Electric gas tube lead wire penetrating method

A technology of electrical pipes and threading, which is applied in the direction of cable laying equipment, etc., can solve the problems of semi-rigid electrical pipes being unsuitable and wasteful, and achieve simple and easy access to equipment and materials, no potential safety hazards, and reduce labor costs and material loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

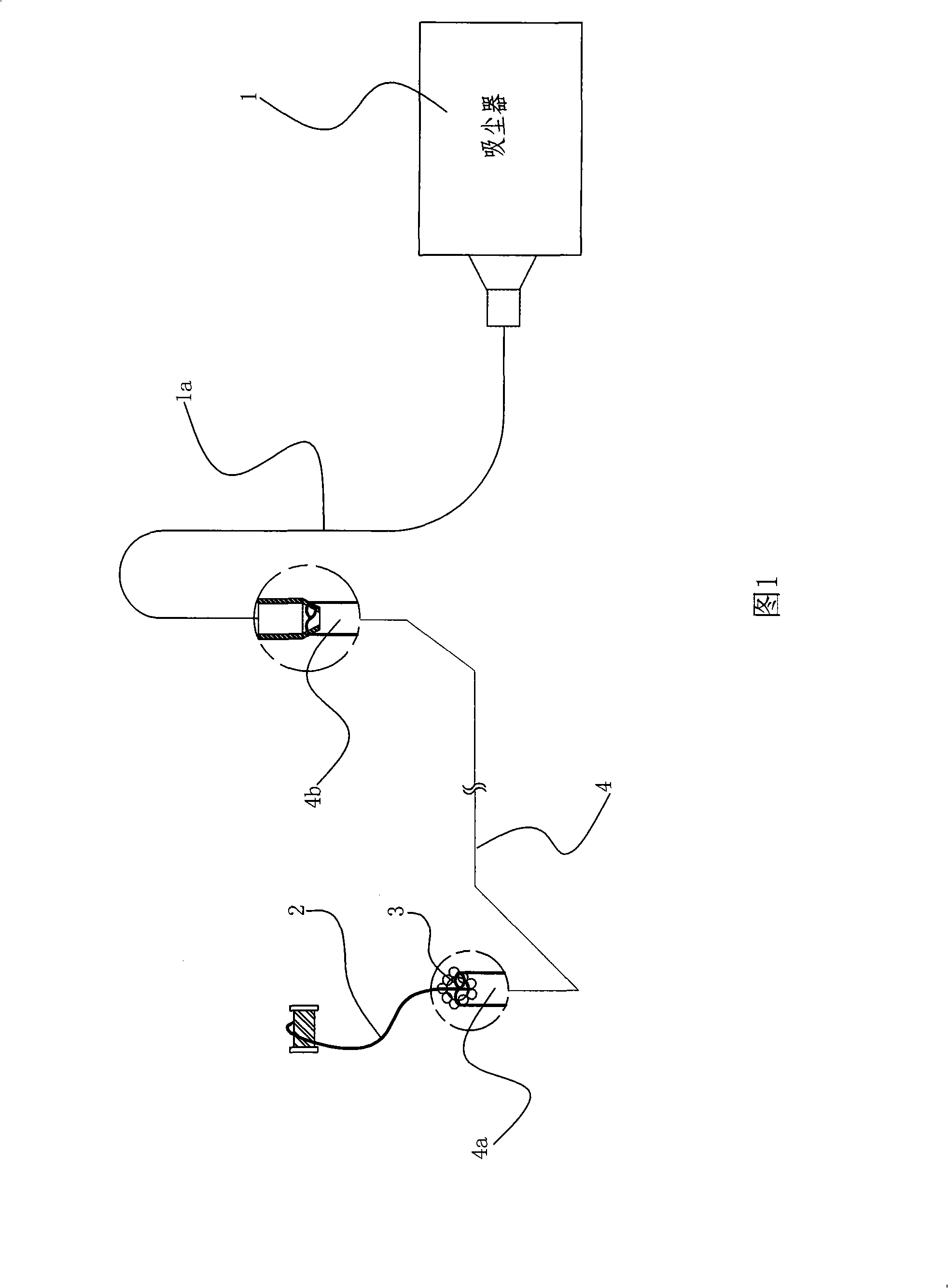

[0014] As shown in FIG. 1 , the equipment and materials used in the method for threading lead wires of electrical pipes are as follows: vacuuming equipment adopts ordinary household vacuum cleaners 1 , flexible lead wires adopt nylon strings 2 , and flexible objects adopt cotton balls 3 .

[0015] Tie the nylon string 2 to the cotton ball 3, and then insert the cotton ball 3 into the initial port 4a of the pre-embedded electrical pipe 4, requiring the cotton ball 3 with the nylon string 2 to be able to seal the initial port 4a of the electrical pipe 4 , and the electrical tube 4 can maintain a tight and suitable fit during the travel of the cotton ball 3, so as to achieve a full seal with the electrical tube 4; insert the suction tube 1a of the vacuum cleaner 1 directly into the terminal 4b of the electrical tube 4, and seal the electrical tube 4 terminal 4b; in this embodiment, the suction pipe of the vacuum cleaner 1 and the terminal 4b of the electrical pipe 4 just reach the...

Embodiment 2

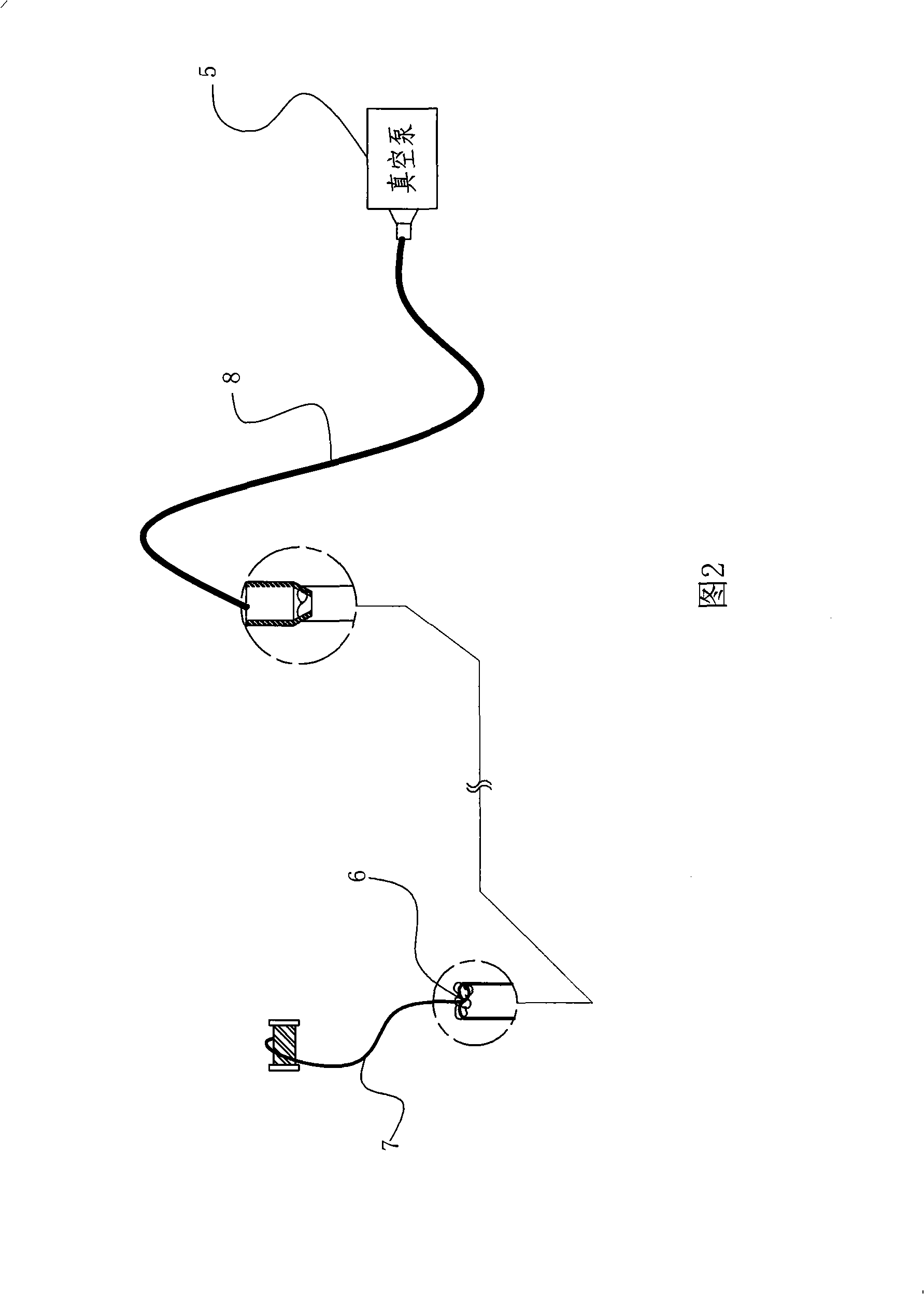

[0020] As shown in Figure 2, the vacuum pumping equipment uses a common vacuum pump 5, and a rubber hose 8 is used to seal the terminal port of the electric pipe and the vacuum pump port. The flexible object uses a sponge ball 6 suitable for the diameter of the electric pipe. Strings adopt 22# galvanized iron wire 7. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com