Preparation method for steel fiber copper-covered steel wire

A copper-clad steel wire and steel fiber technology, which is applied in the field of steel fiber copper-clad steel wire preparation, can solve the problems of slow precipitation at low temperature, decline in electrical conductivity, and coarsening of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

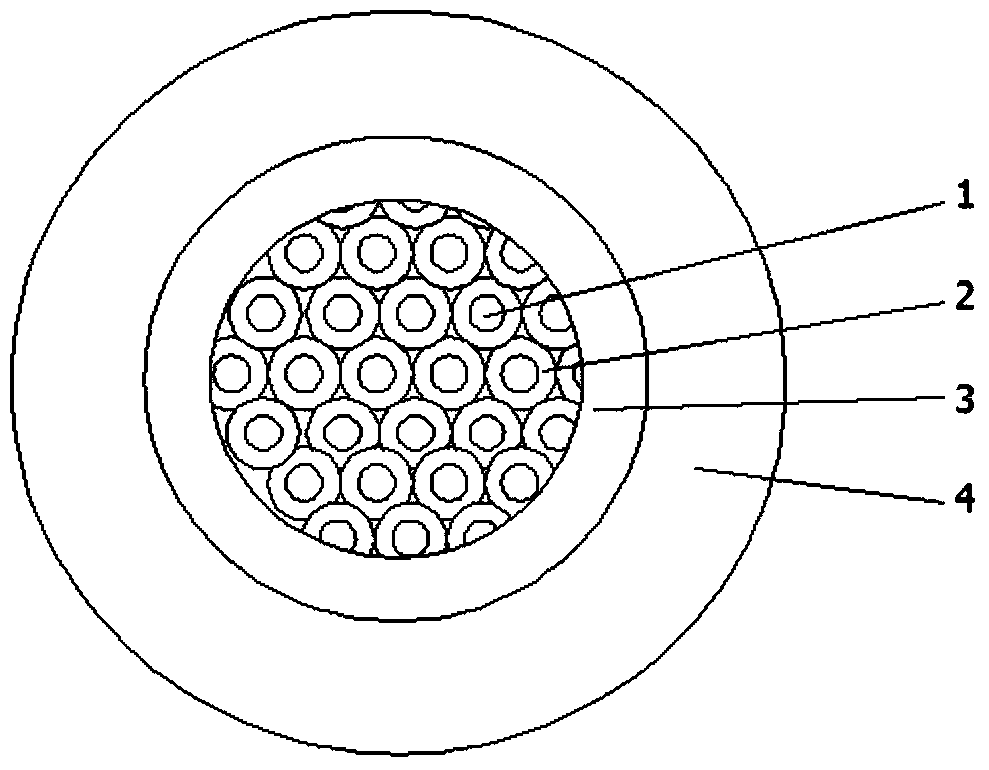

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] The preparation method of steel fiber copper clad steel wire of the present invention comprises the following steps:

[0015] (1) Put the 1mm-diameter in the oil and rust remover, heat it to 60°C, keep it for 10 minutes, after the oil and rust are removed, rinse it with water and dry it in an oven at 100°C. Then put the dried steel fiber into a copper tube with an outer diameter of 2 mm and a wall thickness of 0.2 mm, and draw it three times in a row, each time the deformation is controlled between 15% and 20%.

[0016] In this embodiment, the degreasing and rust removing agents are: 150g / L-200g / L HCl, 15g / L-20g / LH 2 SO 4 , 1g / L-3g / L urotropine, 5g / L-10g / L thiourea, 20g / L NaNO2, 1g / L sodium dodecylsulfonate and the balance water.

[0017] (2) Heat the drawn copper-clad steel fiber to 600°C, and then anneal for 1h.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com