Solvent-free high-temperature resistant coating for high temperature protection on warship components

A high-temperature-resistant coating and solvent-free technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as very high requirements for substrate treatment, unfavorable health of soldiers, and greater health damage to personnel, so as to achieve no flammable and explosive hazards , maintaining strength, simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

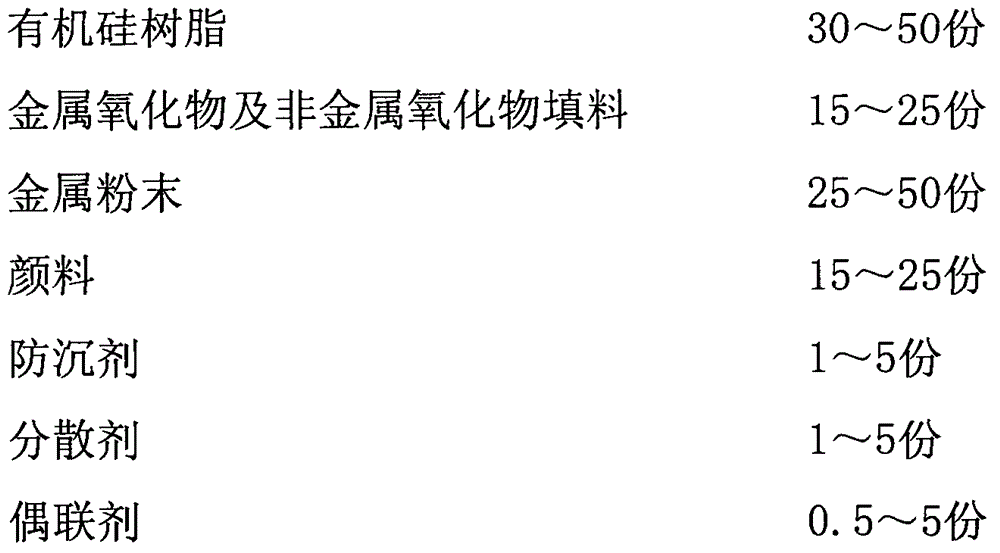

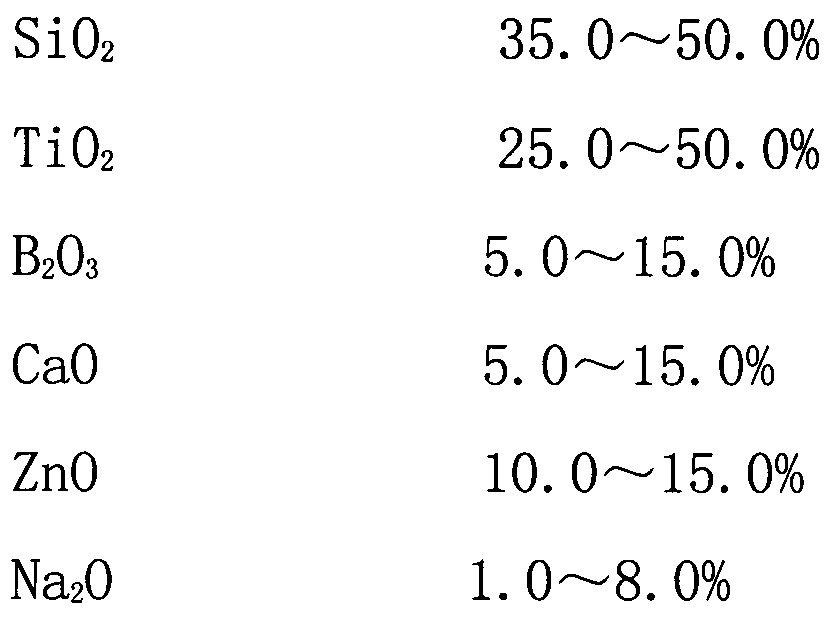

Method used

Image

Examples

Embodiment 1

[0034] The solvent-free high-temperature-resistant coating used for high-temperature protection of ship parts is composed of the following raw materials: solvent-free silicone resin 40Kg; metal oxide and non-metal oxide fillers: silicon dioxide 5Kg, titanium dioxide 5.5Kg, diboron trioxide 1Kg, calcium oxide 1.0Kg, zinc oxide 2Kg, sodium oxide 0.5Kg; metal powder: zinc powder 10Kg, aluminum powder 20Kg; pigment: titanium dioxide 14Kg, cobalt black 4.0Kg; anti-settling agent: fumed silica 3.5Kg; dispersant : acrylate 1.2Kg; coupling agent: isopropyl titanate 0.9Kg.

Embodiment 2

[0036] The solvent-free high-temperature-resistant coating used for high-temperature protection of ship parts is composed of the following raw materials: solvent-free silicone resin 45Kg; metal oxide and non-metal oxide fillers: silicon dioxide 6Kg, titanium dioxide 5Kg, diboron trioxide 1Kg , calcium oxide 1Kg, zinc oxide 2Kg, sodium oxide 1.0Kg; metal powder: zinc powder 15Kg, aluminum powder 15Kg; pigment: iron oxide red 15Kg, cobalt black 4.5Kg; anti-settling agent: fumed silica 3.0Kg; dispersant : Acrylate 1.0Kg; Coupling agent: Isopropyl titanate 1Kg.

Embodiment 3

[0038] The solvent-free high-temperature-resistant coating used for high-temperature protection of ship parts is composed of the following raw materials: solvent-free silicone resin 30Kg; metal oxide and non-metal oxide fillers: silicon dioxide 8Kg, titanium dioxide 8.5Kg, diboron trioxide 2Kg, calcium oxide 2Kg, zinc oxide 3.5Kg, sodium oxide 1.0Kg; metal powder: zinc powder 20Kg, aluminum powder 10Kg; pigment: chromium oxide green pigment 18Kg, cobalt black 4.5Kg; anti-settling agent: fumed silica 3.5Kg ; Dispersant: Acrylic ester 1.0Kg; Coupling agent: Isopropyl titanate 0.5Kg.

[0039] In order to achieve the optimal performance of the coating, the sample should be processed according to the following three steps before coating construction:

[0040] 1) The surface cleanliness after spray cleaning should reach Sa2.5 level (ISO 8501-1). For parts that are not convenient for spray cleaning or fail to meet the requirements, power tool treatment can be used to reach St3 level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com