A supercritical reactor with internal gas product heat exchange

A technology of gas products and reactors, applied in the field of supercritical reactors, can solve the problems of high production costs, high-temperature gas prone to explosion, corrosion, etc., to achieve energy recovery, facilitate follow-up processing, and increase heat transfer area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

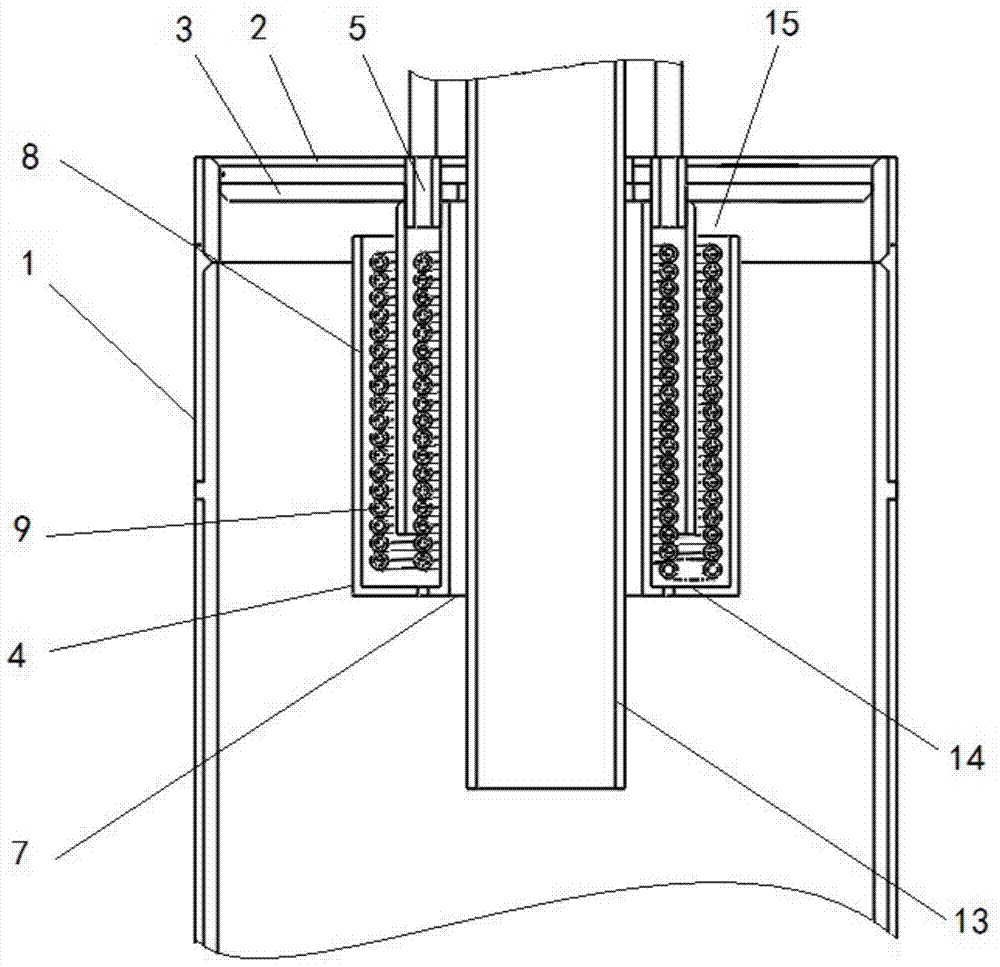

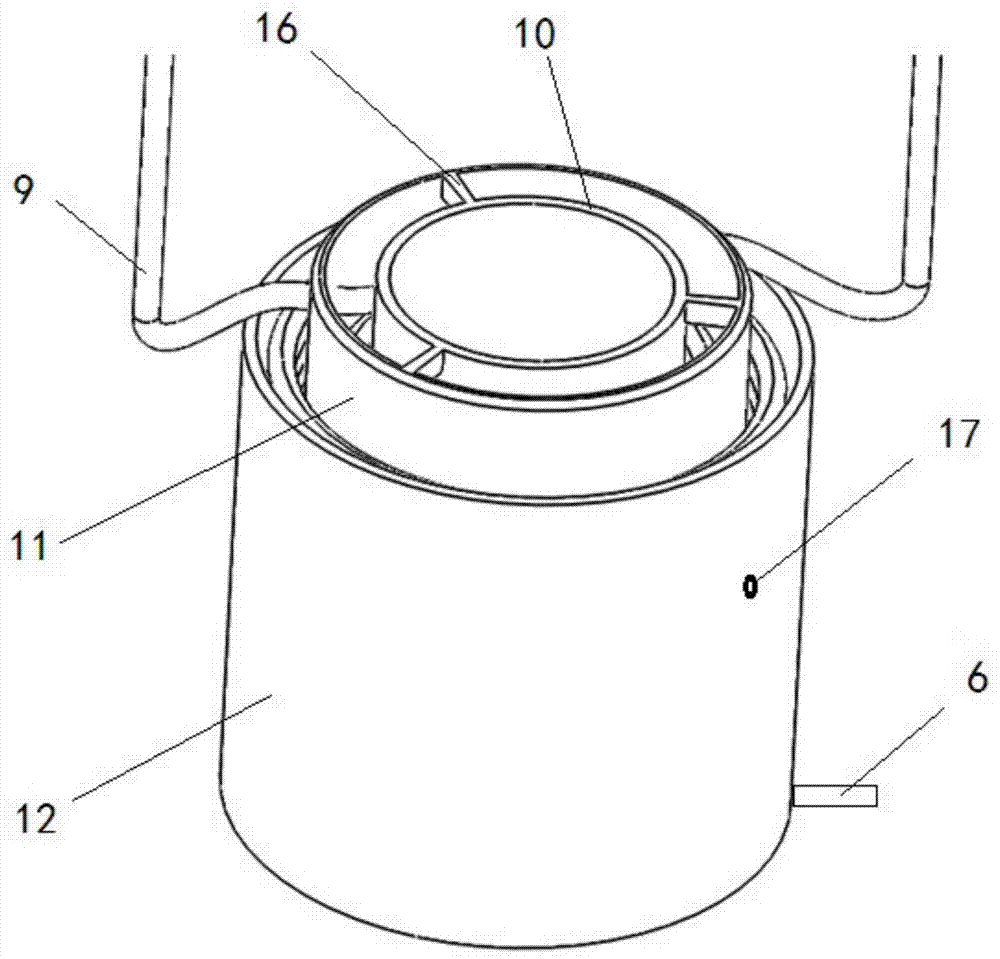

[0032] Such as figure 1 Shown, a kind of supercritical reactor that carries out gas product heat exchange inside, it comprises cylinder body 1, upper end head 2, baffle plate 3 and heat exchange device 4, wherein cylinder body 1 is a sealed cavity, The top is sealed by the upper end head 2, and the bottom is provided with outlets for products such as supercritical reaction inorganic salts. The baffle 3 is fixed in the cylinder body 1 below the upper end head 2, the heat exchange device 4 is fixed under the baffle 3, and the burner nozzle 13 of the reactor passes through the heat exchange device 4 from the upper end head 1. The middle part enters the combustion zone of cylinder body 1. One or more gas phase outlets 5, liquid phase inlets an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com