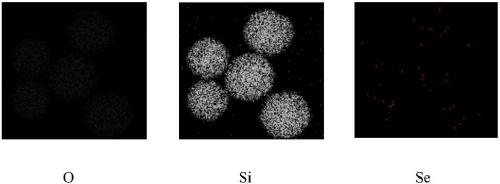

Selenium-doped mesoporous silica antibacterial material and preparation method thereof

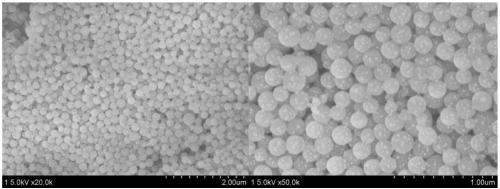

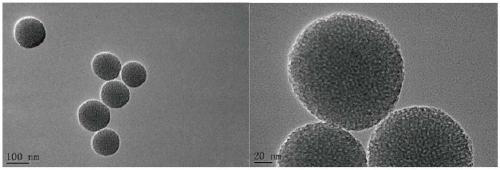

A technology of mesoporous silica and antibacterial materials, applied in the field of antibacterial materials, can solve problems such as tissue damage, and achieve the effects of good dispersion, strong repeatability and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Choose analytically pure sodium selenite, ascorbic acid, cetyltrimethylammonium bromide (CTAB), ammonium fluoride (NH 4 F), Ethyl Orthosilicate (TEOS), by this preparation method, 10% selenium-doped nano-scale MSNs are synthesized.

[0029] The specific steps are:

[0030] (1) First, weigh 0.1g of selenite and 0.4g of ascorbic acid and add them to 10mL of deionized water, stir well to dissolve them in the water, and set aside for later use;

[0031] (2) Weigh 0.36g CTAB, 0.6g NH 4 F, then add 80mL deionized water, the reaction temperature is 80℃, fully stir, the rotor speed is controlled at 200~300rpm;

[0032] (3) After (2) the reaction is carried out for 5 minutes, the two solutions in the first step are quickly mixed and added to the reaction system for 1 hour, the temperature is maintained at 80°C, and the rotor speed is controlled at 200 rpm;

[0033] (4) After reacting for 1 hour, add 1.8 mL of TEOS dropwise to the reaction system, react for 1 hour, and keep the temperature...

Embodiment 2

[0044] Select analytically pure sodium selenite, ascorbic acid, cetyltrimethylammonium bromide (CTAB), triethanolamine (TEA), ethyl orthosilicate (TEOS), and synthesize 5% selenium content by this preparation method Nano-scale MSNs. The specific steps are as follows: (1) Firstly, weigh 0.05 g of selenite and 0.4 g of ascorbic acid and add them to 10 mL of deionized water, stir thoroughly to mix them, and set aside for later use;

[0045] (2) Weigh 0.36g CTAB and 0.2g TEA, then add 80mL deionized water, the reaction temperature is 80℃, fully stir, the rotor speed is controlled at 200rpm;

[0046] (3) After (2) the reaction is carried out for 5 minutes, the two solutions in the first step are quickly mixed and added to the reaction system for 1 hour, the temperature is maintained at 80°C, and the rotor speed is controlled at 200 rpm;

[0047] (4) After reacting for 1 hour, add 1.8 mL of TEOS dropwise to the reaction system, react for 1 hour, and keep the temperature at 80°C;

[0048] (...

Embodiment 3

[0051] Select analytically pure sodium selenite, ascorbic acid, cetyltrimethylammonium chloride (CTAC), ammonium fluoride (NH 4 F), Ethyl Orthosilicate (TEOS), by this preparation method, 10% selenium-doped nano-scale MSNs are synthesized. The specific steps are:

[0052] (1) Firstly, weigh 0.1g of selenite and 0.4g of ascorbic acid and add them to 10mL of deionized water, stir well to mix them, and set aside for later use;

[0053] (2) Weigh 0.36g CTAC, 0.6g NH 4 F, then add 80mL deionized water, the reaction temperature is 80℃, fully stir, the rotor speed is controlled at 200rpm;

[0054] (3) After the reaction of (2) is carried out for 5 minutes, the two solutions in the first step are quickly mixed and added to the reaction system for 1 hour, the temperature is kept at 80°C, and the rotor speed is controlled at 200 rpm;

[0055] (4) After reacting for 1 hour, add 1.8 mL of TEOS dropwise to the reaction system, react for 1 hour, and keep the temperature at 80°C;

[0056] (5) Centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com