Permanent-magnet cylindrical cage type high-gradient magnetic separator with high processing capacity

A technology of high-gradient magnetic separator and permanent magnet cylinder, which is applied in the direction of high-gradient magnetic separator to achieve the effect of reasonable load distribution and mechanical strength structure, and reduce mechanical inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

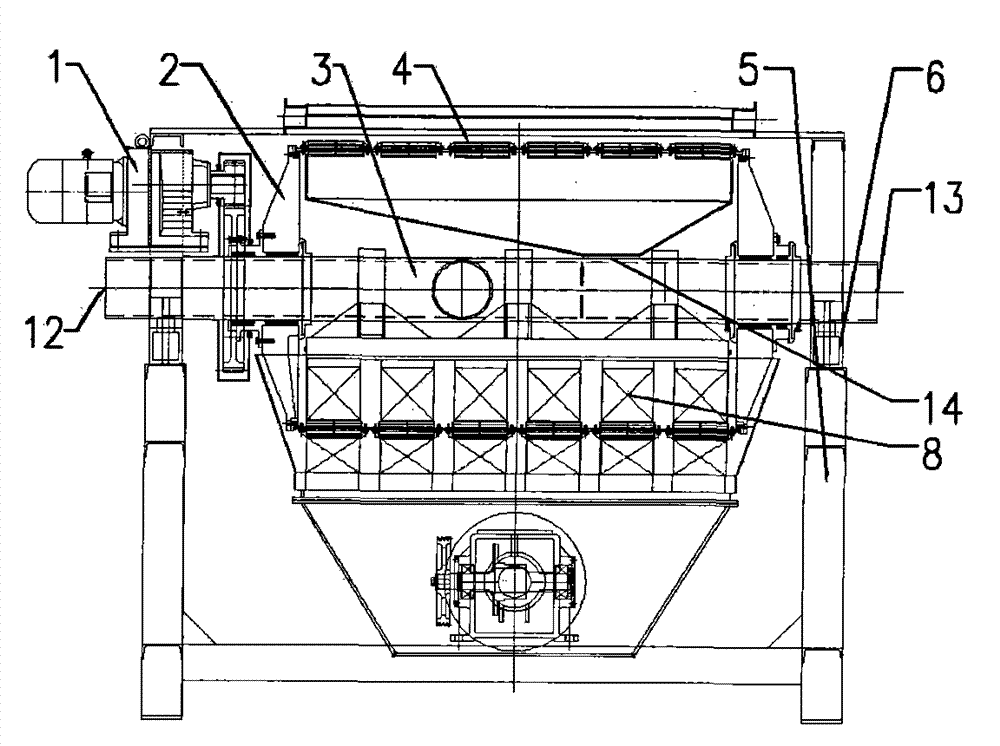

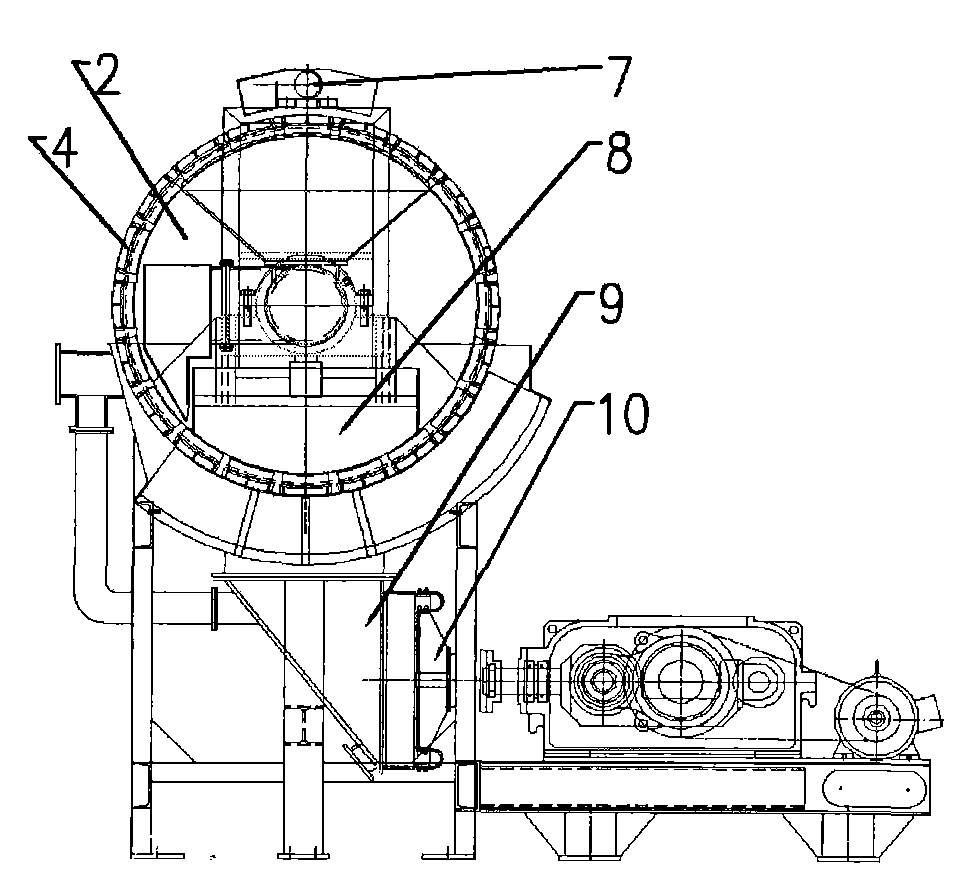

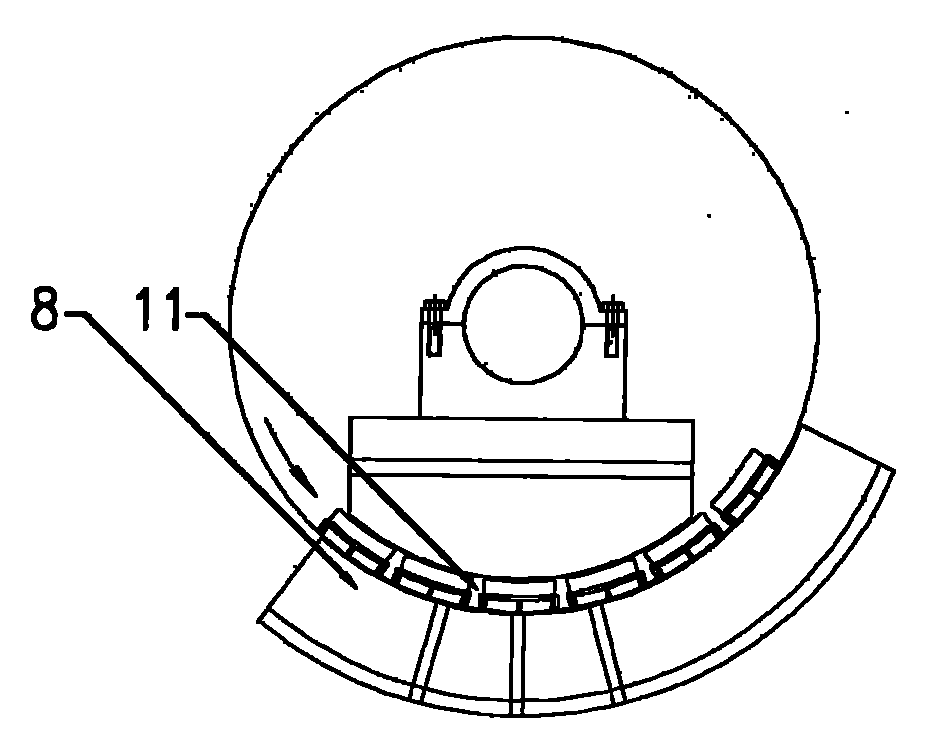

[0027] In order to better describe the present invention, a large-capacity permanent magnet cylinder-cage high-gradient magnetic separator of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Depend on figure 1 Shown in the present invention is a large-capacity permanent-magnet cylinder-cage high-gradient magnetic separator main section structure diagram and figure 2 The schematic diagram of the left section structure shown in combination with image 3 It can be seen that a large-capacity permanent magnet cylinder-cage high-gradient magnetic separator of the present invention includes a separation cylinder 2 and its drive mechanism 1, a magnetic system 8 and a magnetic field adjustment mechanism 6, a concentrate washing device 7, and a frame 5. The tank body 9 installed on the frame 5, the pulsation mechanism 10 connected with the tank body 9, and the concentrate washing device 7 are installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com