Ultrahigh-performance plastic film as well as preparation method and composite material thereof

A plastic film, ultra-high-performance technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of not being pierced under impact force and not cracked under strong tearing, to achieve Effect of reduced material consumption, high economic efficiency, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

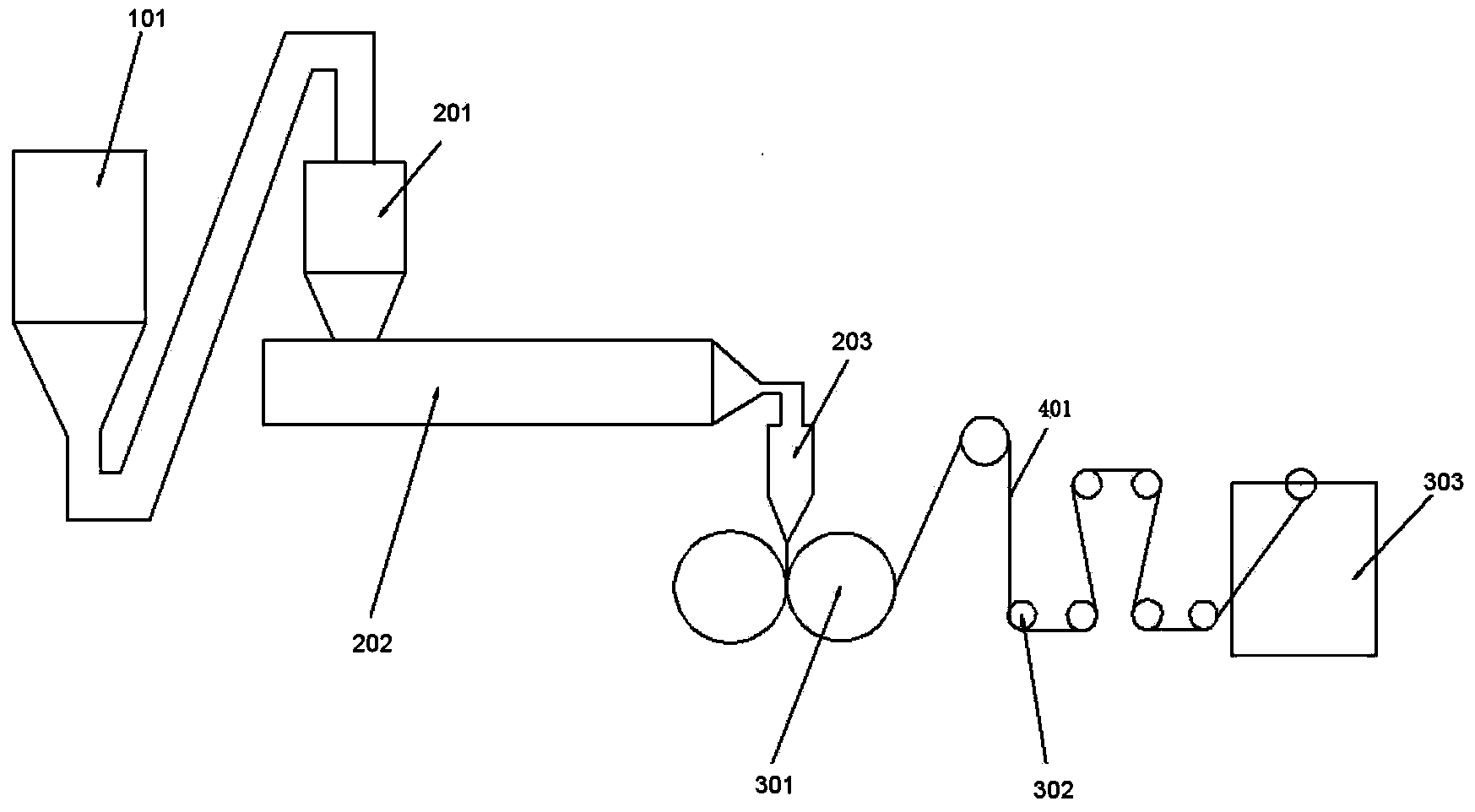

[0061] The ultra-high-performance plastic film in this embodiment has a single-layer structure, and a single-layer extrusion casting process is selected for preparation, and the thickness of the prepared film is 0.097 mm.

[0062] The formula weight composition of the film is as follows: 9.52% ultra-low density polyethylene, 85.72% metallocene linear low-density polyethylene, 3.33% color masterbatch, and 1.43% other additives.

[0063] The performance of the plastic film prepared from the above formula is compared with that of the existing operating tablecloth on the market as follows:

[0064]

[0065] It can be seen that the tensile strength of the film in this embodiment is more than 2 times that of the existing operating tablecloth on the market; the impact of falling darts is more than 5 times that of the existing operating tablecloth on the market; There are more than 1.1 times that of the operating tablecloth.

[0066] The performance of the film prepared by the abo...

Embodiment 2

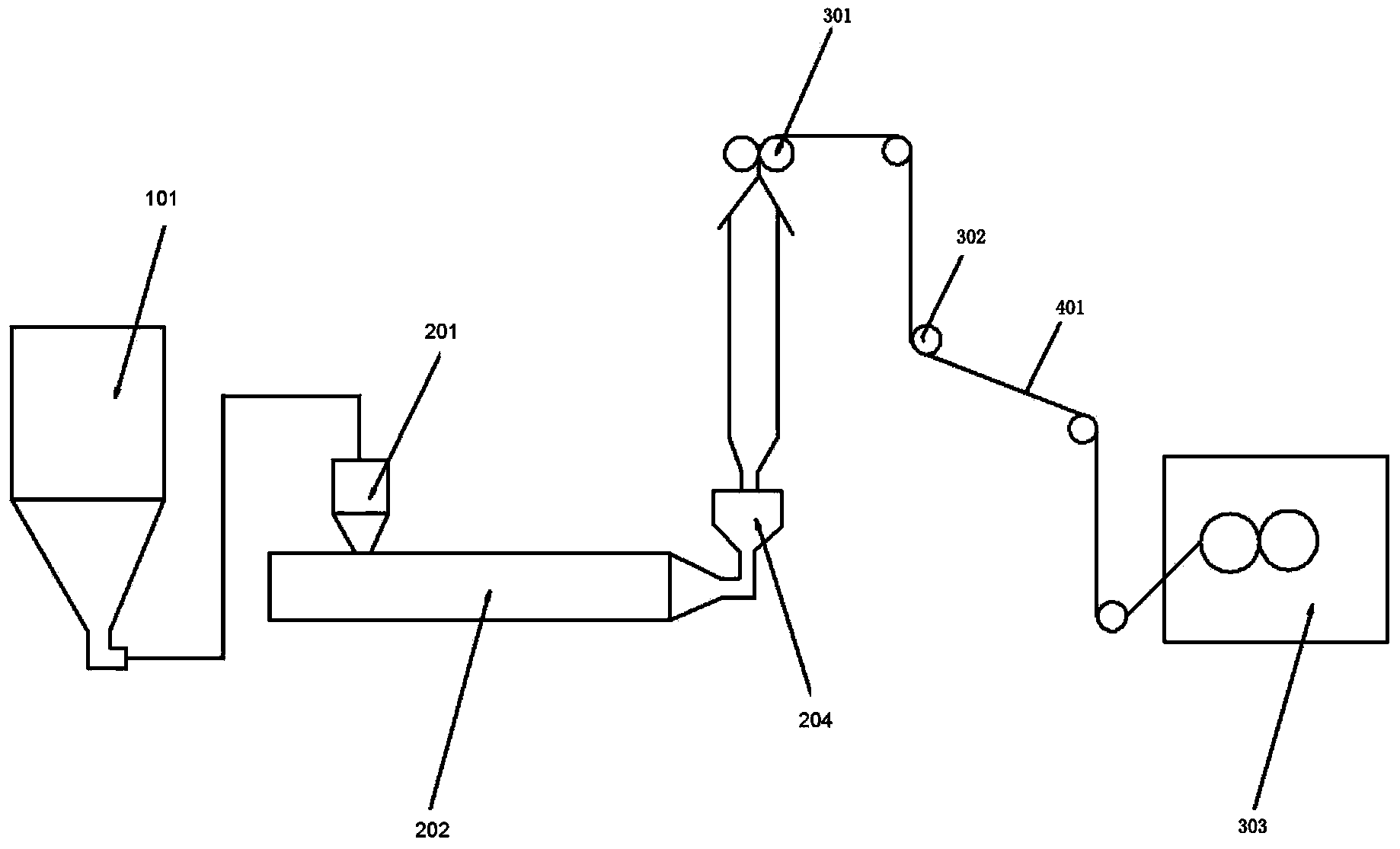

[0070] The ultra-high-performance plastic film in this example has a two-layer structure of A layer and B layer. During the preparation, a two-layer extrusion casting process is selected. The thickness of the prepared film is 0.097mm, and the A layer and B layer structure adopt the following formula :

[0071] The weight composition of layer A formula is as follows: 9.52% ultra-low density polyethylene, 85.72% metallocene linear low-density polyethylene, 3.33% color masterbatch, and 1.43% other additives.

[0072] The weight composition of the B-layer formula is as follows: 9.76% ultra-low density polyethylene, 87.8% metallocene linear low-density polyethylene, 0.98% color masterbatch, and 1.46% other additives.

[0073] The performance of the film prepared from the above formula is compared with that of the existing operating tablecloth on the market as follows:

[0074]

[0075] It can be seen that the tensile strength of the film in this embodiment is more than 2 times ...

Embodiment 3

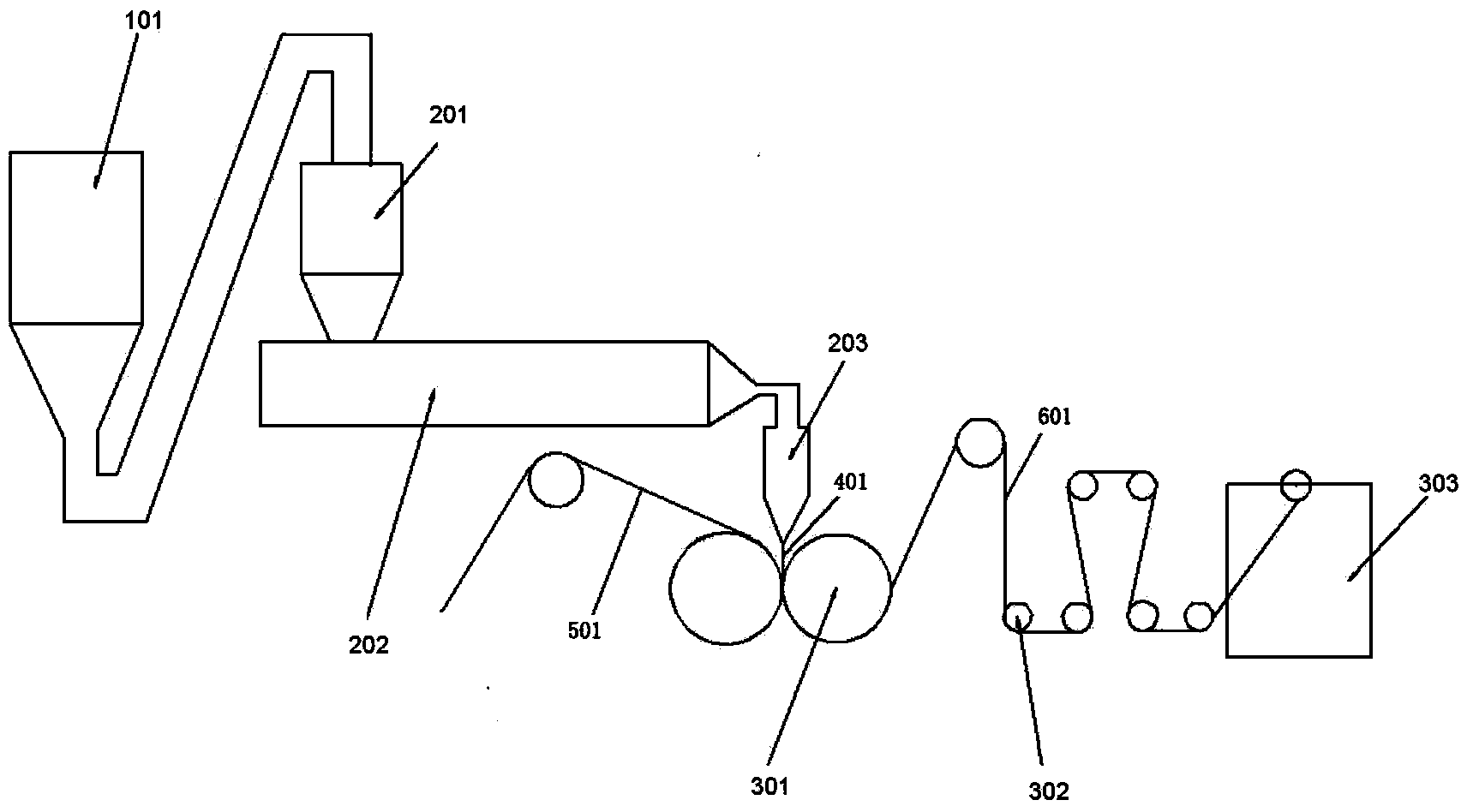

[0080] The ultra-high-performance plastic film in this example has a three-layer structure of A layer, B layer and C layer. When preparing, a three-layer extrusion casting process is selected. The thickness of the prepared film is 0.097mm, wherein A layer, B layer and C layer The layer structure adopts the following recipe:

[0081] The weight composition of the layer A formula is as follows: 22.83% ultra-low density polyethylene, 68.49% metallocene linear low-density polyethylene, 7.31% color masterbatch, and 1.37% other additives.

[0082] The weight composition of the B-layer formula is as follows: 14.63% ultra-low density polyethylene, 68.29% metallocene linear low-density polyethylene, 14.63% high-density polyethylene, 0.99% color masterbatch, and 1.46% other additives.

[0083] The weight composition of the C-layer formula is as follows: 9.52% ultra-low density polyethylene, 85.72% metallocene linear low-density polyethylene, 3.33% color masterbatch, and 1.43% additives....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com