High-toughness steel plate with high-temperature PWHT softening resistance and low welding crack sensitivity coefficient for crude oil storage tank and manufacturing method of high-toughness steel plate

A technology with low welding crack sensitivity coefficient, which is applied in the steel plate for large crude oil storage tanks with low welding crack sensitivity coefficient and high toughness and its preparation field, can solve the problems that the strength of the steel plate cannot be guaranteed, and achieve low reheat crack sensitivity coefficient and low welding Effect of Crack Sensitivity Factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

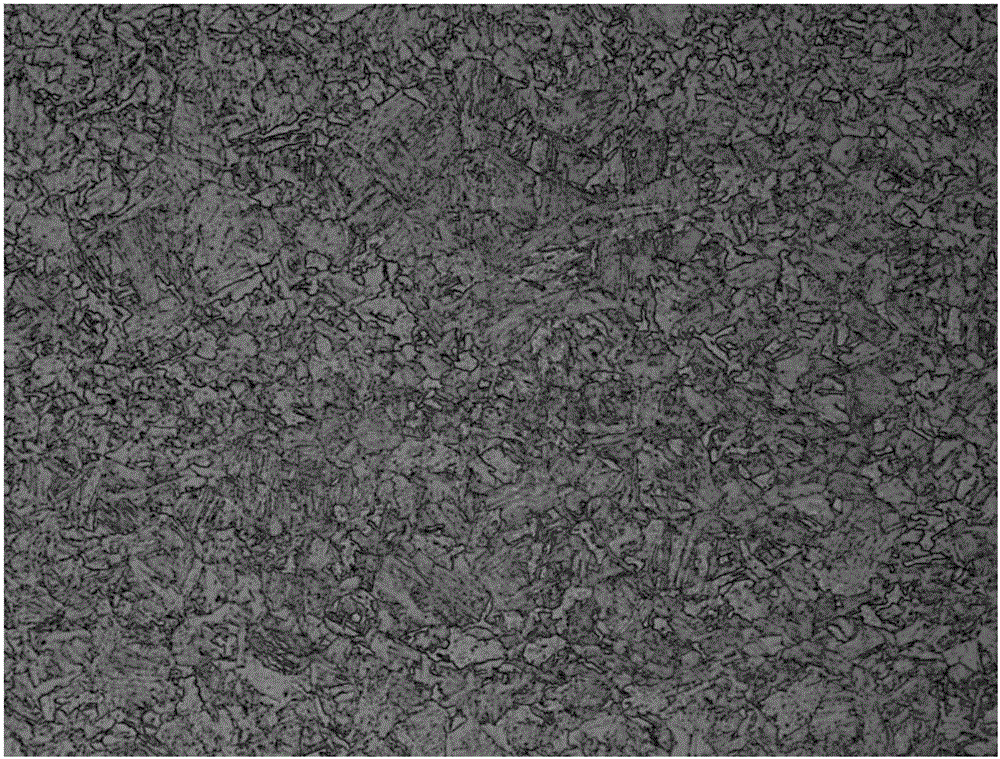

Embodiment 1

[0046] The chemical composition and weight percentage of the steel plate are:

[0047] C: 0.10%, Si: 0.21%, Mn: 1.53%, S: 0.007%, P: 0.013%, Mo: 0.07%, Ni: 0.24%, Nb: 0.023%, V: 0.051%, Ti: 0.016%, Alt: 0.021%, O: 0.0023%, N: 0.0038%, H: 0.00015%, and the rest are Fe and trace impurities. P cm 0.20%, P SR was -1.11%. in

[0048] P cm =C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B

[0049] P SR =Cr+Cu+2Mo+10V+7Nb+5Ti-2

[0050] The manufacturing method of the high-strength toughness steel plate for large crude oil storage tank with low welding crack sensitivity coefficient softening at high temperature and PWHT is as follows:

[0051] (1) Smelting: The molten iron is processed by KR pretreatment, 120-ton top-bottom combined blowing converter smelting, 120-ton LF ladle furnace refining, 120-ton RH vacuum degassing refining and slab continuous casting machine to obtain a section size of 300mm× The 2200mm continuous casting slab is heated by a walking beam heating furnace.

...

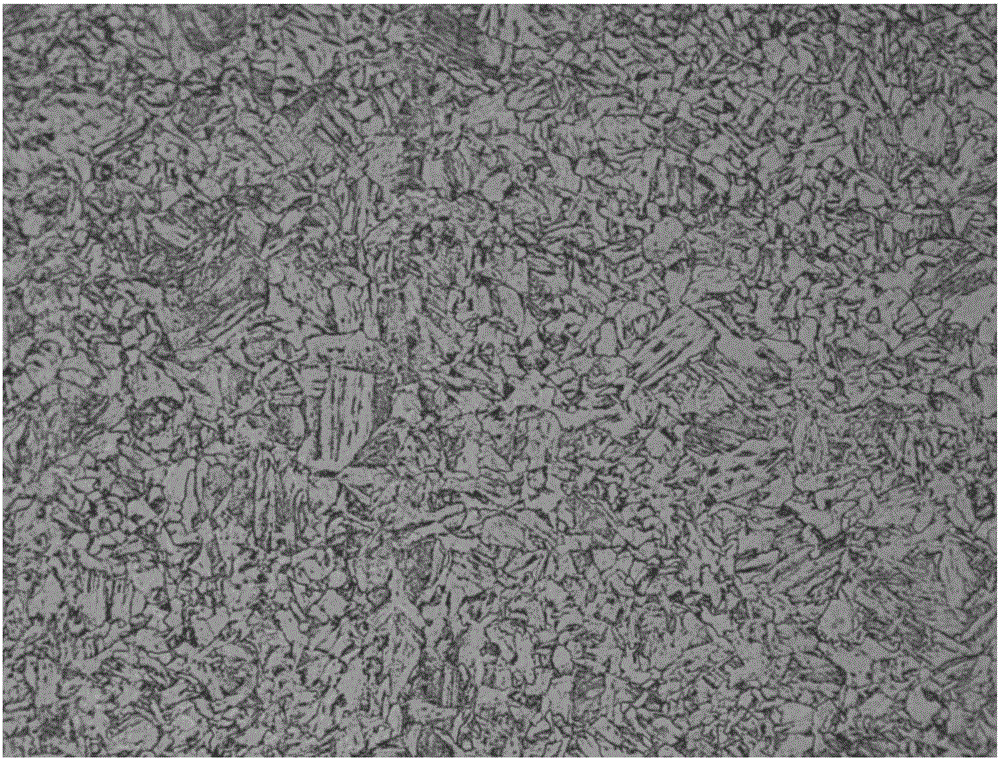

Embodiment 2

[0059] The chemical composition and weight percentage content of the steel plate produced by the method of the present invention are:

[0060] C: 0.09%, Si: 0.22%, Mn: 1.50%, S: 0.005%, P: 0.012%, Mo: 0.08%, Ni: 0.22%, Nb: 0.024%, V: 0.050%, Ti: 0.016%, Alt: 0.025%, O: 0.0024%, N: 0.0036%, H: 0.00015%, and the rest are Fe and trace impurities. P cm 0.19%, P SR was -1.09%. Among them, P cm =C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B, P SR =Cr+Cu+2Mo+10V+7Nb+5Ti-2.

[0061] The production and preparation method process of the present embodiment and the cross-sectional size of the continuous casting slab are the same as in the embodiment 1, the difference is that:

[0062] (1) The final rolling thickness of the steel plate is 27mm, the finish rolling start temperature of the billet is 880°C, and the finish rolling start thickness of the billet is 3.0 times the thickness of the finished steel plate.

[0063] (2) Rolling conditions: the starting cooling temperature is 800°C, ...

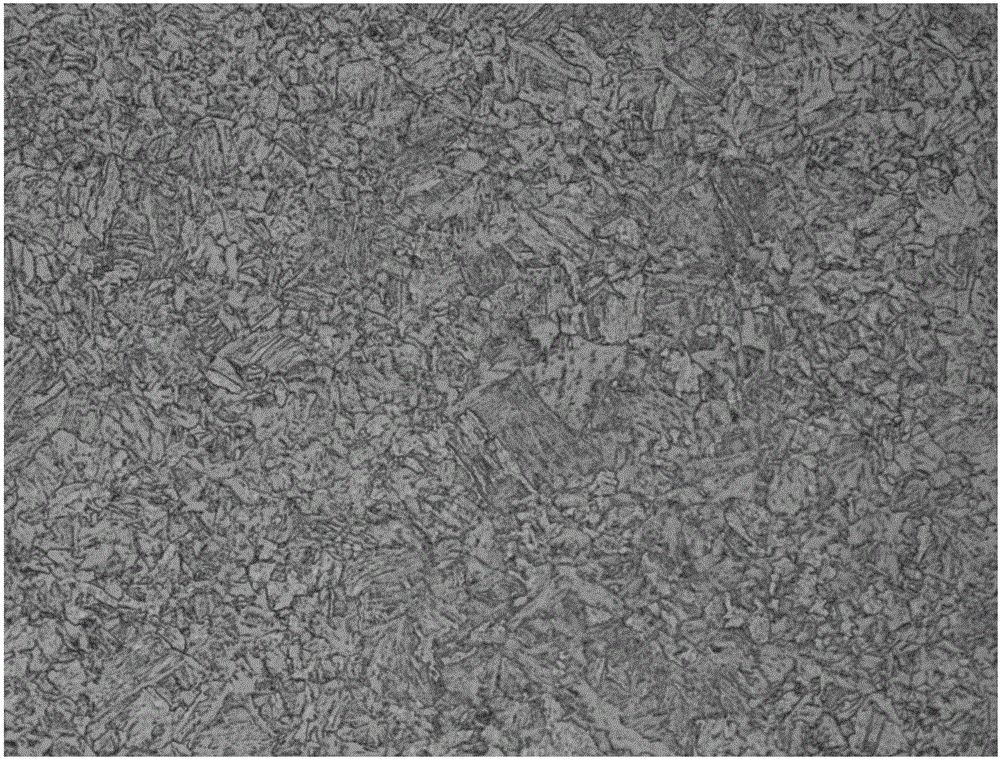

Embodiment 3

[0068] The chemical composition and weight percentage content of the steel plate produced according to the method of the present invention are:

[0069] C: 0.08%, Si: 0.21%, Mn: 1.55%, S: 0.002%, P: 0.010%, Mo: 0.10%, Ni: 0.25%, Nb: 0.026%, V: 0.050%, Ti: 0.017%, Alt: 0.027%, O: 0.0020%, N: 0.0033%, H: 0.00015%, and the rest are Fe and trace impurities. P cm 0.18%, P SR was -1.03%. Among them, P cm =C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B, P SR =Cr+Cu+2Mo+10V+7Nb+5Ti-2.

[0070] The production and preparation method process of the present embodiment and the cross-sectional size of the continuous casting slab are the same as in the embodiment 1, the difference is that:

[0071] (1) The final rolling thickness of the steel plate is 32mm, the finish rolling start temperature of the billet is 870°C, and the finish rolling start thickness of the billet is 3.0 times the thickness of the finished steel plate.

[0072] (2) Rolling conditions: the starting cooling temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com