Patents

Literature

75results about How to "Reasonable strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

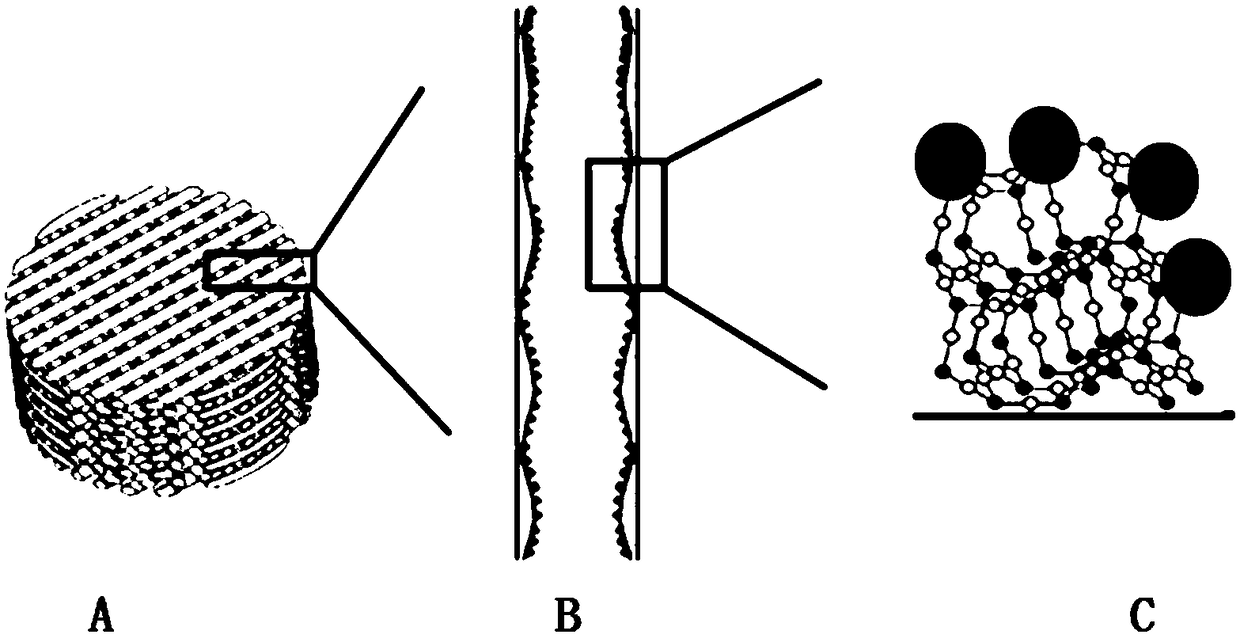

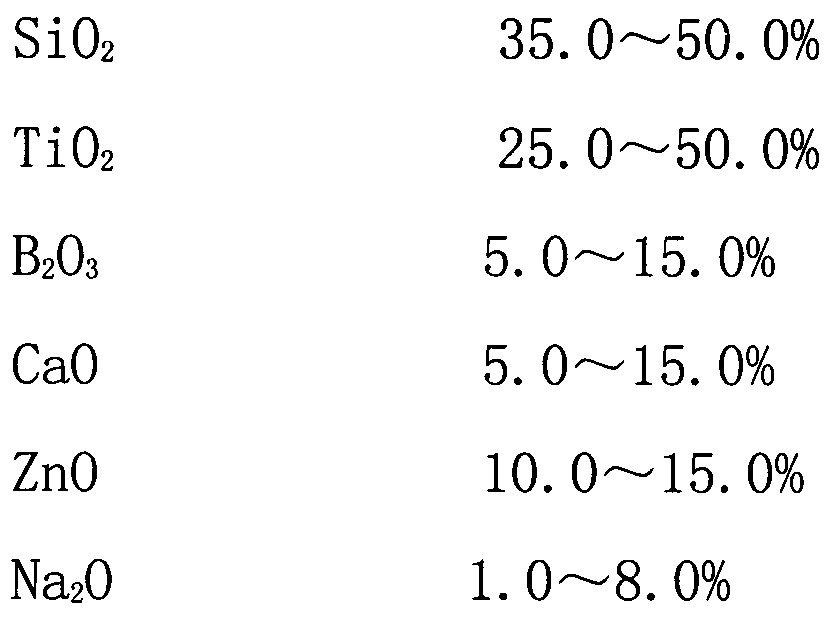

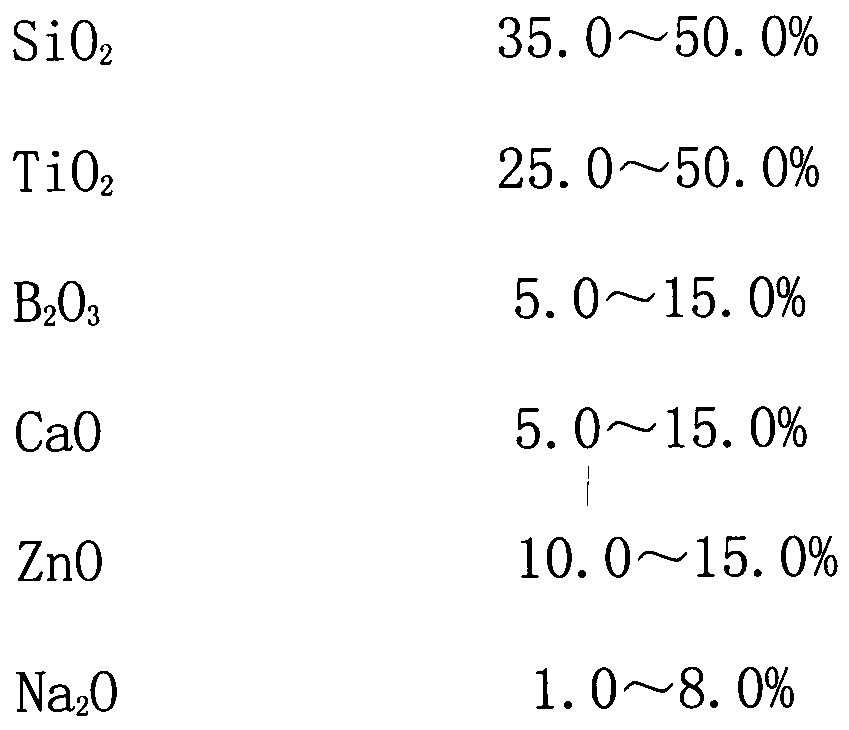

Catalytic cracking co-catalyst for producing diesel oil and its preparing method

InactiveCN1683474AReasonable hole structureReasonable strengthCatalytic crackingIn situ crystallizationSodium oxide

The catalytic cracking co-catalyst for increasing diesel oil yield is prepared through roasting kaolin at over 900 deg.c for in-situ crystallization. The co-catalyst contains type-Y zeolite in 5-20 wt%, as well as magnesia 0.5-3 wt%, RE oxide 0.5-5 wt%, and sodium oxide less than 0.6 wt%, and the zeolite has Si / Al ratio of 4.0-6.0. Adding certain amount of the catalytic cracking co-catalyst without altering the main catalyst in the oil refining apparatus can raise diesel oil yield of FCC catalyzed apparatus, improve product distribution, raise available catalyst utilization, and improve the activity stability of the catalyst system and heavy metal resistance.

Owner:PETROCHINA CO LTD

Ti microalloyed ultra-fine grain hot rolled steel at 700MPa class and production method thereof

InactiveCN101525717AAvoid consumptionAdjust cooling rateTemperature control deviceChemical compositionAbsorbed energy

The invention belongs to the technical field of high-strength weathering steel production, in particular discloses a Ti microalloyed ultra-fine grain hot rolled steel of 700MPa class and a production method thereof. The method utilizes the thin-slab continuous casting and rolling process to further perfect rolling and cooling control aspects by the readjustment of chemical compositions, is combined with the suitable control of grain ultrafining and TiC precipitation strengthening action, comprehensively improves the impact property and particularly improves the low-temperature impact toughness. The invention truly and reasonably matches with the strength and the toughness of the prior high-strength steel of 700MPa class, and the combination properties comprise: the yield strength is larger than or equal to 700 MPa, the tensile strength is larger than or equal to 750 MPa, the specific elongation is larger than or equal to 14 percent, and the impact absorbing energy Akv of a semi-size specimen (5*10*55mm) at 20 DEG C below zero is larger than or equal to 33 J. The production method enables the hot rolled steel to have high strength and high toughness and widens the range of practical application of the high-strength steel of 700MPa class.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

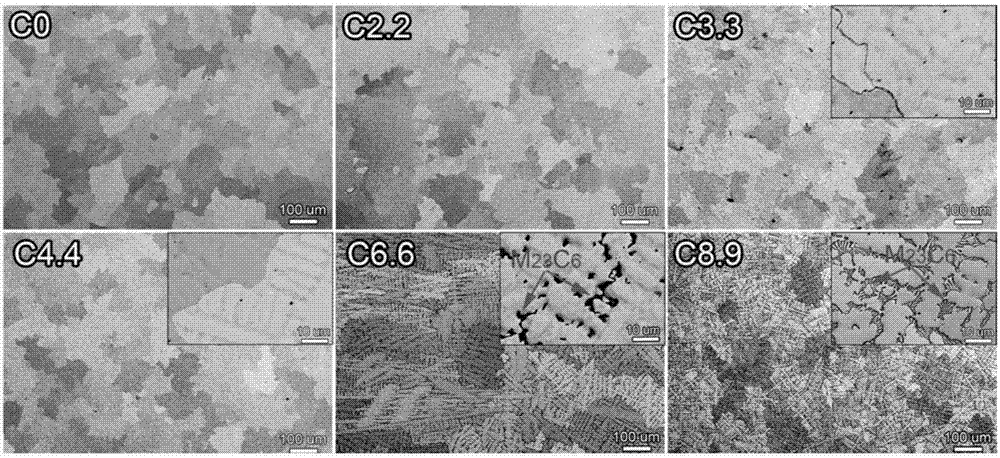

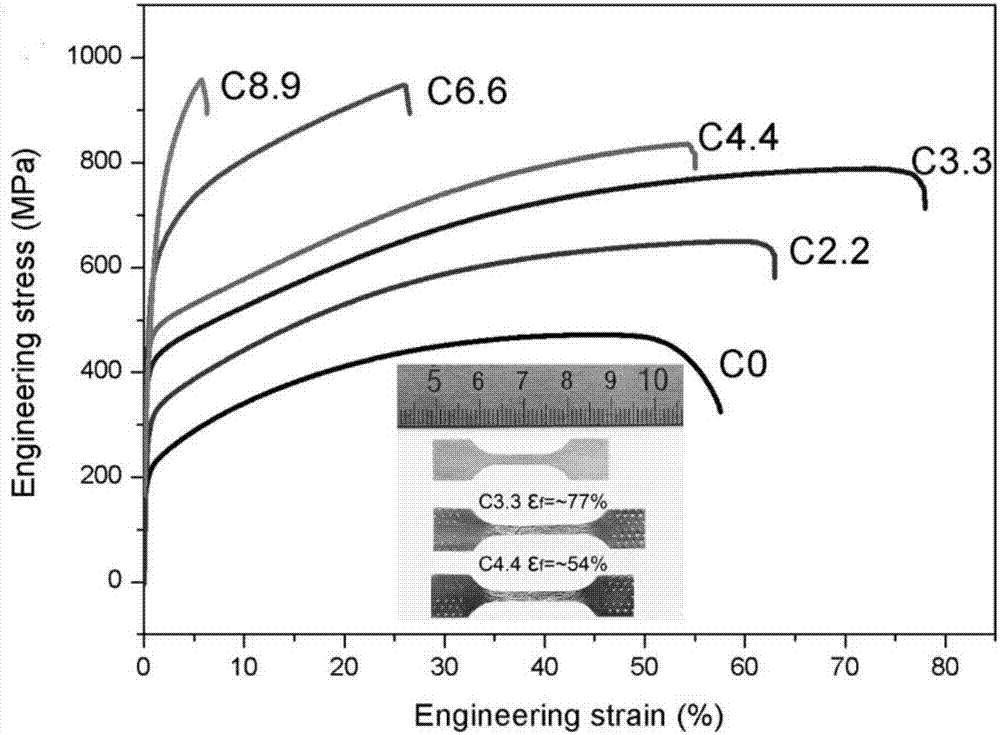

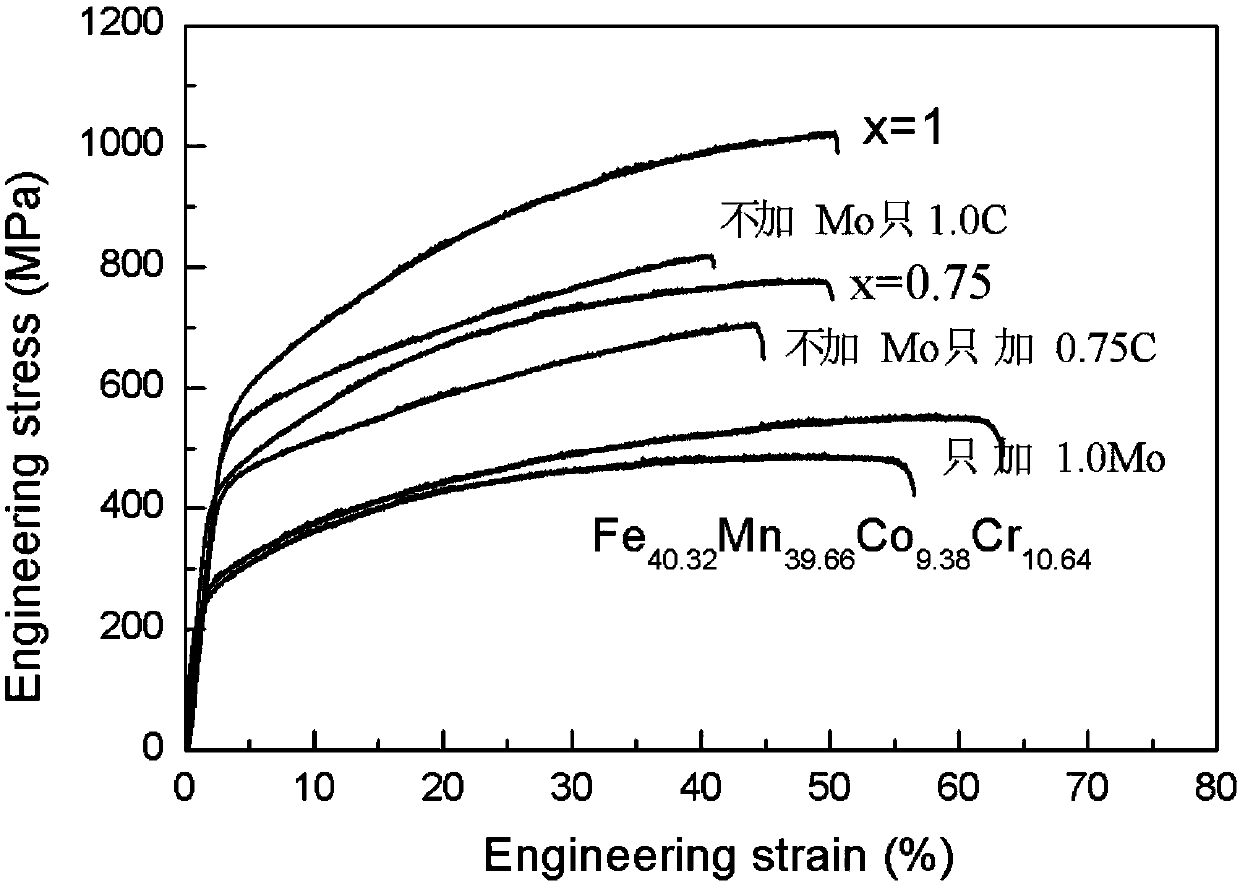

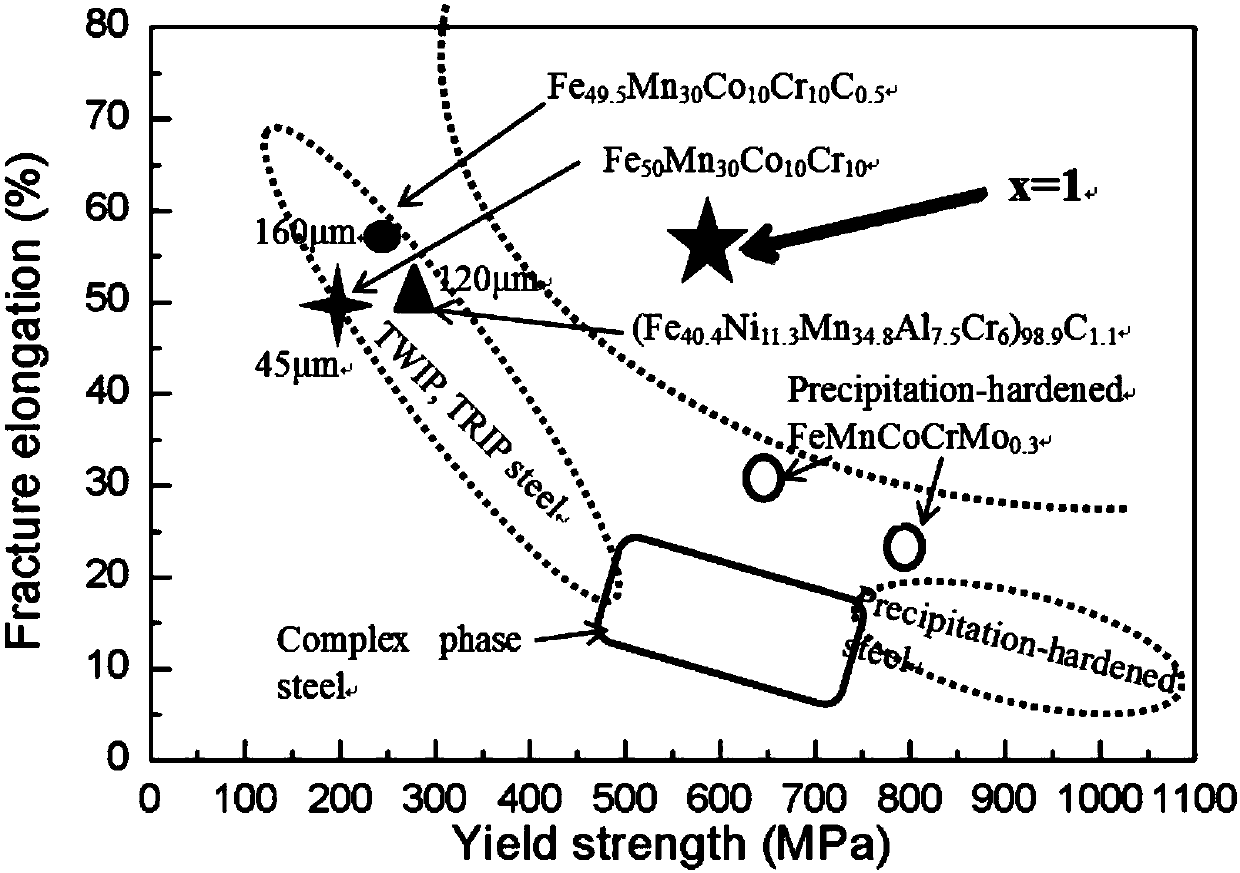

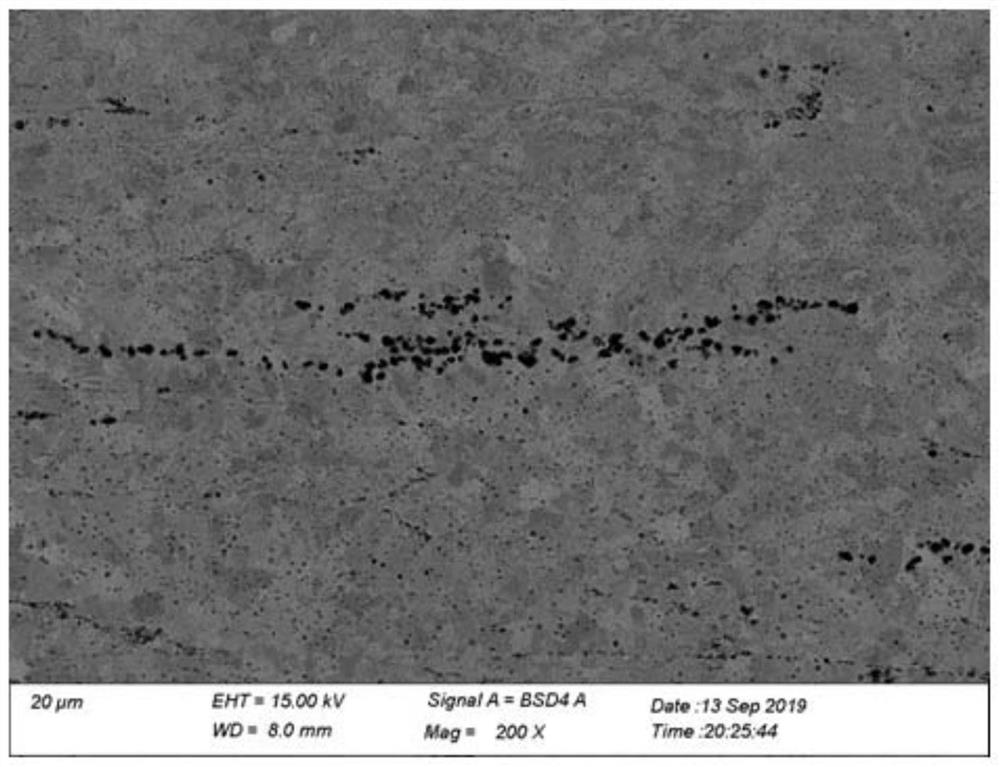

High-performance high-entropy alloy and processing method thereof

The invention discloses a high-performance high-entropy alloy and a processing method thereof. Certain content of an element carbon is added into a Fe40Mn40Co10Cr10 alloy to form an interstitial solid solution with a basal body, so that stacking fault energy of the material can be effectively reduced, twin crystals can be induced under the room-temperature condition, and extra strength increment is provided for the basal body by performing solid solution and separating carbides through the element carbon. The element carbon is used as a good interstitial atom and the carbide is used as an effective precipitation strength phase; heat preservation is performed for a relatively long time at a relatively high temperature in the last step, an as-forged microstructure is partly or completely eliminated, and part of the precipitated phase is dissolved to form a nearly single phase structure, so that the alloy has relatively great performance controllable space again on the basis of higher performance level, further strengthening is favorably performed through other strengthening ways such as deformation strengthening and precipitation strengthening to obtain more reasonable strength and plasticity match; and moreover, content of overall alloy elements is reasonable, cost is low, and economical efficiency is relatively strong.

Owner:深圳市卡德姆科技有限公司

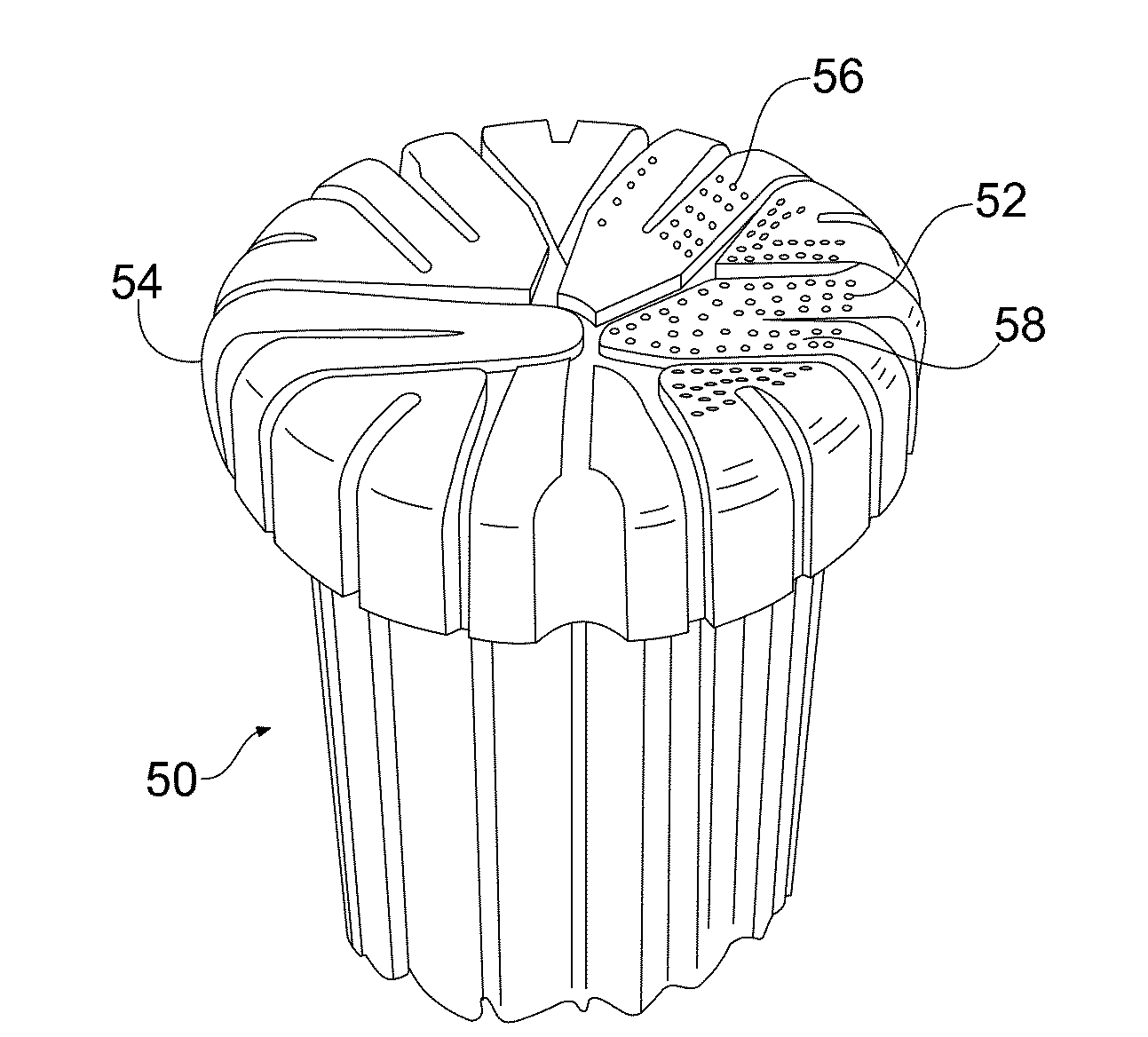

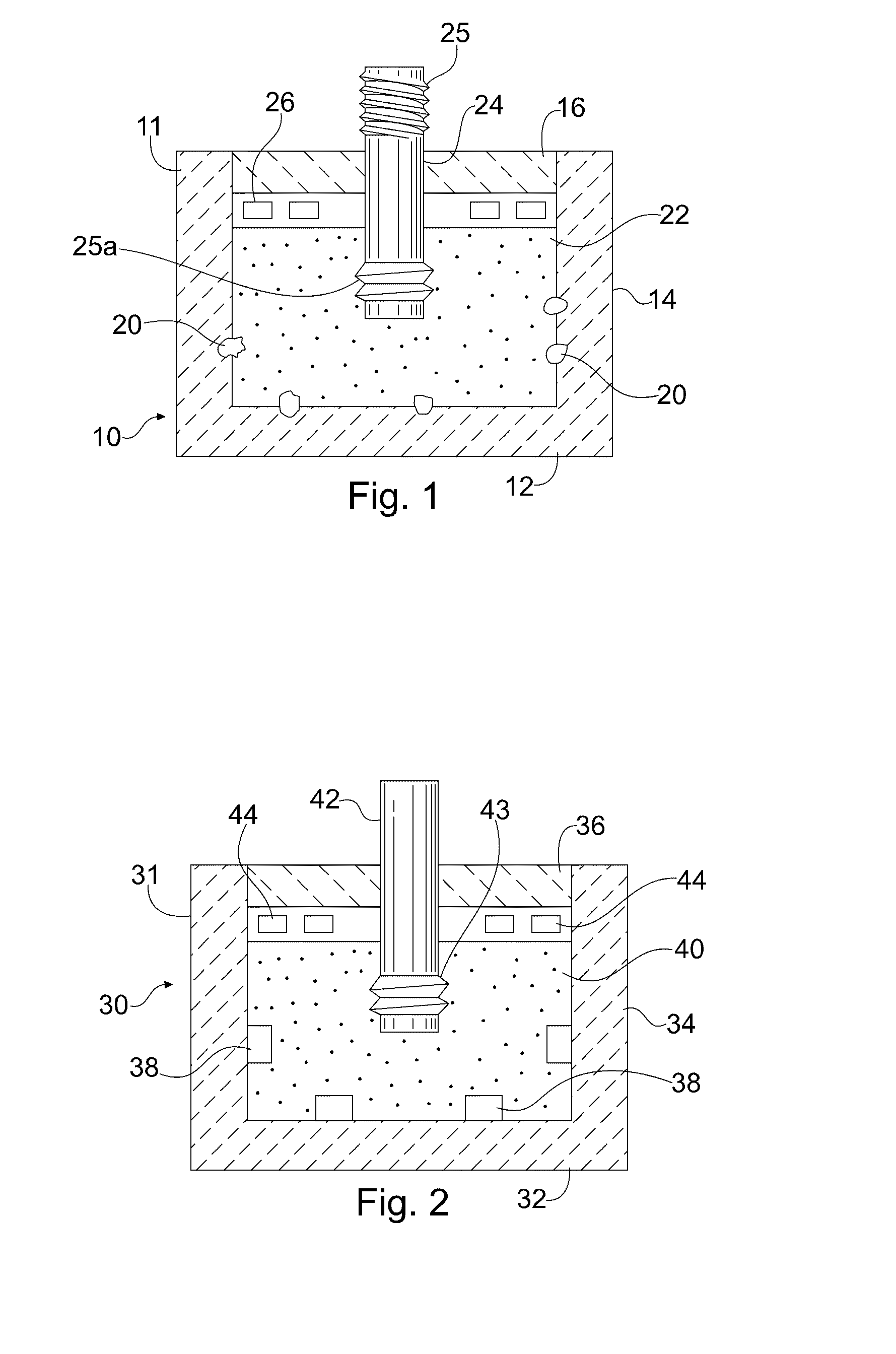

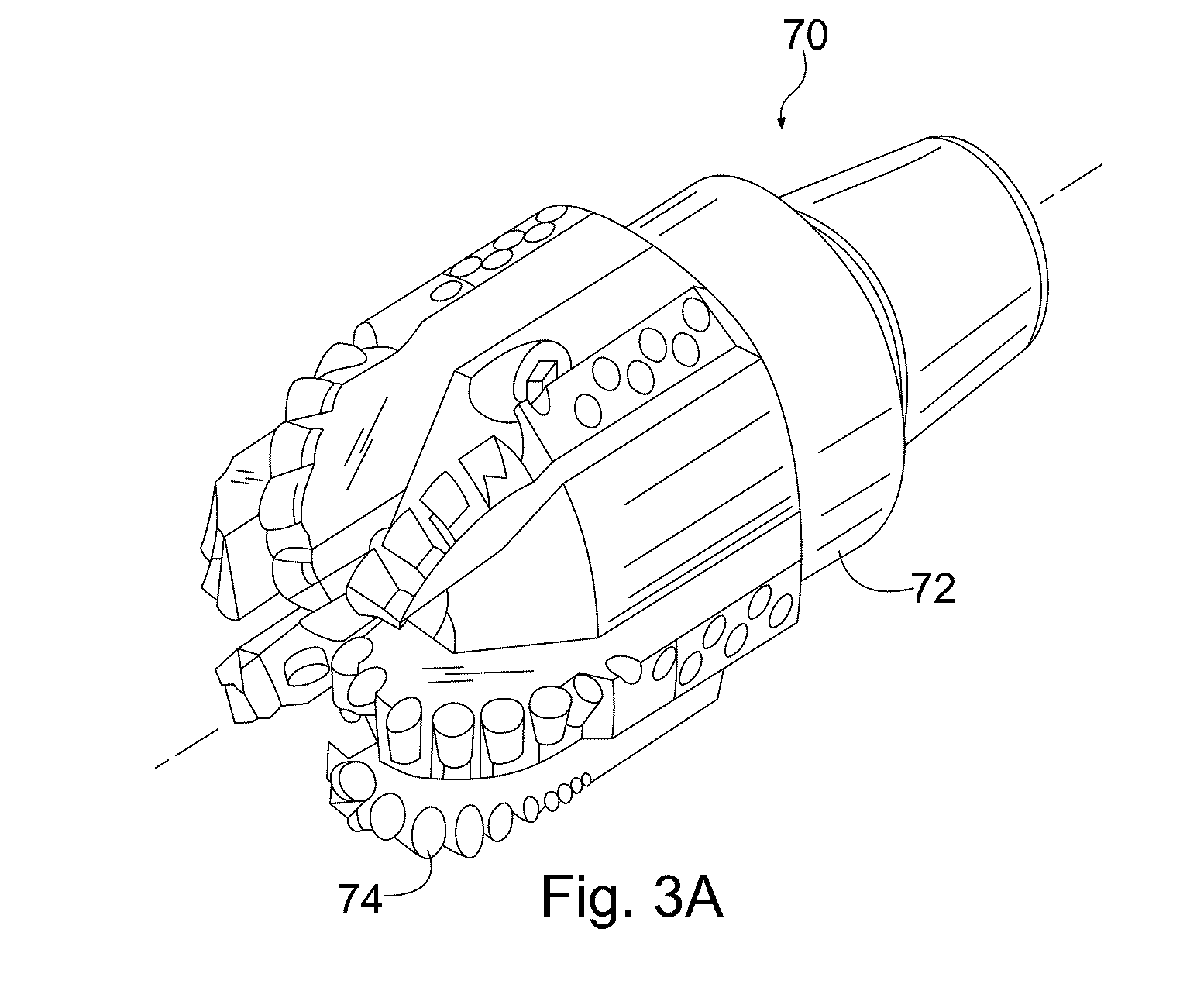

Erosion Resistant Subterranean Drill Bits Having Infiltrated Metal Matrix Bodies

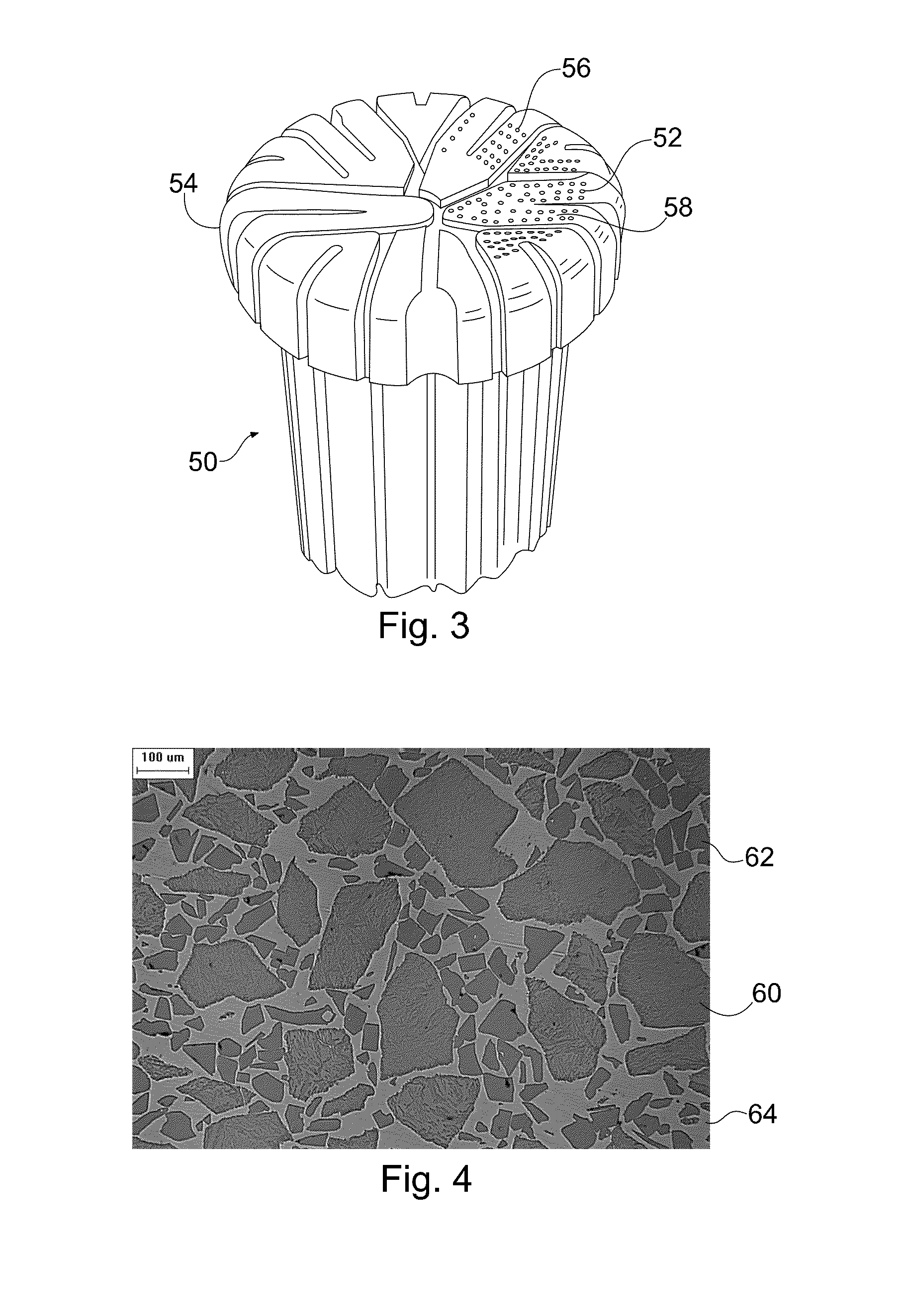

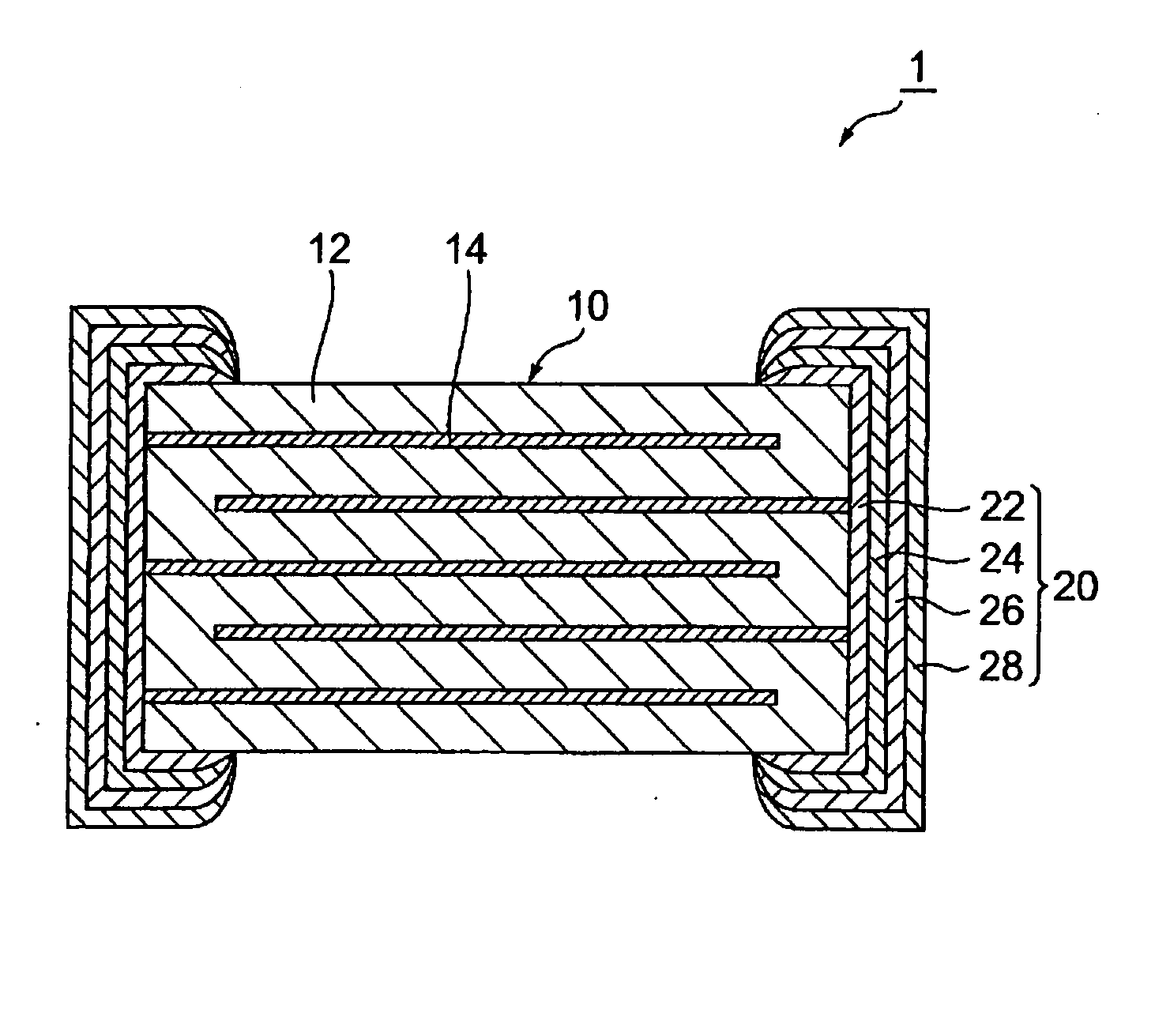

ActiveUS20100320004A1Improve thermal stabilityReasonable strengthDrill bitsOther manufacturing equipments/toolsPowder mixtureThermal stability

Subterranean drill bits having good erosion resistance, strength, toughness, and thermal stability are disclosed. The drill bits comprise a bit body carrying at least one cutting element and having an infiltrated metal matrix. The infiltrated metal matrix comprises a matrix powder composition bound together by an infiltrant. The matrix powder mixture includes cast tungsten carbide powder having a particle size of −30 (600 micron) +140 mesh (106 micron), a second component powder consisting of one or more other types of tungsten carbide particles, and a metal powder.

Owner:KENNAMETAL INC

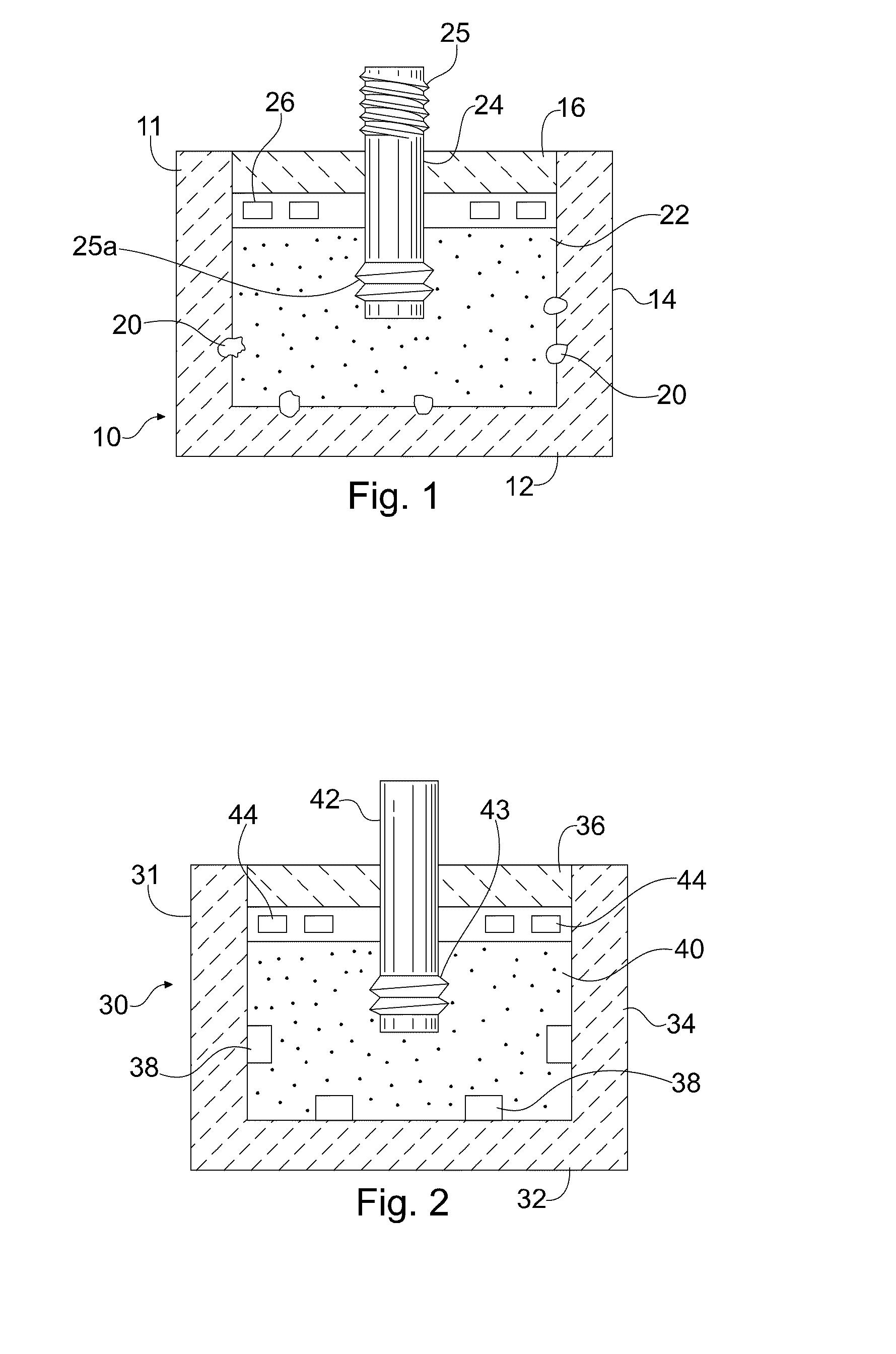

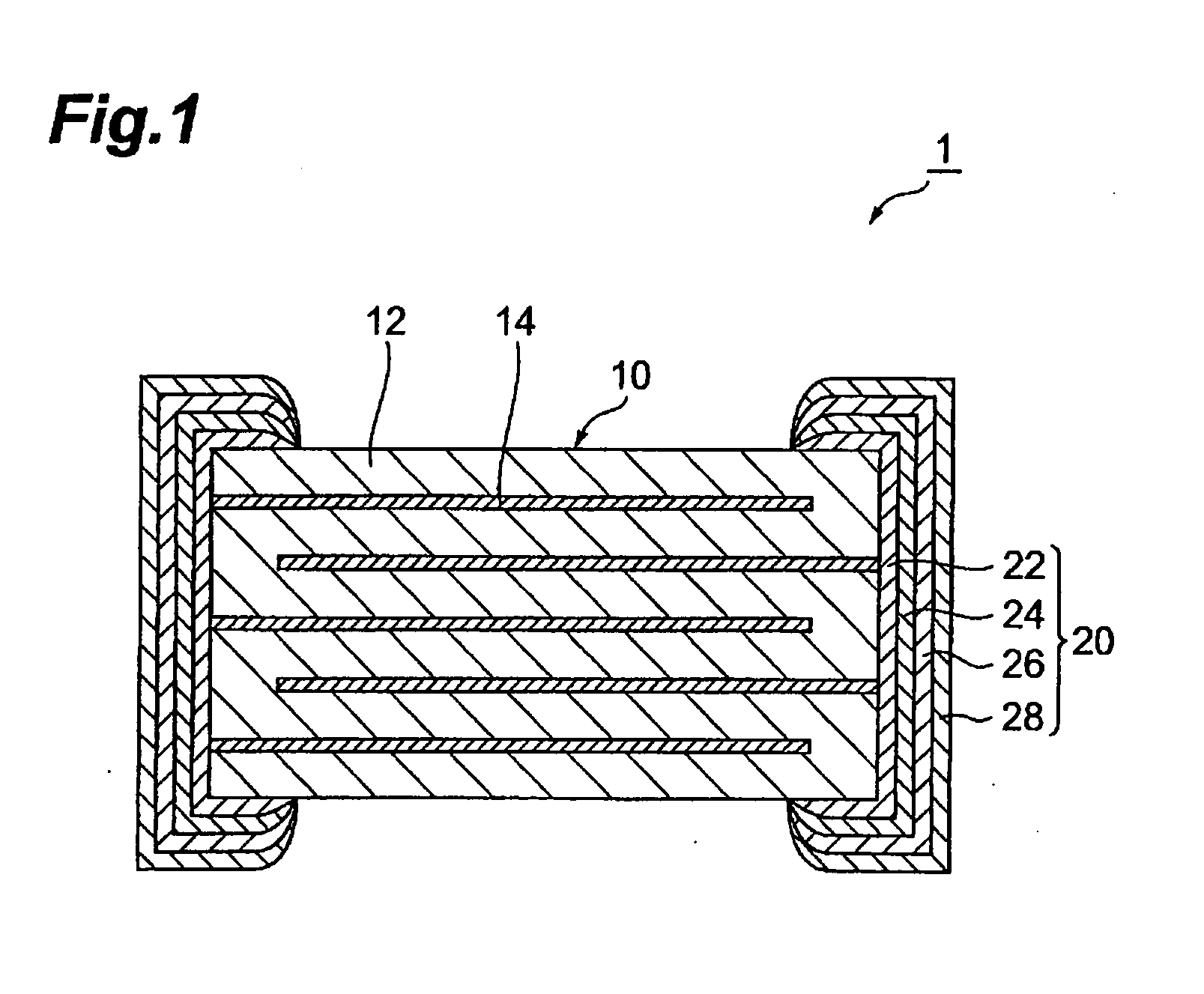

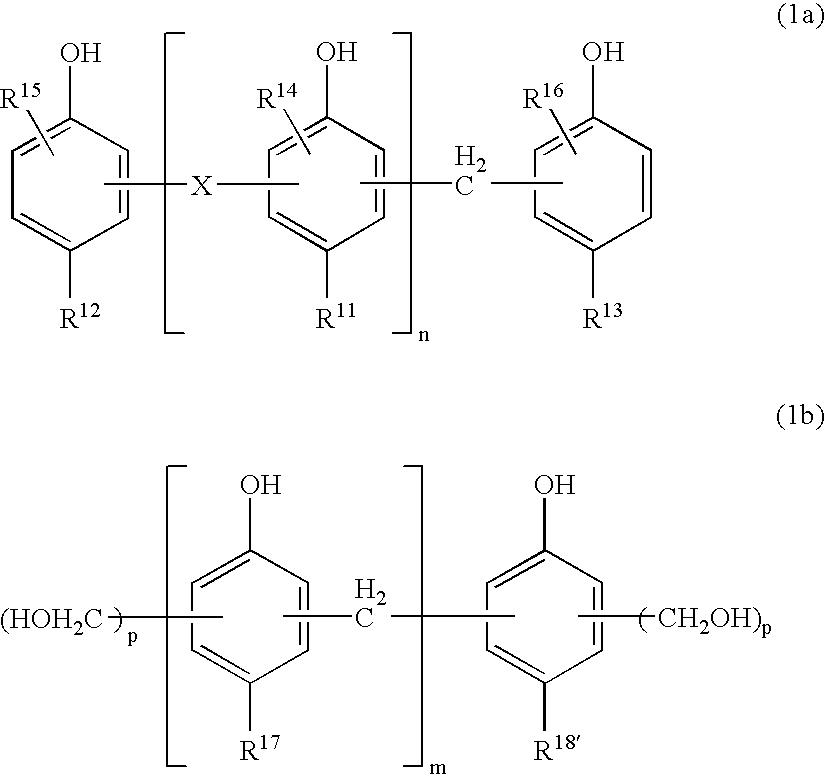

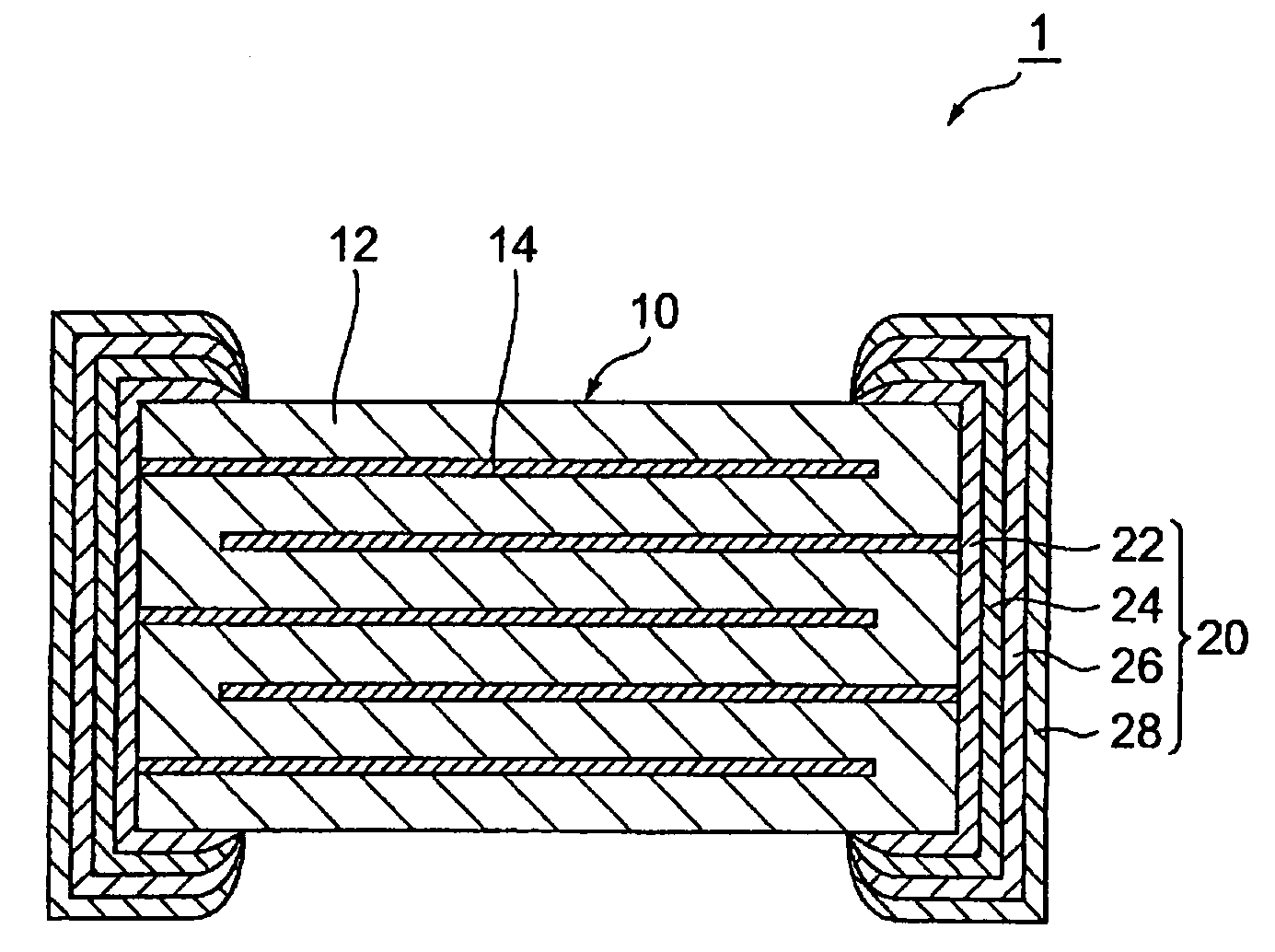

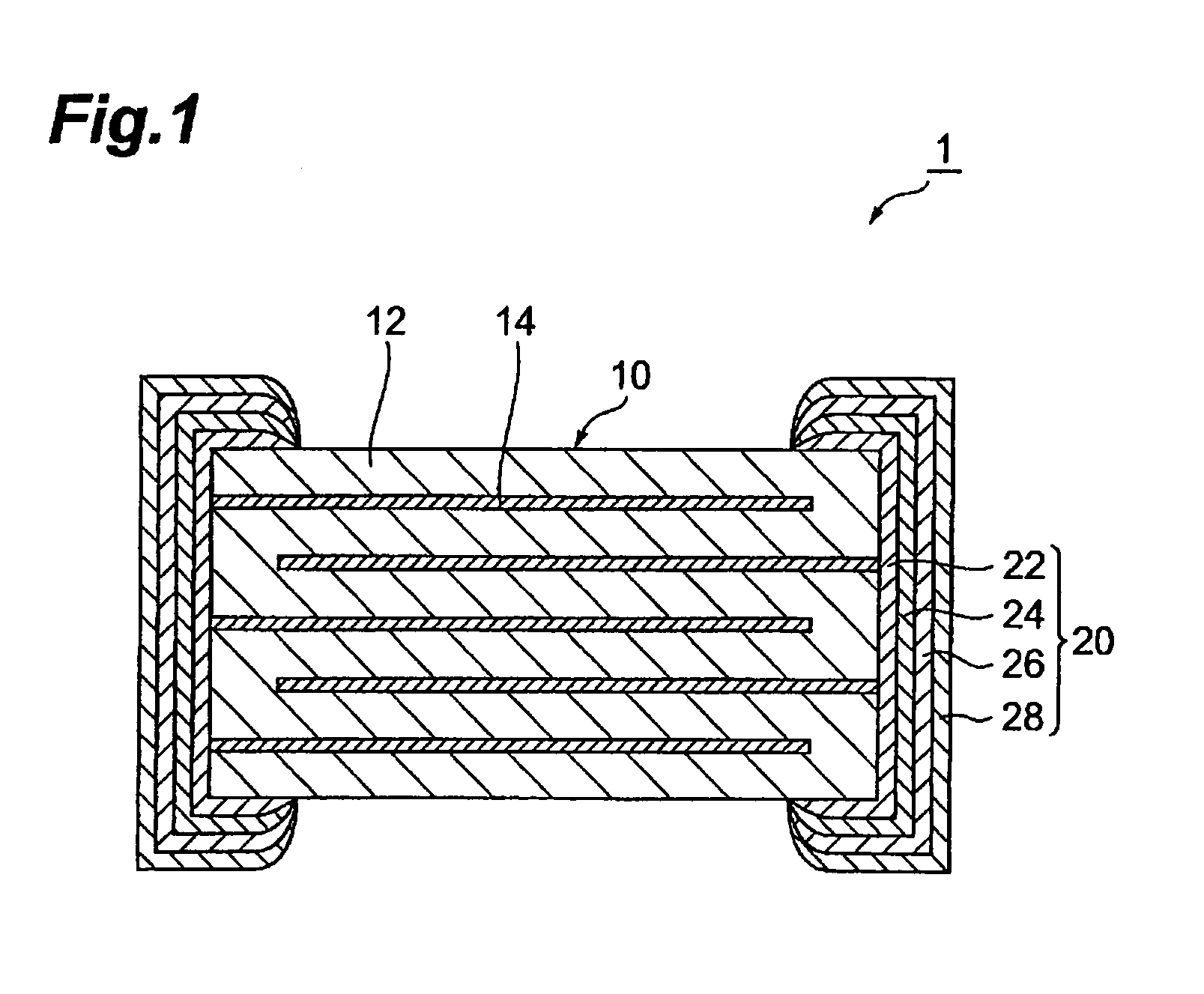

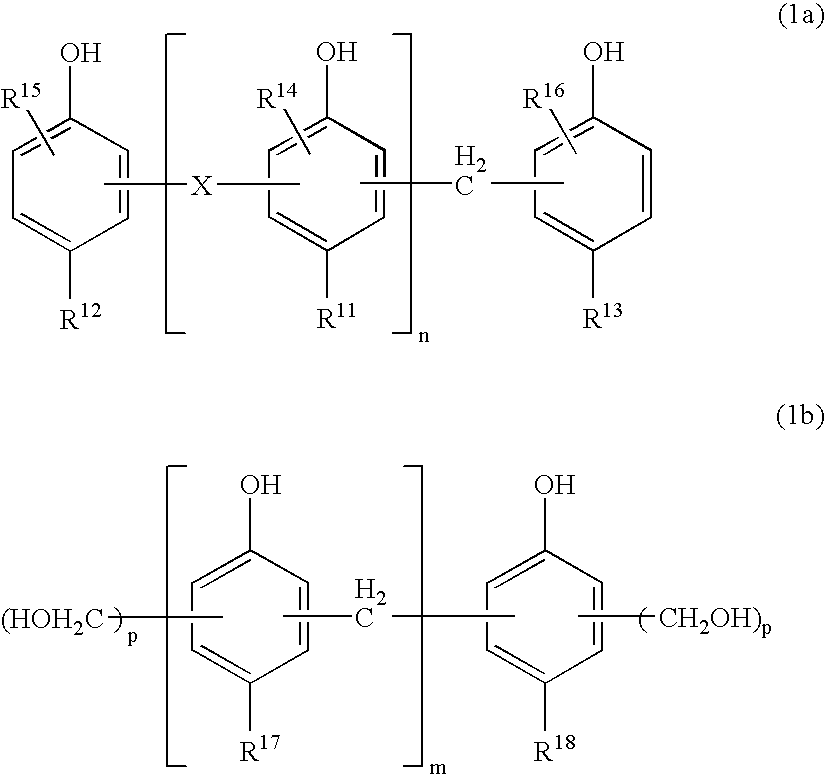

Electronic component

ActiveUS20070201183A1Reduce crosslink densityRelaxation stressPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor electrodesSide chainCeramic capacitor

The present invention aims to provide an electronic component capable of reducing the occurrence of cracks at the joining portion to a board etc. A capacitor 1 (laminated ceramic capacitor) being one example of the electronic component is provided with an element assembly 10 (ceramic) and a pair of external electrodes 20 formed on both side surfaces of the element assembly 10. In the element assembly 10, a dielectric layer 12 and an internal electrode 14 are laminated alternately. The external electrode 20 has such constitution that a first electrode layer connected with the internal electrode, a second electrode layer (electroconductive resin layer) including a hardened product of thermohardening resin containing a polyphenol compound having a side chain composed of an aliphatic group, a third electrode layer composed of Ni and a fourth electrode layer composed of Sn are formed in this order from the element assembly side.

Owner:TDK CORPARATION

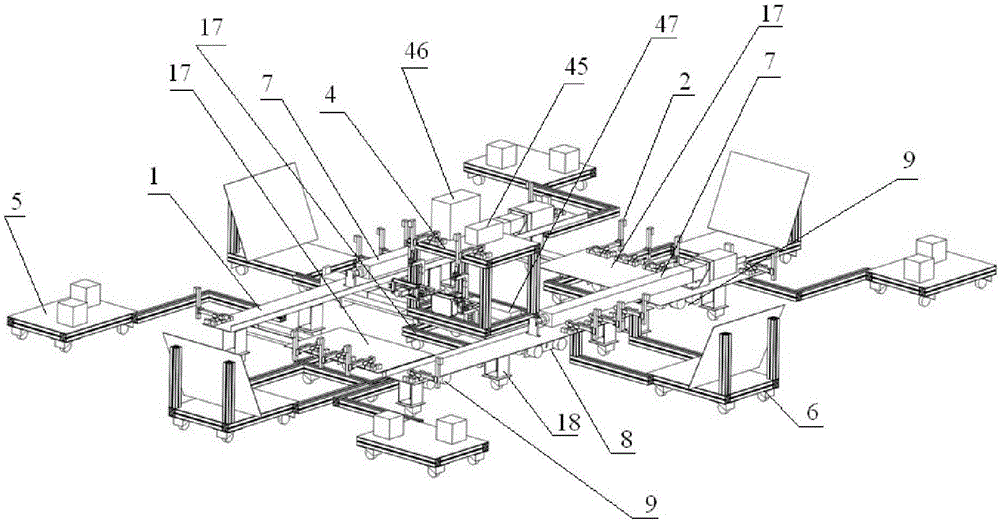

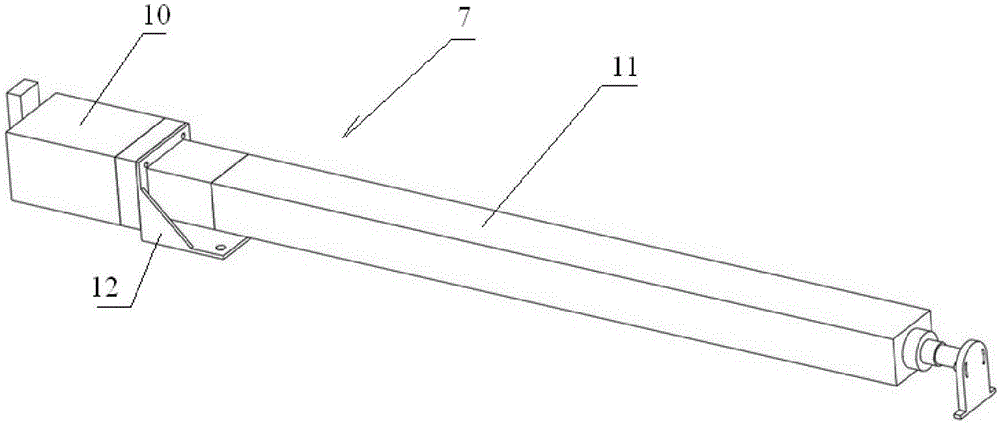

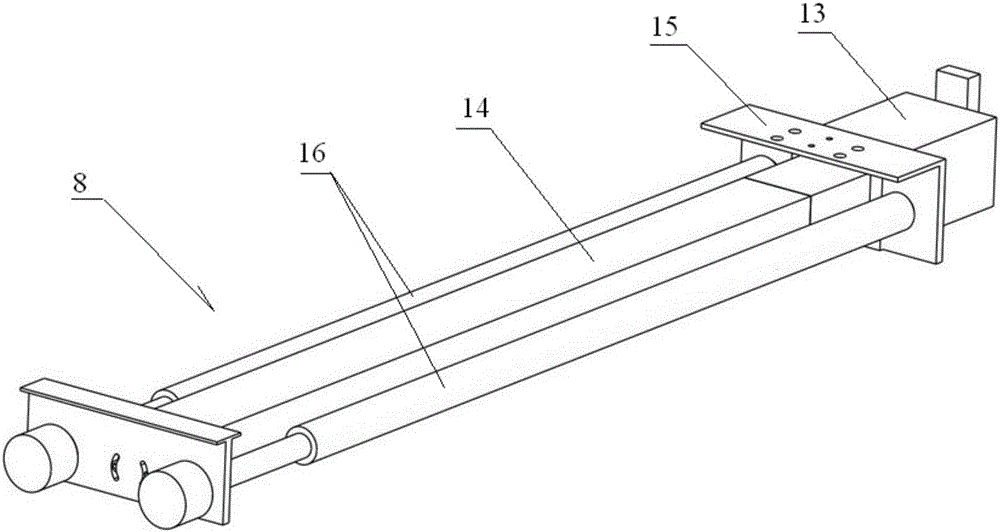

Intelligent electric car testing bench used for environment sensing configuration and testing

InactiveCN106092177ARealize CalibrationAchieve optimizationVehicle testingLoop designCorrelation test

The invention discloses an intelligent electric car testing bench used for environment sensing configuration and testing. The intelligent electric car testing bench comprises a frame body, three-axis moving assemblies, three-axis rotating assemblies, environment sensors, a middle sensing support, three-dimensional calibration assemblies and two-dimensional calibration assemblies, wherein the plurality of three-axis moving assemblies are arranged on the frame body, the middle sensing support is arranged on the middle part of the frame body, the middle sensing support is also provided with a plurality of three-axis moving assemblies, the three-axis rotating assemblies are arranged on the three-axis moving assemblies, the environment sensors are arranged on the three-axis rotating assemblies, and the three-dimensional calibration assemblies and the two-dimensional calibration assemblies are corresponding to the environment sensors. The intelligent electric car testing bench has the advantages that on-loop design of calibration and configuration schemes and related testing of vehicle environment sensors can be realized on expected vehicle types; data of the environment sensors under different calibration or configuration schemes is stored, and the calibration content under a plurality of conditions are further completed; in addition, the cost is lowered, the efficiency is improved, the materials corresponding to parts are reasonably selected, and the service lifetime is long.

Owner:JILIN UNIV

Electronic component

ActiveUS7505249B2Reduce generationReduce crosslink densityPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor electrodesSide chainCeramic capacitor

Owner:TDK CORPARATION

Erosion resistant subterranean drill bits having infiltrated metal matrix bodies

ActiveUS8016057B2Improve corrosion resistanceReasonable strengthDrill bitsOther manufacturing equipments/toolsPowder mixtureThermal stability

Subterranean drill bits having good erosion resistance, strength, toughness, and thermal stability are disclosed. The drill bits comprise a bit body carrying at least one cutting element and having an infiltrated metal matrix. The infiltrated metal matrix comprises a matrix powder composition bound together by an infiltrant. The matrix powder mixture includes cast tungsten carbide powder having a particle size of −30 (600 micron) +140 mesh (106 micron), a second component powder consisting of one or more other types of tungsten carbide particles, and a metal powder.

Owner:KENNAMETAL INC

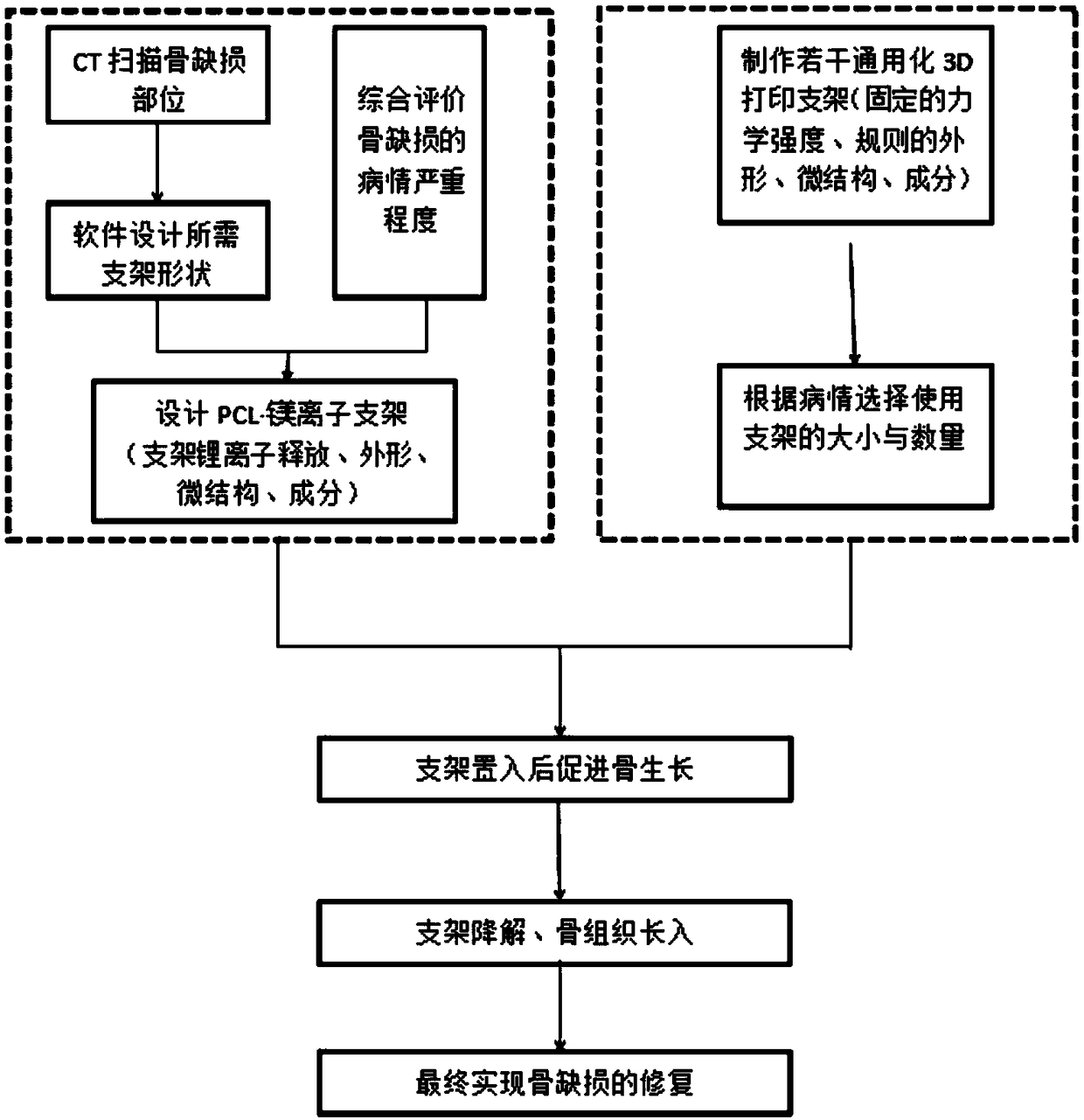

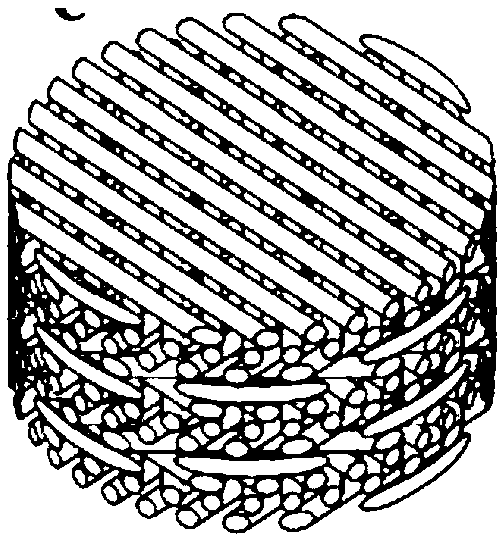

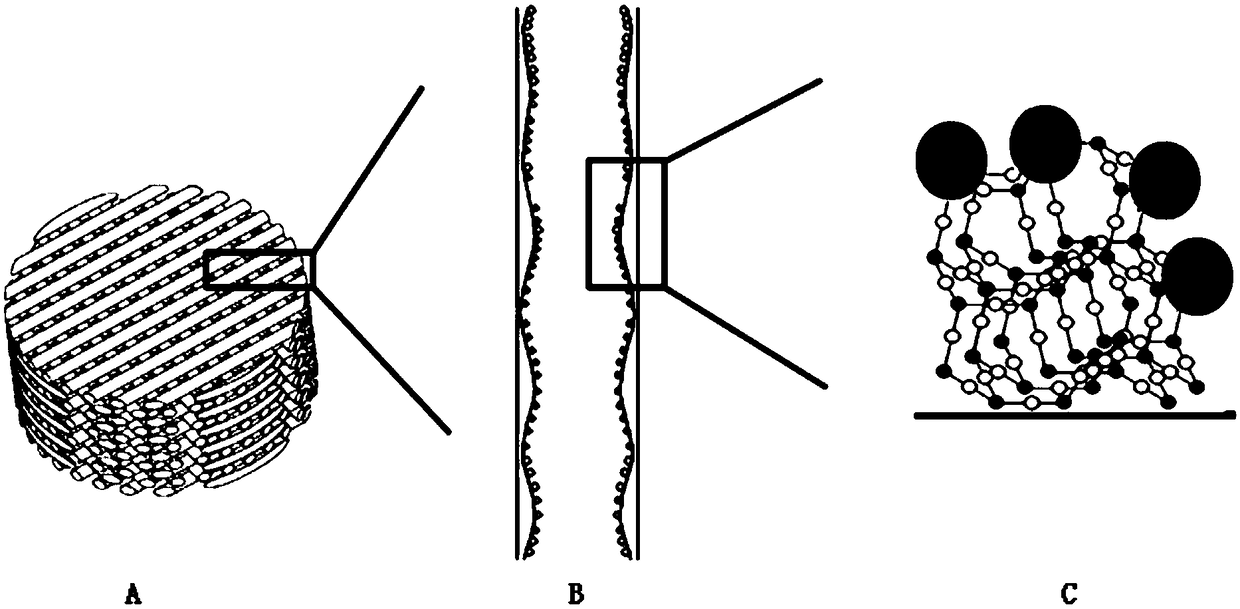

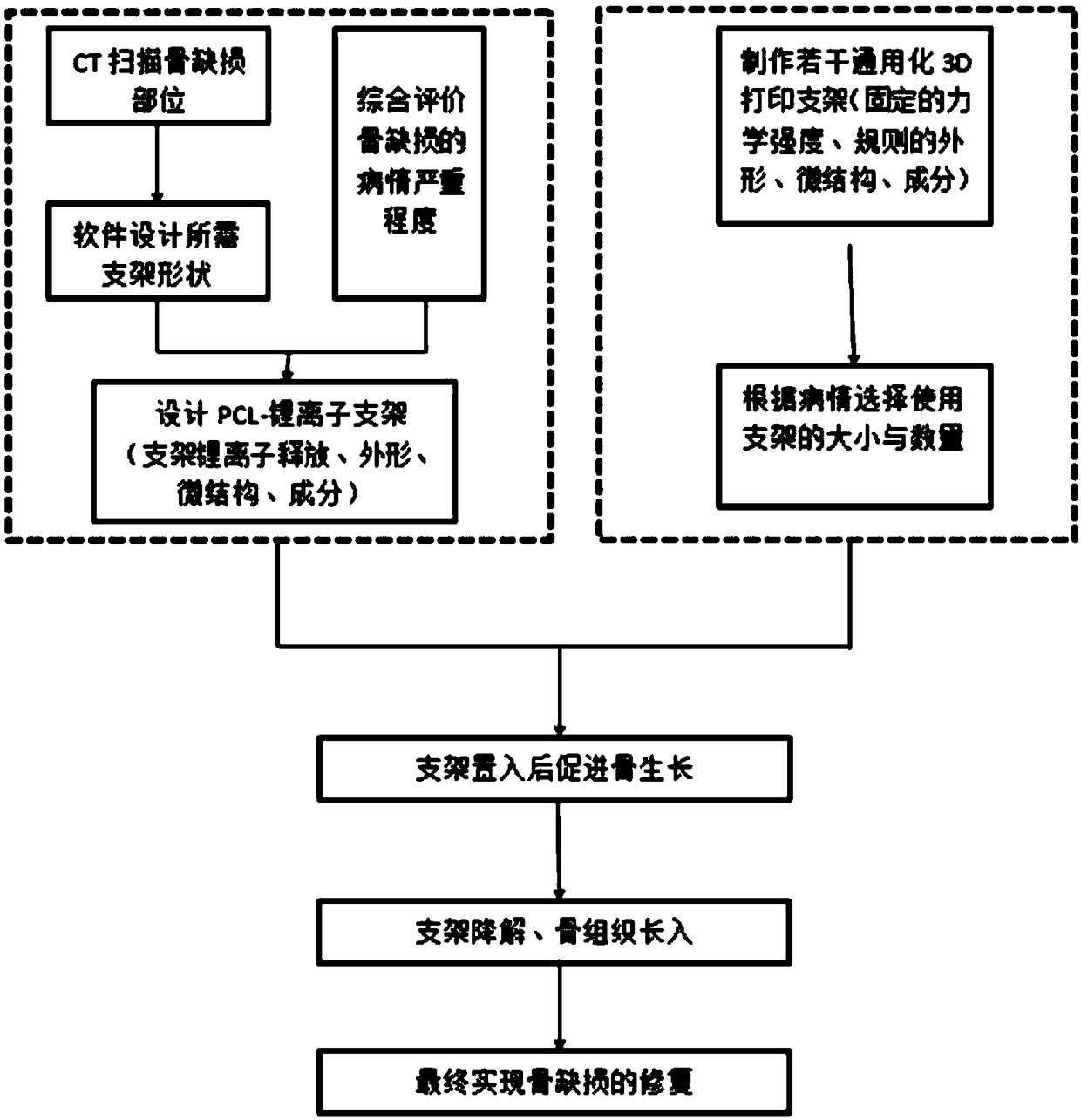

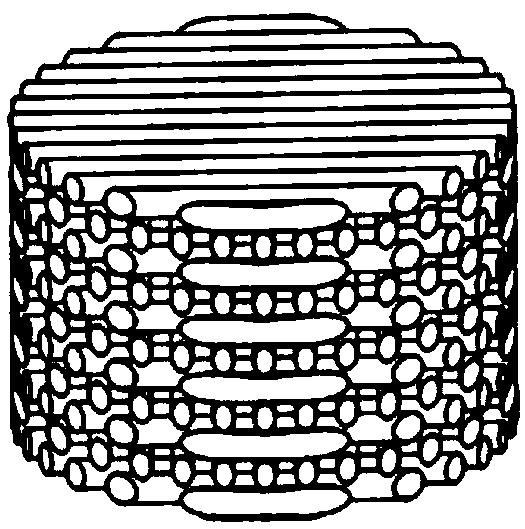

3D printed PCL-Mg bone tissue engineering scaffold and preparation method thereof

InactiveCN108939164AAdjustable loadReasonable strengthAdditive manufacturing apparatusTissue regenerationBone ingrowthMechanical property

The invention discloses a 3D printed PCL-Mg bone tissue engineering scaffold and a preparation method thereof. The 3D printed PCL-Mg bone tissue engineering scaffold is prepared from poly-epsilon-caprolactone PCL and magnesium chloride as raw materials through a 3D printing technology. After being implanted into the human body, PCL as a bioabsorbable material is gradually degraded and releases Mgto promote osteochondral generation. The porous structure of the scaffold can induce bone ingrowth and finally repair bone defects, tumors and bone defects after infection. The 3D printed PCL-Mg bonetissue engineering scaffold has the advantages of simple and reliable structure, controllable shape and microstructure, reliable mechanical property, controllable ion release performance, convenient implantation, small trauma and low cost.

Owner:南京冬尚生物科技有限公司

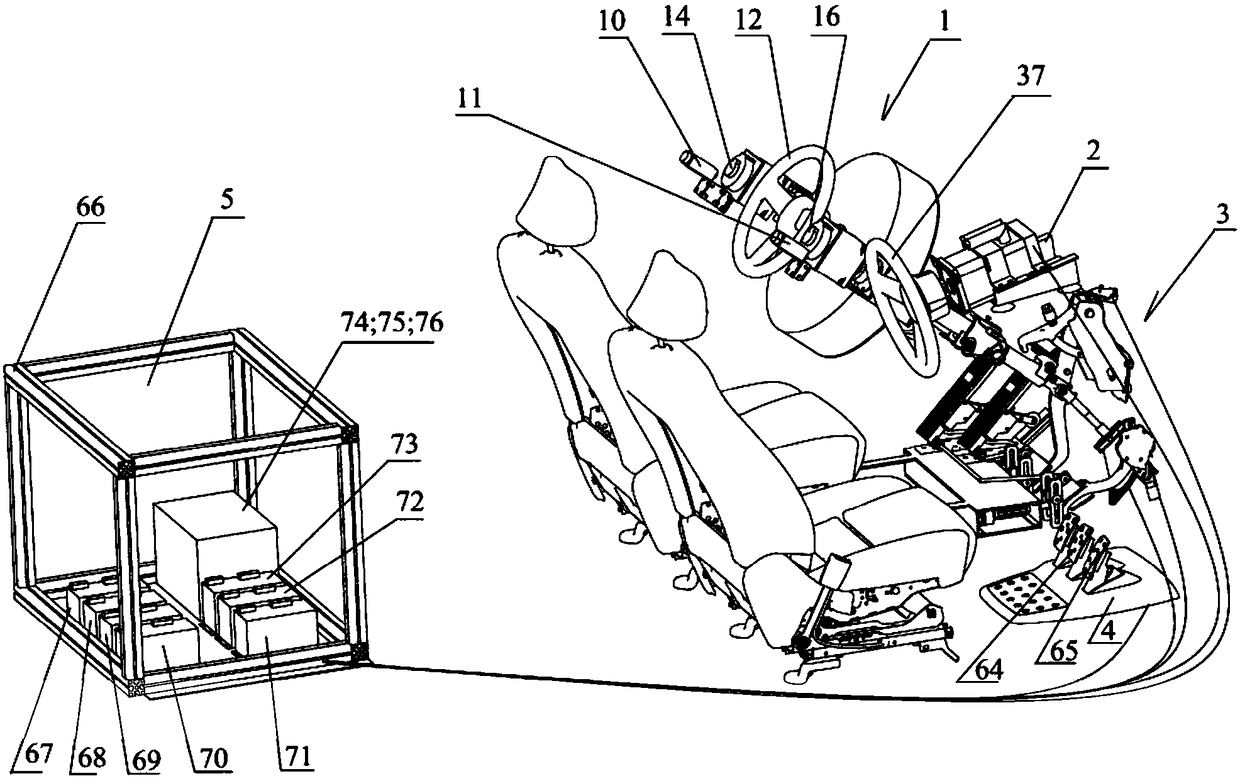

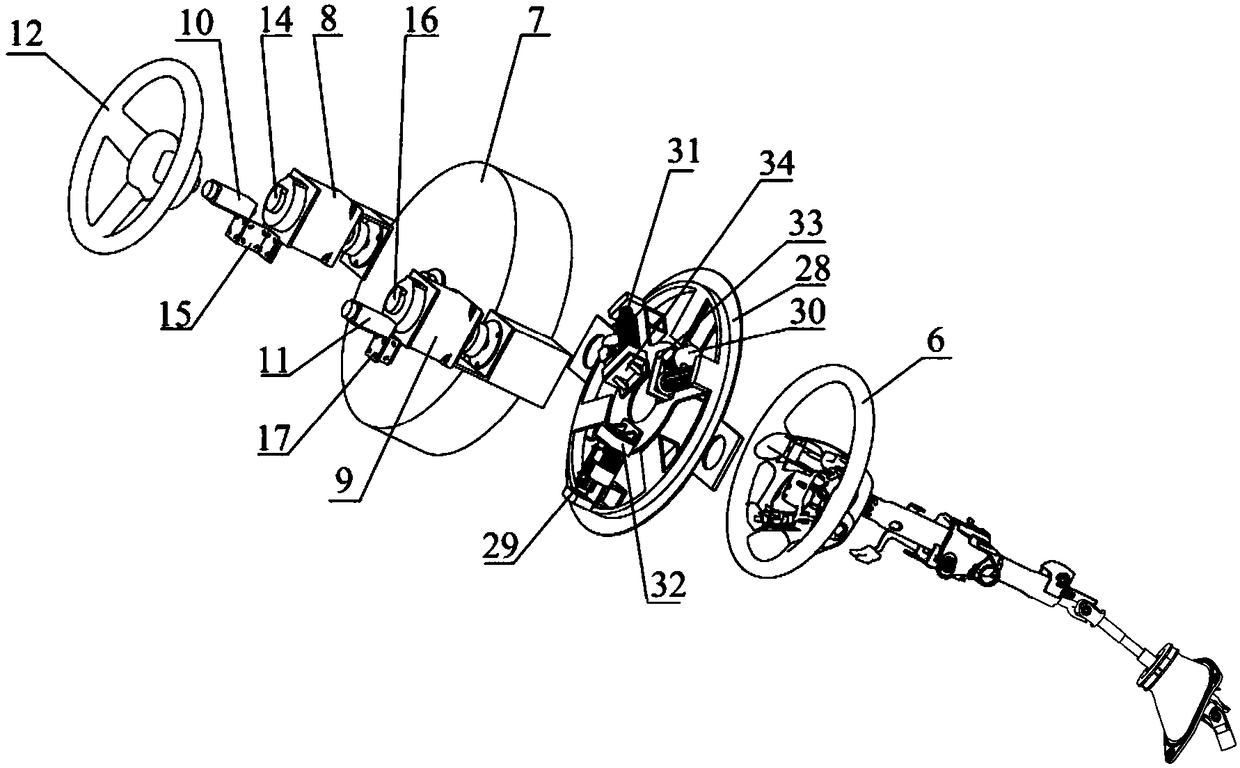

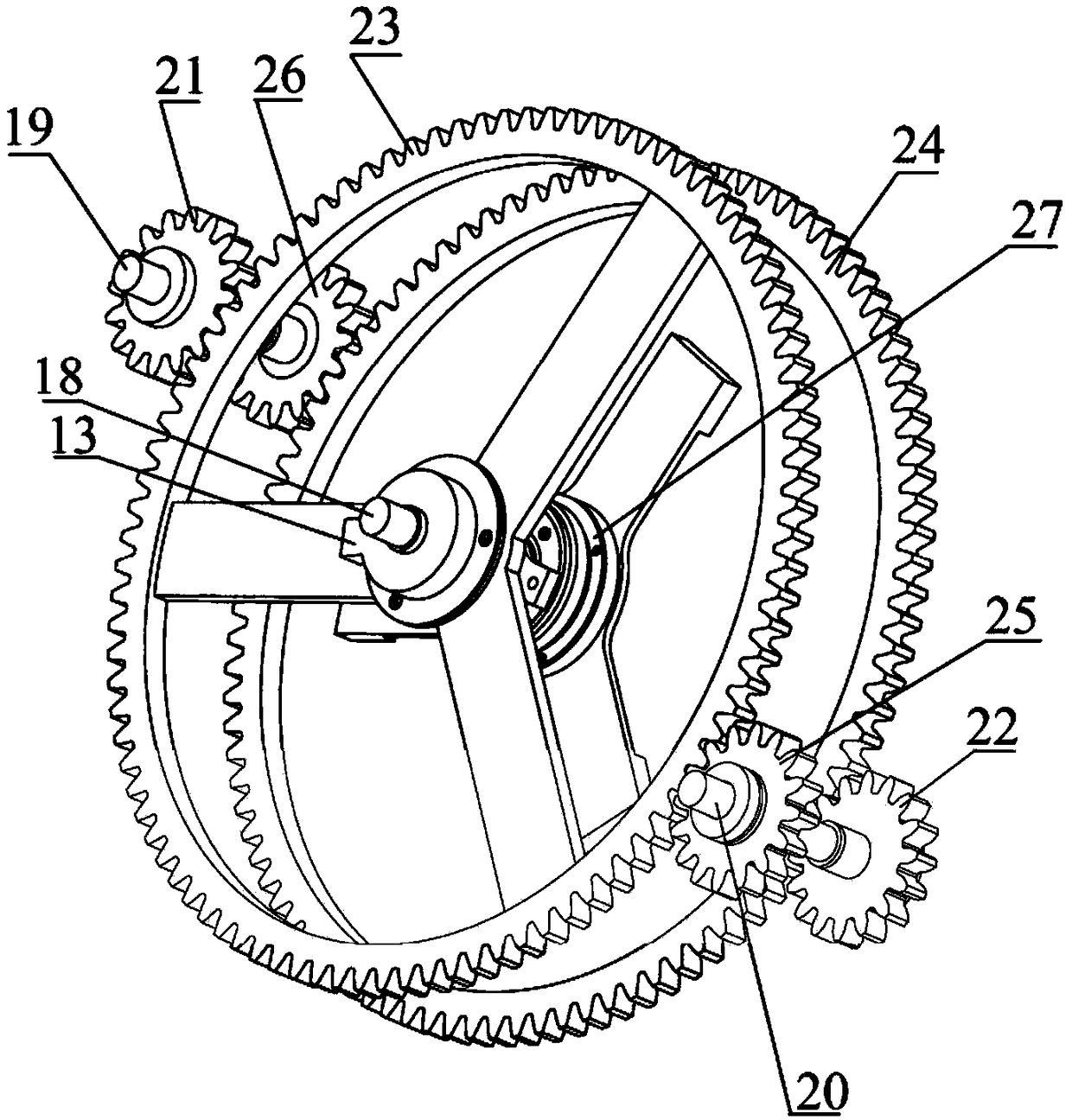

Vehicle-mounted external driving robot for man-machine co-driving and unmanned driving technology and test

ActiveCN108572576AEasy to controlRealize co-pilot assistance functionVehicle testingProgramme control in sequence/logic controllersControl systemMan machine

The invention discloses a vehicle-mounted external driving robot for a man-machine co-driving and unmanned driving technology and test. The vehicle-mounted external driving robot comprises a primary driving steering assembly, a secondary driving steering assembly, a primary driving pedal assembly, a secondary driving pedal assembly and a control system assembly, wherein the primary driving steering assembly is assembled on the steering system of an original vehicle, and is coaxial with the original steering system the original vehicle to transmit; the secondary driving steering assembly is arranged at one side of the primary driving steering assembly; the primary driving steering assembly is horizontally placed on primary driving floor of the original vehicle, and is in bolt connection with a primary driving seat of the original vehicle; the primary driving pedal assembly is in fastening connection with a pedal system of the original vehicle; and the primary driving steering assembly,the secondary driving steering assembly, the primary driving pedal assembly and the secondary driving pedal assembly are connected with the control system, and are controlled by the control system assembly to work. The vehicle-mounted external driving robot has the beneficial effects of greatly reducing real vehicle test cost and improving efficiency; and the part corresponding material selectionis reasonable, and the service life is relatively long.

Owner:JILIN UNIV

3D printed PCL-Li bone tissue engineering scaffold, and preparation method thereof

InactiveCN108926742AAdjustable loadReasonable strengthAdditive manufacturing apparatusTissue regenerationBone ingrowthBone tissue engineering

The invention discloses a 3D printed PCL-Li bone tissue engineering scaffold, and a preparation method thereof. According to the preparation method, epsilon-caprolactone PCL and lithium chloride are taken as raw materials of the 3D printed PCL-Li bone tissue engineering scaffold, 3D printing technology is adopted to prepare the 3D printed PCL-Li bone tissue engineering scaffold. After of implantation of the 3D printed PCL-Li bone tissue engineering scaffold into human body, PCL is degraded gradually as a biologically absorbable material, Li is released to promote osteochondral osteogenesis; and in addition, a porous structure of the 3D printed PCL-Li bone tissue engineering scaffold is capable of inducing bone ingrowth, and repairing of bone defects caused by bone wound, tumor, and infection can be realized. The 3D printed PCL-Li bone tissue engineering scaffold is simple and reliable in structure; the appearance and the microstructure are controllable; the mechanical properties are reliable; ion release properties are controllable; implantation is convenient; wound is small; and cost is low.

Owner:NANJING FIRST HOSPITAL

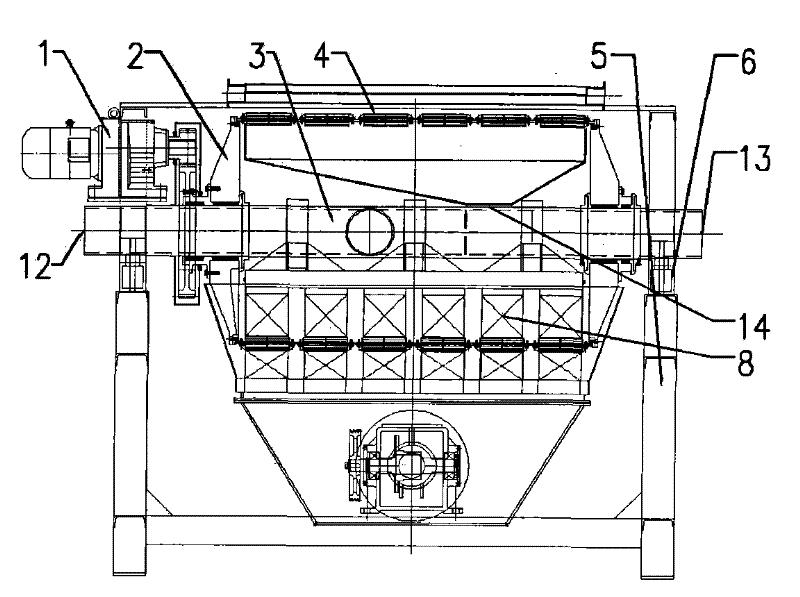

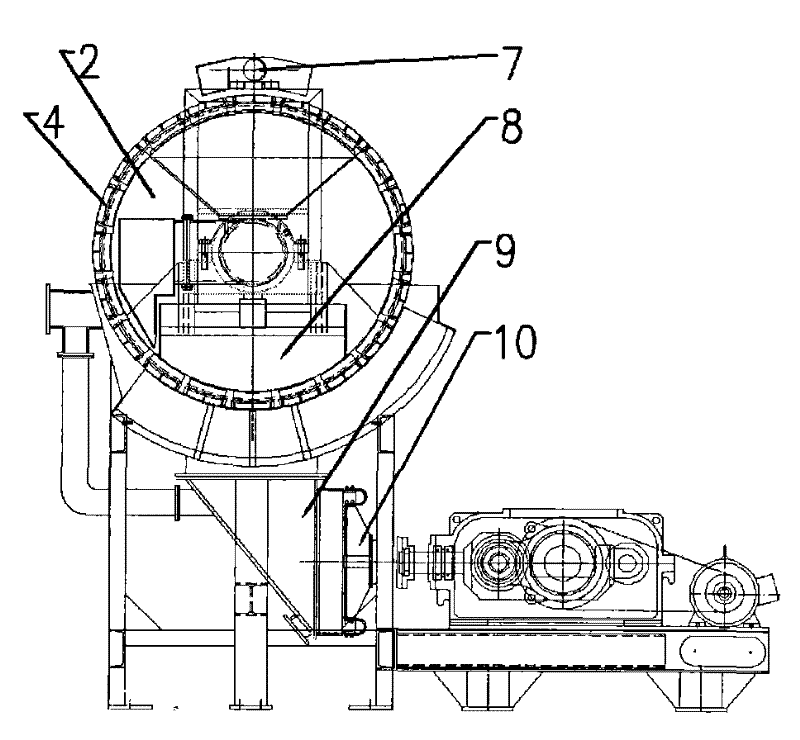

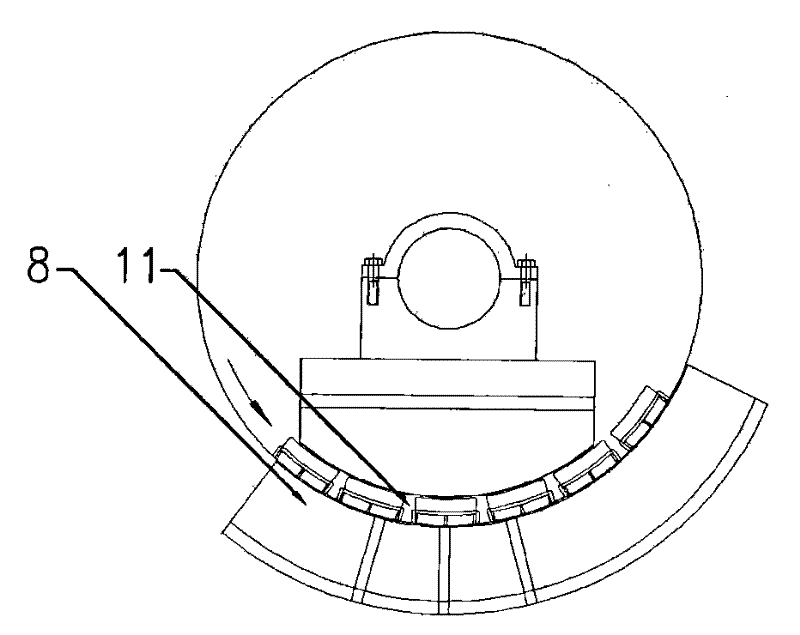

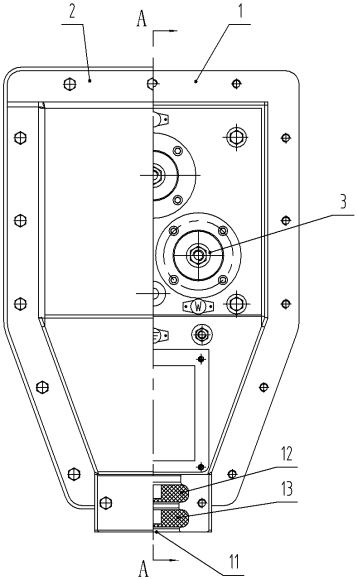

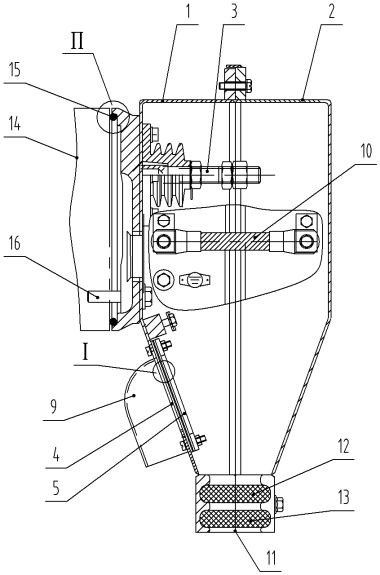

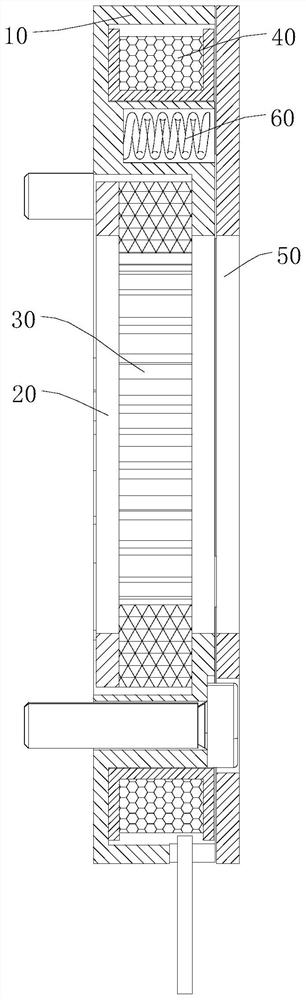

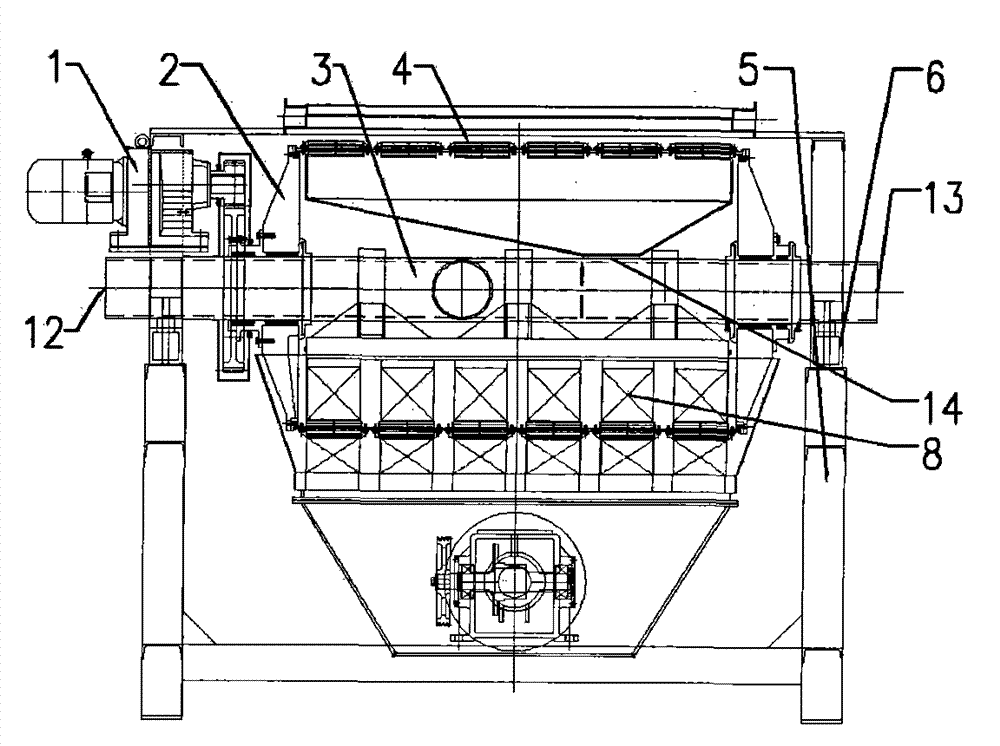

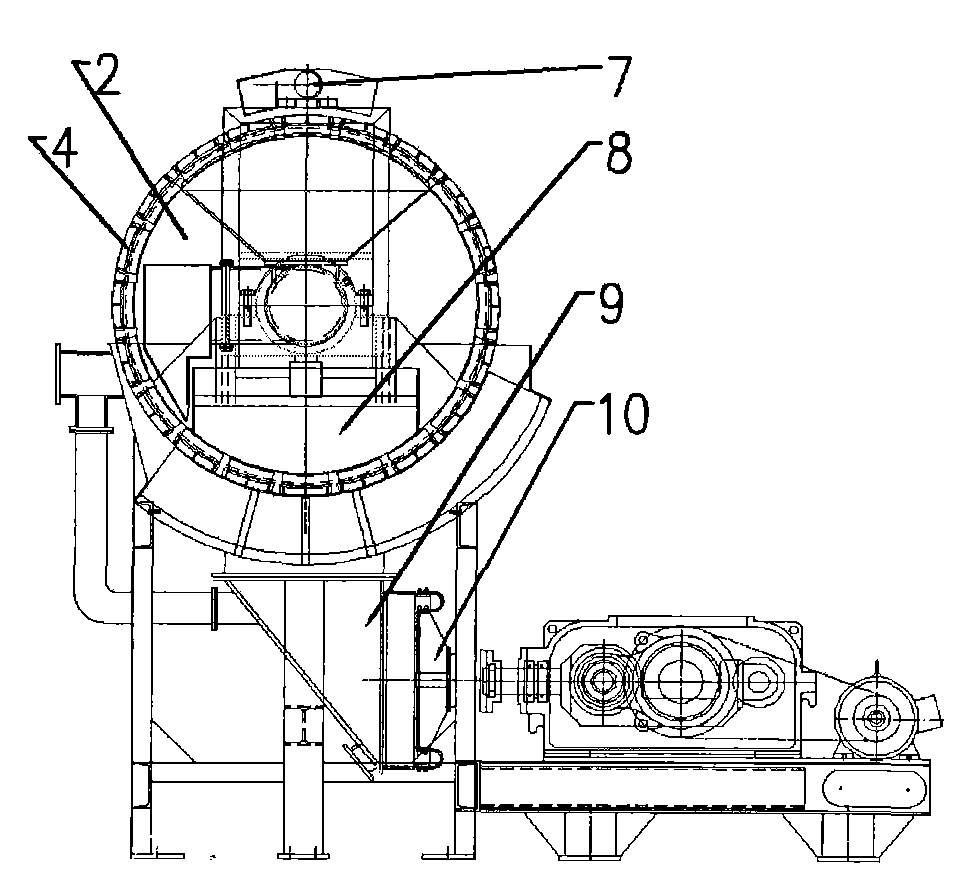

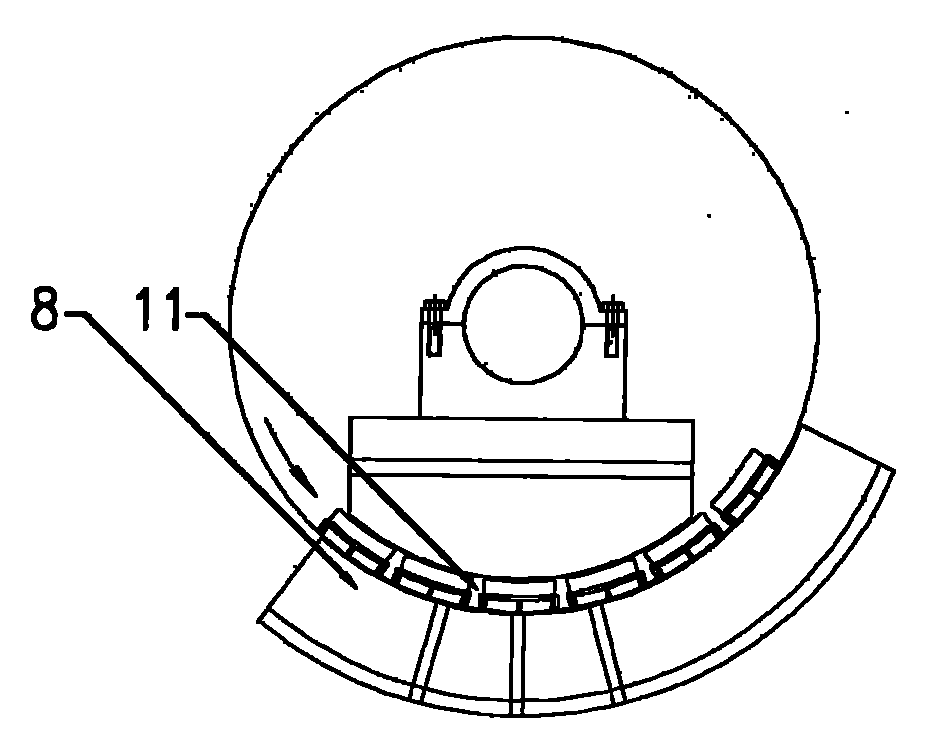

Permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity

ActiveCN102179297AIncrease harvestReasonable load distributionHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention discloses a permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity. A separating cylinder (2) is a cylindrical cage which is a rotary body and is filled with magnetic matrices (4); two ends of the cylindrical cage are supported on a hollow support shaft (3) through bearings; a magnetic system is a permanent-magnet lattice uniform magnetic field system formed by an upper magnetic system and a lower magnetic system, the upper magnetic system is arranged in the cavity of the cylindrical cage and suspended on the hollow support shaft (3), the lower magnetic system is installed outside the cylindrical cage, the hollow support shaft (3) is a non-rotary body, one end of the hollow support shaft (3) is used as an axes feeding port (12),the middle of the hollow support shaft (3) is provided with a baffle plate, and one side of the baffle plate of the hollow support shaft is provided with a separating and feeding port close to the feeding port (12), the other side of the baffle plate of the hollow support shaft is provided with a concentrate feeding port (14), and the other end of the hollow support shaft (3) is used as a concentrate discharging port (13). The permanent-magnet cylindrical cage type high-gradient magnetic separator has the advantages of easiness for maximization, convenience for design and production, low energy consumption, reasonable magnetic distribution, uniform background magnetic field working region as well as high processing capacity and stable separation indexes under limited tonnage and volume.

Owner:马鞍山市天工科技股份有限公司

Anti-explosion main junction box for high-voltage compact motor

ActiveCN101958602APlay the role of insulation and sealingAffect the tightnessSupports/enclosures/casingsEngineeringHigh pressure

The invention discloses an anti-explosion main junction box for a high-voltage compact motor, comprising a box base and a box cover. The box base is detachably and hermetically connected with a motor body; the box cover is detachably and hermetically connected with the box base; a junction post is arranged in the box base; a pressure release hole is arranged on the lower part of the box base; the box base is provided with a hollow pressing plate inside the pressure release hole; two layers of hollow sealing cushions are arranged between the pressing plate and the box base; a layer of pressure release film is arranged between the two layers of sealing cushions; and the box base is provided with a protection cover having an opening outside the pressure release hole. With simple structure, easy installation manufacture and novel valving design, compared with the traditional junction box, the invention greatly improves the security and has the characteristics of reasonable electric gap, creepage distance and shell intensity, more convenient installation and use, high reliability, convenient use, compact structure and attractive appearance.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

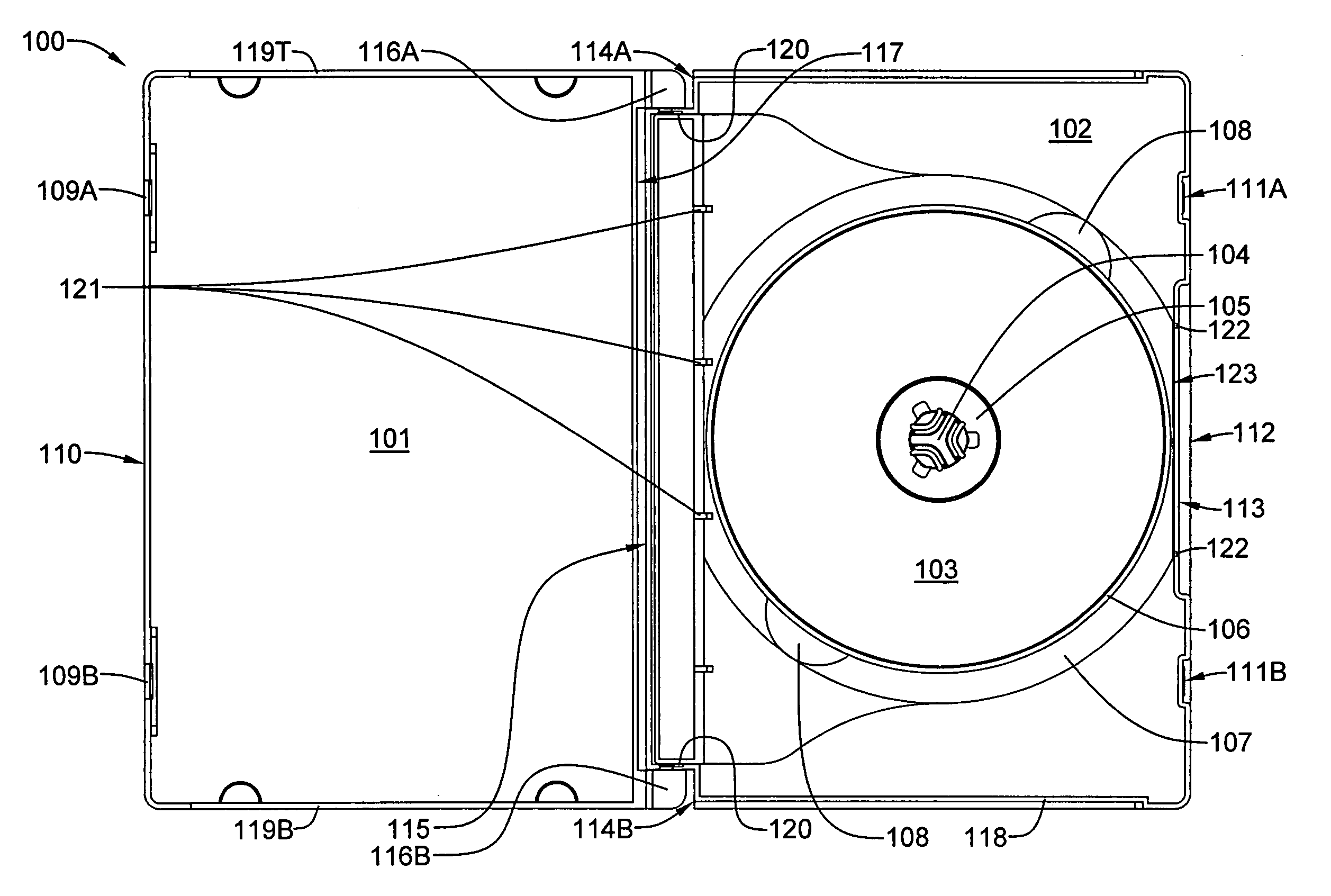

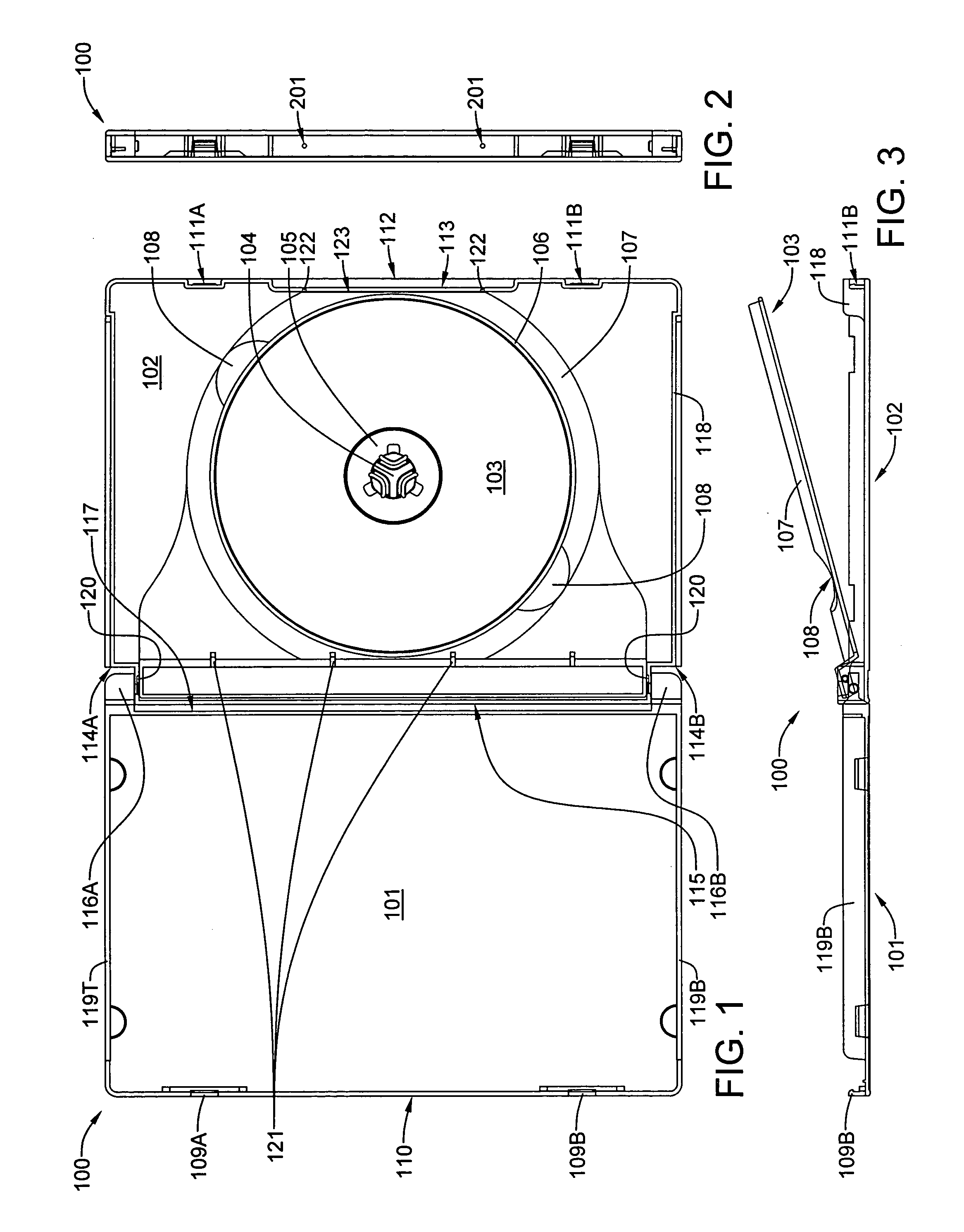

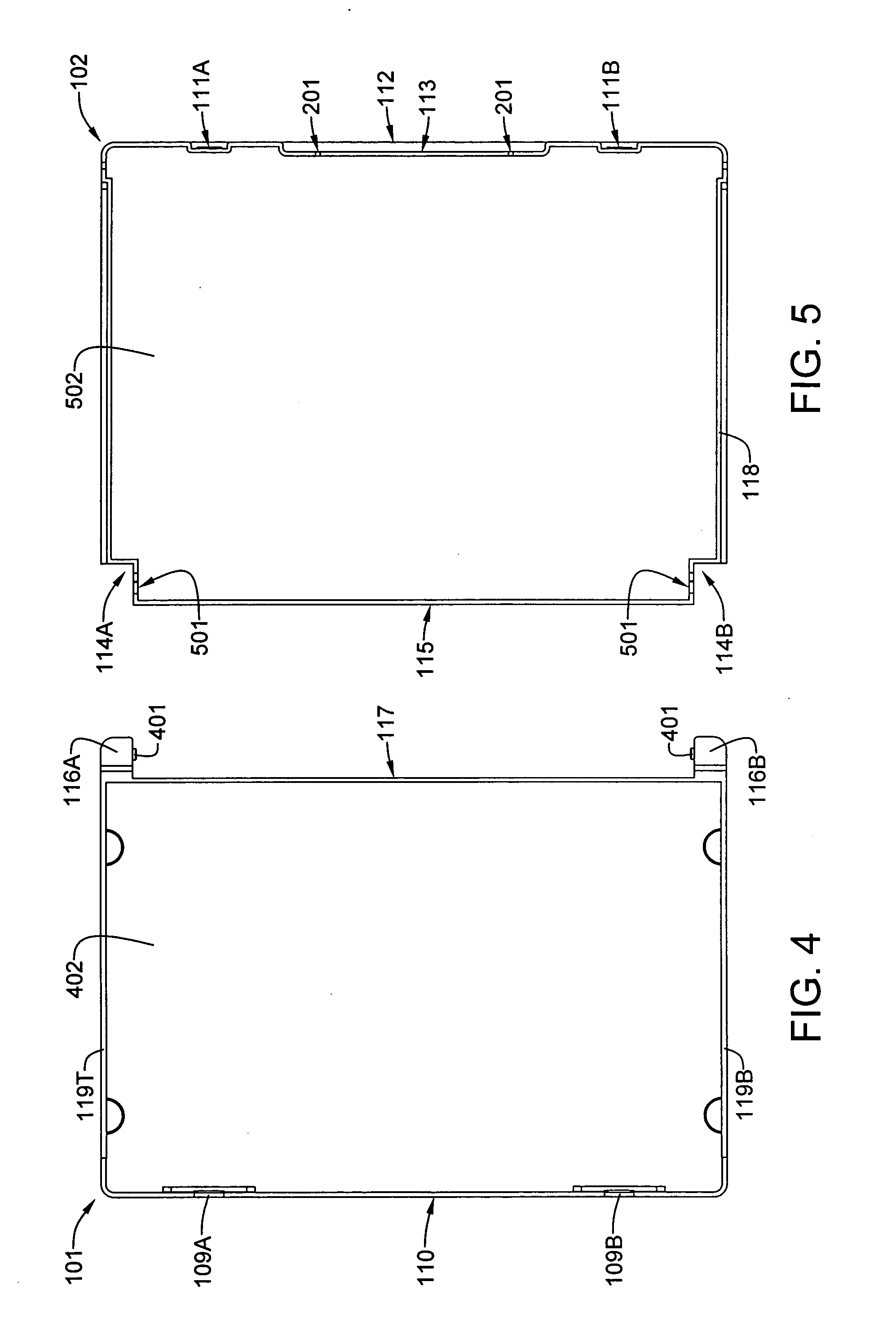

Protective case for information storage disc

InactiveUS20050150791A1More to mechanical damageImprove structural strengthRecord information storageOther accessoriesSolid componentFront edge

A three-piece jewel case for information storage discs, such as CDs and DVDs, is of the clam-shell type, and includes a base portion having a pair of generally rectangular hinge recesses positioned at adjacent corners along a rear side edge thereof, a lid portion having a pair of generally rectangular hinge arms positioned at adjacent corners along a rear side edge thereof, and a media tray having a lid portion supporting hub, which snaps into the base portion. For a preferred embodiment of the case, the media tray is hingeably connected to the base portion along the rear side edge. Each hinge arm has a rectangular solid component that extends from the outer edge to the inner edge and from the front edge to the back edge thereof. This feature rigidifies the rectangular hinge so that it is much more resistant to mechanical damage from crushing or dropping loads.

Owner:OSBORN WARREN R +1

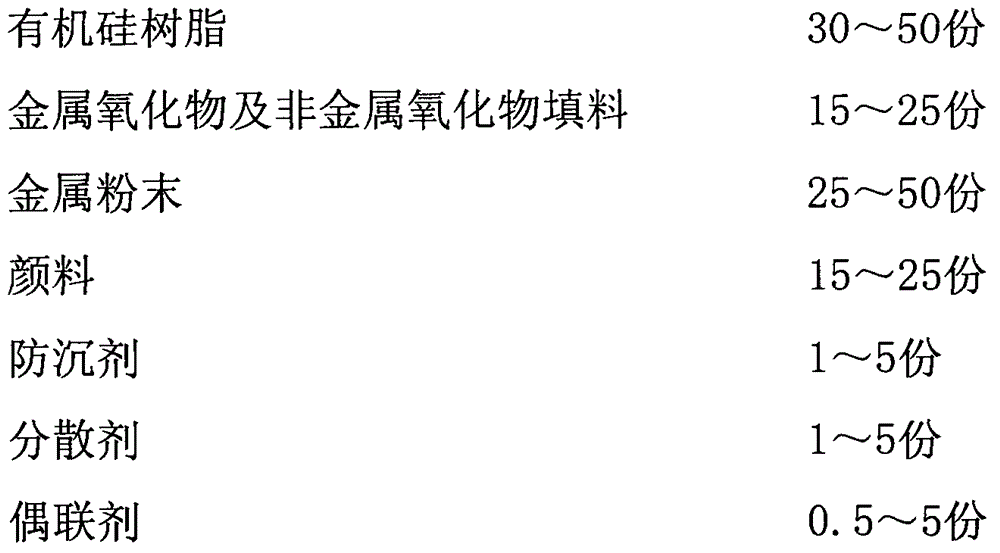

Solvent-free high-temperature resistant coating for high temperature protection on warship components

InactiveCN104419321ANot subject to high temperature corrosionReasonable strengthAnti-corrosive paintsSolvent freeUltraviolet

The invention discloses a solvent-free high-temperature resistant coating for high temperature protection on warship components. The solvent-free high-temperature resistant coating comprises organic silicon resin, metallic oxides, non-metallic oxide packing, metal powder, a dispersing agent, an anti-settling agent and a coupling agent. The solvent-free high-temperature resistant coating for high temperature protection on warship components can be used for preventing high temperature components of warships, such as high temperature pipelines, chimneys, missile firing devices and gun barrels, from being corroded by high temperature when in service, the reasonable strength of steel structures of base bodies can be maintained, the fighting requirements are ensured, and the service life is prolonged; the solvent-free high-temperature resistant coating for high temperature protection on warship components is applicable to environments with high temperature, high humidity, high salty fog and high ultraviolet irradiation and is excellent in high temperature resistance, high in corrosion resistance, and due to the characteristics that the requirement of warships on a high temperature resistant coating is met and no solvent or VOC is used, the solvent-free high-temperature resistant coating is relatively safe to coatand transport along with the warships.

Owner:江阴市大阪涂料有限公司

Method for preparing alumina catalyst carrier

ActiveCN106179520ASolve the problem of dry crackingHigh activityCatalyst carriersCatalyst activation/preparationMixed materials3d printer

The invention discloses a method for preparing an alumina catalyst carrier. The method comprises the following steps: uniformly mixing the following components in the ratio: 30-80 percent of pseudo-boehmite, 10-50 percent of superfine cellulose powder and 5-30 percent of quick-dehydrating powder; uniformly mixing, and grinding the mixed materials; preparing an acid solution in a weight ratio of acid to water being (0.5-30):100; adding the ground powder into a charging container; adding the prepared acid solution into a pressurized and flow-controllable container; printing the charging container filled with powder on a 3D printing mechanism under computer control layer by layer to obtain a finished product of a profiled large active alumina carrier. The method can be used for manufacturing mass integrated active alumina catalyst and preventing the phenomenon of dry cracking.

Owner:JIANGXI ACICHEMSHUN IND

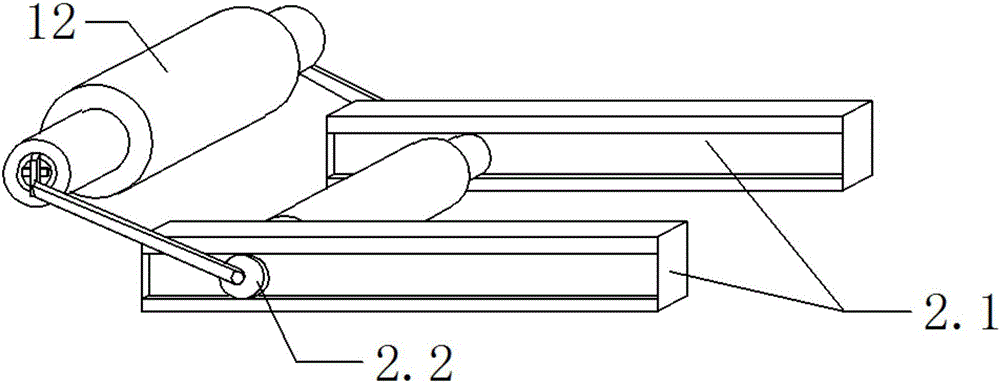

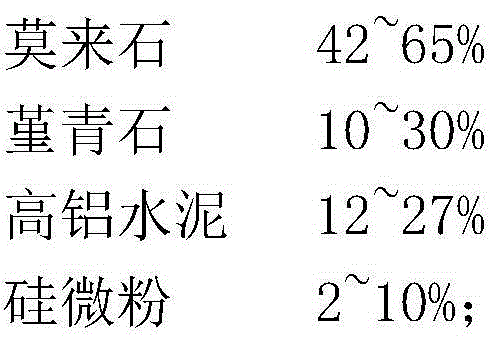

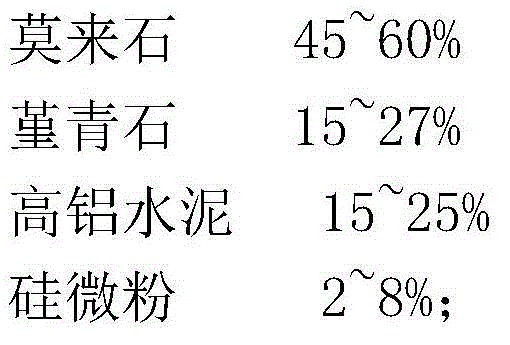

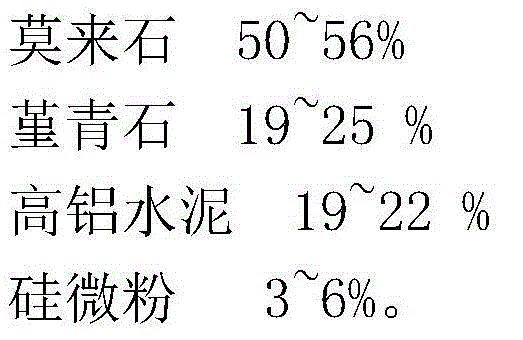

Mullite-based coating material for rocket launching pad and application of mullite-based coating material

The invention discloses a mullite-based coating material for a rocket launching pad. The mullite-based coating material is prepared from mullite, cordierite, high-alumina cement and silica powder. The high-temperature combustion gas stream resistant mullite-based coating material for the rocket launching pad can protect a rocket launching pad metal structure against scouring and high-temperature ablation of high-temperature combustion gas streams, ensure reliability of working of the launching pad and prolong the service life of the launching pad. The mullite-based coating material for the rocket launching pad is applicable to high-humidity, high-salt-mist and high-ultraviolet-irradiation environments, is good in anti-corrosion performance and meets requirements for protecting the base body protection material of the rocket launching pad when the rocket launching pad is developed in coastal regions where transportation and launching are more convenient. The mullite-based coating material construction is easy and convenient. Raw materials for the mullite-based coating material are free of poison and corrosion, have the advantages of saving energy and being environmentally friendly and play an important role in improvement and protection of the environment.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

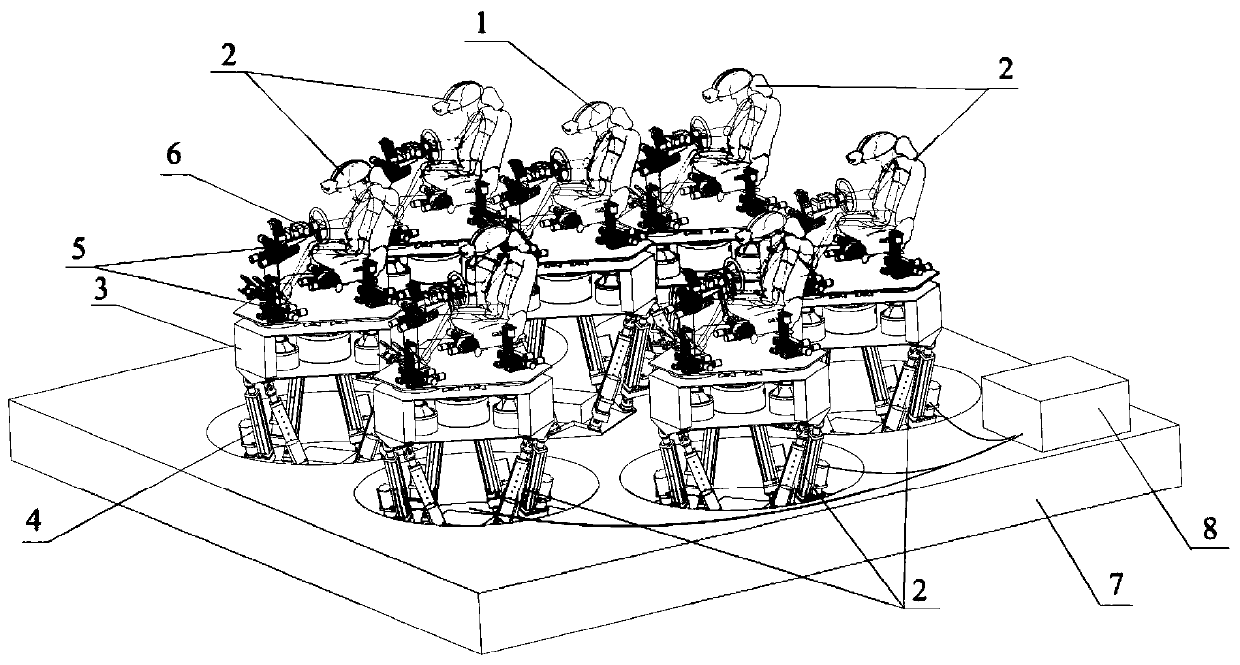

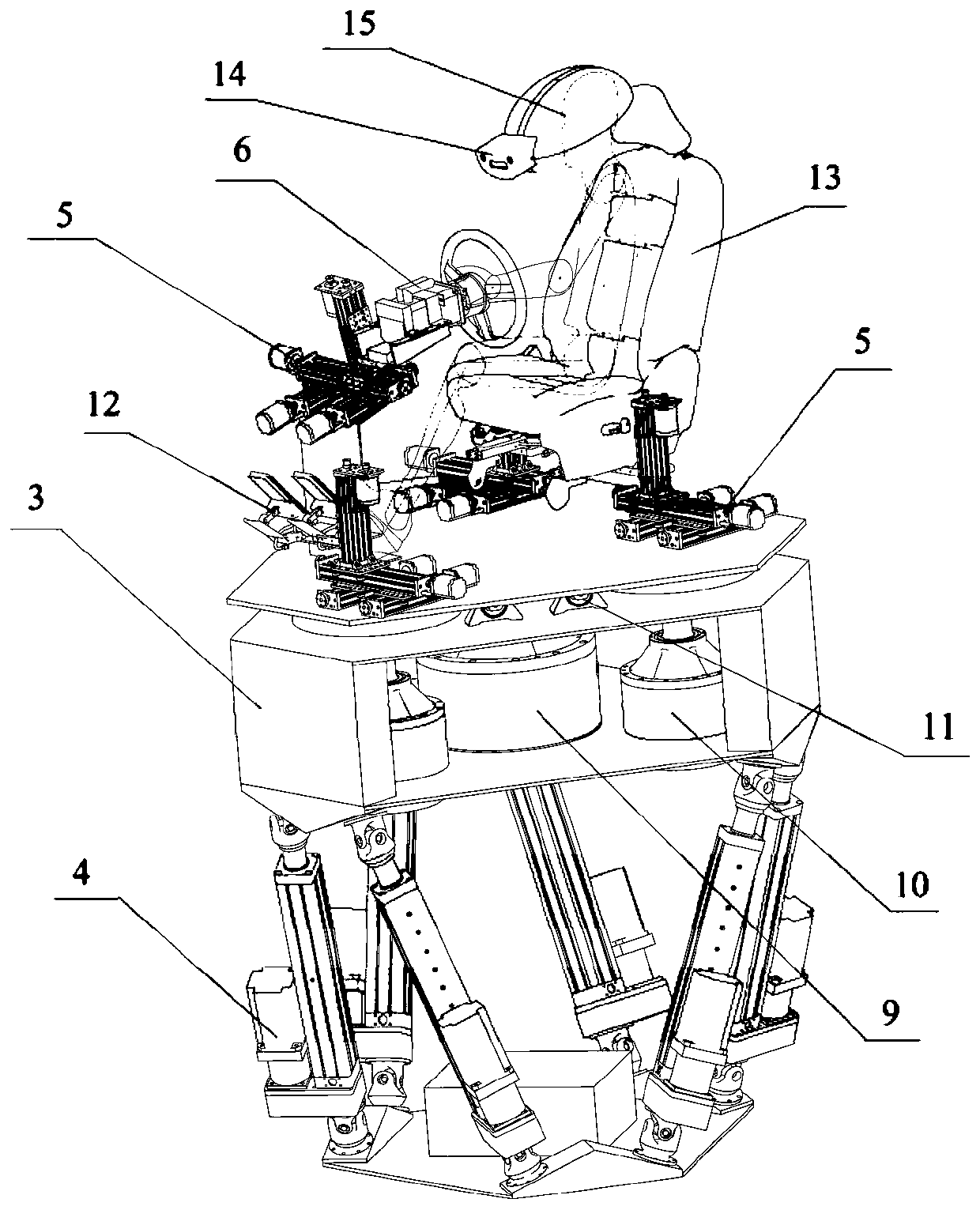

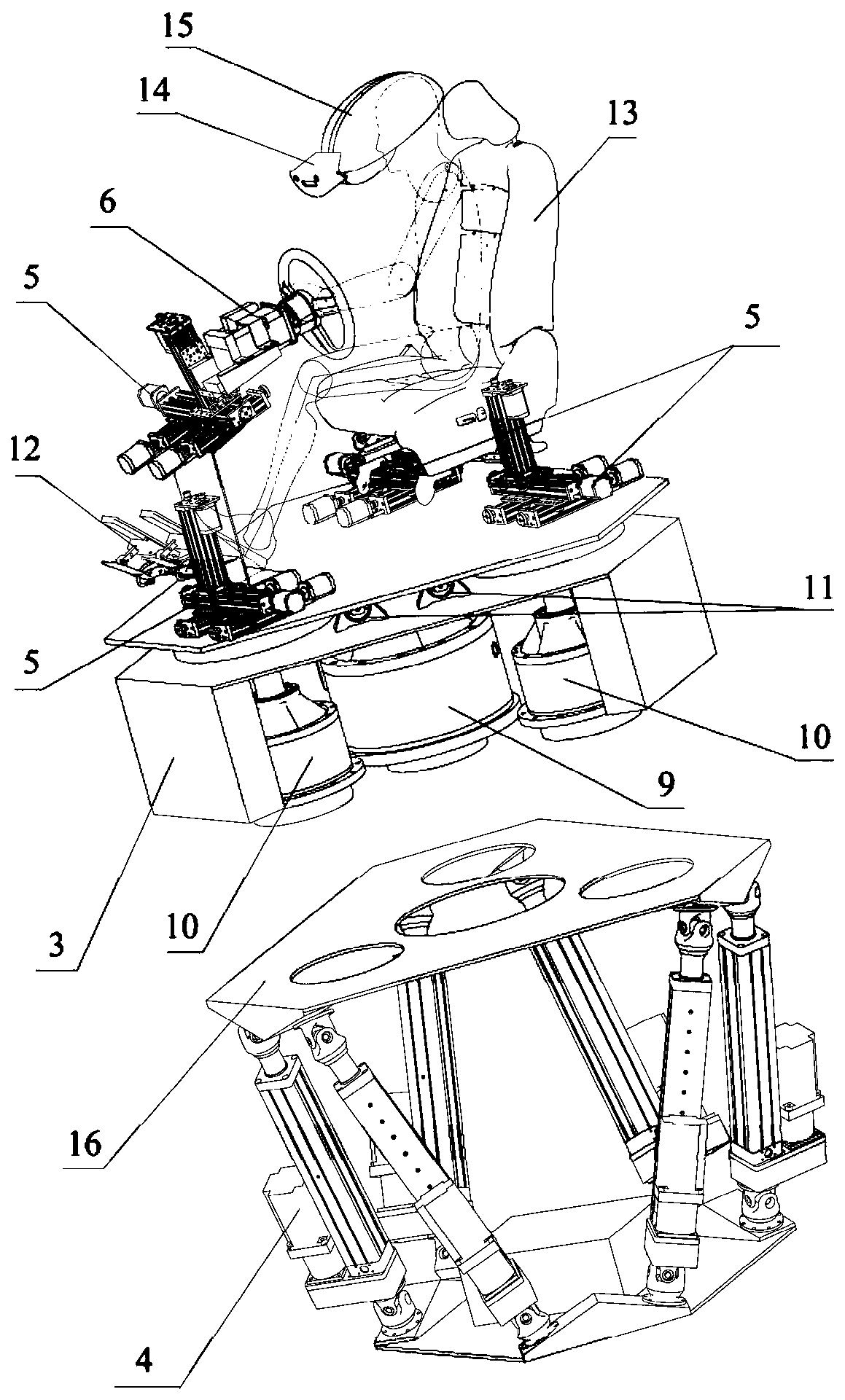

High-precision virtual reality intelligent driving simulator group for universal vehicle types and driving scenes

ActiveCN109785709AHigh simulationImprove test resultsVehicle testingCosmonautic condition simulationsElectricityActuator

The invention discloses a high-precision virtual reality intelligent driving simulator group for universal vehicle types and driving scenes, wherein the simulator group comprises a main vehicle simulator single unit, a plurality of traffic vehicle simulator single units, a controller assembly, a sensor in-ring assembly and an actuator in-ring assembly, the main vehicle simulator single unit and the traffic vehicle simulator single unit have the same mechanical structures and are fixedly connected with the ground infrastructure through a lower motion platform assembly, the plurality of trafficvehicle simulator single units are arranged around the main vehicle simulator single unit, the main vehicle simulator single unit and the plurality of traffic vehicle simulator single units are tangent to each other in an enveloping space formed in the space motion limit of the part above the ground infrastructure, the controller assembly is electrically connected with the main vehicle simulator single unit, the plurality of traffic vehicle simulator single units, the sensor in-ring assembly and the actuator in-ring assembly respectively, and the simulator group has the advantages that the corresponding materials of the parts are reasonably selected, and the service life is higher; the test and verification period based on large-scale road tests is shortened.

Owner:HENAN UNIV OF SCI & TECH

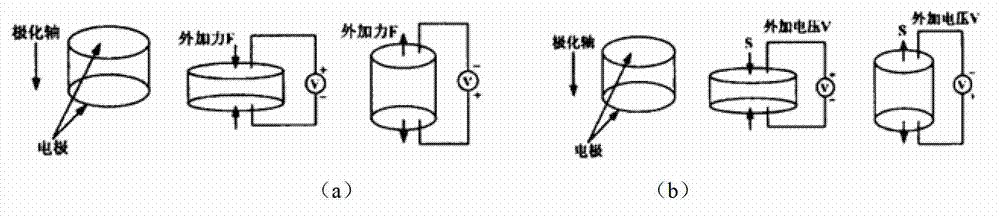

Piezoelectric buried damage self-diagnosis asphalt concrete pavement structure

ActiveCN103114515AEfficient quantitativeEfficient and quantitative decision-making dataIn situ pavingsRoads maintainenceRoad engineeringRoad surface

The invention relates to an intelligent road engineering material and particularly relates to a piezoelectric buried damage self-diagnosis asphalt concrete pavement structure. The piezoelectric buried damage self-diagnosis asphalt concrete pavement structure is characterized by comprising an asphalt concrete pavement structure poured by asphalt concrete, at least two piezoelectric self-diagnosis units which are buried in the asphalt concrete pavement structure during pouring and an auxiliary diagnosis device which is electrically connected with the piezoelectric self-diagnosis units. The asphalt concrete pavement structure can realize self-diagnosis of damages of the asphalt concrete pavement structure by utilizing changes in feature values of stress wave propagation through a piezoelectric effect.

Owner:WUHAN UNIV OF TECH

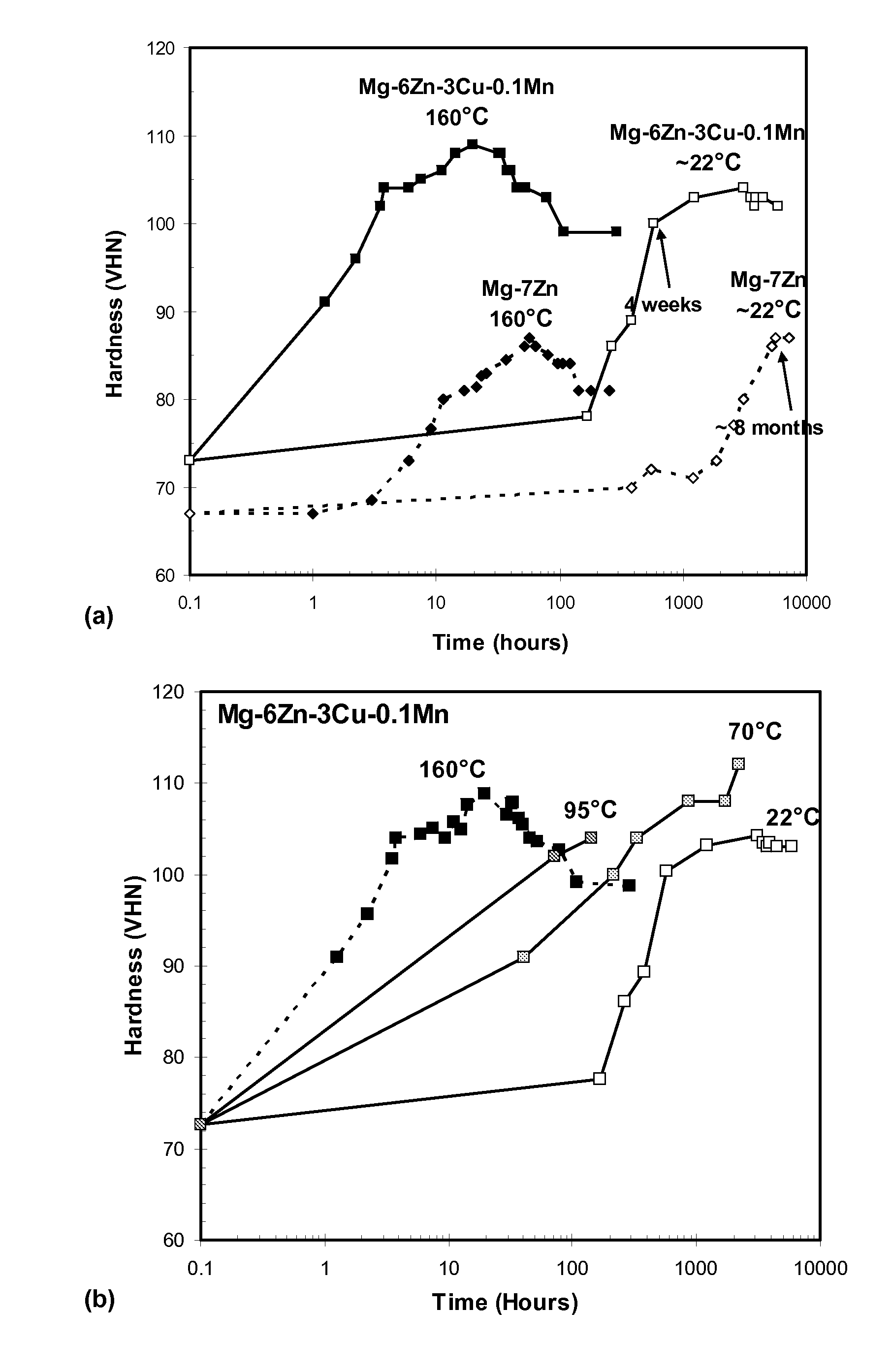

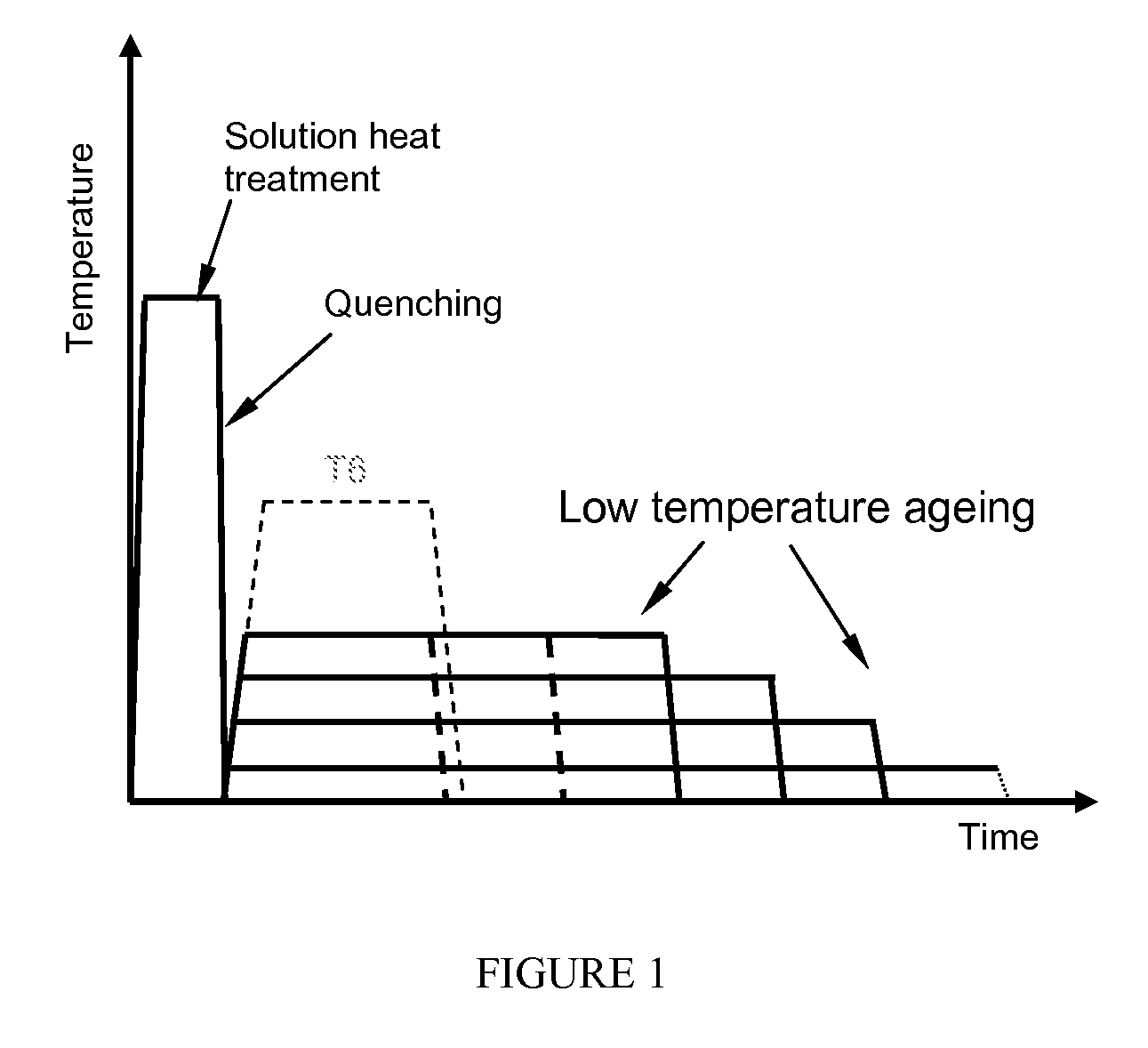

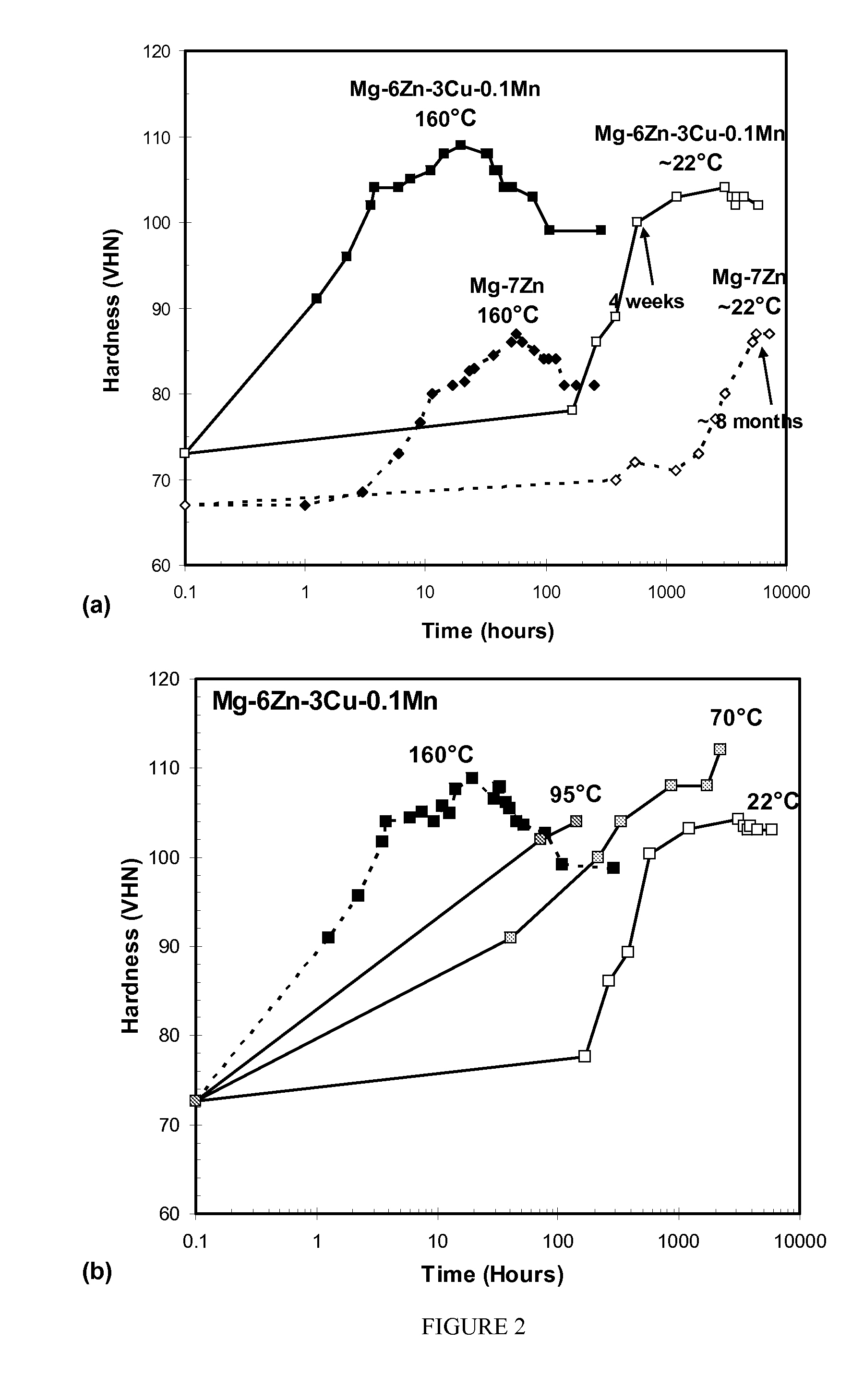

Method of heat treating magnesium alloys

ActiveUS20100132852A1Enhanced ageing responseHigh hardnessFurnace typesHeat treatment furnacesMaterials scienceHeat treating

A method for the low temperature heat treatment of an age-hardenable magnesium based alloy, including following steps:(a) providing a solution heat-treated and quenched age-hardenable magnesium based alloy; and(b) subjecting said alloy to low temperature ageing below 120° C. for a period of time sufficient to develop an enhanced ageing response.

Owner:BUHA JOKA

High temperature resistant combustion-gas stream coating for rocket launching tower and diversion trench

ActiveCN103122209AReasonable strengthEasy to useFireproof paintsAnti-corrosive paintsSolventCorrosion resistant

The invention discloses a high temperature resistant combustion-gas stream coating for a rocket launching tower and a diversion trench. The coating comprises hybrid silicon resin, tetraethylortho silicate, ethyl borate, metallic oxide and non-metallic oxide packing, metal powder and a solvent, wherein the metal powder contains aluminum powder. Due to the high temperature resistant combustion-gas stream coating for the rocket launching tower and the diversion trench, the metal structures of the rocket launching tower and the diversion trench can be prevented from washing and high-temperature corrosion of high-temperature combustion-gas streams, thereby being conducive to keeping reasonable strength of a matrix steel structure, so that the service lives of the rocket launching tower and the diversion trench are prolonged; the high temperature resistant combustion-gas stream coating for the rocket launching tower and the diversion trench is suitable for the environments in high humidity, high salt fog and high ultraviolet radiation, has strong corrosion resistant performance, and meets the requirement on the protection of launcher matrix coatings on basis of developing rocket launching bases to coastal regions at which the transport and the launch are more convenient; the coating is a dry normal coating and is simple and convenient in construction; and the coating is relatively friendly to the environment.

Owner:江阴市大阪涂料有限公司

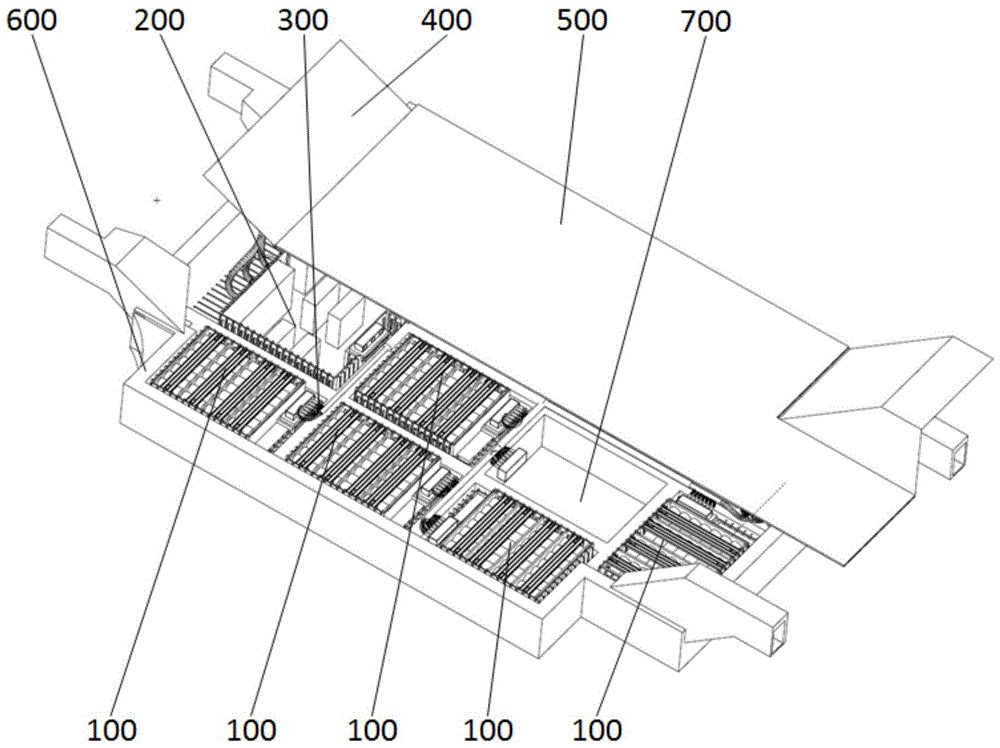

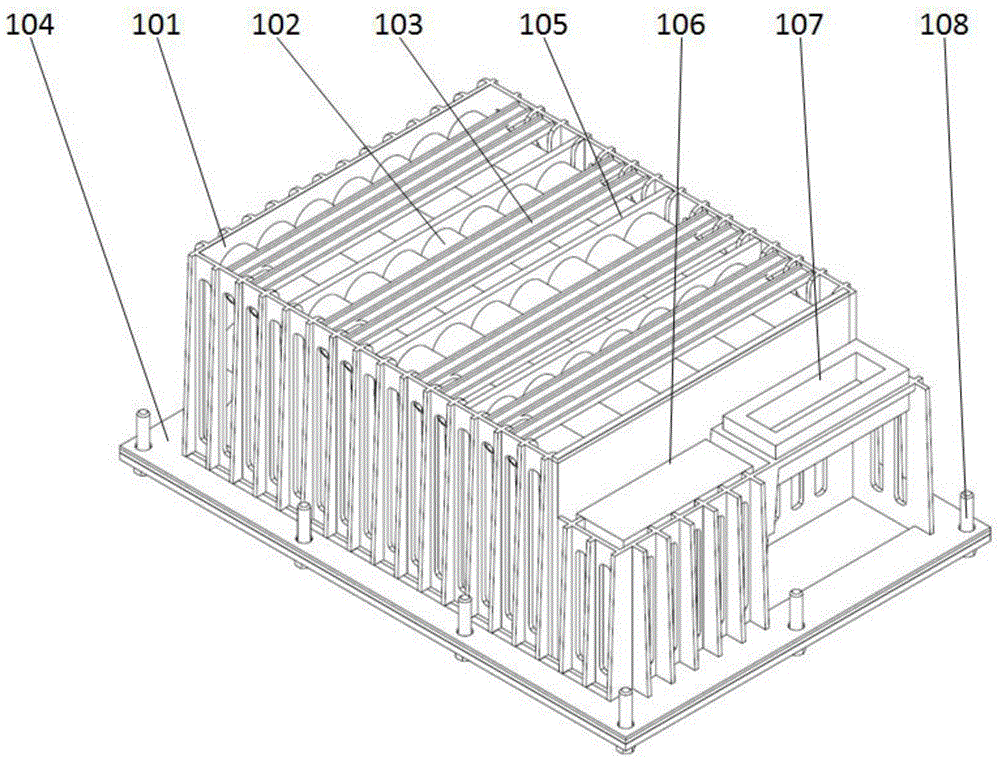

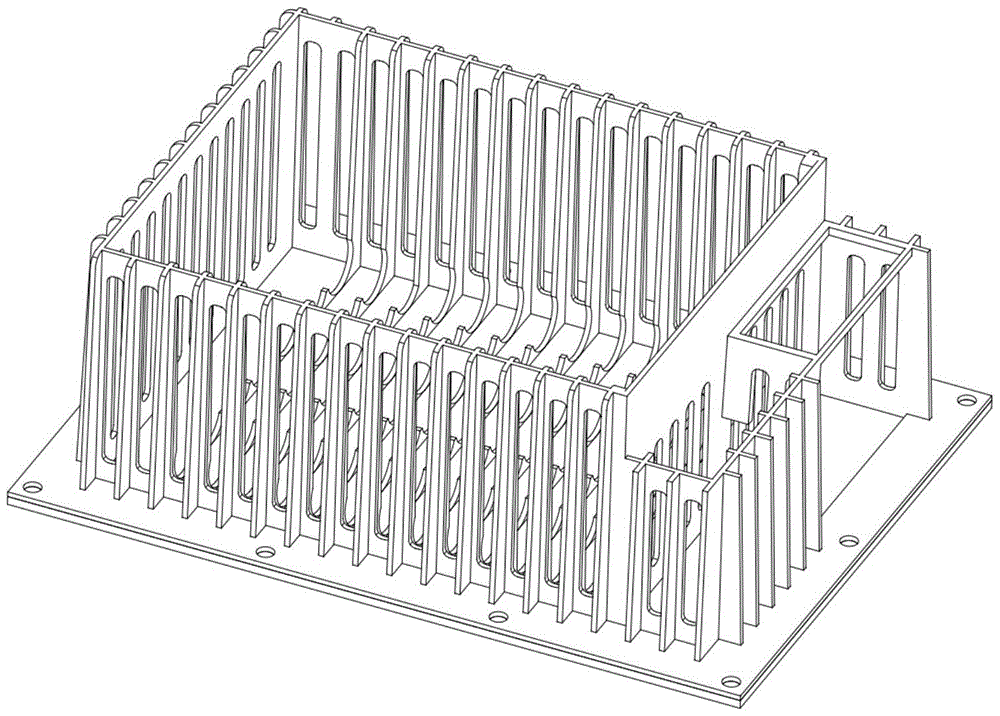

Electric vehicle battery system that can be increased or decreased by using the lower body as the battery box

ActiveCN104393209BReasonable stiffnessReasonable strengthElectric propulsion mountingCell component detailsElectric-vehicle batteryElectrical battery

The invention relates to an electric vehicle battery system that can be increased or decreased by using the lower vehicle body as a battery box, comprising a single battery pack (100), a main control box (200), a connecting wire harness (300), and an underfloor (400) , the upper layer of the floor, the lower body (600), and the sealing plate (700), which are characterized in that: the single battery pack (100) is connected to the lower body (600) by bolts (108), and the main control box (200) is connected by bolts (108) is connected with the lower car body (600), the lower floor (400) is welded together with the lower car body (600), relatively fixed, and the single battery pack connector (301) is installed on the lower floor (400) by threaded connection. ), the main control box connector (303) is also installed on the lower floor (400) through threaded connection, and the present invention uses the lower vehicle body as the box body of the battery box, so that the theoretical design of the stiffness and strength of the whole vehicle is more reasonable; Inventing multiple single battery packs to form a battery system reduces the requirements for the structure and installation structure of the single battery packs.

Owner:HUNAN UNIV

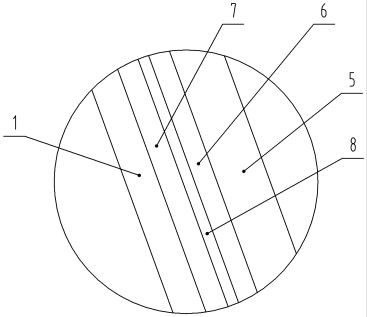

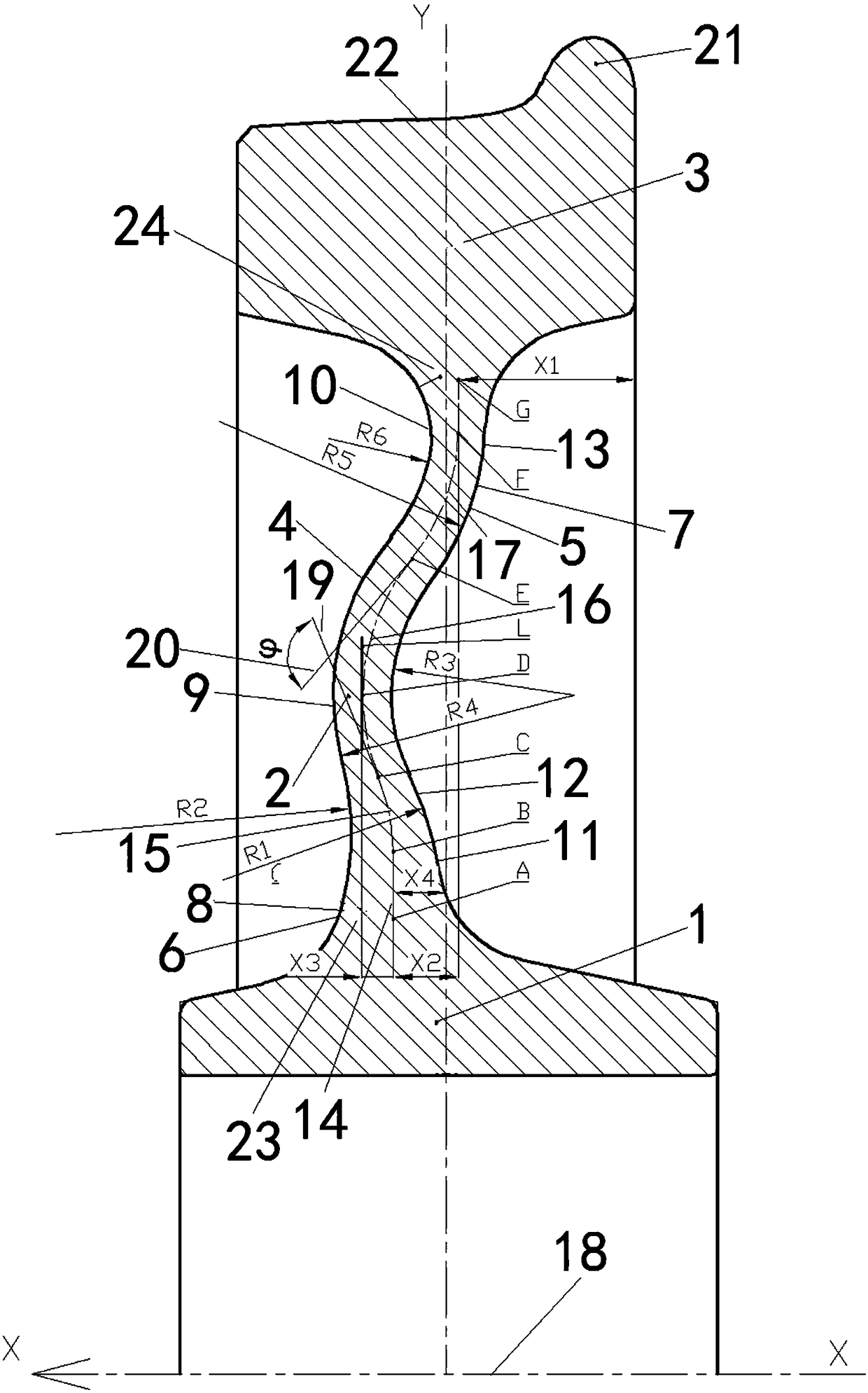

Bent spoke rail wheel

PendingCN108501615AImprove performanceSimple structureRail-engaging wheelsEngineeringMechanical engineering

The invention provides a bent spoke rail wheel applied to the technical field of railway vehicle parts. Each wheel spoke (2) of the bent spoke rail wheel is arranged of a curved surface structure, oneend of each spoke (2) is connected with a hub (1), the other end of each spoke (2) is connected with a rim (3), each wheel spoke (2) comprises a spoke side face I (4) and a spoke side face II (5), multiple side face I curved surfaces (6) are arranged on each spoke side face I (4) from the end connected with the hub (1) to the end connected with the rim (3), and multiple side face II curved surfaces (7) are arranged on each spoke side face II (5) from the end connected with the hub (1) to the end connected with the rim (3). By the adoption of the bent spoke rail wheel, the good braking performance and easy volume production are guaranteed, meanwhile, the wheel is small in weight, the reasonable strength, rigidity and braking thermodynamic performance of the wheel are guaranteed, and competitiveness is improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

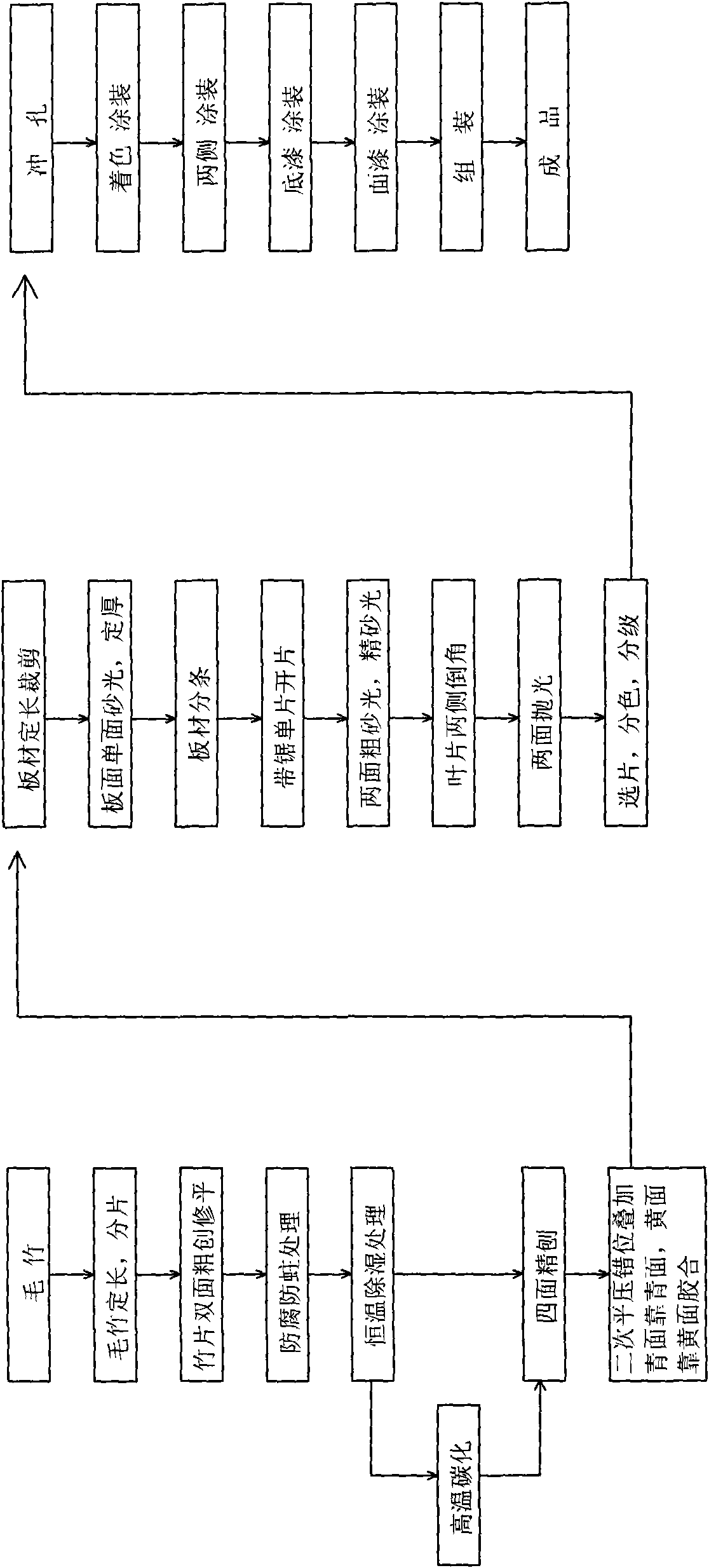

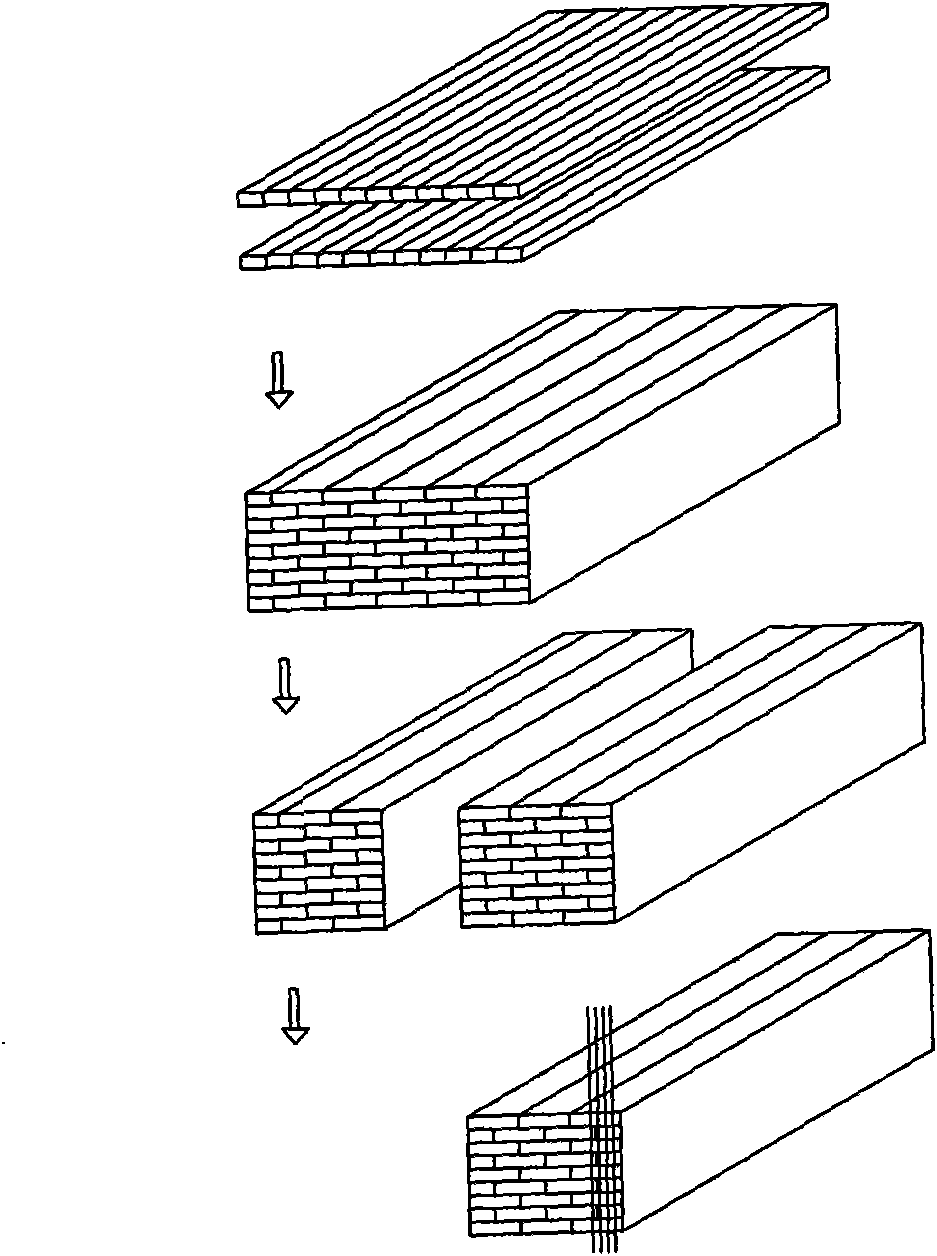

Manufacture method of bamboo curtain sheets

InactiveCN101623892ATake advantage ofPromote sustainable developmentWood veneer joiningFiberAssurance quality

The invention relates to a manufacture method of bamboo curtain blades. The manufacture method comprises the following steps: material selection, pretreatment, agglutination, single blade separation by a band-sawing machine and post treatment. Bamboo splints after the pretreatment are mutually spliced, agglutinated and flatwise pressed to form flat plates during agglutination; then, transversally staggering and stacking 5-16 layers of flat plates as required in a mode that a cyan side closes to another cyan side, and a yellow side closes to another yellow side; and agglutinating the flat plates into a special curtain bamboo rubber plates. The invention uses the band-sawing machine to separate the single blade and can achieve the aims of saving the materials, ensuring the quality and improving the work efficiency because the saw blade of the band-sawing machine has a long stroke, a slice saw blade and a narrow saw path. The invention utilizes the inherent strength of the self compact and fine bamboo fibers, and the flat plates which are formed by staggering, stacking, splicing and twice agglutinating the bamboo splints in the mode that the cyan side closes to another cyan side, and the yellow side closes to another yellow side to more rationalize the strength and the toughness of the product and reduce the lateral bending rate of a product. The Bamboo splints are transversally spliced so as to break through material limitation, widen a selection range of bamboo materials, improve the utilization rate of the bamboo materials, fully utilize the raw materials and ensure the sustainable development of the bamboo resources.

Owner:王长兴

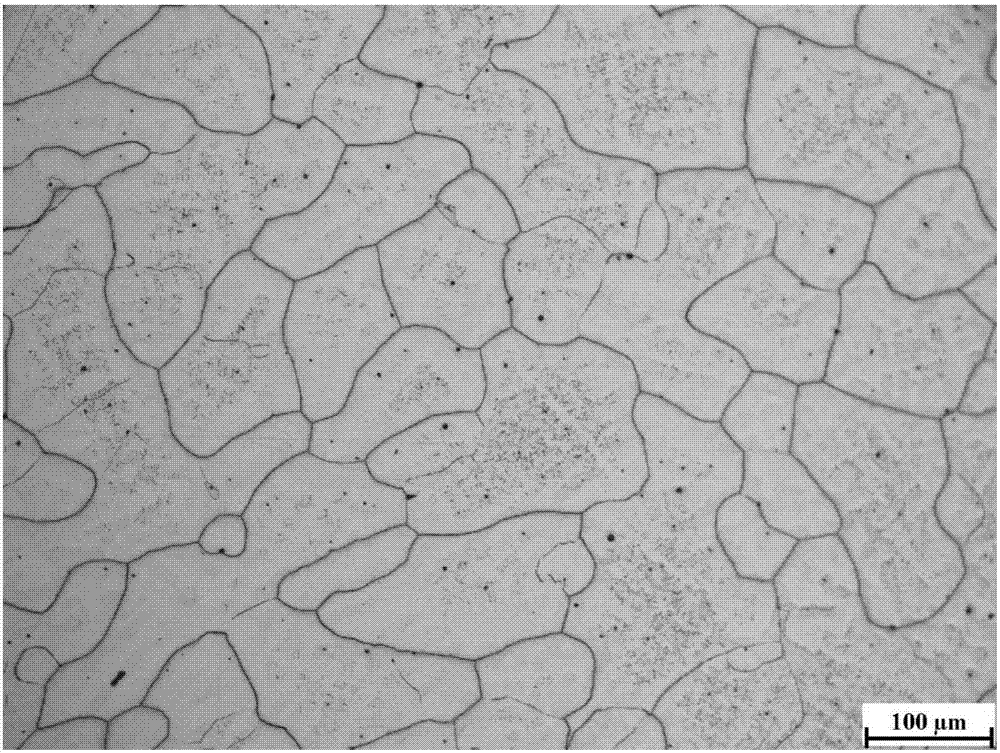

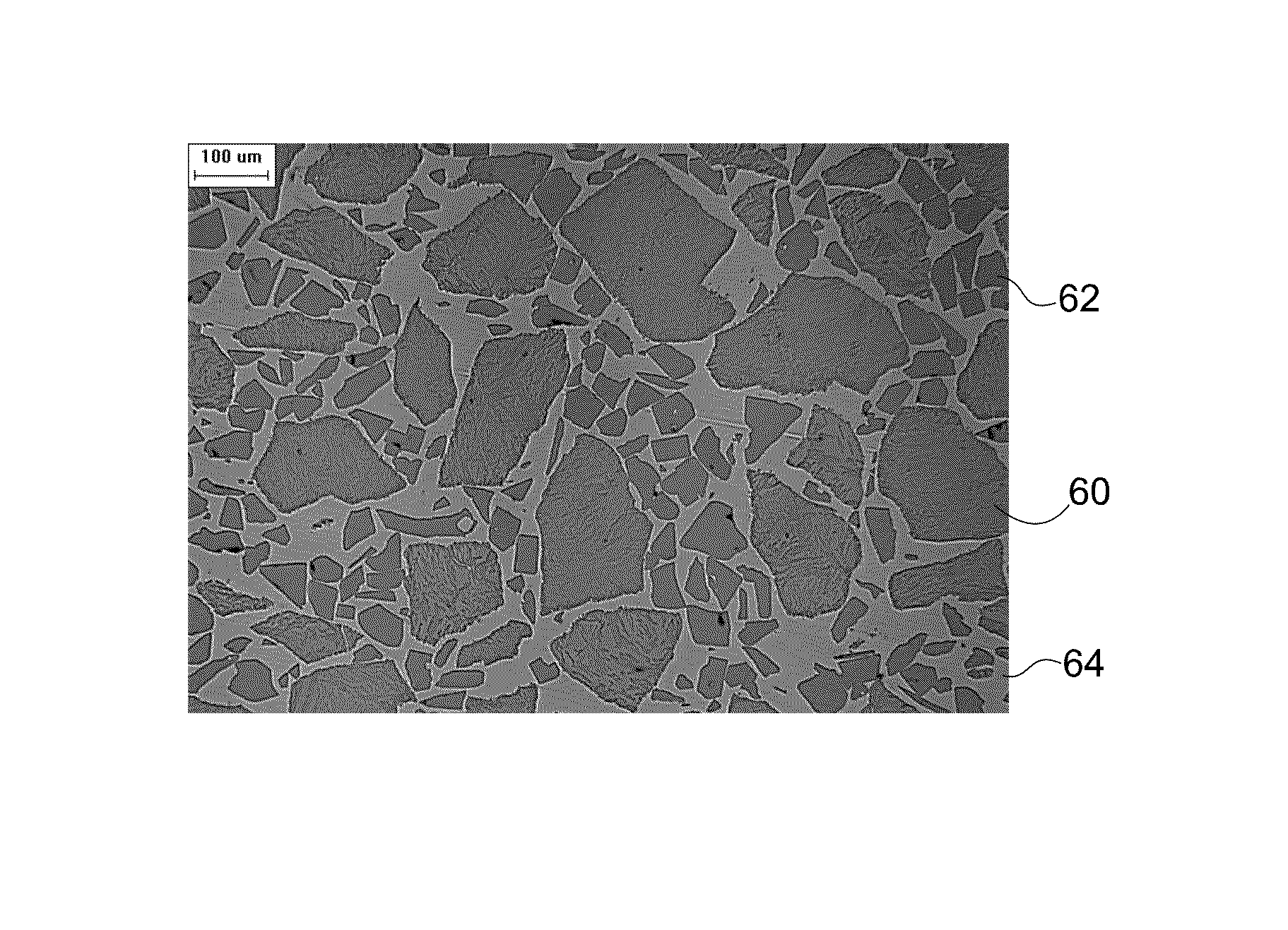

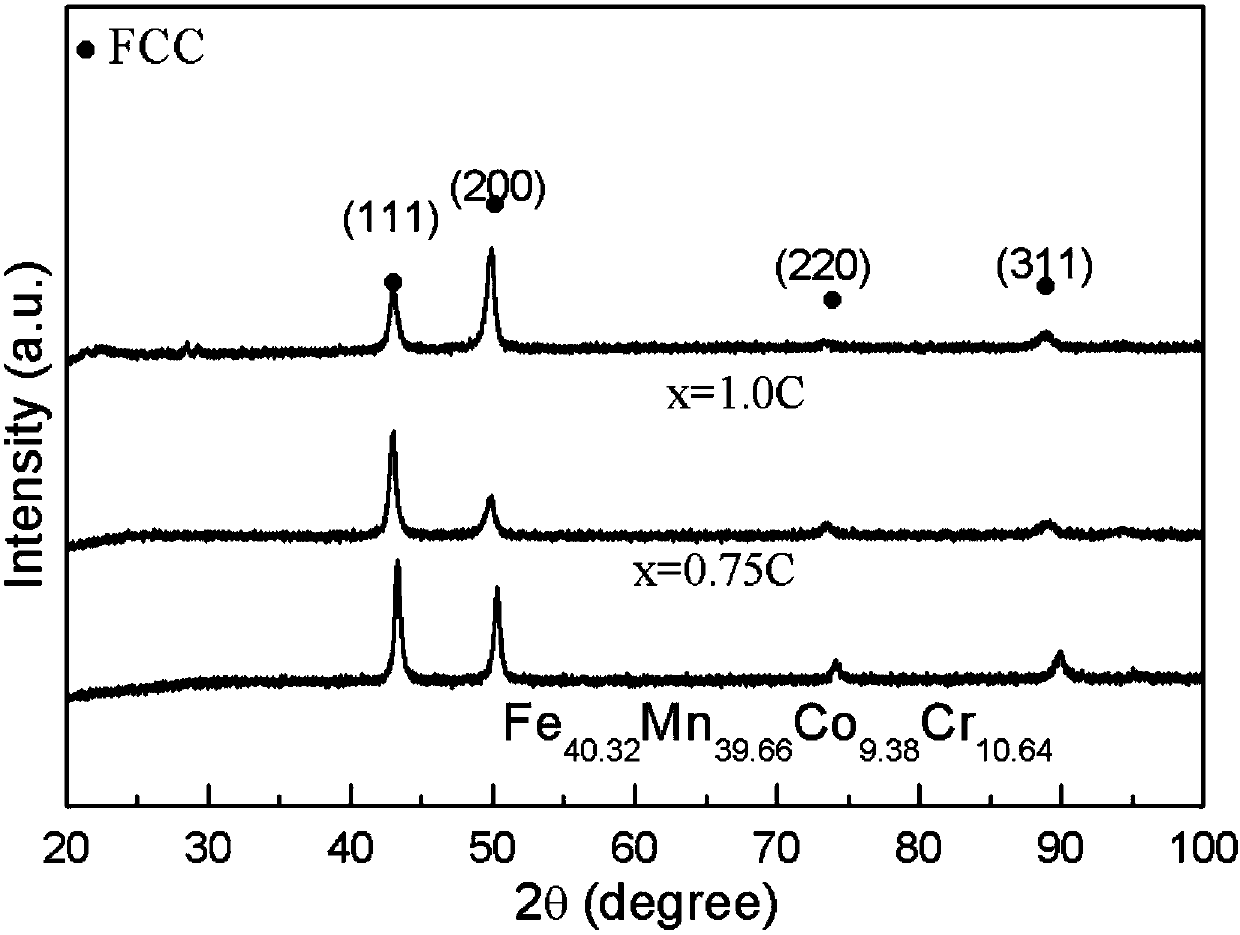

High performance high-entropy alloy and processing method thereof

The invention discloses a high performance high-entropy alloy and a processing method thereof. The mother alloy of the high-entropy alloy is (Fe40.32Mn39.66Co9.38Cr10.64)99-xMo1Cx. The alloy is proportioned according to the nominal compositions and is smelted, wherein the content x of doped carbon is greater than zero but less than or equal to 1wt%. The processing method comprises the following steps: S1, proportioning the mother alloy (Fe40.32Mn39.66Co9.38Cr10.64)99-xMo1Cx according to the nominal compositions, wherein x is greater than zero but less than or equal to 1wt%; and S2, putting each component of the mother alloy into an induction furnace to be smelted to obtain the alloy as cast condition, the grain size of which is between about 100[mu]m and 500[mu]m. The high-entropy alloy disclosed by the invention effectively reduces the stacking fault energy of the material, and is easier to induce twin crystals; the relationship between strength and plasticity is coordinated, and thealloy is low in cost and has a high economical benefit.

Owner:ZHENGZHOU UNIV

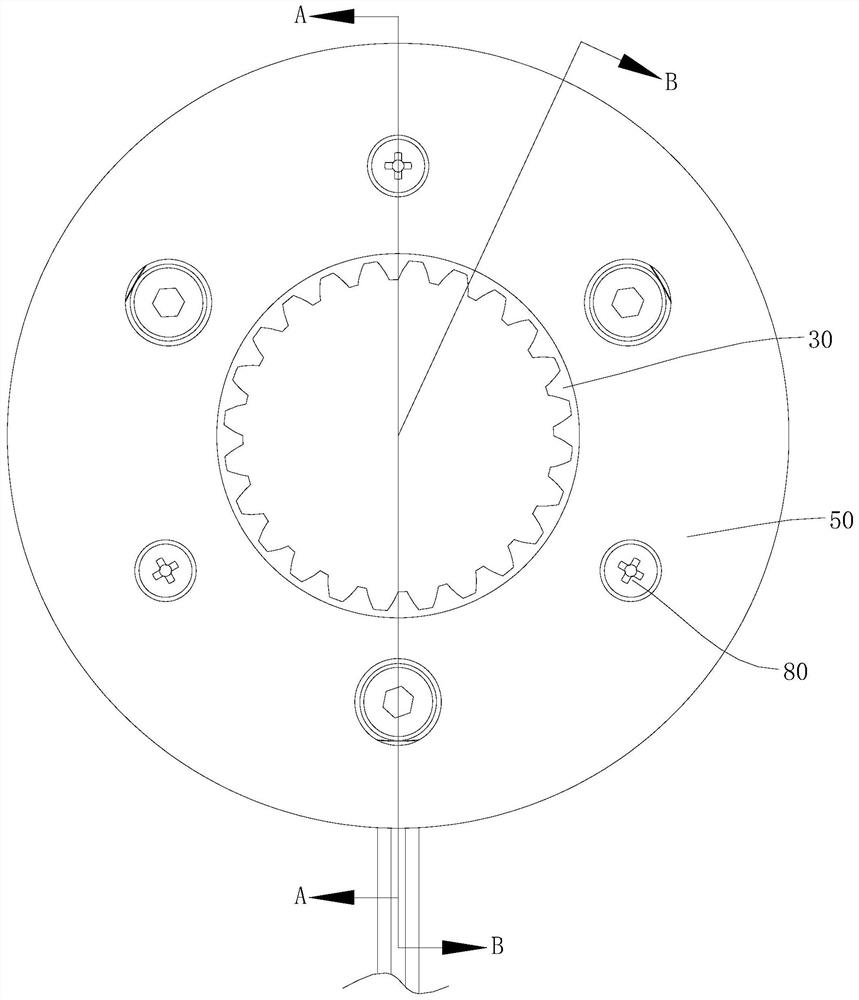

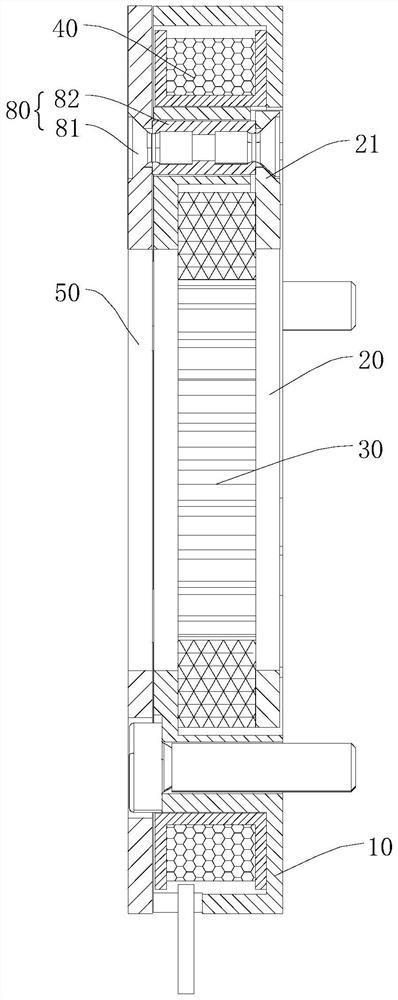

Brake

ActiveCN113685464ACompact structureImprove space utilizationNoise/vibration controlBraking discsBrakeEngineering

The invention provides a brake. The brake comprises a magnet yoke iron core, a movable plate, a friction disk, a coil, an armature and an elastic part, wherein a first mounting space and a second mounting groove are sequentially and concentrically distributed in the magnet yoke iron core from inside to outside; the first mounting space penetrates through the center position of the magnet yoke iron core in the axial direction of the magnet yoke iron core; the opening of the second mounting groove faces the second shaft end of the magnet yoke iron core; the movable plate is located in the first mounting space and is close to the first shaft end of the magnet yoke iron core; the friction disk is arranged in the first mounting space and located at the side, close to the second shaft end, of the movable plate; the coil is arranged in the second mounting groove; the armature is located at the second shaft end of the magnet yoke iron core, and the armature is connected with the movable plate through a connecting part; and the elastic part has pre-tightening force which enables the armature to be far away from the magnet yoke iron core. The brake provided by the invention is relatively thin.

Owner:ALTRA IND MOTION SHENZHEN CO LTD

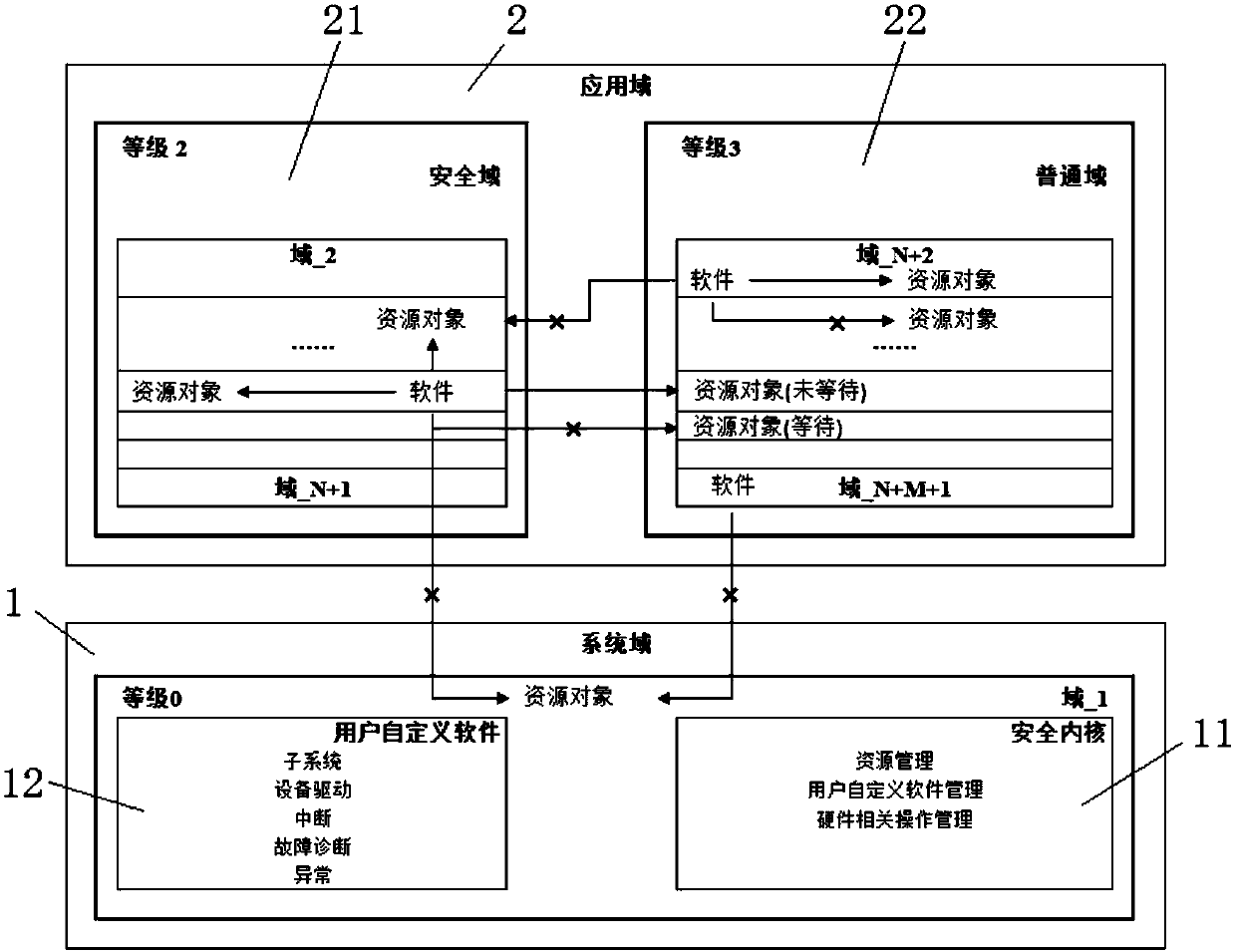

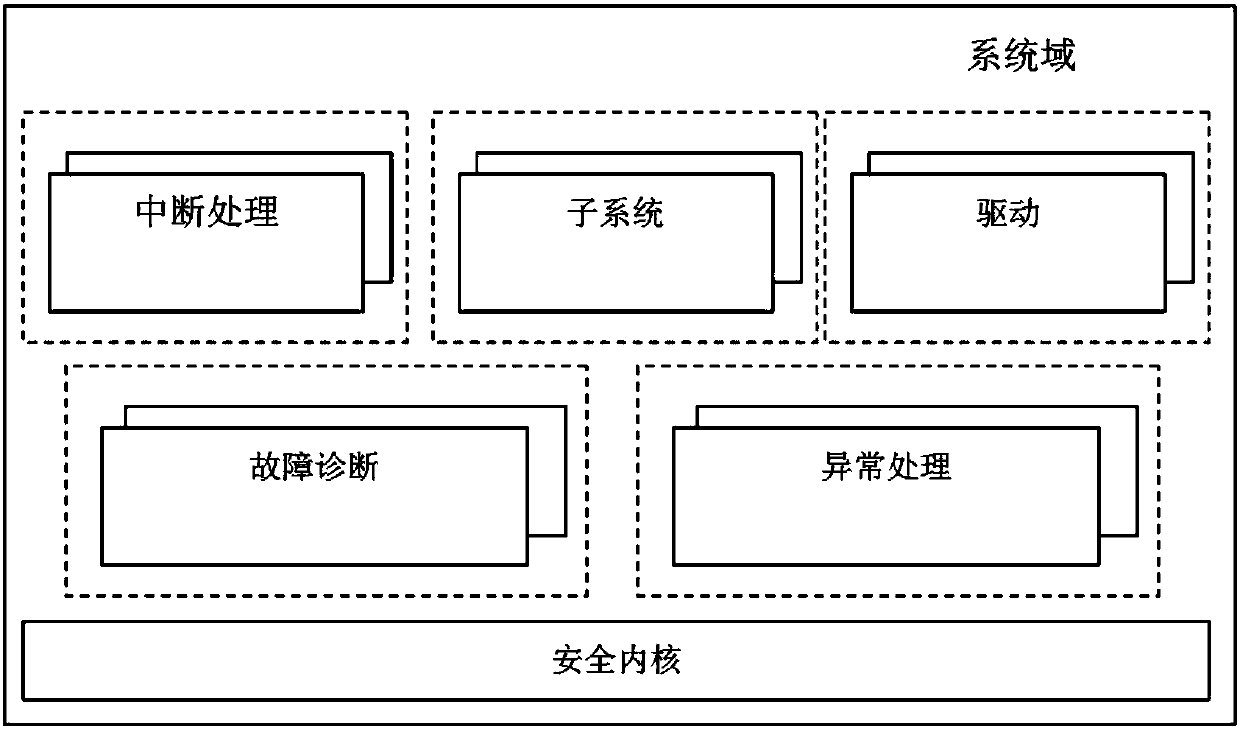

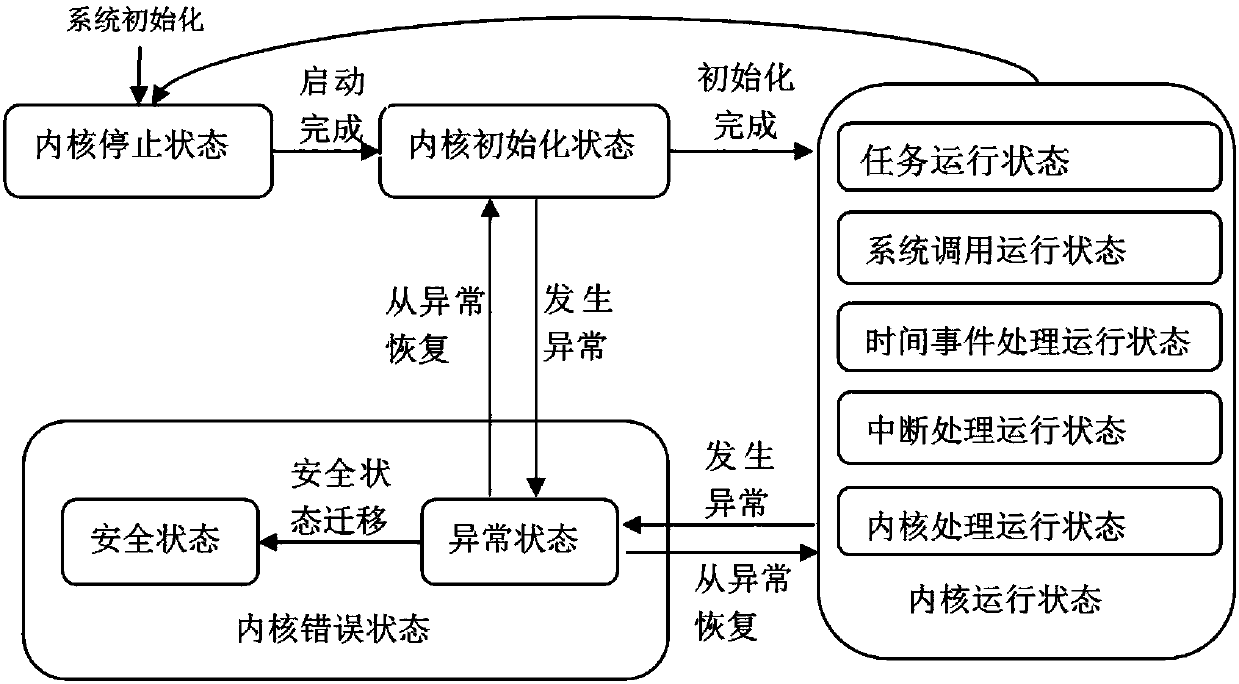

Method and system for establishing security system based on domain mechanism

InactiveCN108021827AFlexible controlReasonable strengthInternal/peripheral component protectionPersonalizationRelevant information

The invention discloses a method and system for establishing a security system based on a domain mechanism. The method includes the following steps of configuring domain management information, setting related information of a resource object, configuring and registering a failure diagnosis routine, starting the failure diagnosis routine, establishing a domain environment, initializing a securitycore, executing scheduling and running software, intersecting a software calling security API of a security domain with the security core, intersecting a software calling ordinary API of an ordinary domain with the security core, and regularly detecting the current system state through the security core. The system comprises system domains and application domains. The application domains include the security domain and the ordinary domain. The smaller the domain value of software is, the higher the authority is; software with high authority can have access to the software itself and resourceswith lower authorities, and software with the same authority can have access to one another. The domain mechanism is sufficiently used, and security isolation is achieved; the individualized securitysystem of different grades can be established; control is flexible, and strength is reasonable; hardware characteristics are not depended on, and portability is high.

Owner:中科开元信息技术(北京)有限公司

Permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity

ActiveCN102179297BIncrease harvestReasonable load distributionHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention discloses a permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity. A separating cylinder (2) is a cylindrical cage which is a rotary body and is filled with magnetic matrices (4); two ends of the cylindrical cage are supported on a hollow support shaft (3) through bearings; a magnetic system is a permanent-magnet lattice uniform magnetic field system formed by an upper magnetic system and a lower magnetic system, the upper magnetic system is arranged in the cavity of the cylindrical cage and suspended on the hollow support shaft (3), the lower magnetic system is installed outside the cylindrical cage, the hollow support shaft (3) is a non-rotary body, one end of the hollow support shaft (3) is used as an axes feeding port (12),the middle of the hollow support shaft (3) is provided with a baffle plate, and one side of the baffle plate of the hollow support shaft is provided with a separating and feeding port close to the feeding port (12), the other side of the baffle plate of the hollow support shaft is provided with a concentrate feeding port (14), and the other end of the hollow support shaft (3) is used as a concentrate discharging port (13). The permanent-magnet cylindrical cage type high-gradient magnetic separator has the advantages of easiness for maximization, convenience for design and production, low energy consumption, reasonable magnetic distribution, uniform background magnetic field working region as well as high processing capacity and stable separation indexes under limited tonnage and volume.

Owner:马鞍山市天工科技股份有限公司

Low-temperature, high-strength high-toughness high-entropy alloy and machining method thereof

ActiveCN112522563AReduce stacking fault energyImprove low temperature performanceHigh entropy alloysCarbide

The invention discloses a low-temperature, high-strength and high-toughness high-entropy alloy and machining method thereof. The molecular formula of a mother alloy of the high-entropy alloy is (Fe40Mn40Co10Cr10)100-x-yCxTiy, wherein, x is carbon content, and x is larger than 0.6 wt% and smaller than or equal to 0.8 wt%; y is titanium content, and y is greater than 1.4 wt% and less than or equal to 2.4 wt%; According to the percentage composition of element atoms, an alloy matrix Fe40Mn40Co10Cr10 of the high-entropy alloy comprises Fe of 35-45%; Mn of 35-45%; Co of 5-15%; and Cr of 5-15%. According to the low-temperature, high-strength high-toughness high-entropy alloy, a certain content of carbon element and titanium element are introduced into the Fe40Mn40Co10Cr10 alloy to form an interstitial solid solution with a matrix, so that on one hand, the stacking fault energy of a material can be effectively reduced, and twinning can be induced under a low-temperature condition, and on theother hand, the carbon element and the titanium element can provide additional strength increment for the matrix through solid solution and precipitation of carbide and titanium compounds, so that thelow-temperature performance of the material is effectively improved; and the titanium element is used as a good interstitial atom and the titanium compound is used as an effective precipitation strengthening phase, so that the performance of the material at low temperature can be greatly improved.

Owner:XIAN FULAI ELECTRICAL ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com