sent from the kiln head by the blower after combustion, and the downstream operation is adopted, that is, the heat source and the polluted soil flow in the same direction. The soil after thermal desorption is discharged into the storage tank through the sealed pipeline through the high-temperature chain plate slag discharger, and a certain proportion of the storage tank is immersed in the cooling water tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com