Patents

Literature

168results about How to "Reduce temper brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

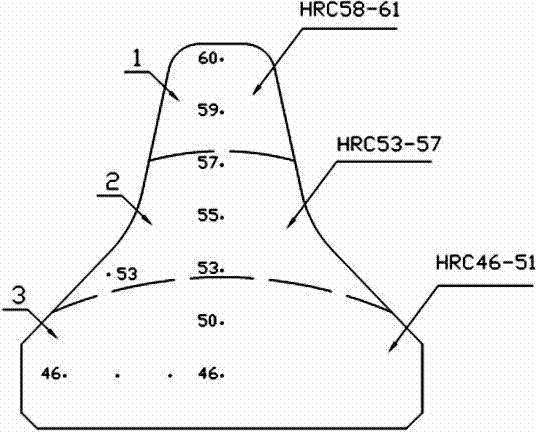

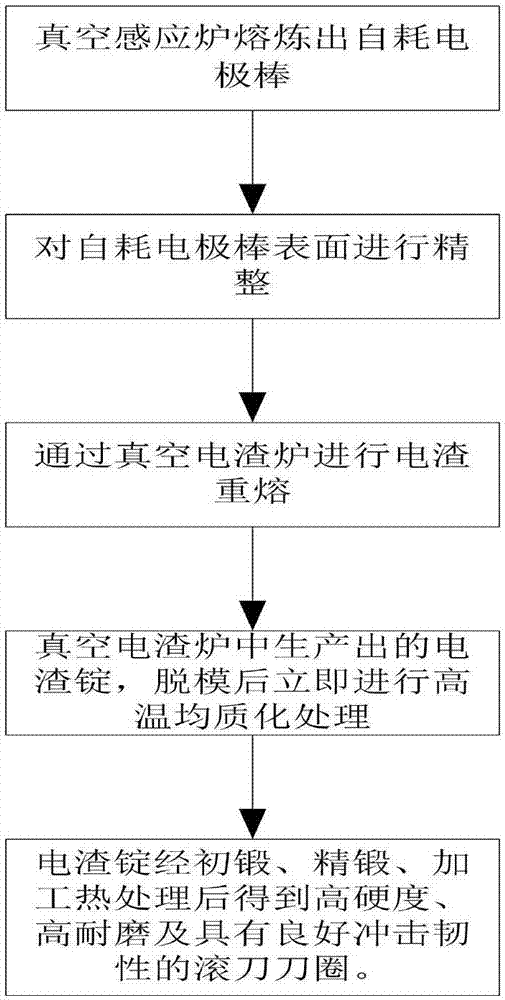

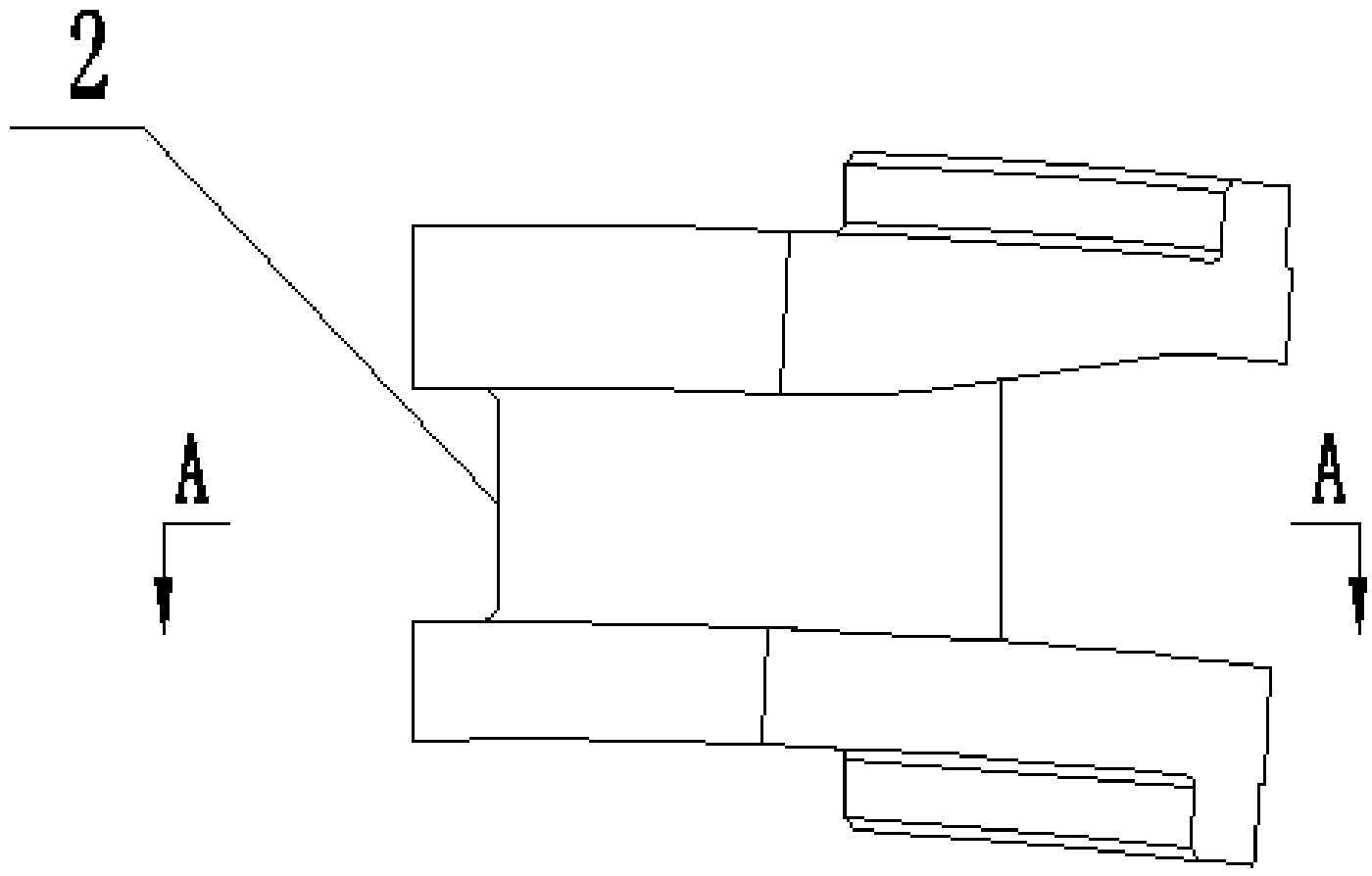

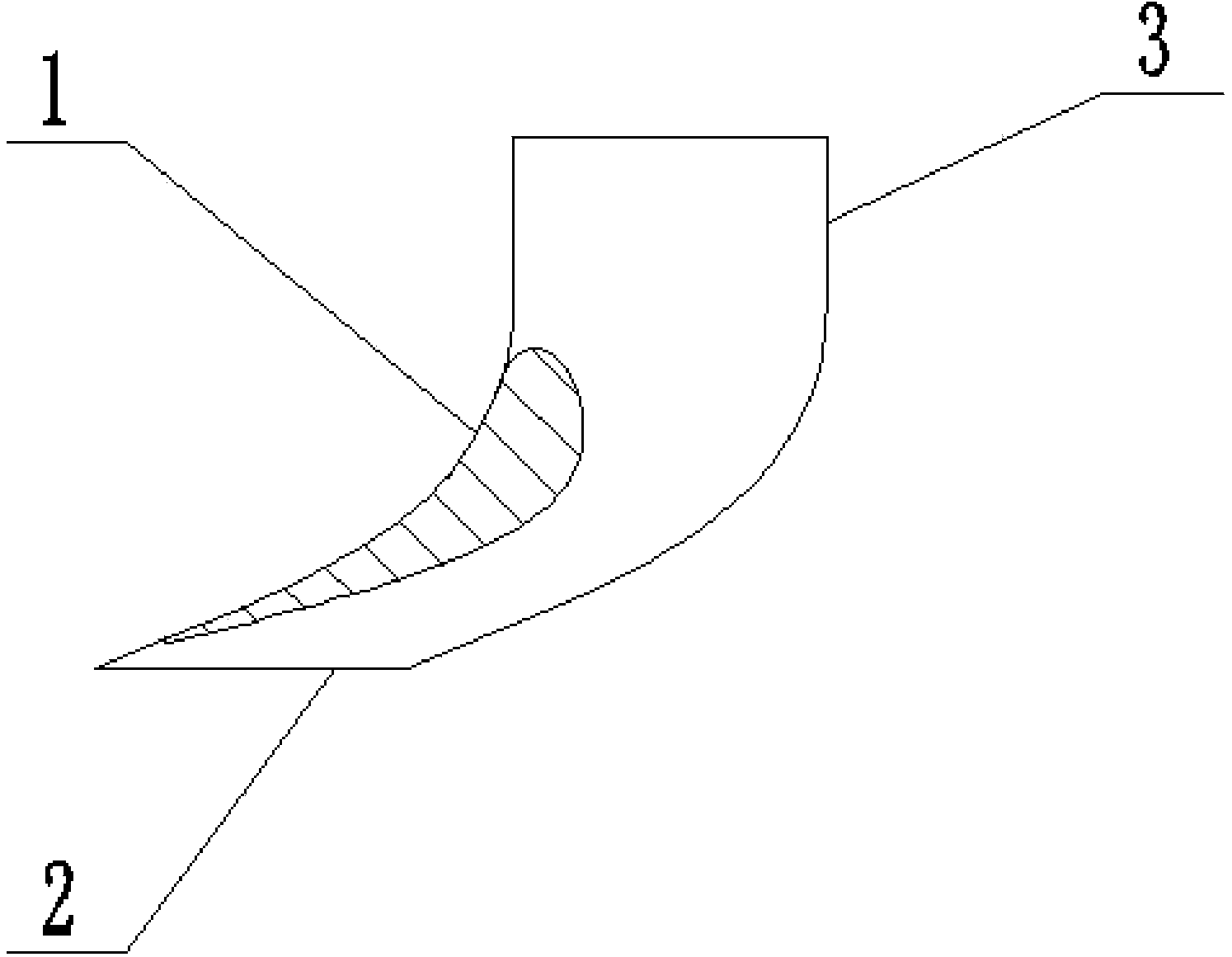

Disk-shaped roller cutter ring and manufacture method thereof

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and manufacturing method thereof

The invention relates to an ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and a manufacturing method thereof. The steel plate comprises the chemical components of: 0.06-0.11% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, 0.20-0.50% of Cr, 0.10-0.30% of Ni, 0.10-0.30% of Mo, 0.02-0.05% of Nb, 0.02-0 .06% of V, 0.008-0.03% of Ti, 0.0005-0.003% of B, 0.02-0.05% of Al, and balance of Fe. According to the invention, through two-stage controlled rolling, and direct quenching and tempering, a refined tempered martensite or lower bainite structure is obtained. Defects such as long process, high energy consumption, large alloy addition amount, and the like of traditional quenching and tempering process are overcome. The obtained steel plate has good toughness and cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

12Cr2Mo1R thick steel plate for equipment contacting hydrogen and method for producing the same

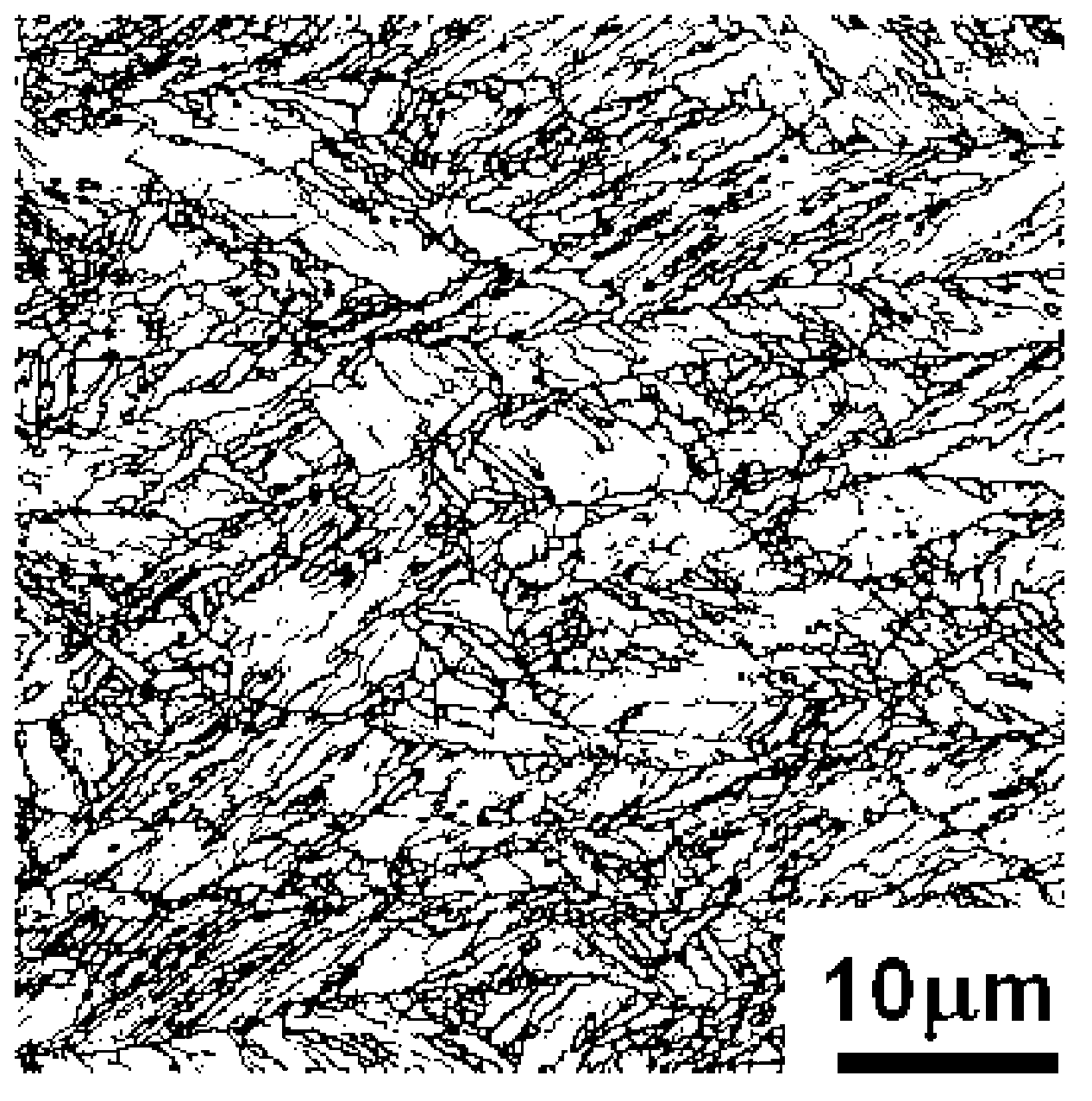

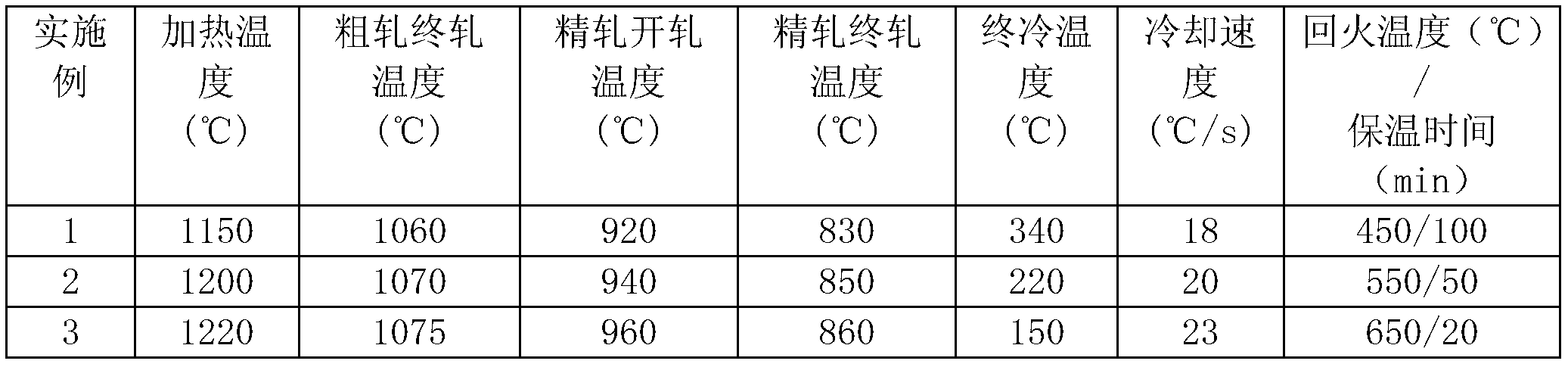

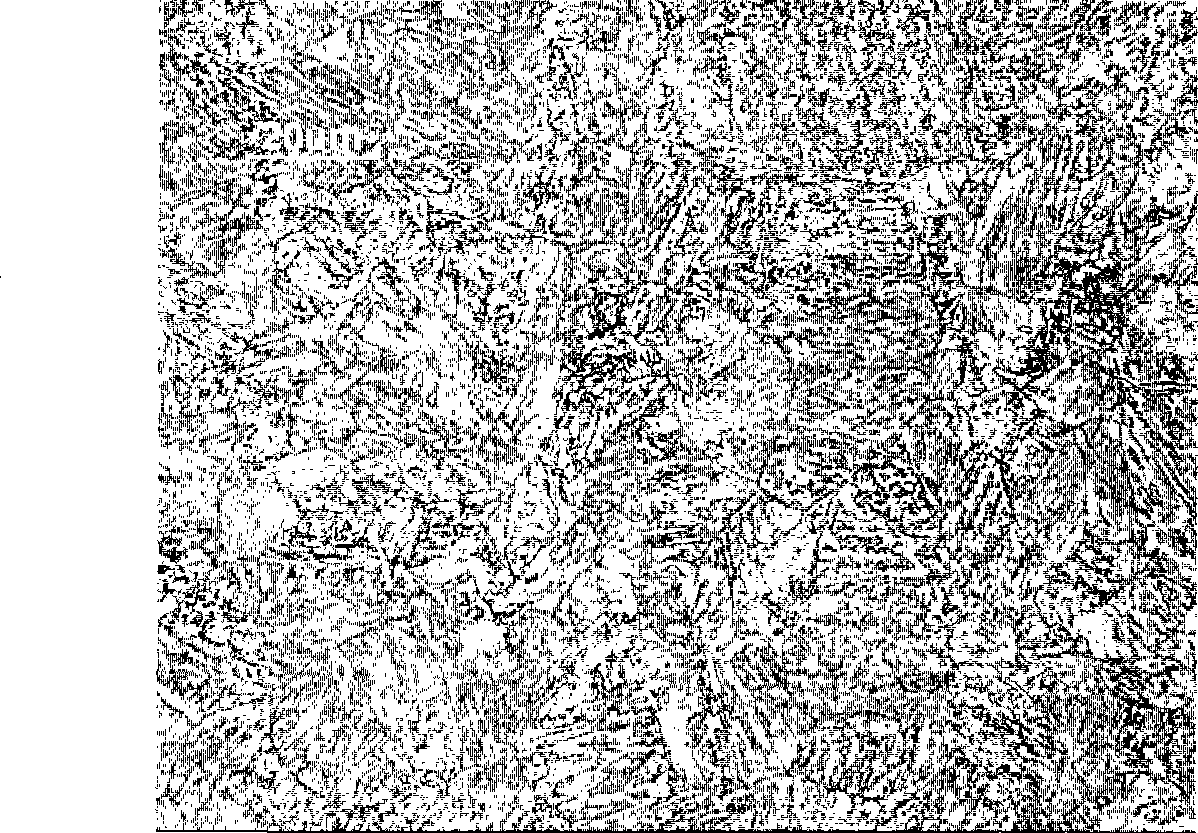

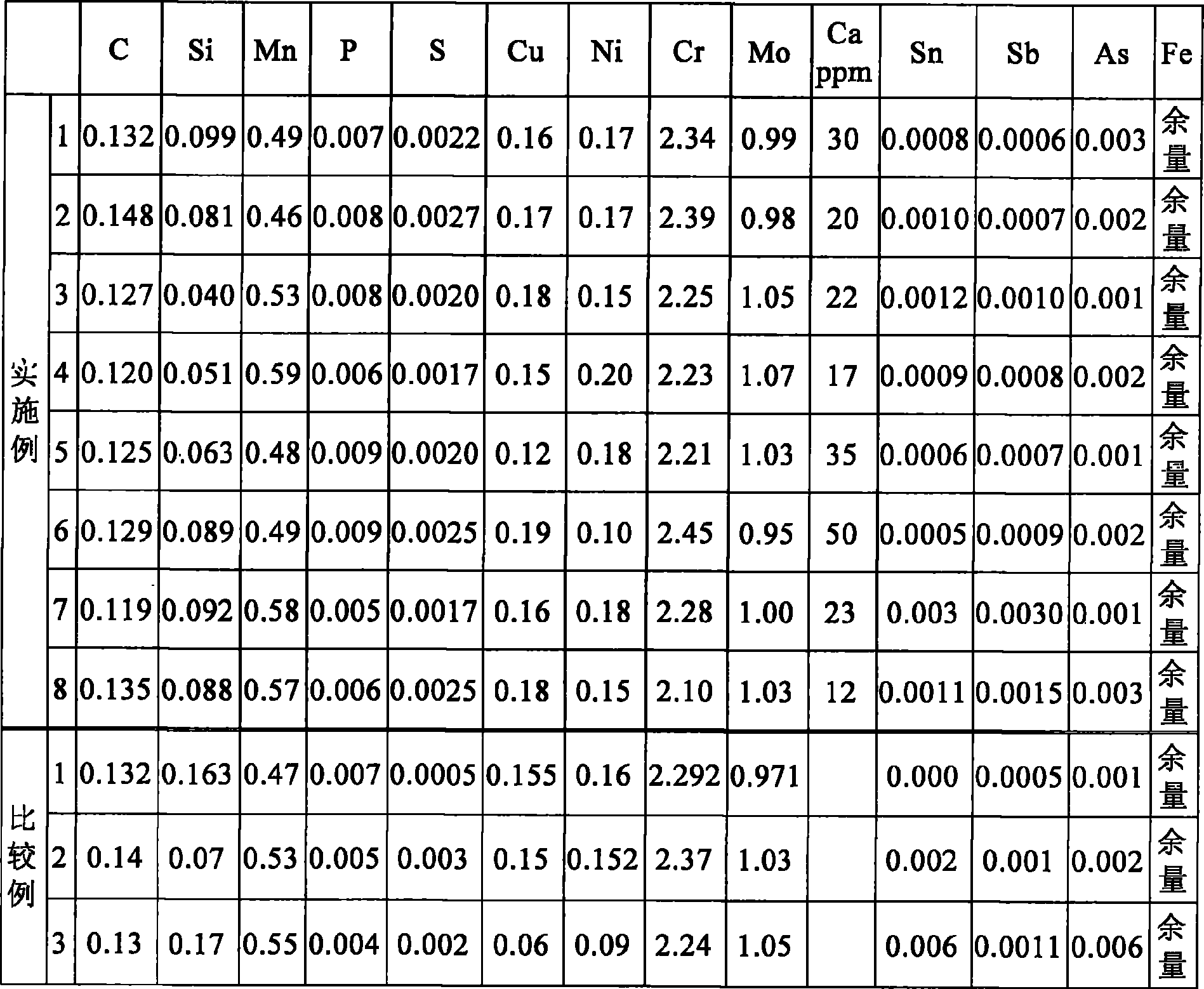

The invention discloses a 12Cr2Mo1R thick steel plate used in equipment contacting hydrogen and a production method thereof which includes the following steps: a) The mass percentage of constituents is as follows: C: 0.10 to 0.15, Si: less than or equal to 0.10, Mn: 0.40 to 0.60, P: less than or equal to 0.010, S: less than or equal to 0.003, Cr: 2.0 to 2.5, Mo: 0.90 to 1.10, Cu: 0.10 to 0.20, Ni: 0.10 to 0.20, Sn is less than or equal to 0.003, Sb is less than or equal to 0.003, As is less than or equal to 0.003, Ca: 0.001 to 0.005, and Fe as the rest; b) The invention adopts converter smelting, and are casted into ingots; c) The ingots are bloomed, cogged and rolled; d) After being rolled, the ingots are normalized, and the temperature is 900 to 950 DEG C; e) Being accelerating-cooled by a pressure quenching machine based on the core part (more than or equal to 0.5 DEG C / s), bainite structures are obtained in whole thickness range; and f) Tempering treatment is carried out at 700 to 760 DEG C. The invention uses the pressure quenching machine, ensures that the microstructure of the finished product plate is tempering bainite by normalizing, accelerating cooling and tempering treatment, and obtains excellent mechanical property and weldability.

Owner:BAOSHAN IRON & STEEL CO LTD

High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

ActiveCN102605297AImprove strength and toughnessMeet manufacturing requirementsFurnace typesHeat treatment furnacesHydrogenWater flow

Disclosed are high low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and a production method thereof. The production method includes the steps: firstly, smelting and casting; secondly, heating plate blanks at 1070-1210 DEG C and rolling the plate blanks according to a compression ratio of 2.7-6.4; thirdly, normalizing within an austenitization temperature range; fourthly, accelerated cooling with water for 4-15 minutes; and fifthly, tempering at 700-750 DEG C; and sixthly cooling, wherein the steel plates comprise, in weight percentage, 0.10-0.15% of C, 0.50-0.60% of Si, 0.40-0.60% of Mn, not more than 0.010% of P, not more than 0.003% of S, 1.25-1.50% of Cr, 0.45-0.65% of Mo, 0.08-0.18% of Cu, 0.07-0.17% of Ni, 0.020-0.045% of Al, not more than 0.003% of Sn, not more than 0.003% of Sb, not more than 0.003% of As, 0.0020-0.0070% of N, the balance of Fe and unavoidable impurities, low-pressure section water flow of a pressure quenching machine is 18-38m<3> / min, top-to-bottom water volume ratio of each steel plate is 1:1.0-1.3, and the surface temperature of the steel palate at an outlet of the pressure quenching machine is not more than 120 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel suitable for drill rod joint in low-temperature environment and heat treatment process of steel

InactiveCN102140610AOvercome shortcomingsIncrease low temperature toughness reserveDrilling rodsDrilling casingsFiberTrace element

The invention relates to steel suitable for a drill rod joint in a low-temperature environment and a heat treatment process of the steel. The steel used for a drill rod joint comprises the following components by weight percent: C 0.25-0.35%, Mn 0.50-1.00%, P<=0.015%, S<=0.008%, Mo 0.15-1.00%, Ni 0.75-1.50%, Cr 0.80-1.50%, two or more of Si<=0.30%, Al<=0.03%, V<=0.10%, Ti<=0.03% and Re<=0.005%, and the balance of Fe and inevitable trace elements. The heat treatment process of the steel suitable for a drill rod joint is as follows: heating the steel in a furnace to 900-960 DEG C; carrying out heat insulation for 1.0-1.5 hours; putting the steel into a quenching medium and cooling down completely; tempering at the temperature of 660-690 DEG C; carrying out heat insulation for about 2.0-2.5 hours; and then taking the steel out of the furnace. After the steel is treated according to the process, when the yield strength of the steel is 905MPa, longitudinal and full-size charpy impact power average value at -60 DEG C is 110J, the fracture fiber rate is 100% on the average, and the ductile-brittle transition temperature is -85 DEG C.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +1

Process for improving rare-earth high-strength steel impact toughness

The invention discloses a process for improving rare-earth high-strength steel impact toughness. The process comprises the following steps of KR desulfurization slagging off, converter smelting, LF refining, RH refining and rare-earth treating, continuous casting, heating, rolling, accelerated cooling and heat treating. According to the process, aiming at the influence on the microstructure of low-alloy high-strength steel in the case that rare-earth exists, a research shows that rare-earth cerium Ce can improve the forms of inclusions and purify grain boundaries, so that the strength of the grain boundaries is improved, the possibility that cracks extend due to the through defects is reduced, and the impact toughness is improved; and addition, the impact toughness can be improved throughrefining austenite grain boundaries, and meanwhile, adding the rare-earth cerium Ce can enable the ductile-brittle transition temperature of the steel to reduce by about 10 DEG C.

Owner:BAOTOU IRON & STEEL GRP

High-strength steel plate for light goods shelves and forging process thereof

The invention discloses a high-strength steel plate for light goods shelves and a forging process thereof. The high-strength steel plate for the light goods shelves is composed of, by weight percentage, 0.22-0.24% of carbon, 0.32-0.38% of boron, 0.52-0.54% of palladium, 0.02-0.04% of selenium, 0.02-0.04% of arsenic, 3.23-3.25% of rubidium, 0.45-0.48% of vanadium, 5.36-5.39% of titanium, 6.63-6.67% of copper, 4.57-4.59% of tin, 8.7-8.9% of chromium, 0.06-0.08% of molybdenum, 8.78-8.79% of nickel, 0.36-0.38% of barium, 3.42-3.44% of magnesium, 3.21-3.23% of neodymium, 0.25-0.35% of promethium, 0.45-0.48% of praseodymium, 1.2-1.5% of holmium, 0.04-0.06% of dysprosium, balancing Fe and inevitable impurities.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

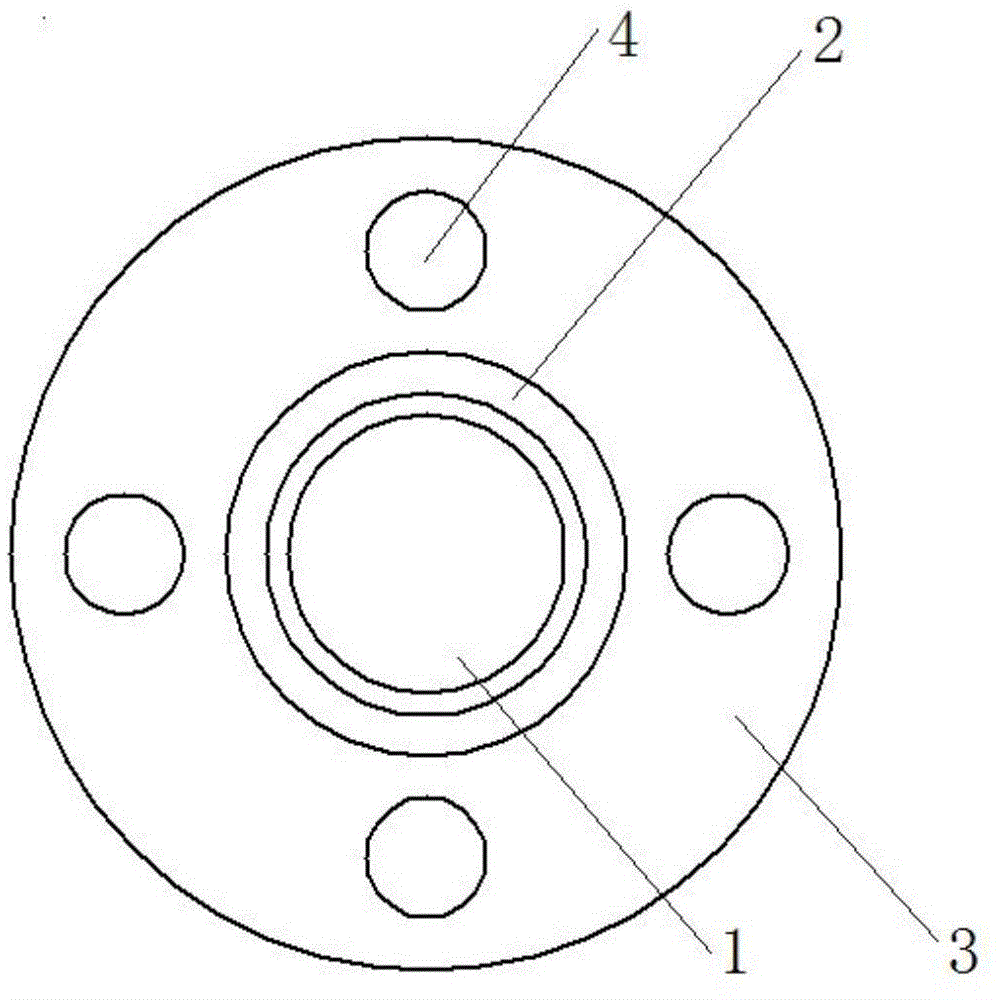

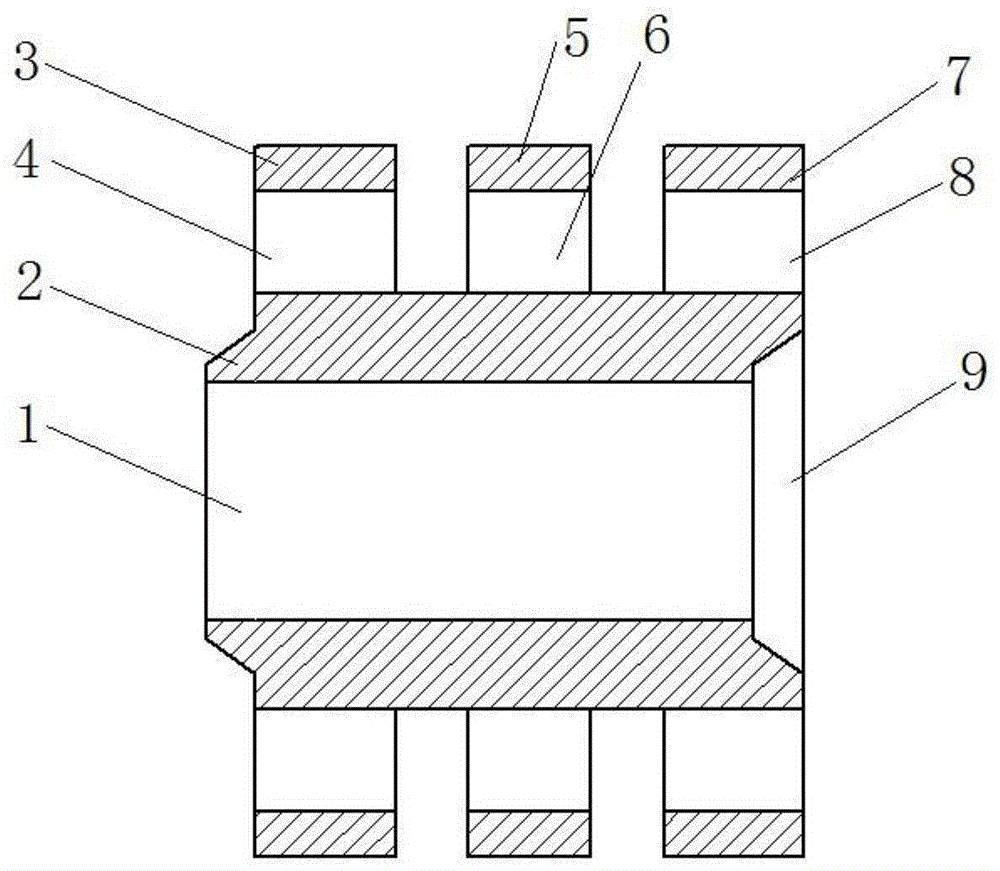

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

Anticorrosion coating for metal surface and preparation method of anticorrosion coating

InactiveCN104789958AHigh strengthImprove corrosion resistanceHeat inorganic powder coatingNiobiumManganese

The invention discloses an anticorrosion coating for a metal surface and a preparation method of the anticorrosion coating. The anticorrosion coating comprises the following components in mass percent: 0.23-0.25% of carbon, 4.62-4.65% of manganese, 7.52-7.58% of chromium, 6.43-6.45% of vanadium, 8.52-8.55% of nickel, 0.51-0.55% of strontium, 1.24-1.27% of niobium, 1.42-1.45% of molybdenum, 2.22-2.24% of zirconium, 0.25-0.29% of tungsten, 4.32-4.35% of zinc, 3.45-3.48% of lanthanum, 12.27-12.29% of neodymium, 5.43-5.45% of promethium, 2.2-2.4% of gadolinium, 3.62-3.65% of terbium, 3.5-3.8% of an auxiliary, and the balance of iron.

Owner:SUZHOU TONGMING MACHINERY

Alloy material for valve casting and processing process thereof

The invention discloses an alloy material for valve casting. The alloy material comprises the following chemical components in percentage by mass: 0.2-0.3% of C, 0.1-0.3% of Si, 0.5-0.8% of Mn, 0.015-0.030% of P, 0.010-0.025% of S, 0.20-0.50% of Cr, 0.12-0.35% of Ni, 0.1-0.2% of Mo, 0.05-0.25% of Cu, 0.02-0.03% of V, 0.12-0.15% of rear earth and the balance of Fe and trace impurities. The invention further discloses a processing process of the alloy material for valve casting. The alloy material improves the corrosion resistance, the wear resistance and the oxidation resistance of a valve, so that the valve can be adapted to various harsh working environments and has high strength; the alloy material is long in service life, the cost is reduced, and the heat temperature resistance is improved.

Owner:YANCHENG OAK VALVE CO LTD

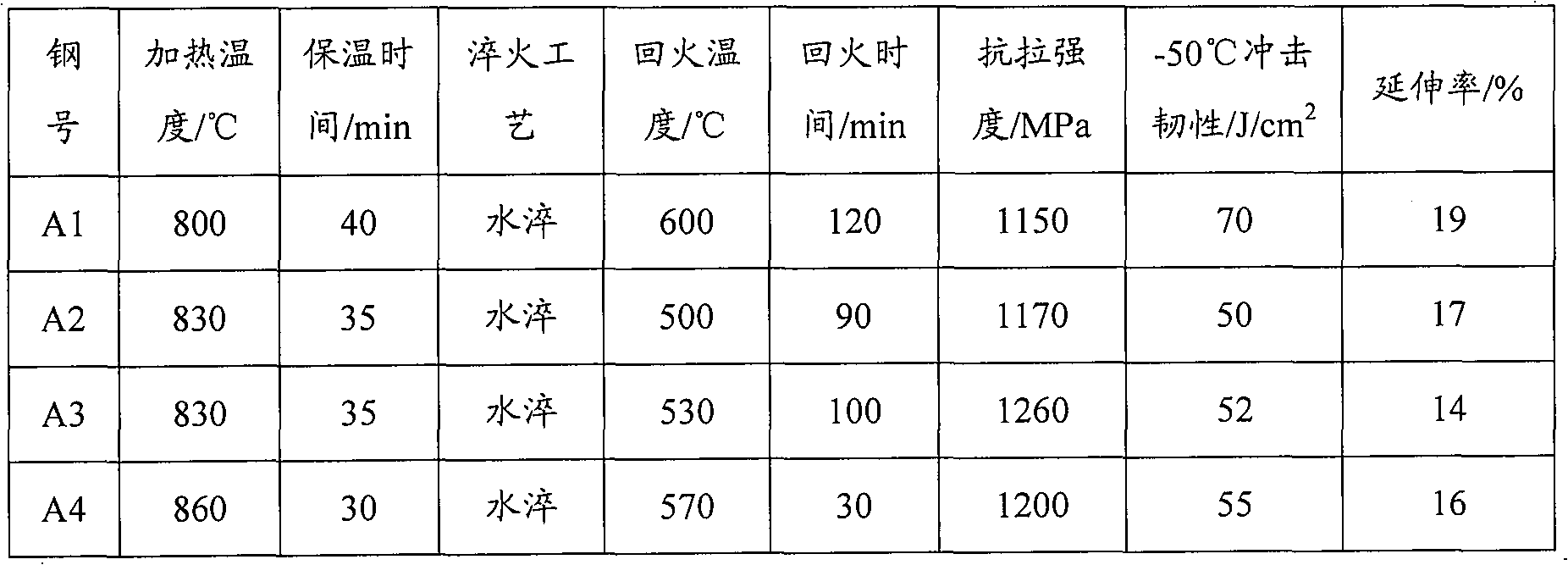

Alloy steel for high-strength gas cylinder, gas cylinder and manufacturing method thereof

The invention relates to alloy steel for a high-strength gas cylinder. The alloy steel consists of the following chemical components in percentage by weight: 0.30-0.38 percent of C, 0.15-0.37 percent of Si, 0.60-0.90 percent of Mn, 0.80-1.20 percent of Cr, 0.15-0.30 percent of Mo, 0.01-0.05 percent of Al, 0.00-0.25 percent of Ti, 0.02-0.25 percent of Nb, 0.03-0.20 percent of W, less than or equal to 0.010 percent of P, less than or equal to 0.010 percent of S, 0.002-0.004 percent of Ca, less than or equal to 0.0035 percent of N and the balance of Fe and inevitable impurities, wherein Ti+Nb is more than or equal to 0.07 percent; and the total quantity of impurity elements is less than 0.05 percent. A manufacturing method of the high-strength gas cylinder comprises the following steps of: smelting, refining, performing VD (Vacuum Distillation) treatment, controlling the content of elements P and S in the steel, and adjusting the content of N simultaneously; before tapping, feeding Si-Ca wires in an amount of 2-3 meters into every ton of steel for denaturalizing inclusions; pouring a square billet with a large square billet continuous casting machine under the protection of argon gas, blooming at the temperature 1,050-1,090 DEG C, and cogging to obtain a square billet material; manufacturing a seamless gas cylinder; preserving the heat of the seamless gas cylinder at the temperature 800-940 DEG C for 30-60 minutes, and performing water quenching treatment; and tempering at the temperature 500-650 DEG C, and preserving heat for 30-120 minutes. The obtained gas cylinder steel has a tempered sorbite structure, the tensile strength is over 1,100 MPa, and the low-temperature impact toughness at the temperature 50 DEG C below zero is over 45 J / cm<2>.

Owner:BAOSHAN IRON & STEEL CO LTD

High temperature-resistant coating for metal surfaces and preparation method of coating

InactiveCN104878378AHigh strengthImprove corrosion resistanceAnti-corrosive paintsPressure inorganic powder coatingNiobiumLanthanum

The invention discloses a high temperature-resistant coating for metal surfaces and a preparation method of the coating. The high temperature-resistant coating is prepared from the following components in percentage by mass: 0.4-0.6% of carbon, 2.6-2.8% of magnesium, 6.5-6.8% of chromium, 3.0-3.2% of vanadium, 12.5-12.8% of nickel, 0.3-0.5% of calcium, 0.2-0.5% of niobium, 2.4-2.6% of molybdenum, 2.7-2.9% of barium, 0.2-0.4% of tungsten, 3.2-3.5% of titanium, 0.2-0.5% of aluminum, 3.5-3.8% of lanthanum, 4.8-5.1% of neodymium, 2.3-2.5% of promethium, 1.2-1.4% of europium, 4.2-4.5% of dysprosium and the balance of iron; the high temperature-resistant coating is further coated with an anti-corrosion oil paint.

Owner:SUZHOU TONGMING MACHINERY

High-toughness steel plate with high-temperature PWHT softening resistance and low welding crack sensitivity coefficient for crude oil storage tank and manufacturing method of high-toughness steel plate

ActiveCN105671436AImprove toughnessLow welding crack sensitivity coefficientChemical compositionToughness

The invention discloses a high-toughness steel plate with high-temperature PWHT softening resistance and a low welding crack sensitivity coefficient for a crude oil storage tank and a manufacturing method of the high-toughness steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.07-0.12% of C, 0.15-0.30% of Si, 1.40-1.60% of Mn, less than or equal to 0.010% of S, less than or equal to 0.015% of P, 0.05-0.15% of Mo, 0.20-0.35% of Ni, 0.015-0.035% of Nb, 0.030-0.060% of V, 0.010-0.030% of Ti, 0.015-0.045% of Alt, less than or equal to 0.0030% of O, 0.0020-0.0045% of N, less than or equal to 0.00015% of H and the balance Fe and unavoidable trace impurities. The steel plate for the crude oil storage tank also has a relatively low welding crack sensitivity coefficient and a relatively low reheating crack sensitivity coefficient while having high toughness and high-temperature PWHT softening resistance and is suitable for constructing 100000-150000m<3> large crude oil storage tanks.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

High strength steel bar for pre-stressed concrete and production technology thereof

ActiveCN104404380AImproved resistance to hydrogen-induced delayed fractureAvoid inhalationSpinningChemical composition

The invention discloses a high strength steel bar for pre-stressed concrete. The steel bar is composed of the following chemical components in percentage by weight: 0.20 to 0.25% of C, 1.50 to 1.85% of Si, 0.20 to 0.50% of Mn, 0.07 to 0.09% of Cr, 0.30 to 0.35% of Mo, 0.25 to 0.35% of V, 0.05 to 0.08% of Nb, 0.42 to 0.61% of Ti, 0.15 to 0.25% of Ni, 0.25 to 0.40% of Ca, not more than 0.025% of S, not more than 0.025% of P, not more than 0.20% of Cu, 0.15 to 0.30% of composite rare earth, and the balance being Fe. The invention further discloses a production technology of the steel bar. The production technology comprises the following steps: smelting to obtain a steel blank, rolling the steel blank, cooling the rolled steel blank, rolling the steel blank for a second time, carrying out a thermal treatment and a stabilizing treatment, performing a gas nitrogenation treatment, spinning, winding, bundling, and storing the bundles in a warehouse.

Owner:溧阳市万兴特种建材有限公司

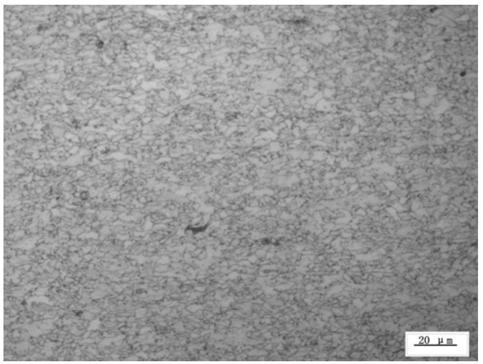

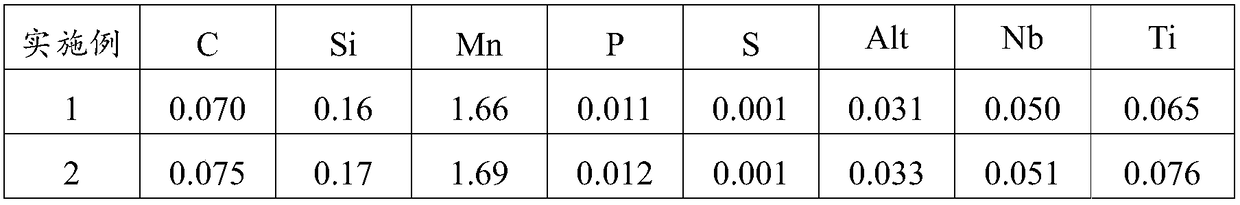

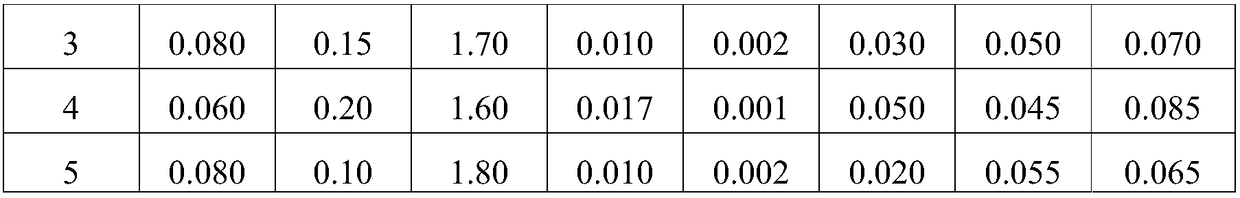

700 MPa level automobile beam steel belt and preparation method thereof

The invention provides a 700 MPa level automobile beam steel belt and a preparation method thereof. The beam steel belt comprises the following chemical components in percentages by weight: 0.06% to 0.08% of C, 0.10% to 0.20% of Si, 1.60% to 1.80% of Mn, 0 to 0.017% of P, 0 to 0.002% of S, 0.020% to 0.050% of Alt, 0.065% to 0.085% of Ti, 0.045% to 0.055% of Nb and the balance of Fe and unavoidableimpurities. The 700 MPa level automobile beam steel belt provided by the invention has an excellent mechanical property, particularly low-temperature toughness, simultaneously has good welding performance, and can be used for automobile structural parts such as automobile cross beams and longitudinal beams with good forming processability and high strength requirement.

Owner:BAOTOU IRON & STEEL GRP

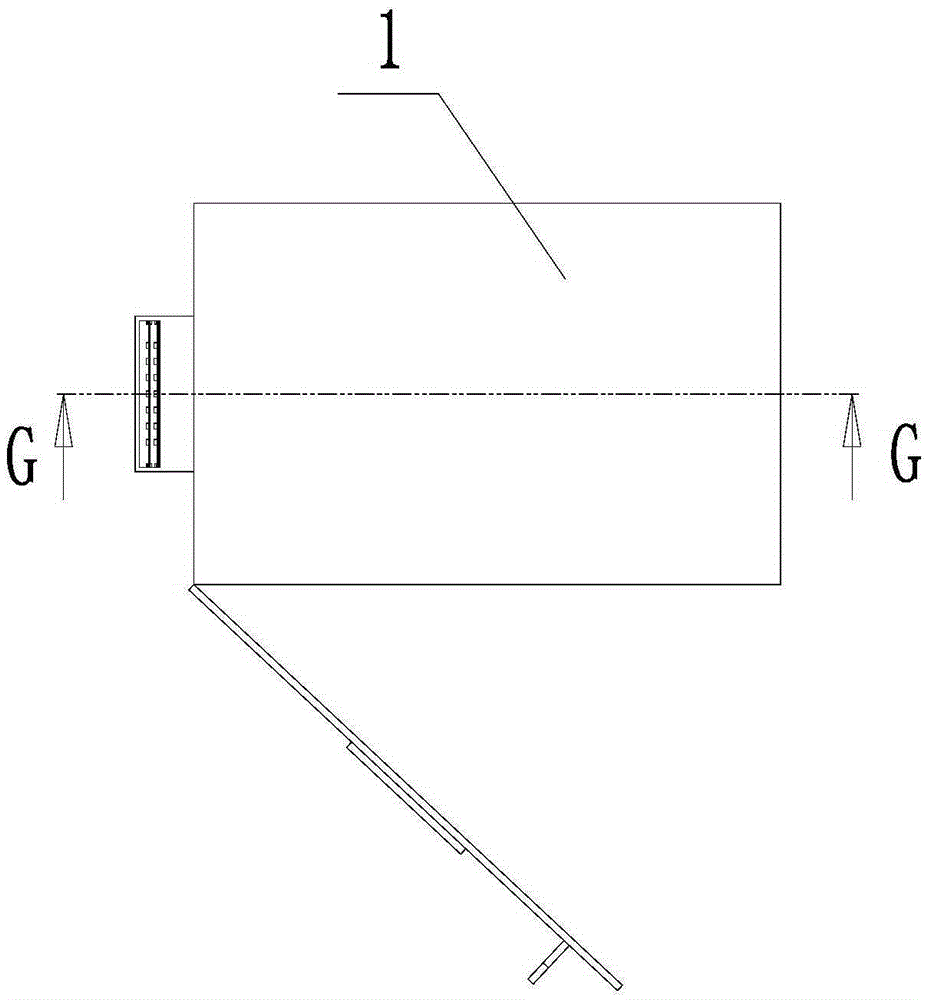

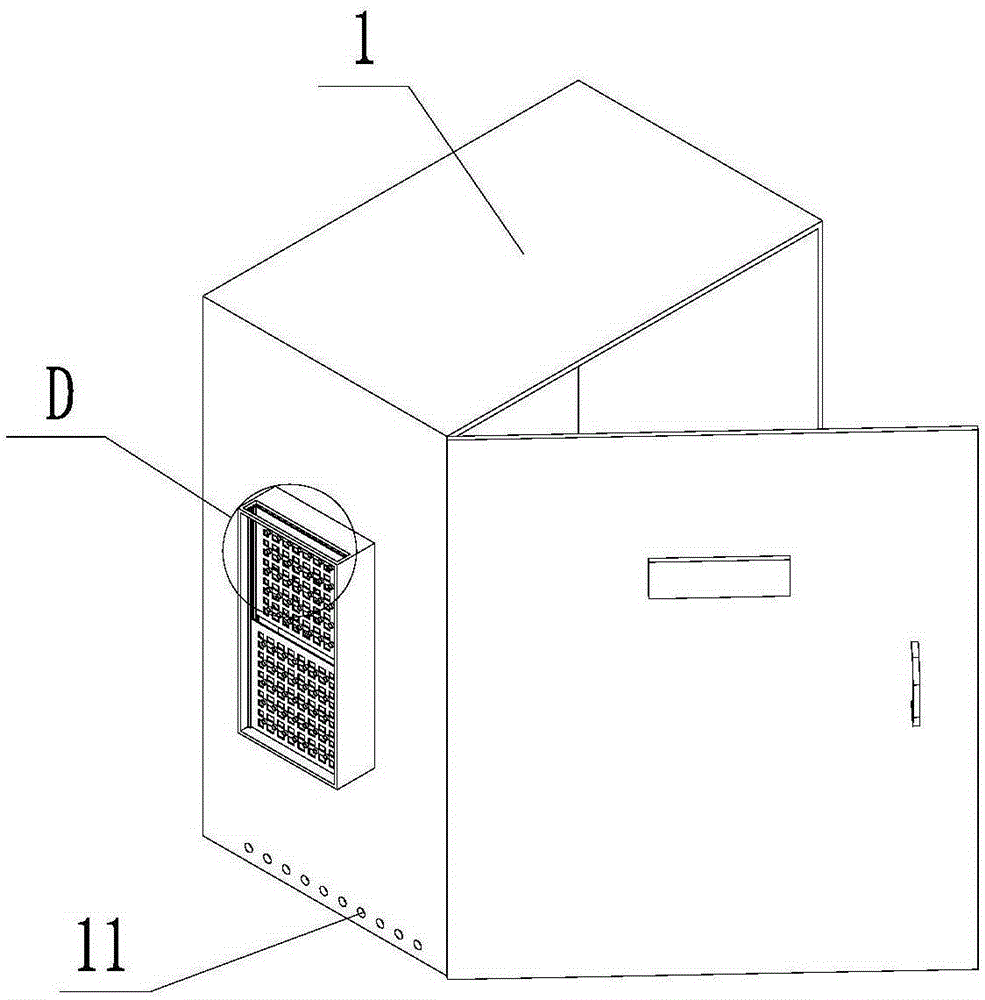

High-low-voltage switch cabinet having dust removing function

InactiveCN105244784AImprove securityImprove reliabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlStructural engineering

The invention discloses a high-low-voltage switch cabinet having a dust removing function. The high-low-voltage switch cabinet comprises a switch cabinet body which is horizontally arranged, wherein an installation empty cavity is formed inside the switch cabinet body, a bracket is arranged on a side wall of the switch cabinet body, a support is arranged inside the bracket, an axial flow fan is arranged on the support, the bracket is provided with a ventilation net on the outer side of the axial flow fan, the surface of the ventilation net is provided with a plurality of magnets, and a plurality of air outlets are formed in the switch cabinet body. the high-low-voltage switch cabinet is simple in structure and convenient in operation, can reduce temperature inside the switch cabinet, prolongs the service life of the switch cabinet, has a function of absorbing metal dust, greatly reduces the metal dust entering into the switch cabinet, ensures the normal operation of internal electrical components, avoids safety problems of causing short circuit and the like, is stable and reliable in operation, and reduces costs.

Owner:鼎圣集团有限公司

Bronze alloy material for valve casting and treatment process thereof

The invention discloses a bronze alloy material for valve casting. The alloy material contains the chemical ingredients in percentage by mass: 0.55-0.58% of C, 0.33-0.36% of Mn, 2.25-2.45% of Cr, 4.35-4.55% of Ni, 0.52-0.55% of Mo, 0.38-0.40% of W, 0.12-0.15% of V, 0.11-0.13% of Nb, 22.3-22.5% of Zn, 0.25-0.28% of rare earth and the balance of Cu and trace impurities. The invention further discloses a treatment process of the bronze alloy material for valve casting. According to the bronze alloy material for valve casting and the treatment process thereof, the corrosion resistance, wear resistance and oxidation resistance of valves are improved, the valves can adapt to various harsh environments and are high in strength and long in service lives, the cost is reduced, and the high-temperature resistance is improved.

Owner:盐城市大丰区亿然阀门有限公司

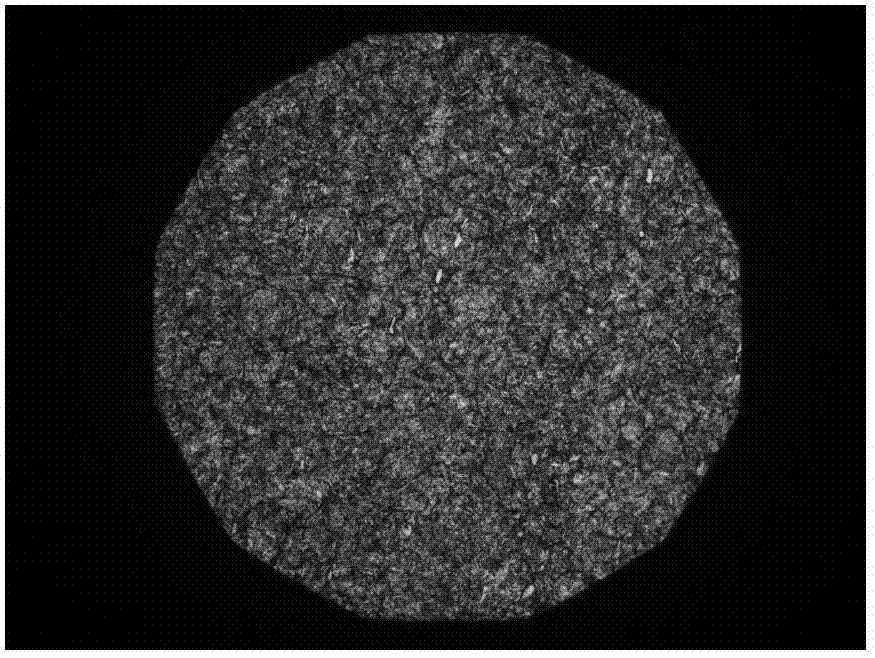

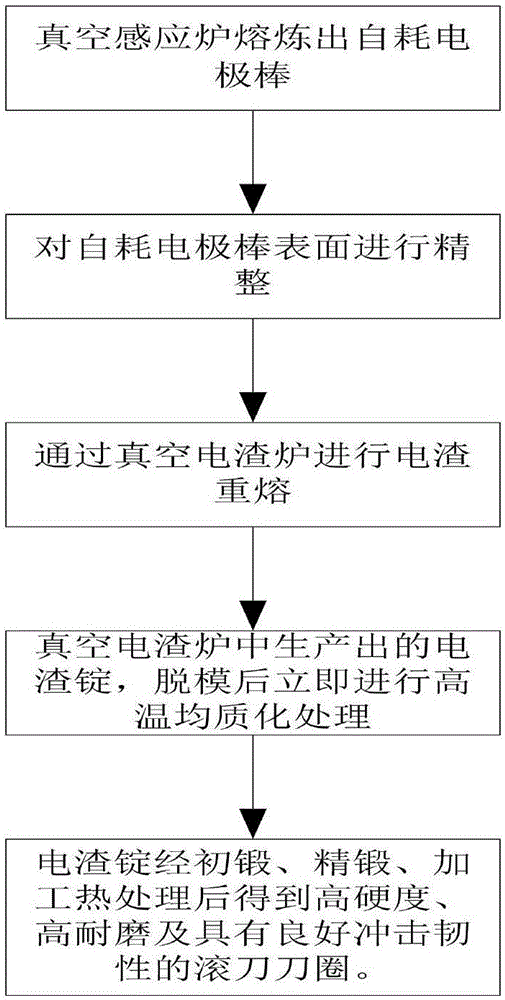

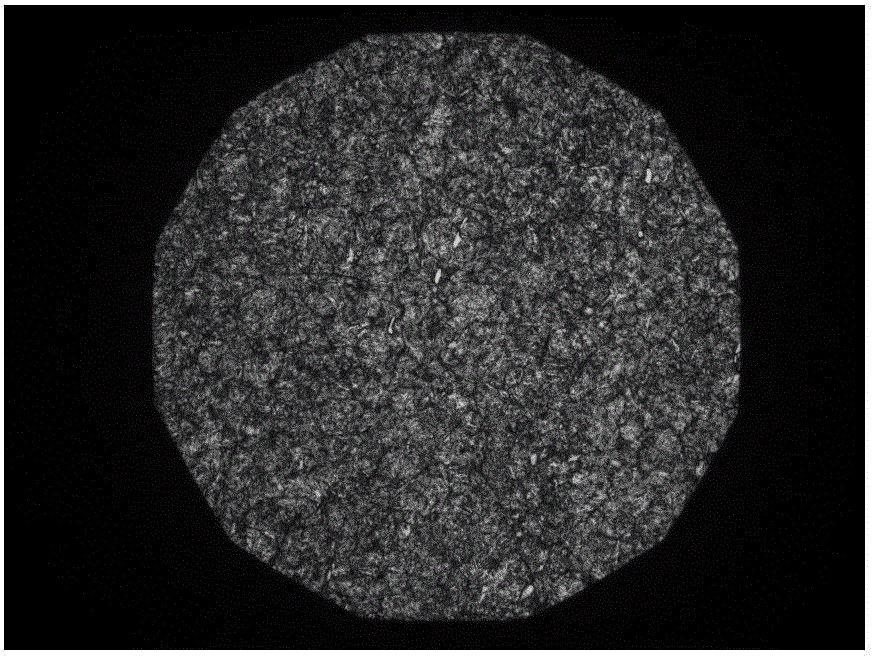

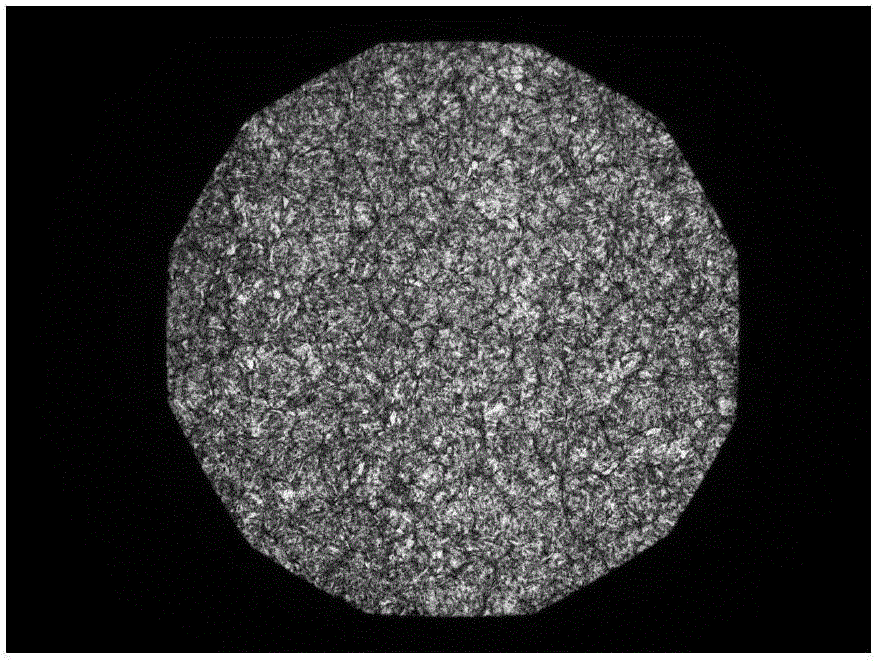

High performance disc hob cutter ring material and its production process

ActiveCN106566983BImprove impact toughnessExtended service lifeIncreasing energy efficiencyElectric furnaceChemical compositionHobbing

The invention belongs to the technical field of cutter ring machining and manufacturing, and relates to a high-performance disc-type hobbing cutter ring material and a production process thereof. The technical problems that in the prior art, due to the fact that the carbon content is increased and hardness is improved, toughness is reduced, tooth breakage and cracking happen to the blade portion of a cutter ring during use in hard rock, and the phenomenon that the cutter ring is broken happens in severe case are solved. The cutter ring material is prepared from 0.35%-0.42% of C, 0.8%-1.2% of Si, 0.20%-0.50% of Mn, smaller than 0.010% of P, smaller than 0.005% of S, 5.00%-5.50% of Cr, 1.80%-2.50% of Mo, 0.80%-1.20% of V,2.00%-2.50% of Co, smaller than 0.30% of Ni and the balance Fe. A hobbing cutter ring machined through the hobbing cutter ring material has the beneficial effects of being high in hardness and wear resistance and good in impact toughness.

Owner:凌远科技股份有限公司

Metal coating for hydraulic cylinder and preparation method of metal coating

The invention discloses a metal coating for a hydraulic cylinder and a preparation method of the metal coating. The metal coating for the hydraulic cylinder includes the following components in mass percent: 0.65-0.67% of carbon, 1.06-1.08% of potassium, 2.95-2.98% of silicon, 1.53-1.55% of vanadium, 9.73-9.75% of nickel, 0.23-0.25% of manganese, 0.42-0.45% of scandium, 0.74-0.76% of molybdenum, 1.56-1.58% of bromine, 1.22-1.24% of tungsten, 3.12-3.15% of titanium, 0.22-0.25% of zirconium, 3.34-3.36% of rare earth, 2.61-2.64% of auxiliaries, and the balance of ferrum.

Owner:SUZHOU JIN YUAN OIL MACHINERY

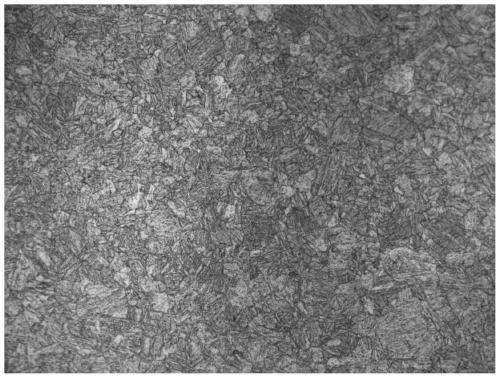

Thermal treatment method of martensitic stainless steel liner plate

ActiveCN104060054AReduce crackingImprove final organizationFurnace typesHeat treatment process controlMartensitic stainless steelRoom temperature

The invention provides a thermal treatment method of a martensitic stainless steel liner plate. The thermal treatment method comprises the following steps: quenching for the first time, namely increasing the temperature from the room temperature to 700 DEG C at a temperature increasing rate of less than or equal to 50 DEG C per hour, equalizing the temperature at 700 DEG C for 3 hours, increasing the temperature from 700 DEG C to 980 DEG C at a temperature increasing rate of less than or equal to 40 DEG C per hour, preserving heat at 980 DEG C for more than 5 hours, and then cooling to 60 DEG C; quenching for the second time, namely increasing the temperature from the room temperature to 700 DEG C at the temperature increasing rate of less than or equal to 50 DEG C per hour, equalizing the temperature of the liner plate at 700 DEG C for 4 hours, increasing the temperature from 700 DEG C to 980 DEG C by the temperature increasing rate of less than or equal to 40 DEG C per hour, preserving heat at 980 DEG C for more than 6 hours, and then cooling to 60 DEG C and carrying out medium-temperature tempering; medium-temperature tempering, namely increasing the temperature from the room temperature to 350 DEG C at a rate of less than or equal to 50 DEG C per hour, preserving heat at 350 DEG C for 1 hour, increasing the temperature from 350 DEG C to 500 DEG C at the temperature increasing rate of less than or equal to 50 DEG C per hour, preserving heat at 500 DEG C for more than 8 hours, and then taking out the liner plate out of an oil tank after the oil is cooled below 100 DEG C. The thermal treatment method has the advantages that the thermal treatment process of double continuous quenching is adopted and the twice quenching is carried out continuously without time interval, and therefore, the cracking of the liner plate during quenching is reduced, the grain size is refined to the utmost extent and the comprehensive mechanical properties of the liner plate are improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

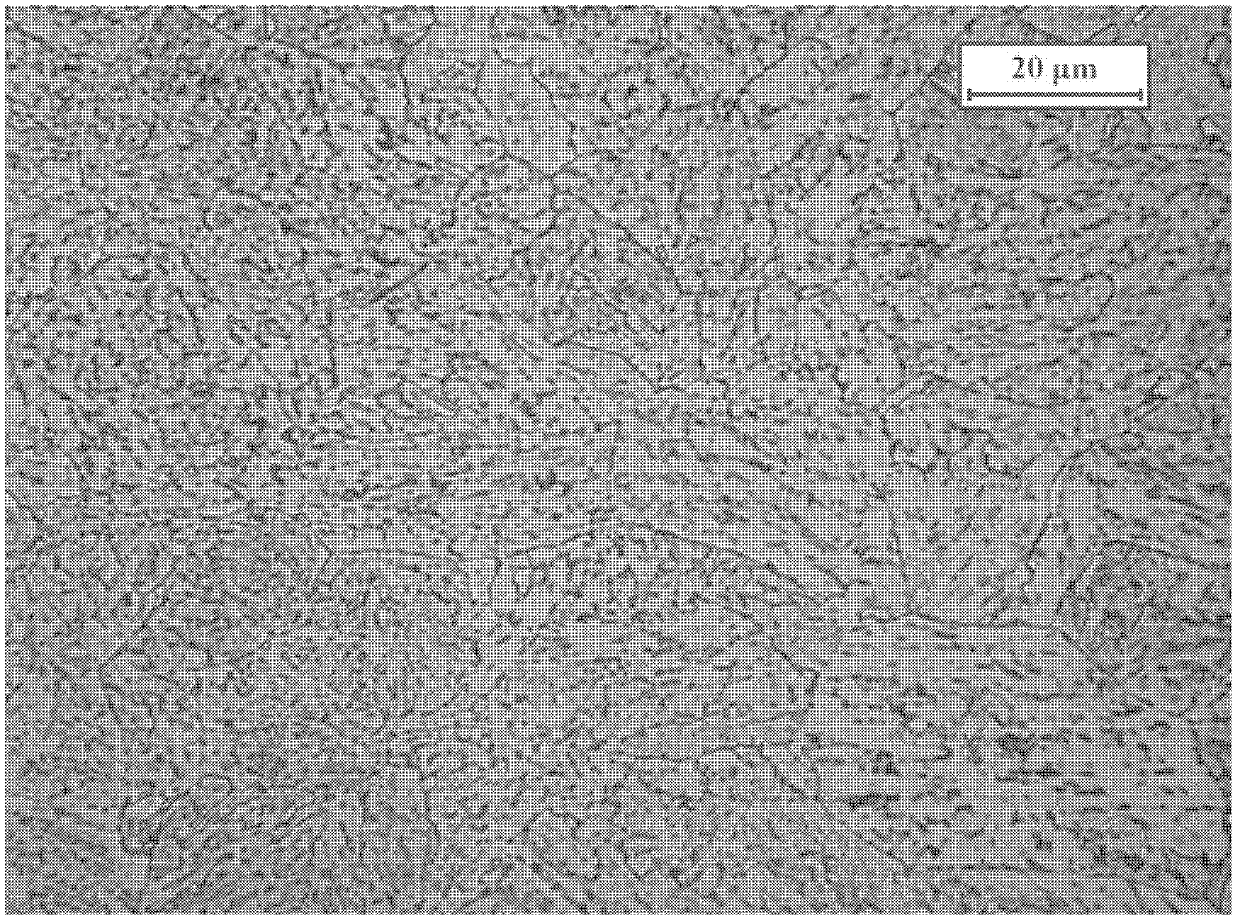

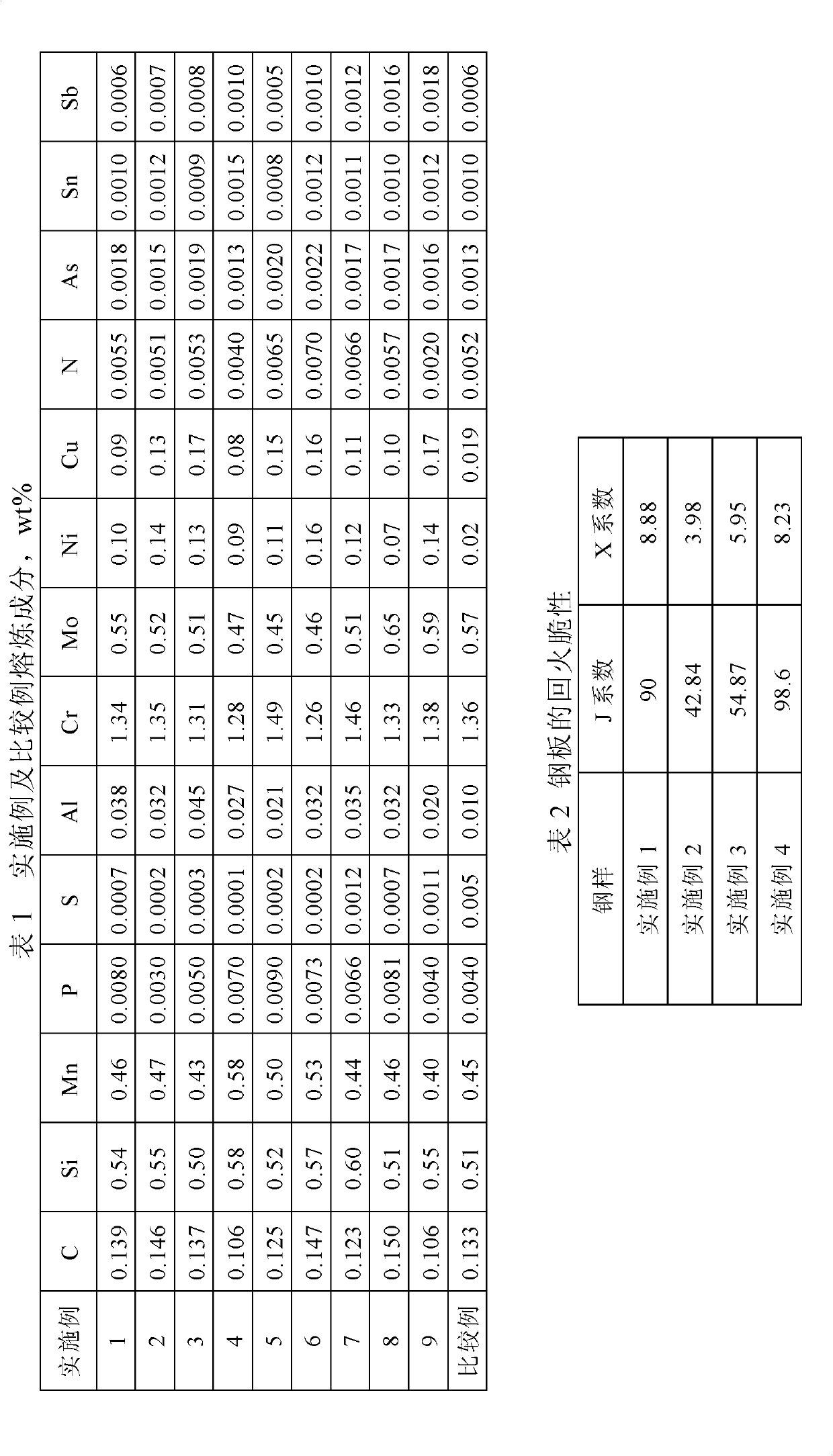

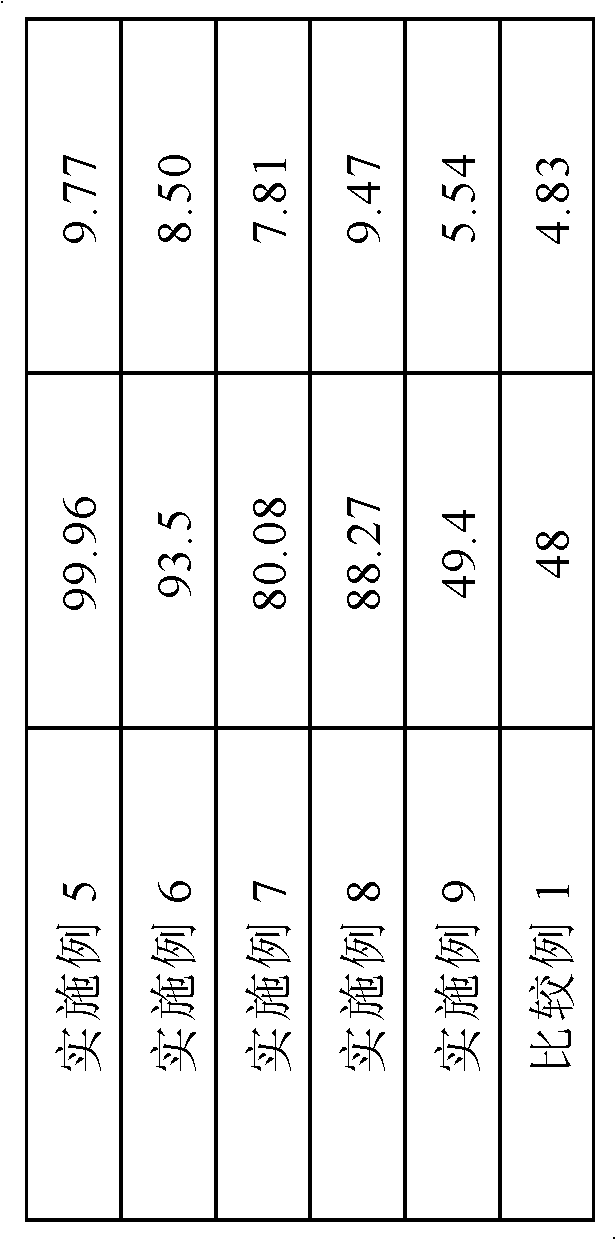

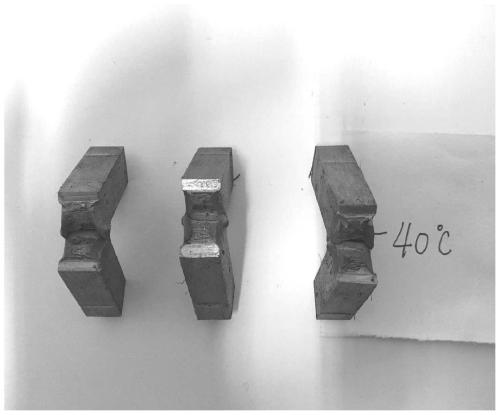

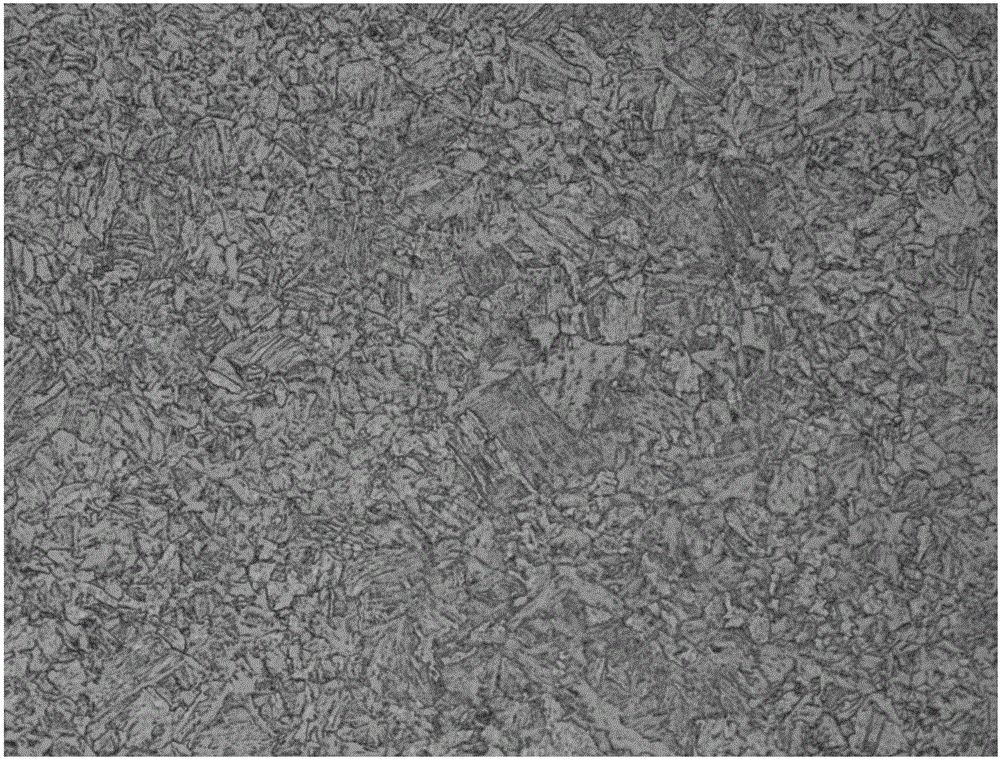

Low-temper-brittleness Cr-Mo steel plate for high temperature resisting pressure-bearing equipment and preparation method of steel plate

The invention discloses a low-temper-brittleness Cr-Mo steel plate for high temperature resisting pressure-bearing equipment and a preparation method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.05-0.17 percent of C, smaller than or equal to 0.30 percent of Si, 0.40-0.65 percent of Mn, smaller than or equal to 0.035 percent of S, smaller than or equal to 0.015 percent of P, 0.80-1.15 percent of Cr, 0.45-0.60 percent of Mo, smaller than or equal to 0.005 percent of Sn, smaller than or equal to 0.005 percent of Sb, smaller than or equal to 0.005 percent of As and the balance of Fe and trace of impurities. By composite addition of Cr and Mo alloy elements, reasonable Si and Mn content design, strict control on low P content and extremely low residual element Sn and implementation of technologies of 4300mm double-frame rolling, normalization, high-temperature tempering and the like, the steel plate for the high temperature resisting pressure-bearing equipment can be obtained. The steel plate has the characteristics of being low in temper brittleness coefficient and mechanically stable, lasting in high temperature in a core part of a thick-specification steel plate, high in mechanical properties and the like, and is suitable for manufacturing high temperature pressure-bearing equipment.

Owner:SHANDONG IRON & STEEL CO LTD

Ultra-wear-resistant H13 mold steel

The invention discloses ultra-wear-resistant H13 mold steel, and belongs to the field of mold steel. The ultra-wear-resistant H13 mold steel comprises the following chemical element ingredients in parts by weight: 0.46 to 0.49 part of C, 0.81 to 0.92 part of Si, 0.32 to 0.46 part of Mn, 0.008 to 0.011 part of P, 0.001 to 0.003 part of S, 4.36 to 6.25 parts of Cr, 0.04 to 0.23 part of Ni, 0.01 to 0.1 part of Cu, 1.01 to 1.36 parts of Mo, 0.08 to 1.27 parts of V and the balance of Fe. By aiming at the problem of poor wear resistance of the H13 mold steel in the prior art, the ultra-wear-resistant H13 mold steel has the advantages that the wear-resistant performance of the H13 mold can be improved.

Owner:马鞍山精创工程刀具制造有限公司

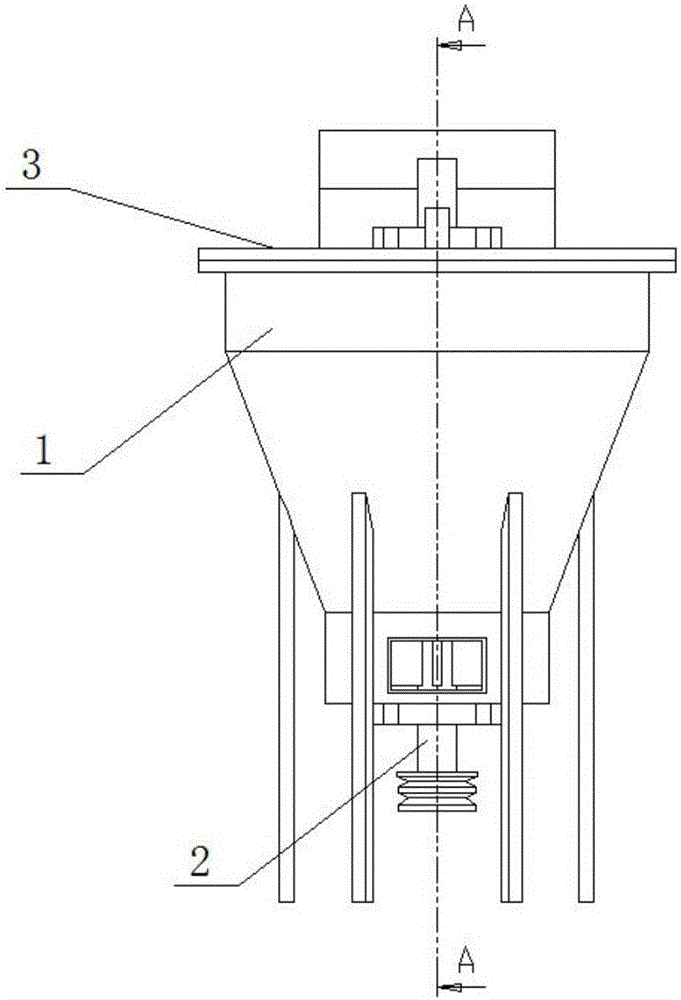

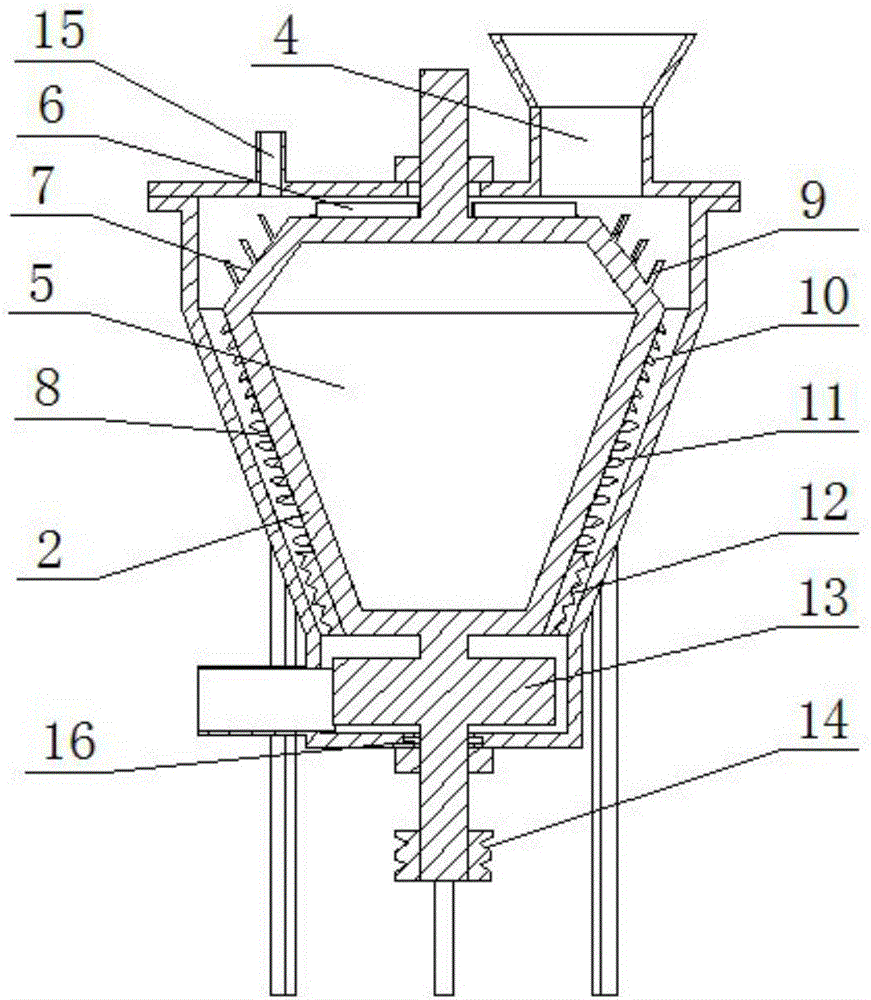

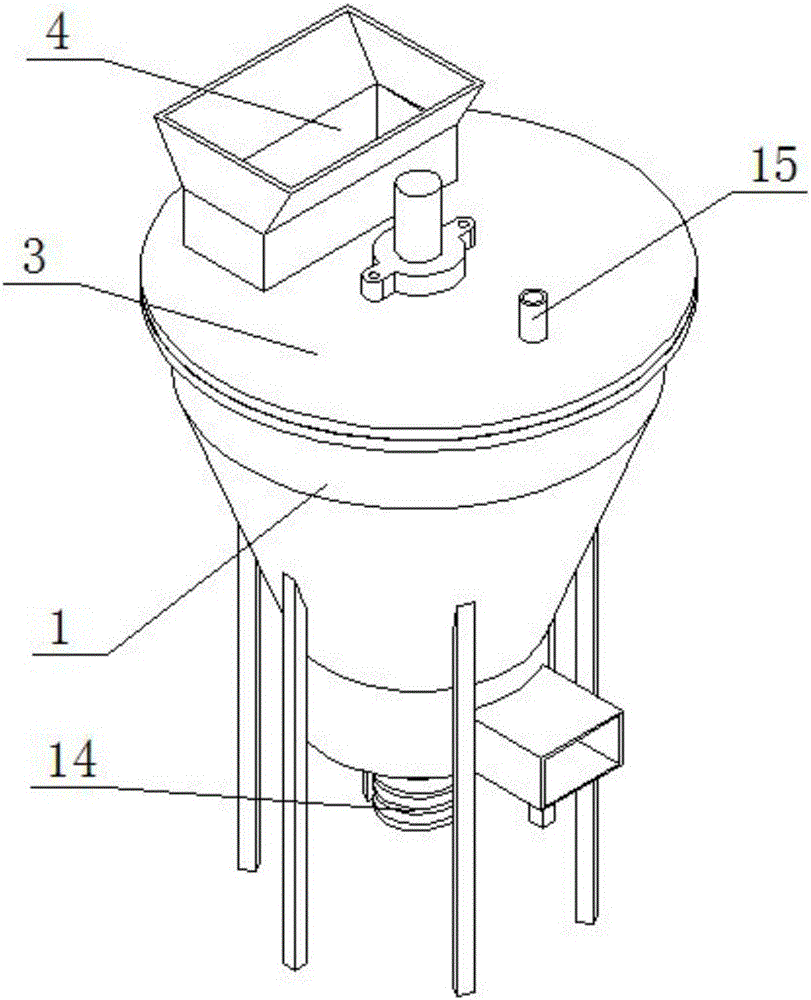

Smashing and grinding device used in garbage fertilizer making system

InactiveCN106607136AExtended service lifeStable crushing qualityGrain treatmentsPressure inorganic powder coatingEngineeringEvening

The invention discloses a smashing and grinding device used in a garbage fertilizer making system. The smashing and grinding device comprises a horizontally placed machine seat. The section of the machine seat is in a V shape. A smashing roller is vertically arranged in the machine seat. The shape of the smashing roller is matched with the machine seat. An end cover used for fixing the smashing roller is arranged at the upper end of the machine seat and is provided with a feed inlet. A cavity is arranged in the smashing roller. A material evening plate is horizontally arranged on the upper end face of the smashing roller. A discharge face and a smashing face are arranged on the outer surface of the smashing roller sequentially from top to bottom. The discharge face and the smashing face are both arranged obliquely. The discharge face is provided with a first crushing cutter. A smashing cutter set, a rough grinding cutter set and a fine grinding cutter set are arranged on the discharge face sequentially from top to bottom. The smashing cutter set comprises a plurality of smashing cutters. The smashing and grinding device is simple in structure, long in service life, convenient to operate, low in cost, safe, reliable, capable of fast and effectively smashing and grinding garbage, particularly some garbage difficult to smash, high in structural strength and wide in usage range.

Owner:JIANGSU QINGSHI TECH

Blade of steam turbine and process for machining blade

ActiveCN104033189AImprove corrosion resistanceGood chemical propertiesBlade accessoriesMachines/enginesSteam turbine bladeProcess engineering

The invention discloses a blade of a steam turbine. The blade of the steam turbine comprises, by mass, 0.1-0.12% of C, 0.5-0.8% of Si, 0.3-0.6% of Mn, 0.01-0.02% of S, 0.1-0.022%Of P, 12-13% of Cr, 0.02-0.06% of Ni, 0.1-0.3% of Cu, 0.2-0.5% of Mo, 0.05-0.36% of W, 0.33-0.55% of V, 0.5-0.8% of Nb, the balance Fe and the balance trace impurities. The invention further provides a process for machining the blade of the steam turbine. The blade of the steam turbine and the process have the advantages that the blade of the steam turbine is long in service life and applicable to working in various harsh environments, the corrosion resistance, the abrasion resistance and the oxidation resistance of the blade can be improved, the cost can be reduced, the cutting property of the blade can be obviously improved, the machining cost can be reduced by the process, and the work efficiency can be enhanced by the process.

Owner:南京赛达科技有限公司

Anti-corrosion steel plate for shuttle type storage rack and thermal treatment process thereof

The invention discloses an anti-corrosion steel plate for a shuttle type storage rack and a thermal treatment process thereof. The steel plate comprises the following components by weight percentage: 0.12-0.14% of carbon, 2.32-2.38% of manganese, 0.54-0.56% of gallium, 0.02-0.04% of calcium, 0.01-0.03% of sodium, 1.23-1.25% of cobalt, 2.16-2.18% of vanadium, 3.36-3.39% of titanium, 2.63-2.67% of copper, 0.57-0.59% of tin, 12.7-12.9% of chromium, 0.06-0.08% of molybdenum, 5.11-5.13% of nickel, 0.36-0.38% of zirconium, 2.42-2.44% of magnesium and the balance of Fe and unavoidable impurities; and an anti-corrosion coating is sprayed on the surface of the steel plate.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Steel for high-strength corrosion-resistant reinforcing steel bar containing rare earth elements and heat treatment technology thereof

The invention discloses steel for a high-strength corrosion-resistant reinforcing steel bar containing rare earth elements and a heat treatment technology thereof. The steel comprises the following chemical compositions by mass percent: 0.02-0.05% of C, 5.3-5.6% of Ni, 2.47-2.49% of Cr, 1.23-1.26% of Si, 2.35-2.38% of Mn, 2.8-3.2% of Cu, o.26-0.28% of V, 0.31-0.38% of Mo, 0.036-0.038% of P, 0.65-0.68% of W, 1.15-1.18% of rare earth elements and the balance of Fe. The steel for the high-strength corrosion-resistant reinforcing steel bar containing rare earth elements is high in strength, long in service life, low in production cost, simple in heat treatment technology and high in working efficiency, the corrosion resistance, oxidation resistance and high temperature resistance are obviously improved, the design requirement can be reached by reducing the using amount of steel in the application, and the safety is high.

Owner:TIANSHUN GROUP

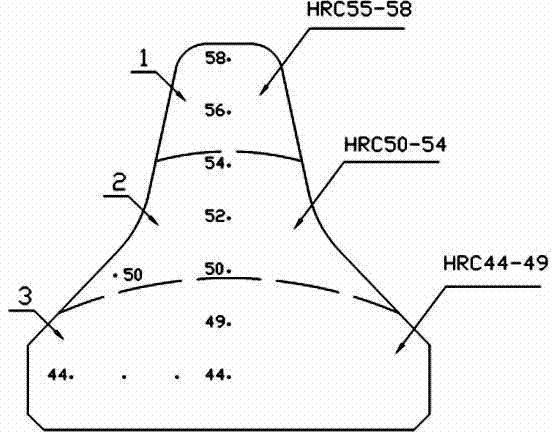

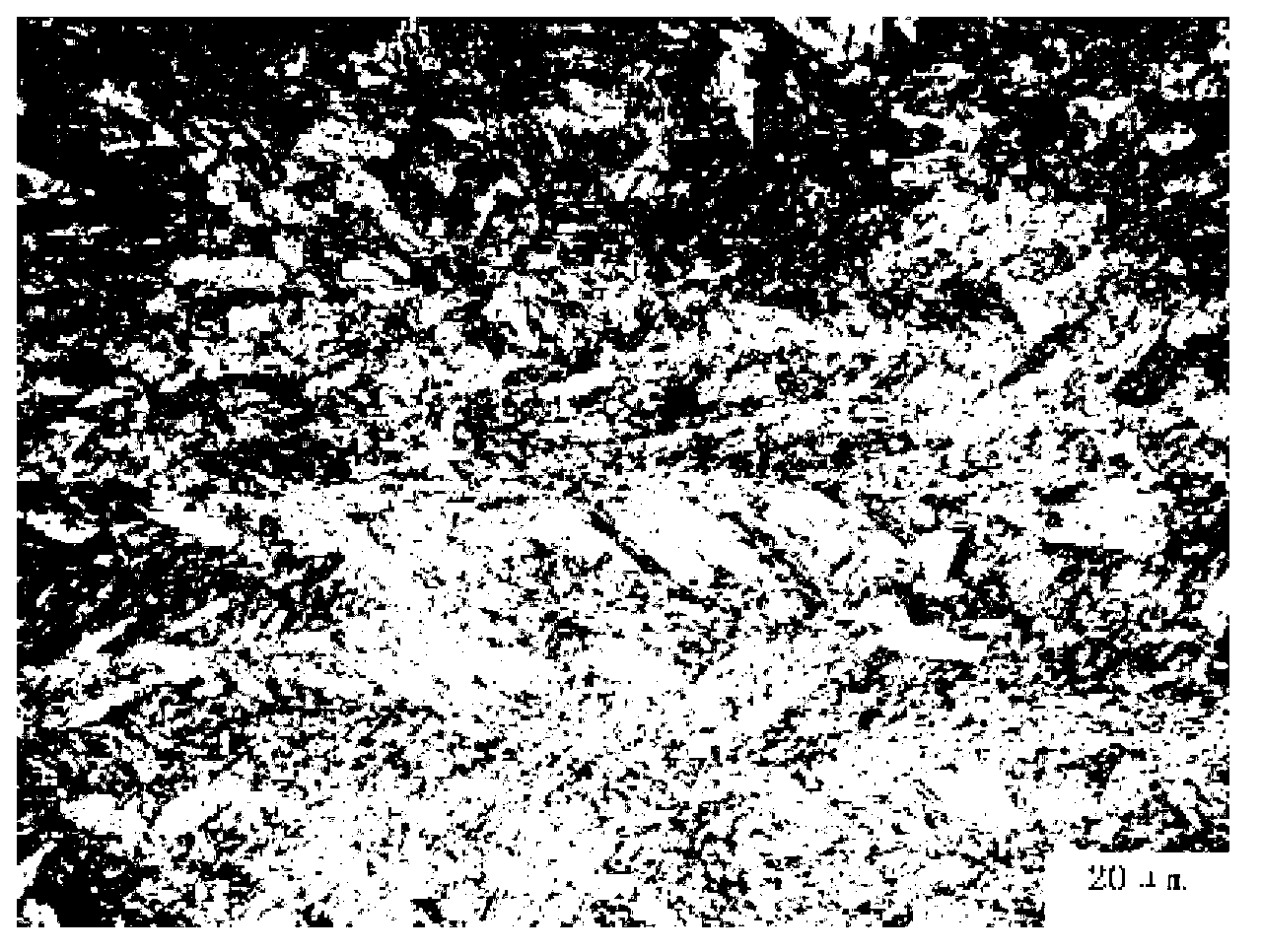

High-performance disc-type hobbing cutter ring material and production method thereof

ActiveCN106566983AImprove impact toughnessExtended service lifeIncreasing energy efficiencyElectric furnaceHobbingChemical composition

The invention belongs to the technical field of cutter ring machining and manufacturing, and relates to a high-performance disc-type hobbing cutter ring material and a production process thereof. The technical problems that in the prior art, due to the fact that the carbon content is increased and hardness is improved, toughness is reduced, tooth breakage and cracking happen to the blade portion of a cutter ring during use in hard rock, and the phenomenon that the cutter ring is broken happens in severe case are solved. The cutter ring material is prepared from 0.35%-0.42% of C, 0.8%-1.2% of Si, 0.20%-0.50% of Mn, smaller than 0.010% of P, smaller than 0.005% of S, 5.00%-5.50% of Cr, 1.80%-2.50% of Mo, 0.80%-1.20% of V,2.00%-2.50% of Co, smaller than 0.30% of Ni and the balance Fe. A hobbing cutter ring machined through the hobbing cutter ring material has the beneficial effects of being high in hardness and wear resistance and good in impact toughness.

Owner:凌远科技股份有限公司

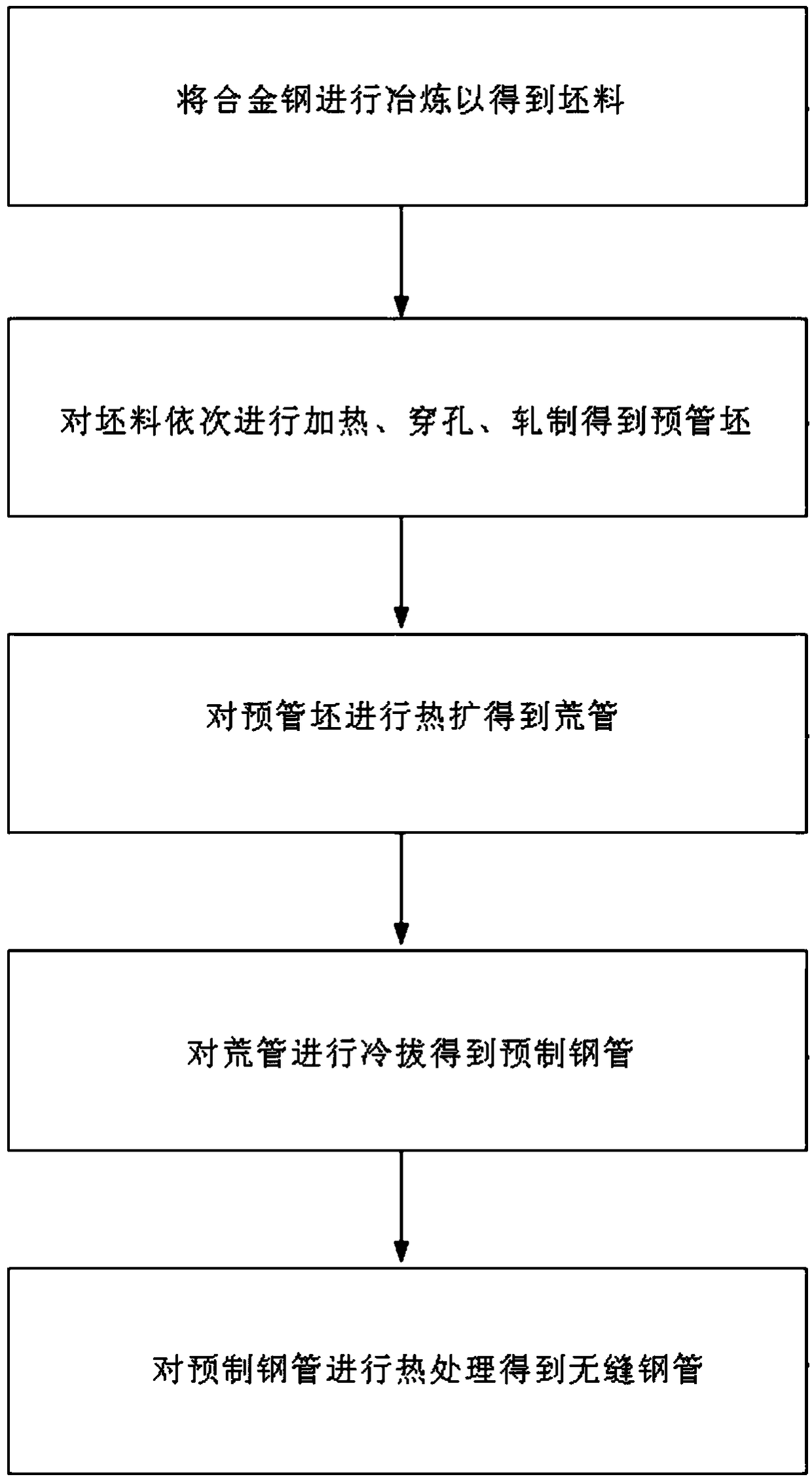

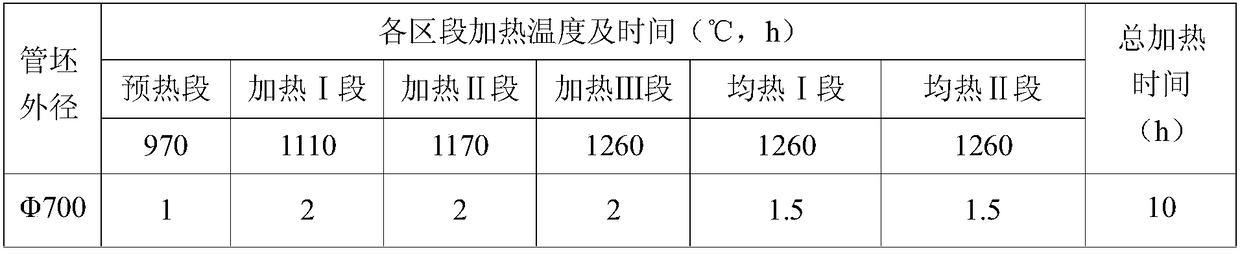

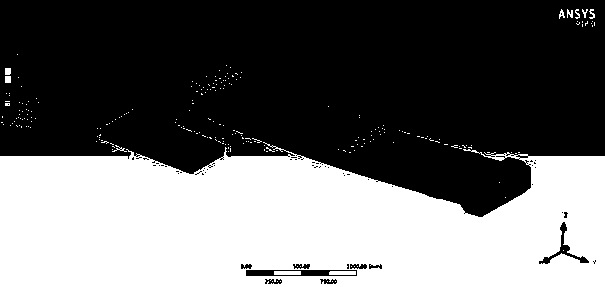

Alloy steel, seamless steel pipe, manufacturing method thereof and well drilling water separating pipe

InactiveCN109457178AHigh strengthGood welding performanceDrilling rodsUnderwater drillingWell drillingMetallurgy

Owner:HENGYANG VALIN STEEL TUBE

Preparation method of vibration exciting beam of pavement crushing vehicle

ActiveCN110653566AExtended service lifeProtect the surfaceRoads maintainenceSurface roughnessStructural engineering

The invention provides a preparation method of a vibration exciting beam of a pavement crushing vehicle. The preparation method comprises the steps of 1, casting and molding a beam body in a mold cavity; 2, hot forging the beam body; 3, tempering the beam body; 4, finishing the beam body to a preset size, and rounding all broken line positions; and 5, lapping the surface of the beam body to ensurethat the surface roughness is lower than Ra1.6 [mu]m, thereby obtaining the vibration exciting beam of the pavement crushing vehicle through the steps. By adopting the scheme, the service life of thevibration exciting beam under the vibration working condition can be greatly prolonged. The broken line positions of the beam body are all of rounded structures, and micro cracks can be prevented from being generated as fracture source regions. The vibration exciting beam has low surface roughness by adopting a surface lapping process, and the micro cracks under the vibration working condition can be avoided.

Owner:YICHANG JIANGXIA MARINE MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com