Heat-conducting high-heat-conductivity aircraft tire tread rubber

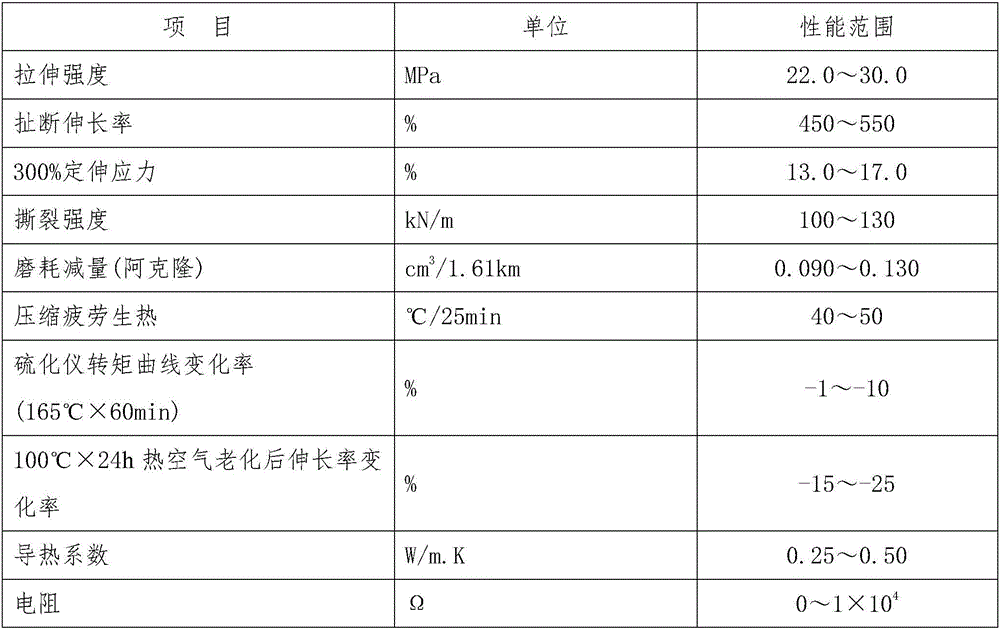

A technology for aviation tires and tread rubber, which is used in special tires, tire parts, transportation and packaging, etc., can solve the problem of the decline in the bonding strength of rubber and skeleton materials, the wear resistance of tread rubber and other properties, which affect the flight of aircraft. Safety and other issues, to achieve the effect of safe use, long service life and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

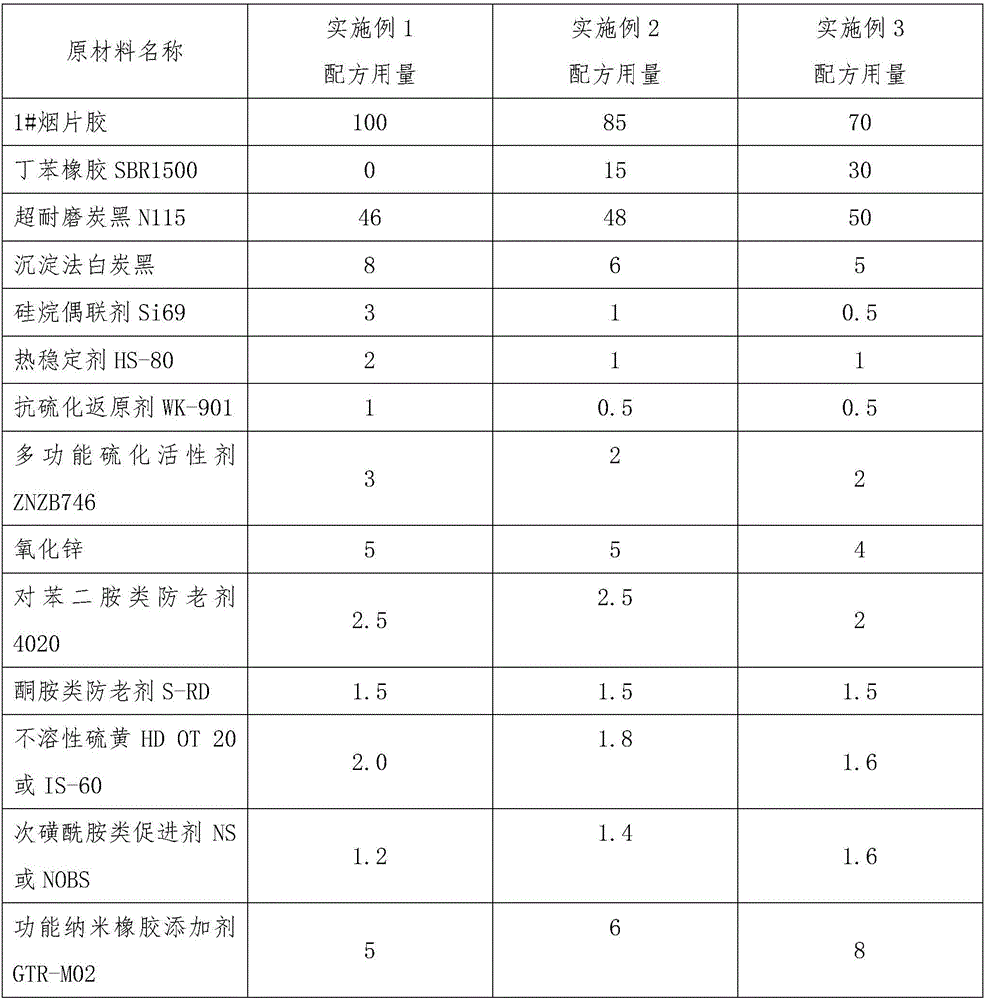

[0034] The present invention will be further elaborated below by embodiment.

[0035]

[0036] The compounded rubber is produced by mixing with an internal mixer, and the compounded rubber is extruded by an extruder to make a semi-finished tread, and the semi-finished tread is attached to the upper part of the carcass on the molding machine to make a tire blank , and the green tire is vulcanized by a vulcanizer to become a finished aviation tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com