High-strength abrasion-resistant steel for engineering machinery and manufacturing method thereof

A technology of high-strength wear-resistant steel and construction machinery, applied in the field of wear-resistant steel production, can solve the problems of high-strength wear-resistant steel performance requirements and high cost of difficult steels, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

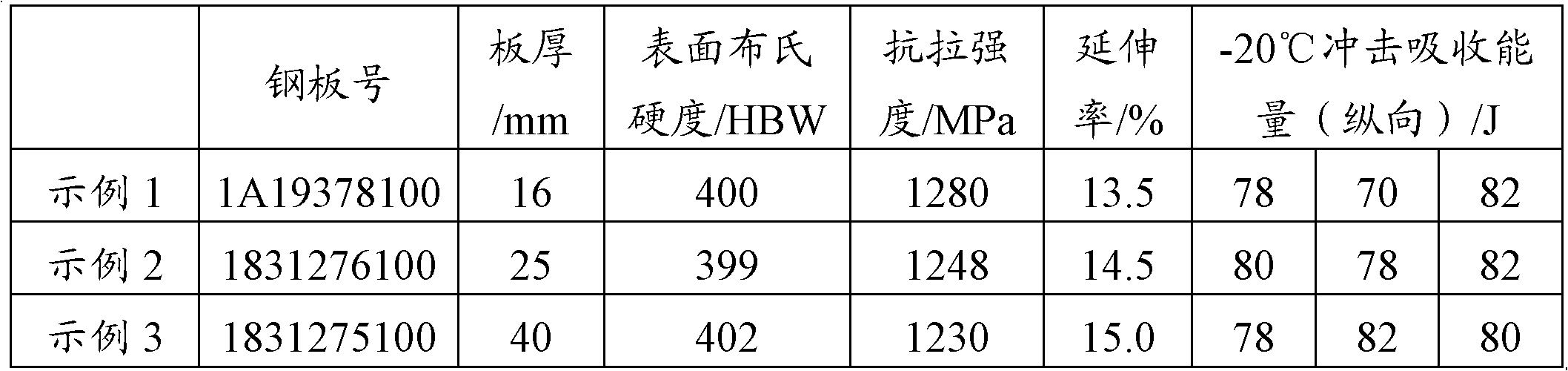

Examples

preparation example Construction

[0013] The preparation method of high-strength wear-resistant steel for engineering machinery according to the present invention comprises the following steps: smelting target molten steel, the components of which are C: 0.15-0.30%, Si: 0.20-0.65%, Mn: 1.20~1.60%, S≤0.010%, P≤0.020%, B: 0.0010~0.0040%, Cr: 0.30~1.00%, V: 0.030~0.080%, Al: 0.015~0.050%, [N]: 80~200 ×10 -6 、[H]≤2×10 -6 、[O]≤40×10 -6 And the balance of Fe and unavoidable impurities.

[0014] The O element affects the shape and distribution of oxide inclusions in steel. If the oxygen content in steel is too high, oxide inclusions and macro inclusions increase, which seriously affects the cleanliness of steel. Oxide inclusions in steel are one of the sources that affect the toughness of steel, and endanger various properties of steel; especially when the diameter of inclusions is greater than 50 μm, it seriously deteriorates various properties of steel. In order to prevent oxide inclusions with a diameter great...

example 1

[0038] In this example, the production process of high-strength wear-resistant steel is molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, RH refining, slab continuous casting, controlled rolling and cooling, and heat treatment.

[0039] The specific operation steps are as follows:

[0040] Desulfurization of hot metal is strictly carried out in accordance with the process regulations, the sulfur in the hot metal is controlled at 0.002%, the temperature is 1280°C, and the slag on the surface of the hot metal is removed after desulfurization. The pretreated molten iron enters the converter for smelting, and the slagging materials such as lime are added 3 minutes before the end point, and the basicity of the final slag is controlled at R=4.0~5.0. The final pressure gun time is 65 seconds. Before tapping the converter, first add desulfurizer to the bottom of the ladle, and use Al-Mn-Ti to deoxidize. The amount of Al-Mn-Ti added is 3.5kg / t stee...

example 2

[0048] In this example, the production process of high-strength wear-resistant steel is molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, RH refining, slab continuous casting, controlled rolling and cooling, and heat treatment.

[0049] The specific operation steps are as follows:

[0050] Desulfurization of hot metal is strictly carried out in accordance with the process regulations. The sulfur in the hot metal is controlled at 0.001%, the temperature is 1221°C, and the slag on the surface of the hot metal is removed after desulfurization. The pretreated molten iron enters the converter for smelting, and the slagging materials such as lime are added 3 minutes before the end point, and the basicity of the final slag is controlled at R=4.0~5.0. The final pressure gun time is 72 seconds. Before tapping the converter, first add desulfurizer to the bottom of the ladle, and use Al-Mn-Ti to deoxidize. The amount of Al-Mn-Ti added is 3.5kg / t stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com