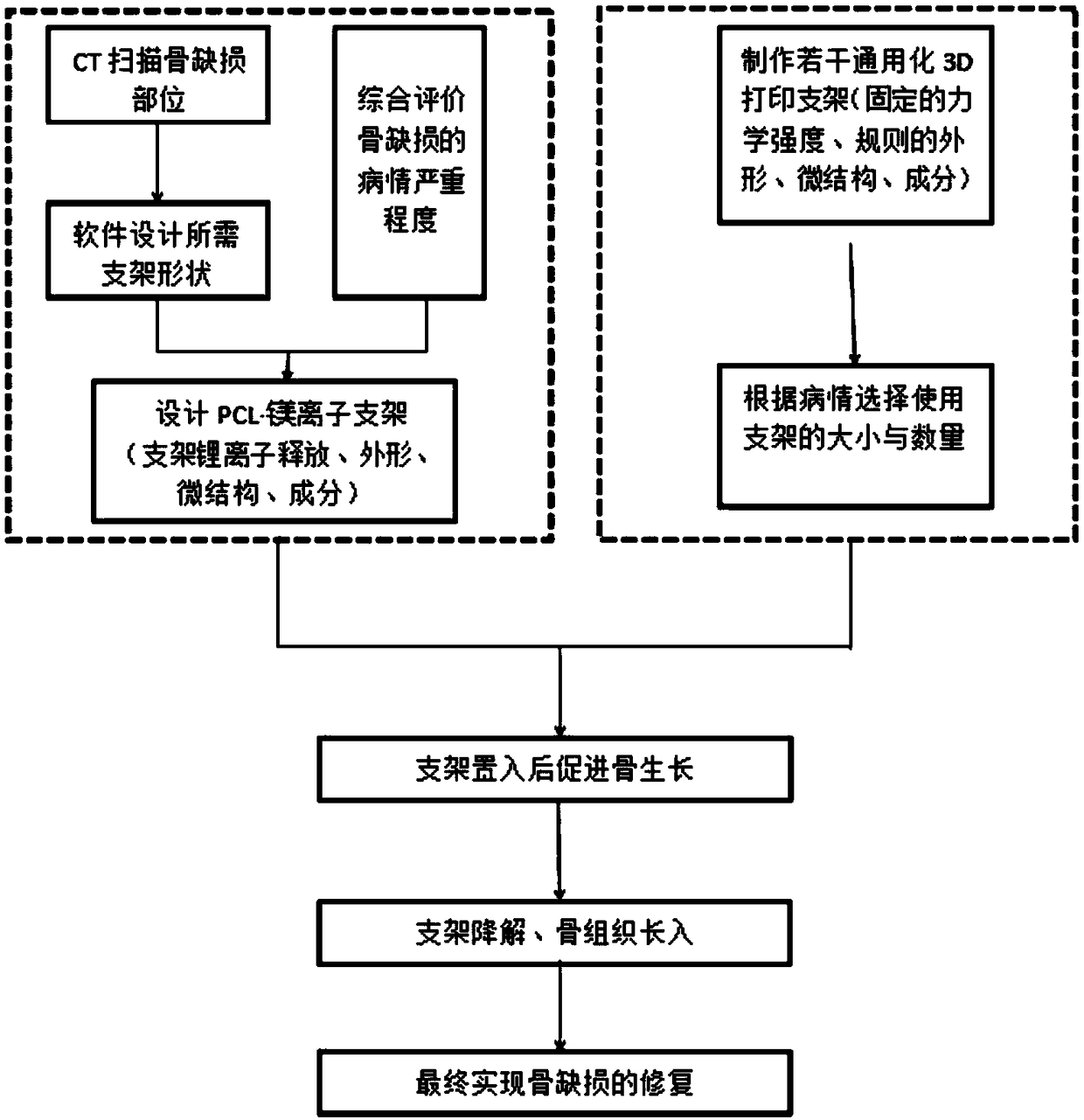

3D printed PCL-Mg bone tissue engineering scaffold and preparation method thereof

A tissue engineering scaffold, bone tissue engineering technology, applied in tissue regeneration, additive processing, medical science and other directions, can solve the problems of repeated use, unsatisfactory long-term effect, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of PCL-Mg particles

[0039] Dissolve PCL and magnesium chloride in tetrahydrofuran at a ratio of 60.04:39.96 to form a solution with a mass volume ratio of 25%. Put the PCL-Mg mixed solution in a rotary evaporator at 80°C in a water bath to suck out the solvent tetrahydrofuran under negative pressure to obtain a PCL-Mg mixture, which was shredded to obtain PCL-Mg particles with a diameter of about 500 microns.

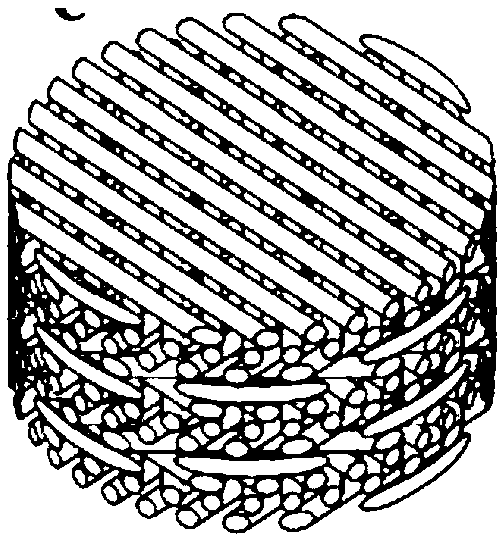

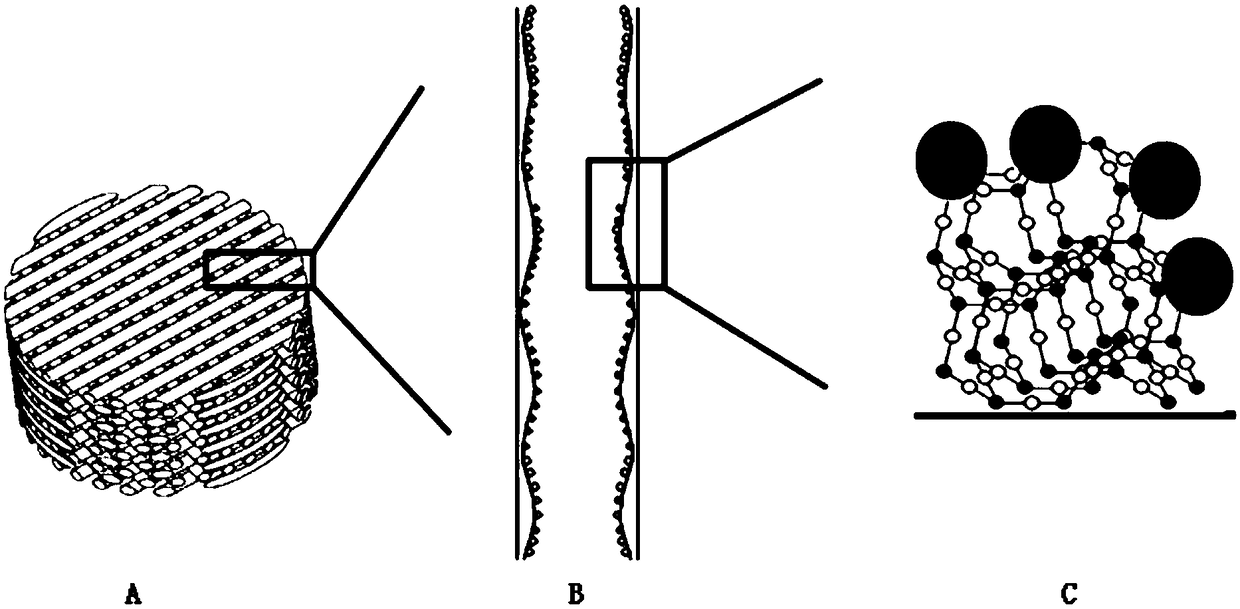

[0040] 2. Preparation of 3D printed PCL-Mg scaffolds

[0041] The PCL-Mg particles were heated to 100°C through the heating system of Fused Deposition Modeling (FDM) 3D printing to become liquid. Extrude the molded fiber bundles, and obtain the 3D printing scaffold through the splicing structure of different layers and angles of the fiber bundles. A scaffold with a square microstructure in which the fibers are stacked at 0-45-90-135-180°. The aperture of the scaffold is 500 microns, square, and the porosity is 85%. Figure 5 It is the physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com