Patents

Literature

453 results about "Borium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Borium is a product that consists of tungsten carbide granules embedded in a matrix of softer metal. Borium is used in farriery to improve traction for horses. Other applications include ploughshares, saw teeth, cane knives and drill bits.

Steel for steam-temperature ultra-supercritical thermal power unit and preparation method thereof

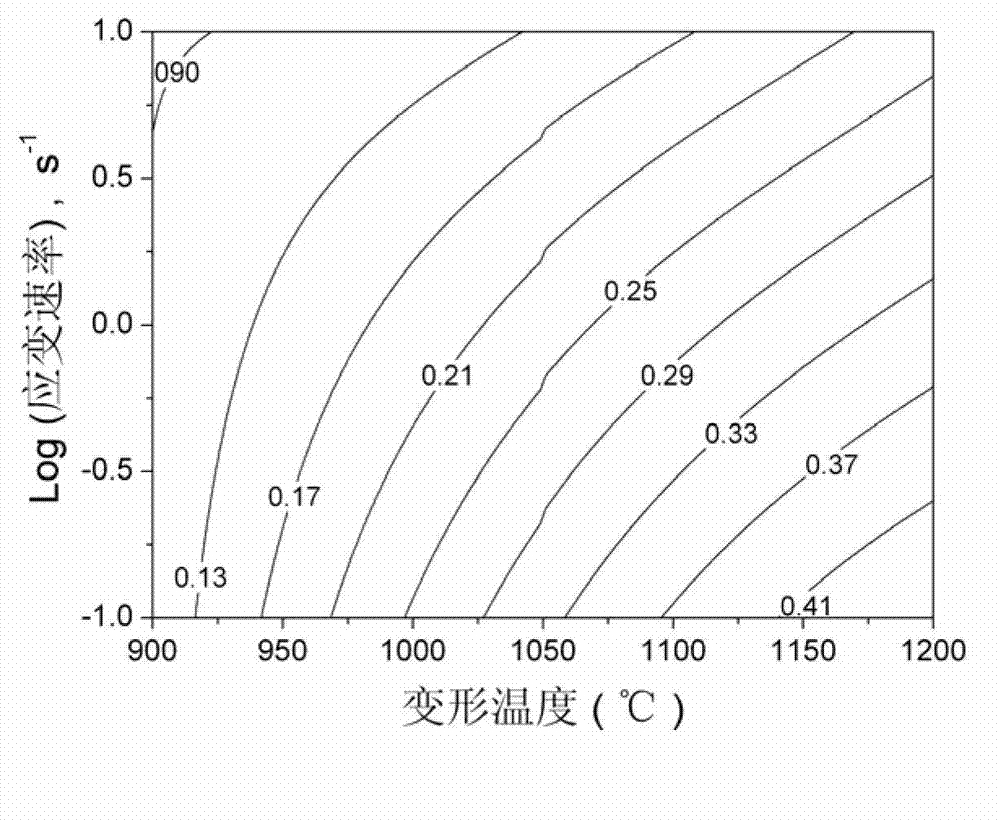

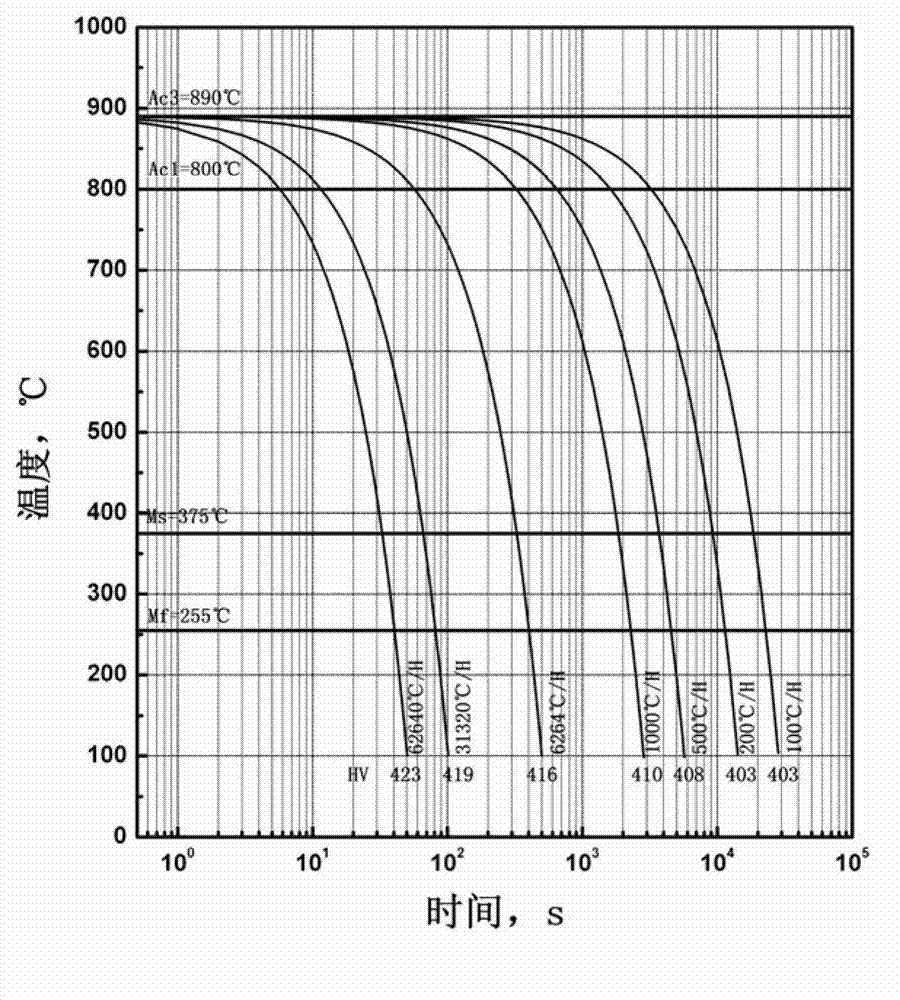

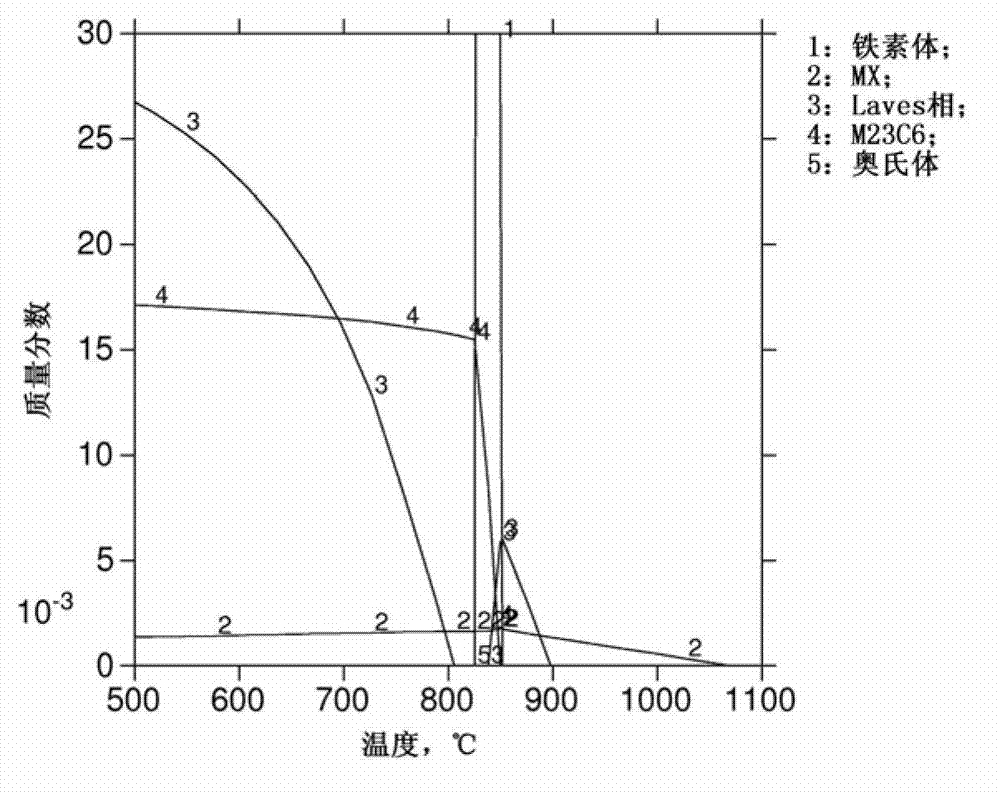

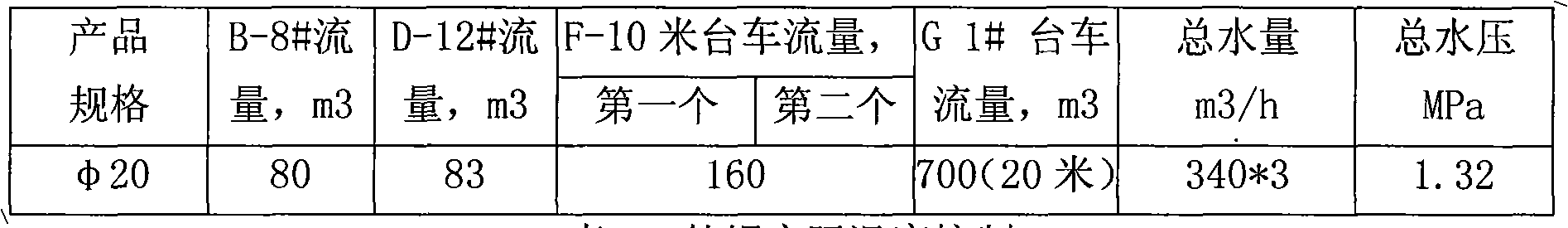

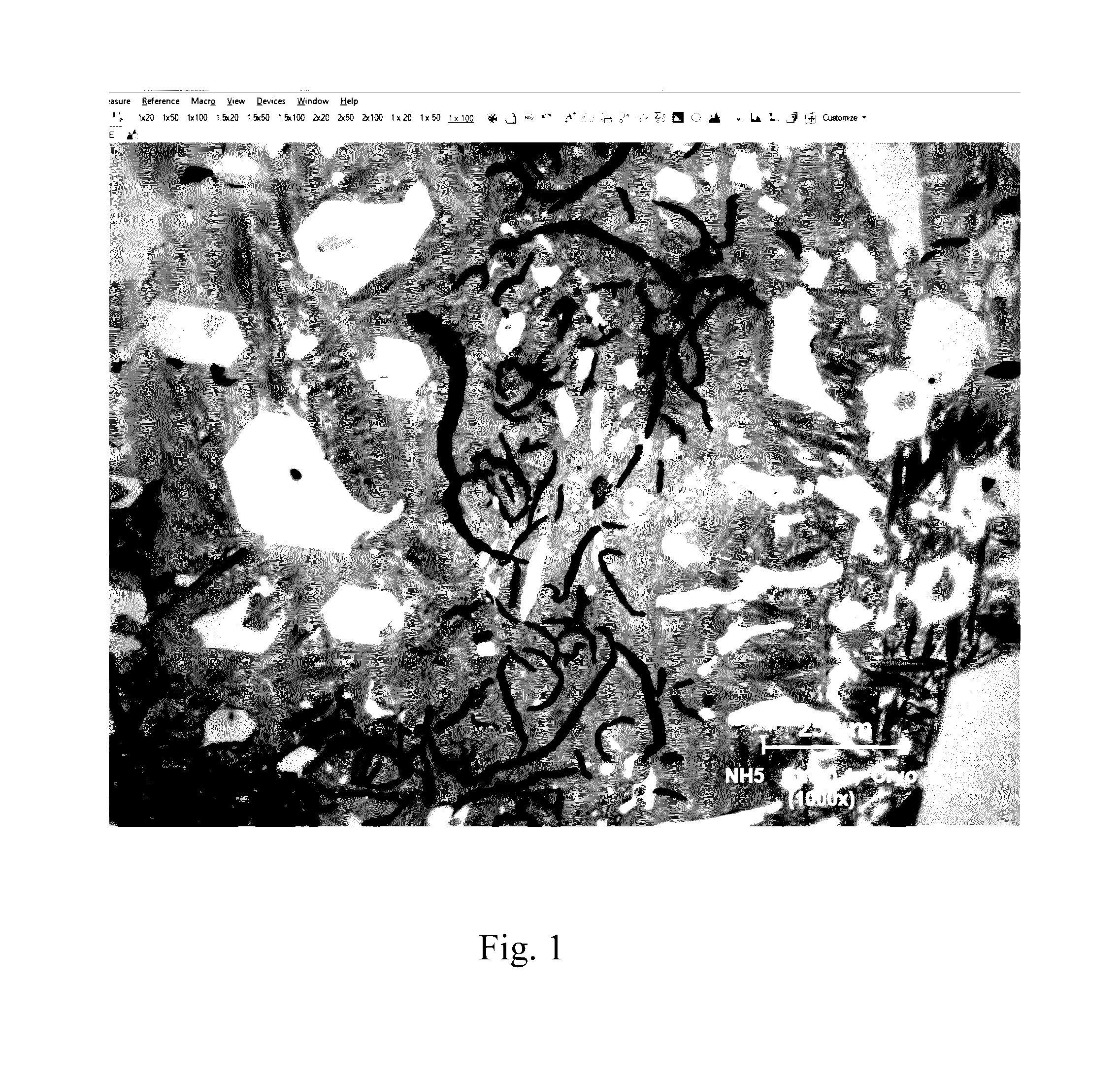

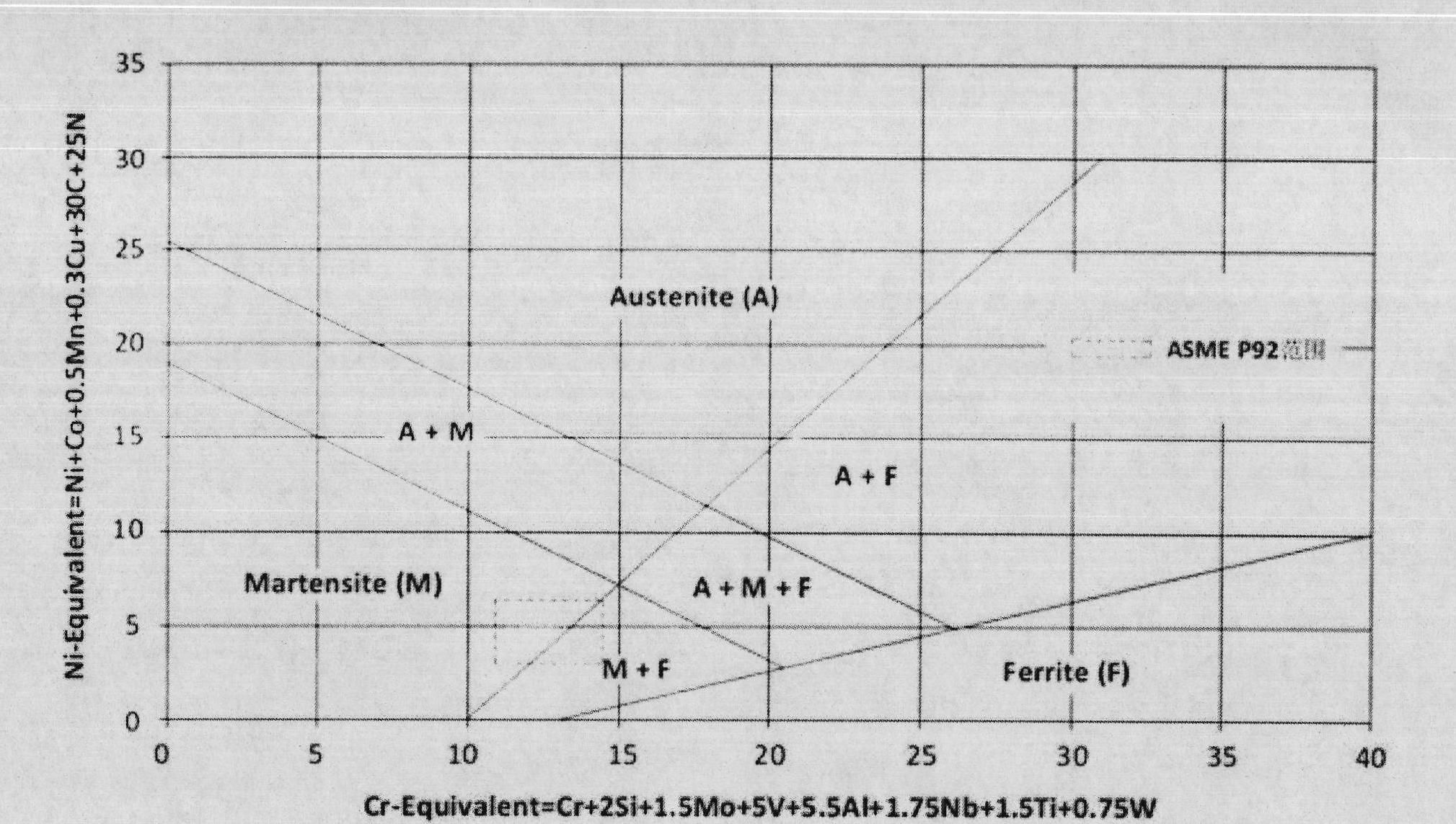

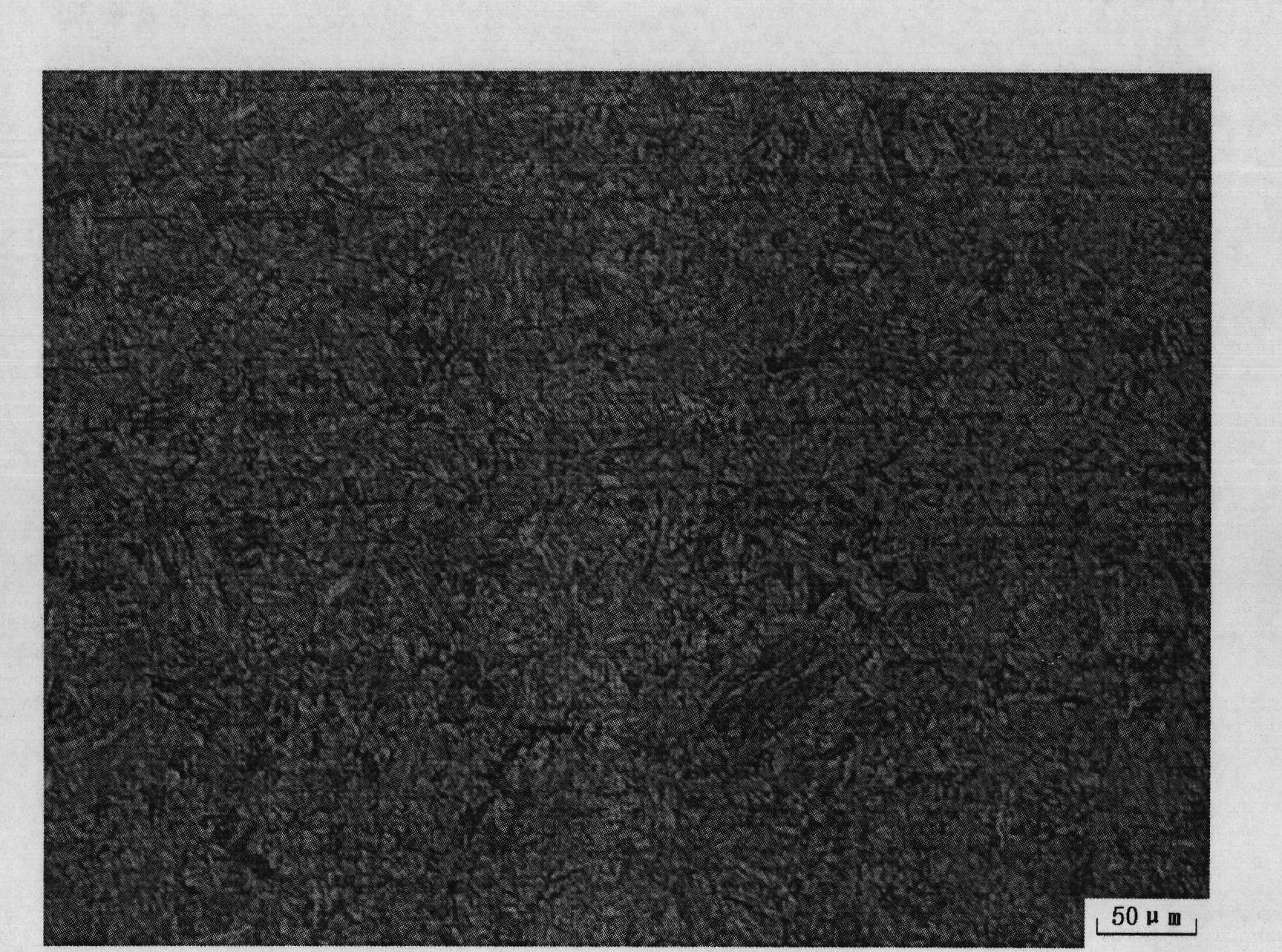

The invention relates to steel for a steam-temperature ultra-supercritical thermal power unit and a preparation method thereof, belonging to the technical field of heat resistant steel. The steel comprises the following chemical compositions by weight percentage: 0.06-0.10 percent of carbon, 0.1-0.5 percent of silicon, 0.2-0.8 percent of manganese, not more than 0.004 percent of phosphorous, not more than 0.002 percent of sulfur, 8.0-9.5 percent of chromium, 2.5-3.5 percent of tungsten, 2.5-3.5 percent of cobalt, 0.03-0.07 percent of niobium, 0.10-0.30 percent of vanadium, 0.80-1.20 percent of copper, 0.006-0.010 percent of nitrogen, 0.010-0.016 percent of boron, 0.01-0.04 percent of rare-earth cerium, not more than 0.01 percent of nickel, not more than 0.005 percent of aluminum, not more than 0.01 percent of titanium, not more than 0.01 percent of zirconium and the balance of ferrum and inevitable impurity elements. The steel has the advantages that the steel can be used for preparing G115 steel of 650 DEG C of steam-parameter ultra-supercritical thermal power unit and a large-diameter boiler tube thereof, and the room-temperature mechanical property, the impact property, the high-temperature mechanical property and the permanence property of the steel are much higher than those of P92 steel in the Gb5310 and ASME standard.

Owner:CENT IRON & STEEL RES INST

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

Rare earth boron micro-alloyed high manganese steel

One kind of rare earth boraxium alloying high manganese steel that has the mass ratio of ingredient: C 0.9-1.6, Mn 13-30, B 0.0005-0.02, Re 0.01-0.05, Si 0.3-1.0, Cr<3, Mo<2, Ni<1, Cu<1, V+Ti+Nb+Zr+N+Al+Ca<2 S<0.04, P<0.07, the residue is Fe. Its process includes blending, melting, tapping of molten steel, adding alterant, packing. Its advantages include a good abradability of more than two fold than formal high manganese steel.

Owner:NORTHEASTERN UNIV

Steel with high mechanical strength and wear resistance

ActiveCN1957101AHardening does not changeLess detrimental to split poly seamsRare earthHigh wear resistance

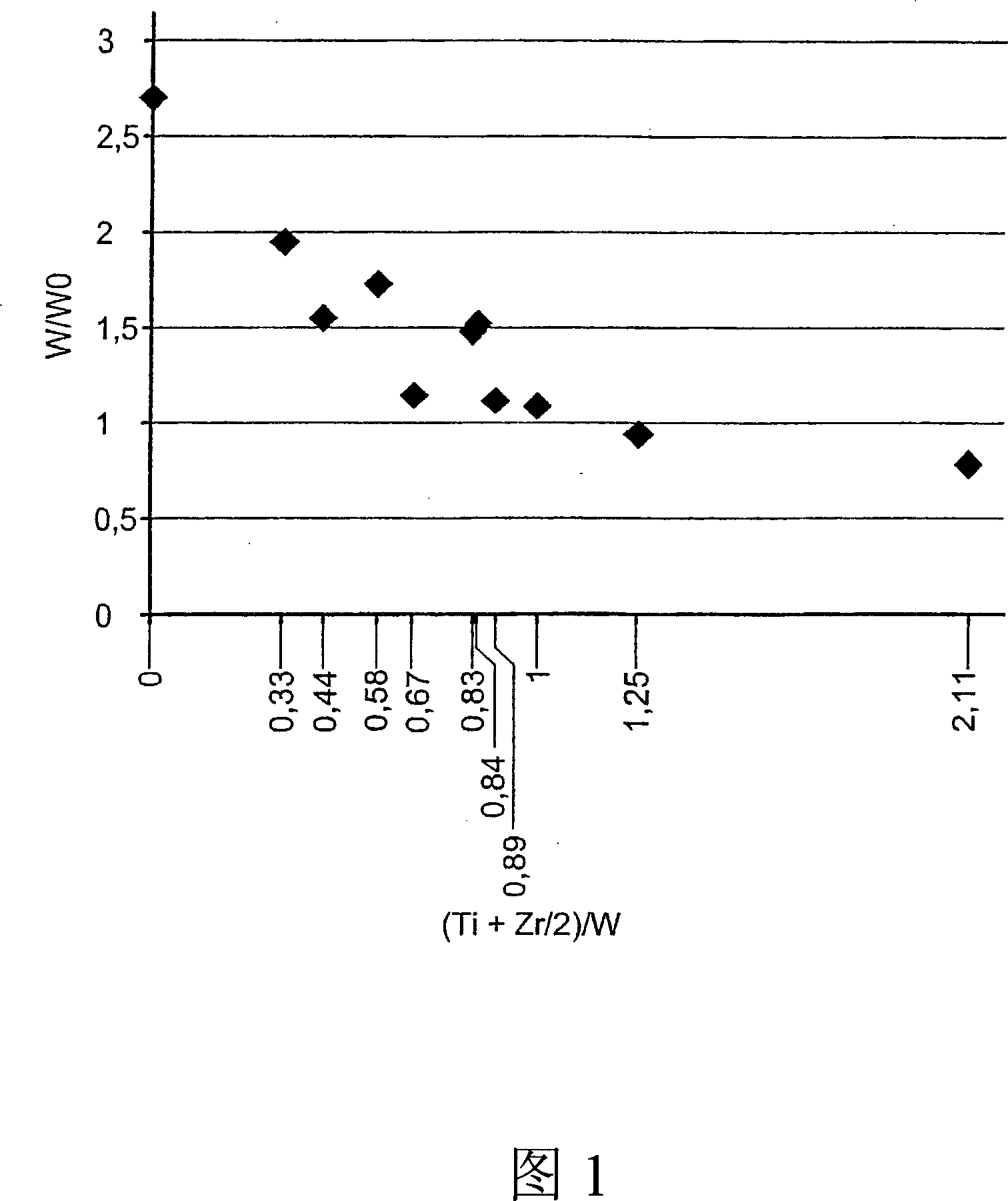

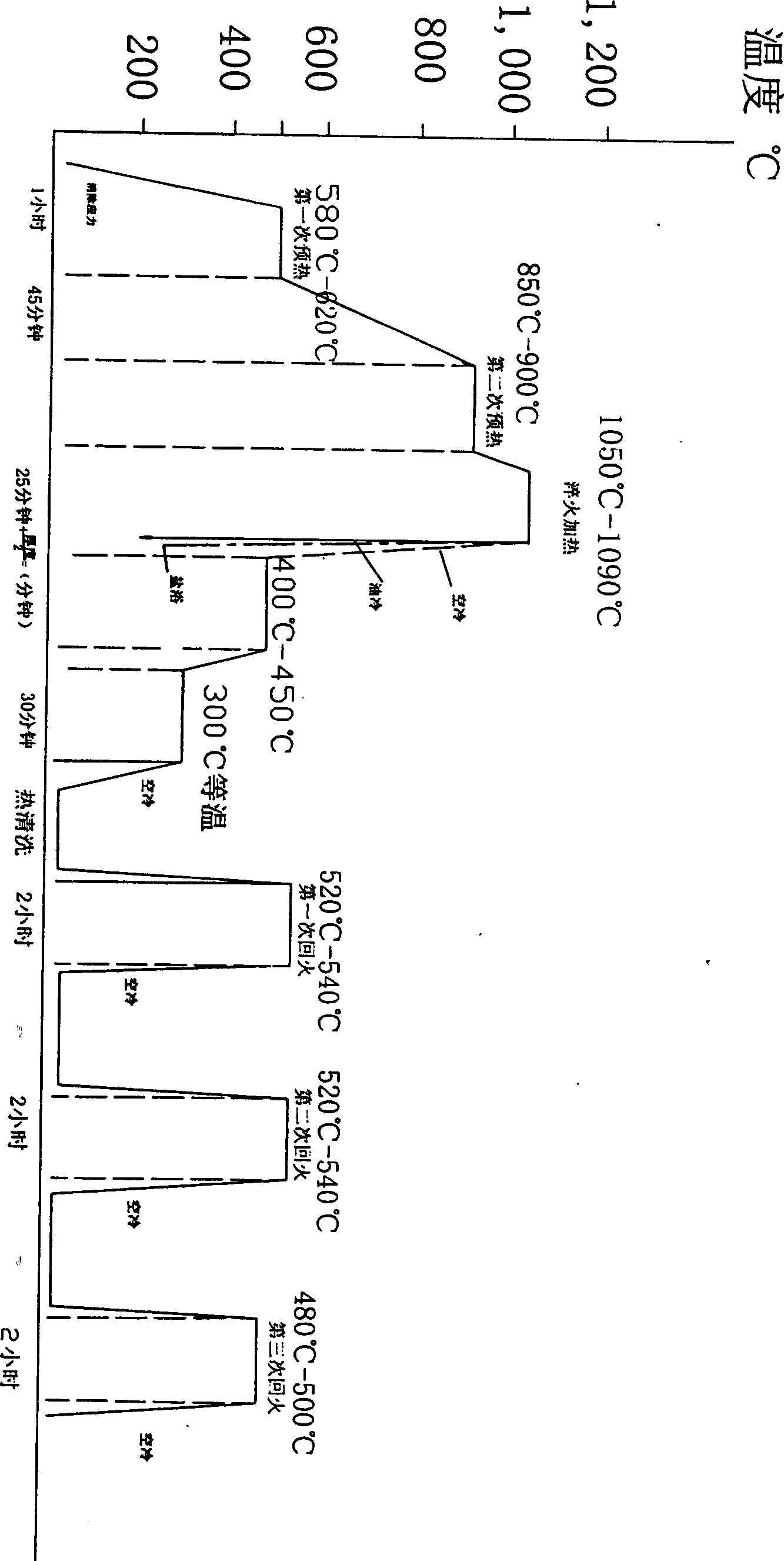

The invention relates to a steel with high mechanical strength and wear resistance. More specifically, the invention relates to a method of reducing the segregated veins of a steel having high mechanical strength, high wear resistance and the following weight composition: 0.30% <= C <= 1.42%; 0.05% <= Si <= 1.5%; Mn <= 1.95%; Ni <= 2.9%; 1.1% <= Cr <= 7.9%; 0.61% <= Mo <= 4.4%; optionally V <= 1.45%, Nb <= 1.45%, Ta <= 1.45% and V+Nb / 2 + Ta / 4 <= 1.45%; less than 0.1% borium, 0.19% (S + Se / 2 + Te / 4), 0.01% calcium, 0.5% rare earths, 1% aluminium, 1 %copper; the remainder being iron and impurities resulting from the production thereof. The composition also comprises: 800 <= D <= 1150, where D = 540(C)<0.25> + 245 (Mo + 3 V + 1.5 Nb + 0.75 Ta)<0.30> + 125 Cr<0.20 >+ 15.8 Mn + 7.4 Ni + 18 Si. According to the invention, all or part of the molydenum is replaced by a double proportion of tungsten, such that W >= 0.21%, and Ti, Zr, C are adjusted so that, after said adjustment, Ti + Zr / 2 >= 0.2 W, (Ti + Zr / 2) * C >= 0.07, Ti + Zr / 2 <= 1.49 % and D is unchanged at 5 %. The invention also relates to the steel obtained and to a method of producing a steel part.

Owner:INDUSTEEL FRANCE

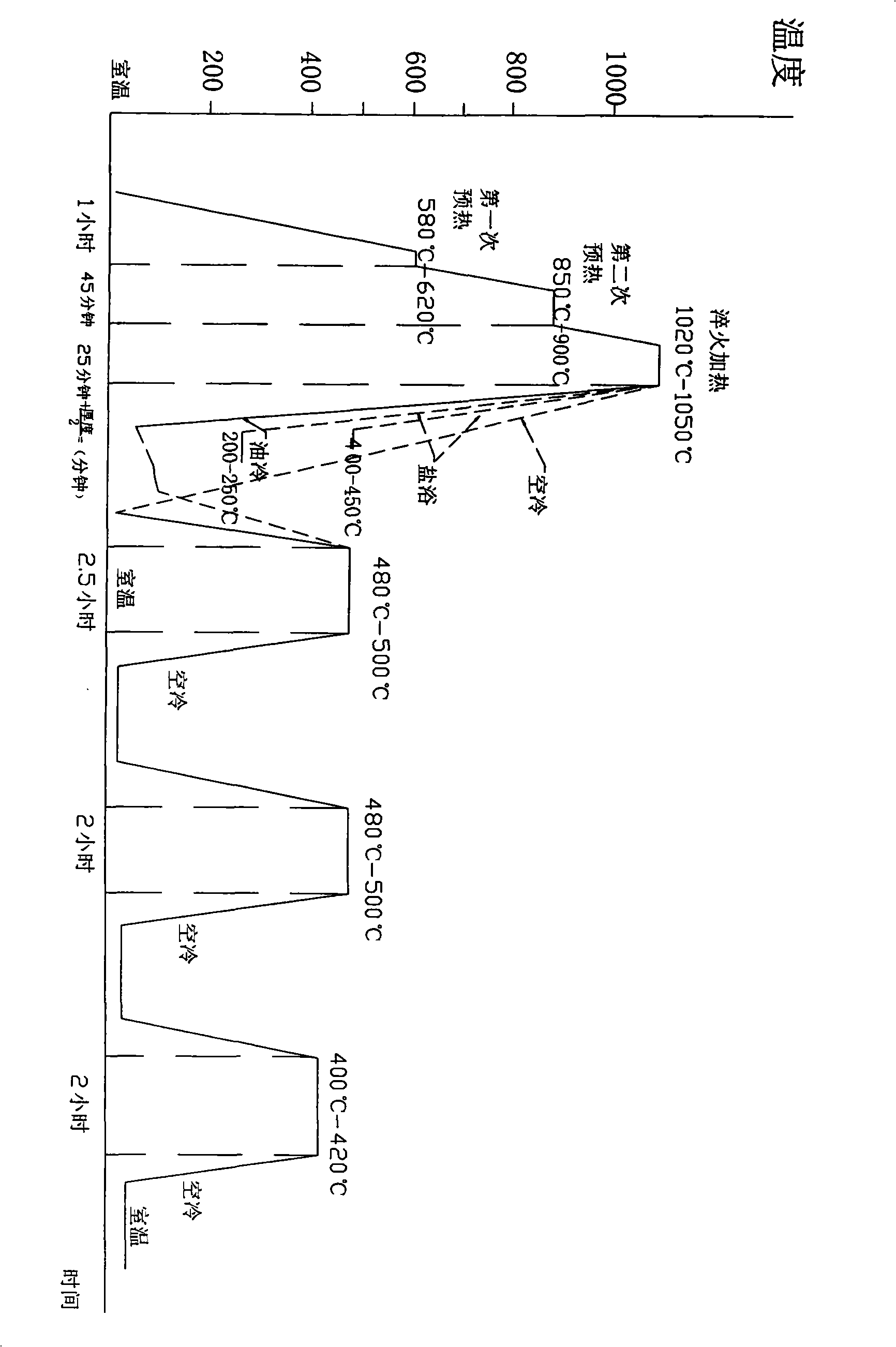

Novel chromium system hot die steel and thermal treatment process thereof

InactiveCN101368247AReduce contentSolve the problem of poor thermal brittleness and easy crackingQuenchingChromium

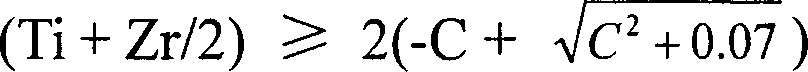

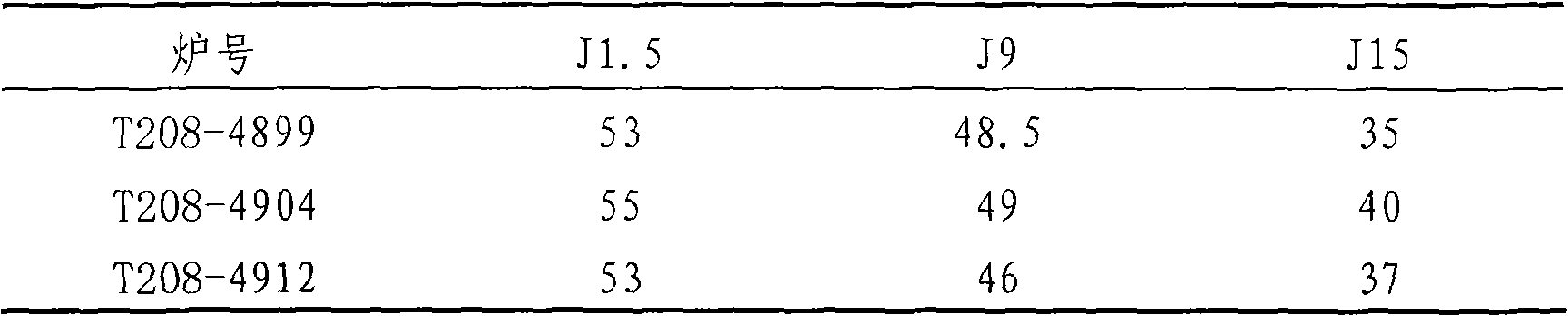

The invention relates to chromium hot work die steel which belongs to hot work die steel, in particular to hot work die steel containing lower tungsten and a thermal processing technique thereof. Counted by weight percentage, the die steel includes 0.3 to 0.8 percent of C, 0.2 to 0.8 percent of Si, 0.2 to 0.8 percent of Mn, 6.0 to 8.0 percent of Cr, 1.0 to 2.4 percent of W, 0.8 to 2.0 percent of Mo, 0.3 to 1.0 percent of V, 0.3 to 8.0 percent of Co, 0.3 to 1.5 percent of Ni, equal to or less than 0.005 percent of S, equal to or less than 0.030 percent of P and 0.03 to 0.10 percent of B; the content range of a nitride is as follows: the nitride is equal to or more than 0.02 percent, or equal to or less than 0.20 percent; the content range of N is as follows: the N is equal to or more than 0.02 percent, or equal to or less than 0.10 percent; and the rest is Fe. The grains of the steel are thinner; the effects of greatly increased heat resistance, toughness and anti-pressing intensity are generated; the rigidity is between 55 and 61HRC which is more than three times than the durable times of the existing die steel. The invention also provides a thermal processing technique with a lower quenching temperature between 1050 and 1090 DEG C for the steel.

Owner:周向儒

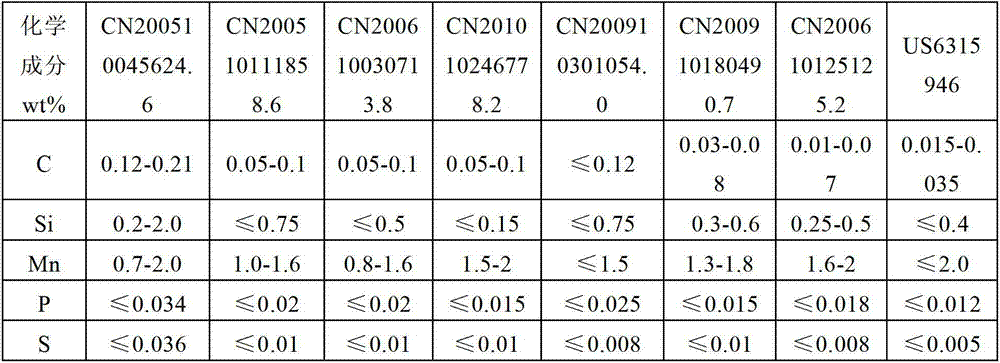

Carbon-manganese composite microalloyed steel for engineering machinery and preparation method thereof

InactiveCN101654761AHigh hardenability and stabilityEasy to controlTemperature control deviceElectric furnaceMechanical componentsChemical composition

The invention relates to a carbon-manganese composite microalloyed steel for engineering machinery and a preparation method thereof. The steel comprises the following chemical compositions by weight percent: 0.32-0.37% of C, 0.15-0.30% of Si, 1.20-1.40% of Mn, 0.030% or less of P, 0.030% or less of S, 0.0005-0.0030% of B, 0.10-0.60% of Cr, 0.01-0.07% of Al and the balance Fe and trace impurities,wherein the content of available boron in the steel is not less than 95%. The invention also provides a preparation method of the composite microalloyed steel and the method controls the ratio of Ti to N to be 3-6 and the acid soluble aluminium content to be 0.030-0.050% so as to ensure that boron in the steel is almost available boron. The preparation method of the invention controls the contentof trace element boron and ensures the hardenability of steel so that the steel is suitable to be used for the preparation of important mechanical parts.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength casted air-colled bainite wear-resisting steel and preparing method

InactiveCN1775983AImprove mechanical propertiesImprove toughnessMolten metal pouring equipmentsFoundryWear resistant

The invention relates to a high strength foundry air cooling bainite wear resistant steel that the chemical constituents is 0.32-0.65 C, 0.8-3.0 Si, 1.2-3.0 Mn, 0.5-0.8 Cr, 0.3-0.8 Cu, 0.001-0.008 B, 0.18-0.35 Al, 0.05-0.15 Y, 0.05-0.20 Ti, 0-0.12 Mg, 0-0.12 Ca, 0-0.15 Zn, and 0.10<Mg+Ca+Zn<0.25, the else is Fe and trace impurities. The process includes the following steps: smelting waste steel, pig iron, ferrochrome iron and copper board, adding ferrosilicon and ferromanganese preliminary deoxidation into melting down and alloying; heating to 1600-1660 degree centigrade after adjusting the constituents adding aluminum deoxidatioin and alloying and blast furnace tapping; putting the compounding modification particle of Yt, boron, titanium, magnesium, calcium, and zinc on the bottom of pouring ladle, taking modification process to the molten steel; molding the molten steel after modification process into normal matrix for casting. The invention could prolong the useful life of antifriction component, improve working efficiency, and have good economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel chromium system hot die steel and thermal treatment process thereof

The invention relates to novel chrome hot work die steel belonging to hot work die steel, particularly relating to the hot work die steel with low content of tungsten and the thermal treatment process thereof. The hot work die steel comprises 0.35-0.7 percent of C, 0.3-1.3 percent of Si, 0.3-1.3 percent of Mn, 7.0-11.0 percent of Cr, 0.4-1.2 percent of W, 0.4-1.2 percent of Mo, 0.4-1.2 percent of V, 1.0 percent of Ni, 0.005 percent or less of S, 0.030 percent or less of P, 0.03 percent of-0.10 percent of B, equal to or more than 0.02 percent and equal to or less than 0.20 percent of nitride, equal to or more than 0.02 percent and equal to or less than 0.10 percent of N, and the rest of Fe by weight percent. The steel of the invention has finer crystal grain, generates greatly increased heat resistance, toughness and compressive strength and has more than three times of durable frequencies than the existing die steel. The invention further provides the thermal treatment process with relatively low steel quenching temperature of 1020-1050 DEG C.

Owner:周向儒

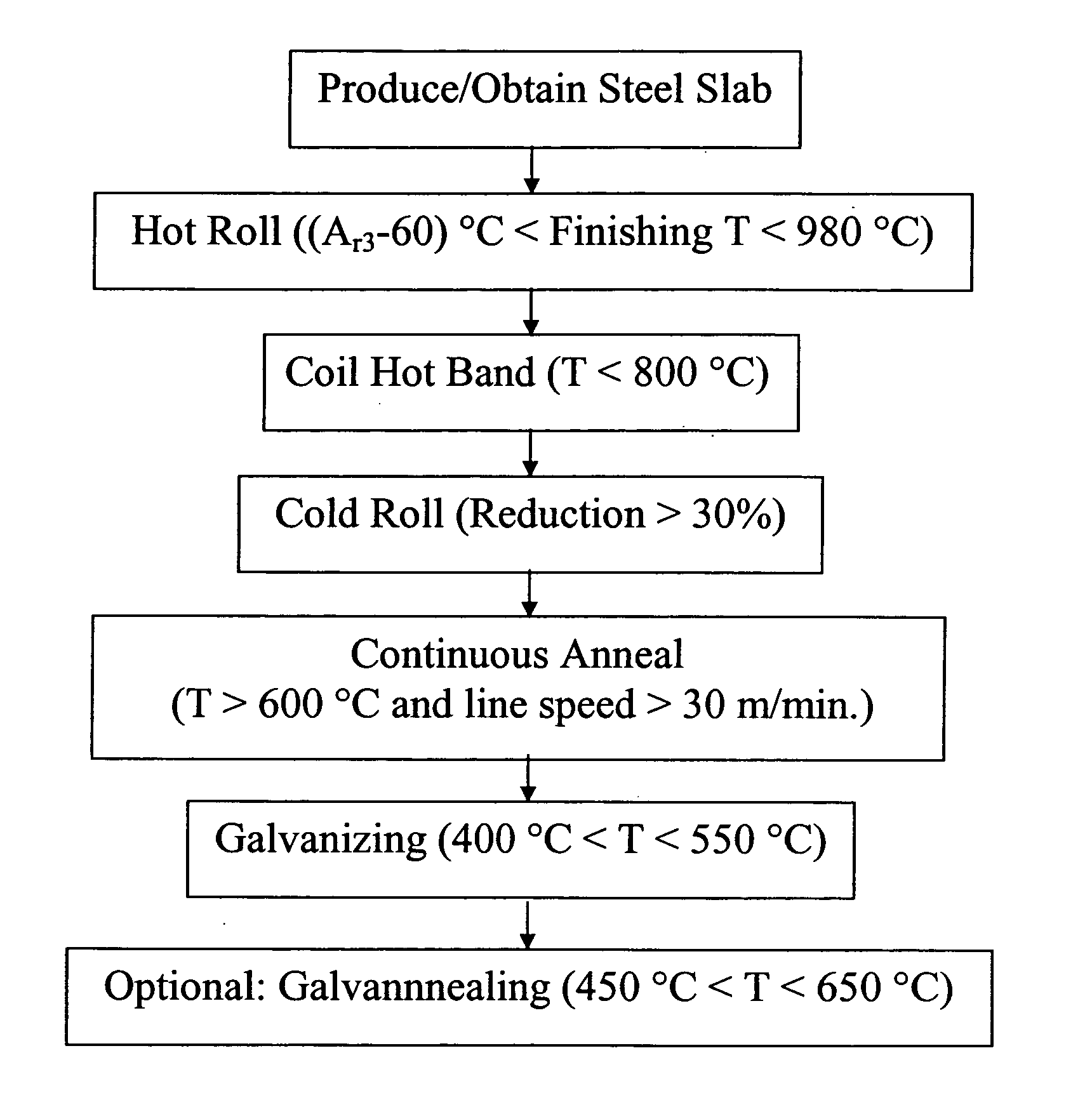

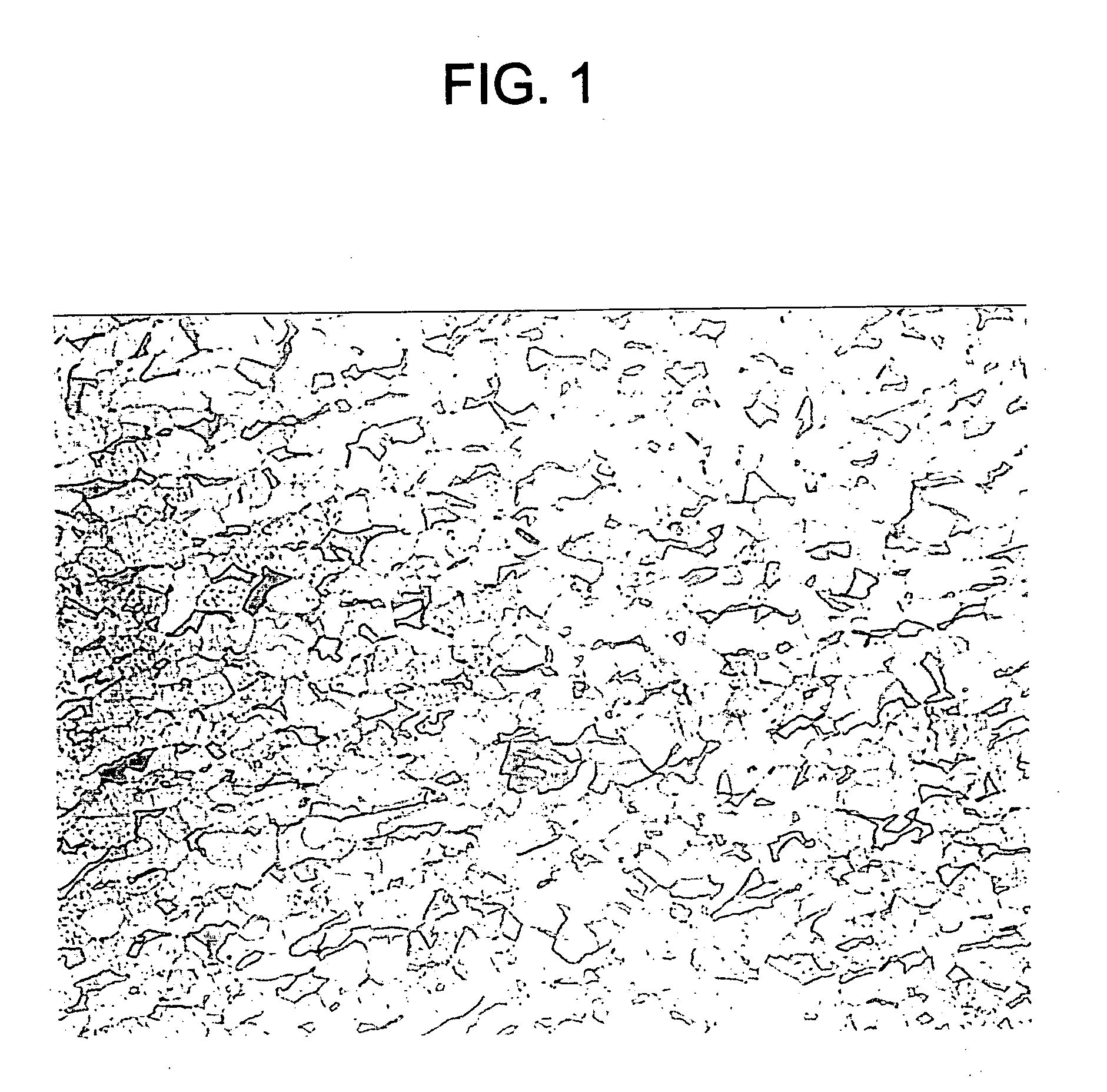

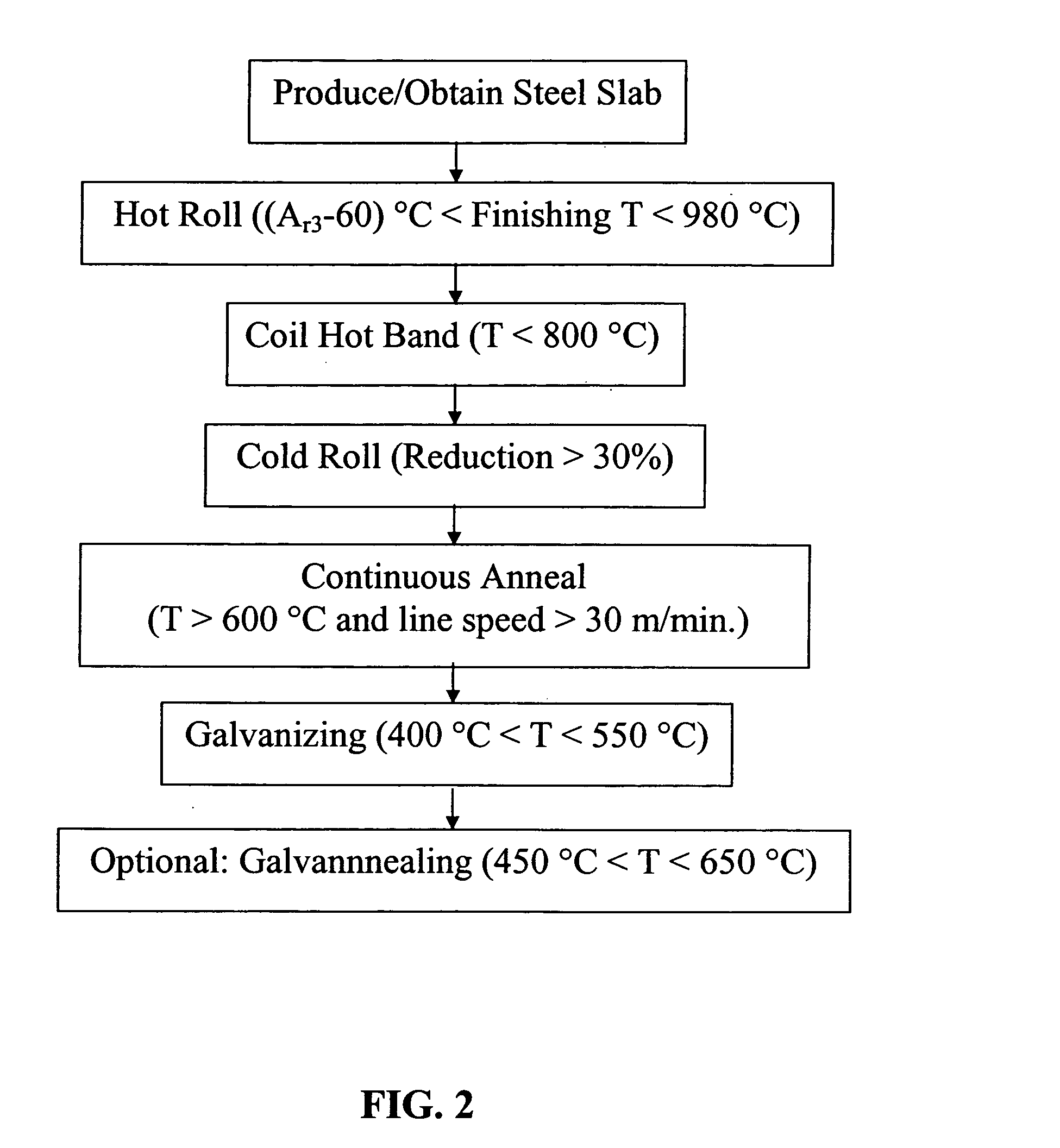

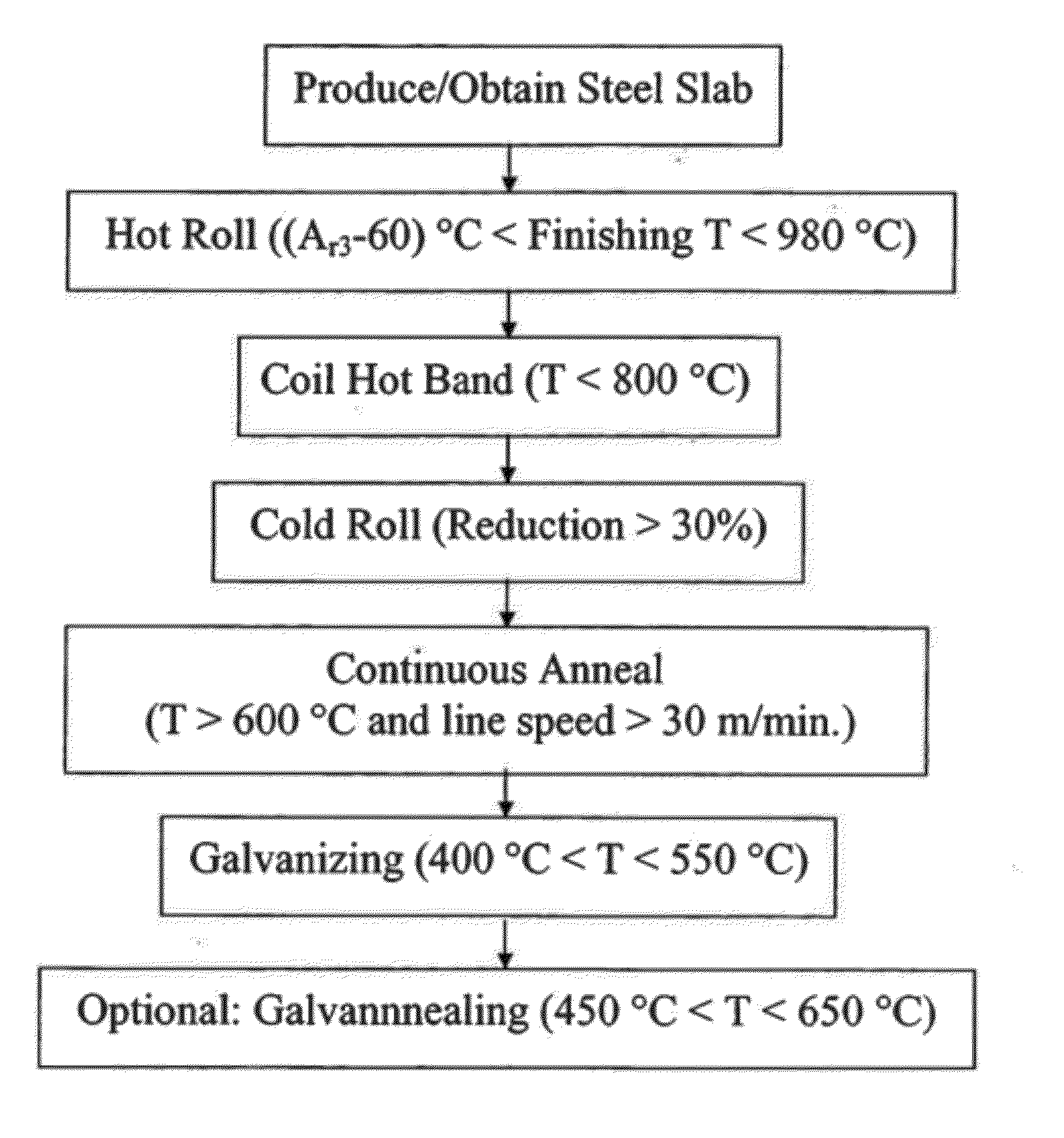

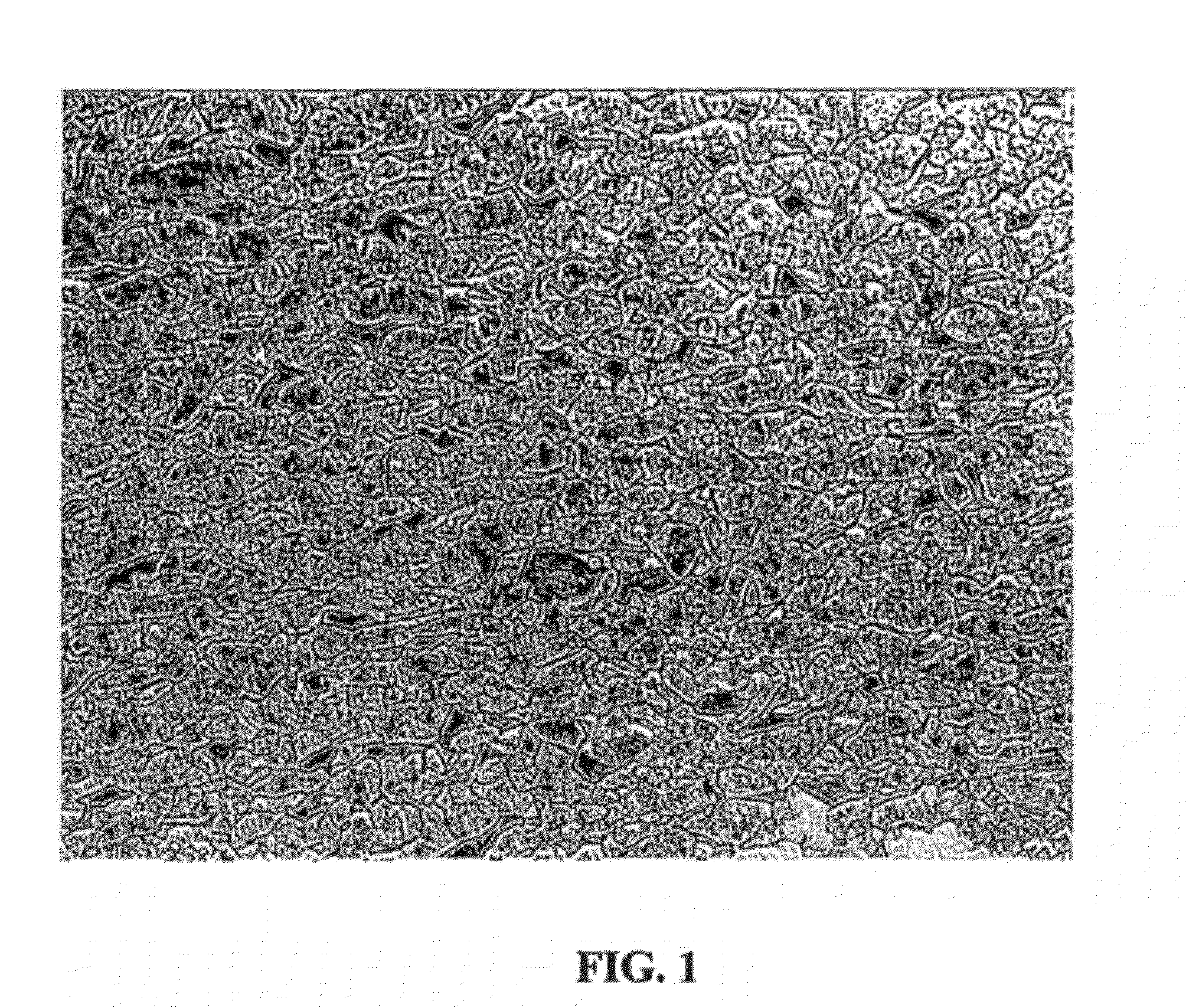

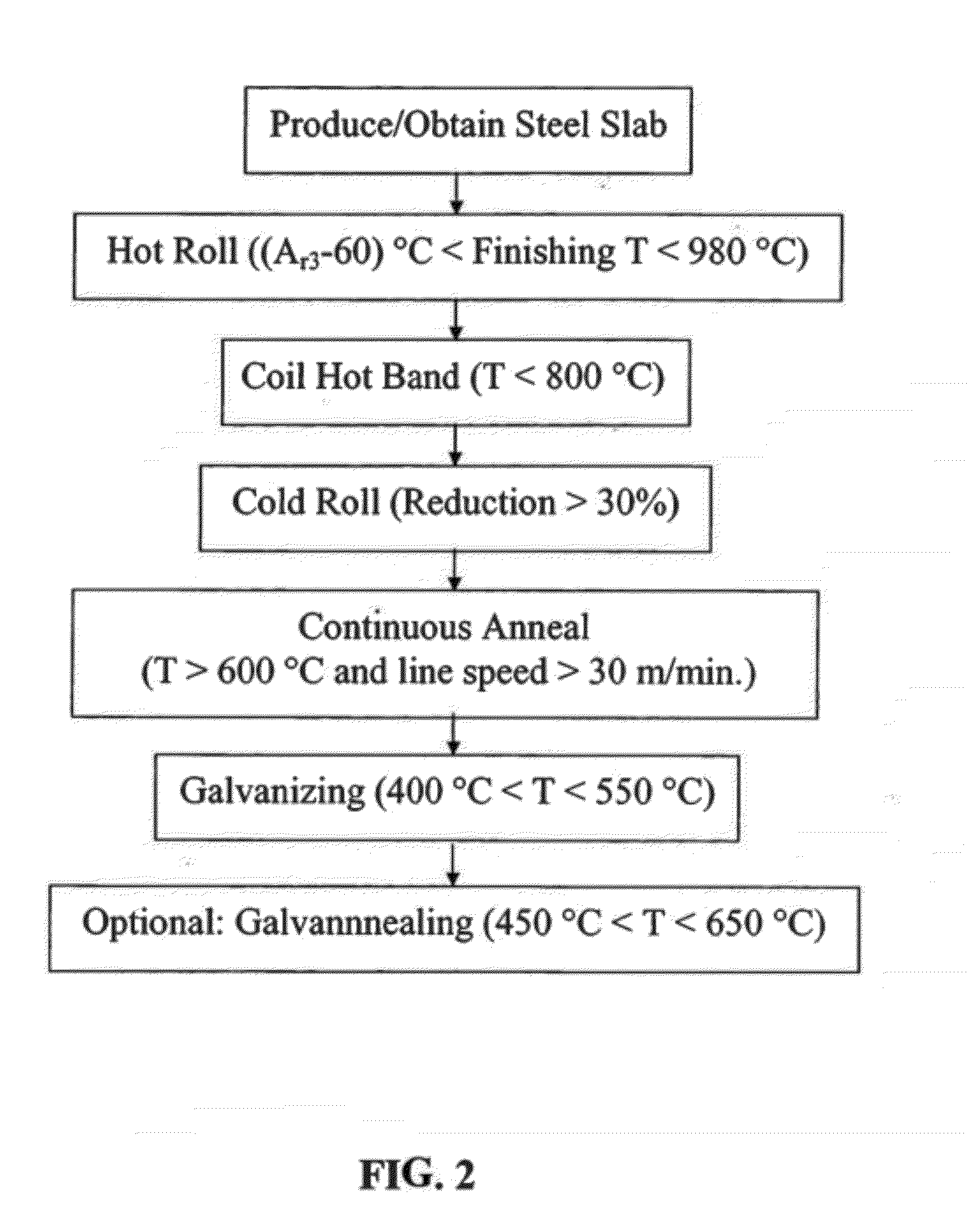

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20080075971A1Good energyGood formabilityHot-dipping/immersion processesFurnace typesNiobiumManganese

A galvanized steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: carbon in a range from about 0.01% to about 0.18%; manganese in a range from about 0.2% to about 3%; silicon ≦ about 1.2%; aluminum in a range from about 0.01% to about 0.1%; one or both of chromium and nickel in a range from about 0.1% to about 3.5%; calcium in a range from about 0.0003% to about 0.01%; phosphorus ≦ about 0.01%; sulfur ≦ about 0.03%; nitrogen ≦ about 0.02%; molybdenum ≦ about 1%; copper ≦ about 0.8%; one or more of niobium, titanium, and vanadium ≦ about 1%; and boron ≦ about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. In one embodiment, the steel sheet is both galvanized and galvannealed.

Owner:NUCOR CORP

Boron-containing weather-proof thin strip steel and manufacturing method thereof

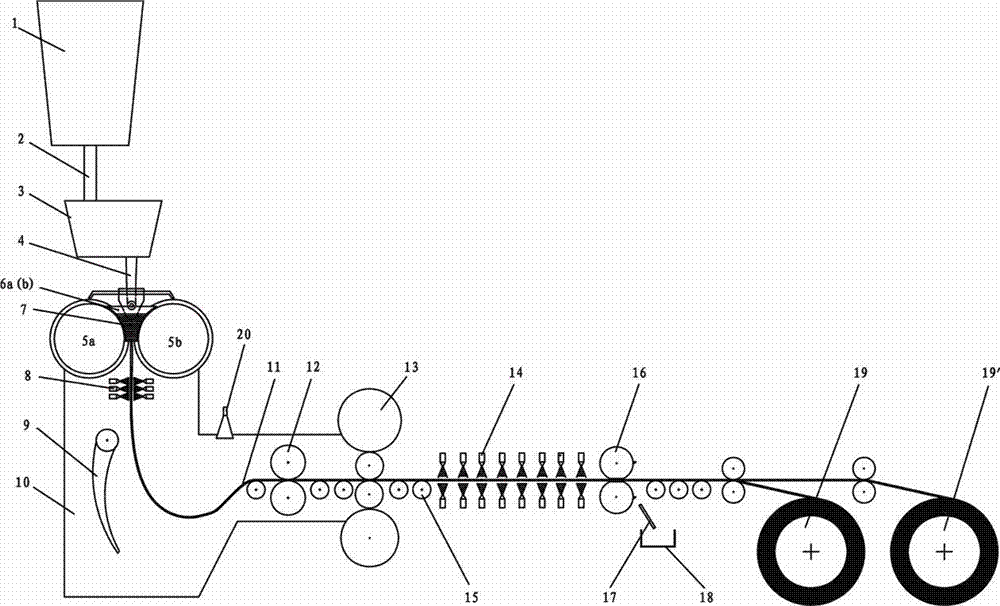

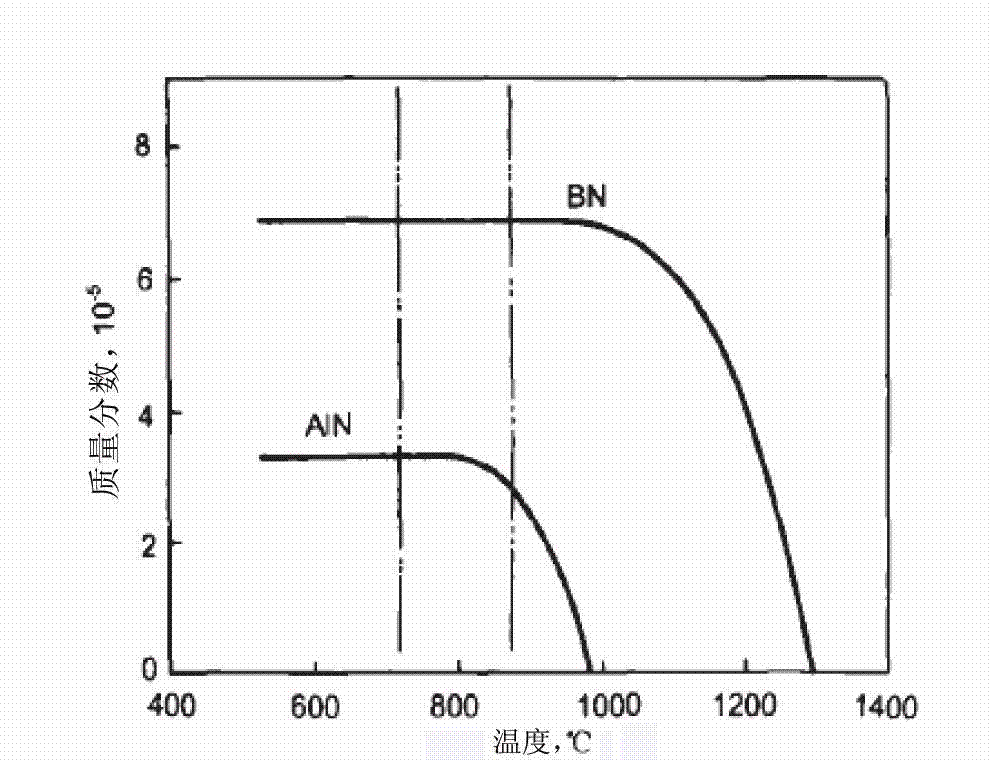

Provided are boron-containing weather-proof thin strip steel and a manufacturing method thereof. The manufacturing method comprises performing double roller thin strip continuous casting to produce boron-containing weather-proof steel; after a cast strip is processed through a crystallizing roller, adopting a mode of spraying dry ice to perform uniform strengthened cooling on the cast strip, rapidly cooling the cast strip to below 1,280 DEG C, and enabling the cooling speed to be 200-300 DEG C / s, so that precipitation of thick and large BN in the cooling mode is promoted, emergency of low-melting-point-phase B203 and precipitation of tiny AlN are avoided, and the aims of homogenizing austenite grains and reducing yield ratio are achieved; then performing austenite on-line recrystallization rolling; then performing anti-oxidizing rapid cooling to cool the strip steel undergoing hot rolling, and enabling the cooling temperature to be 80-200 DEG C / s; and enabling coiling temperature to be 500-600 DEG C. Steel with low yield ratio can be obtained through the manufacturing method, and the problems that steel produced by thin strip continuous casting are universally uneven in structure, high in yield ratio and difficult to form and cannot meet the requirements for cold rolling materials are effectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat resistant austenitic stainless steel

InactiveUS6485679B1High creep rupture strengthGood steam oxidation resistanceRigid pipesHeat exchange apparatusAustenitic stainless steelTungsten

A heat resistant austenitic stainless steel with high strength at elevated temperatures, good steam oxidation resistance, good fire side corrosion resistance, and a sufficient structural stability, suitable for use in boilers operating at high temperatures has a composition (by weight) of. 0.04 to 0.10% carbon (C), not more than 0.4% silicon (Si), not more than 0.6% manganese (MN), 20 to 27% chromium (Cr), 22.5 to 32% nickel (Ni), not more than 0.5% molybdenum (Mo), 0,20 to 0.60% niobium (Nb), 0.4 to 4.0% tungsten (W), 0.10 to 0.30% nitrogen (N), 0.002 to 0.008% boron (B), less than 0.05% aluminium (Al), at least one of the elements Mg and Ca in amounts less than 0.010% Mg and less than 0.010% Ca, and the balance being iron and inevitable impuities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

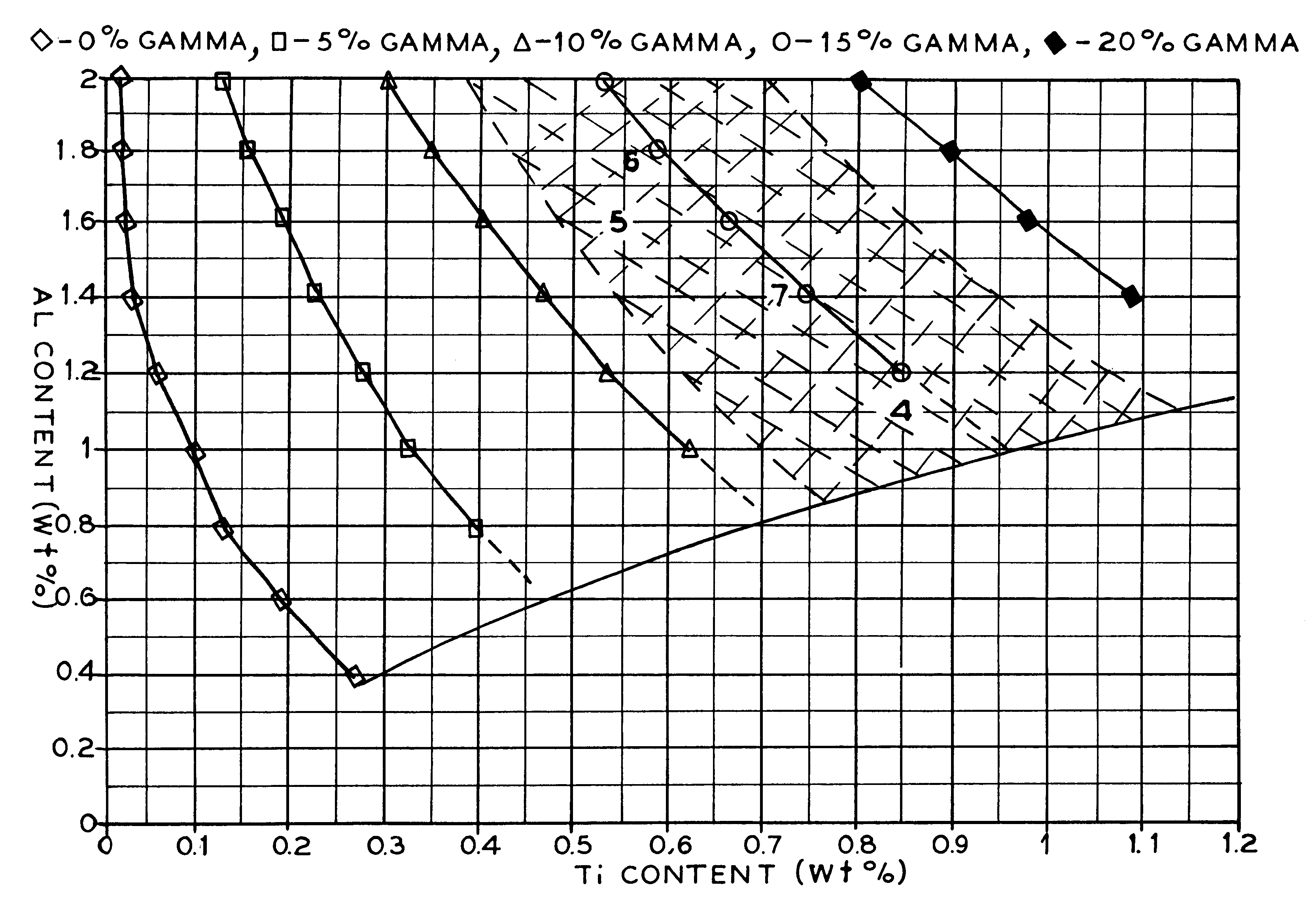

Advanced ultra-supercritical boiler tubing alloy

An ultra supercritical boiler tubing alloy characterized by a microstructure stabilized and strengthened for 375 bar / 700.degree. C. steam, in weight percent, service and alloyed to resist coal ash / flue gas corrosion for 200,000 hours consisting of 10 to 24 cobalt, 22.6 to 30 chromium, 2.4 to 6 molybdenum, 0 to 9 iron, 0.2 to 3.2 aluminum, 0.2 to 2.8 titanium, 0.1 to 2.5 niobium, 0 to 2 manganese, 0 to 1 silicon, 0.01 to 0.3 zirconium, 0.001 to 0.01 boron, 0.005 to 0.3 carbon, 0 to 4 tungsten, 0 to 1 tantalum and balance nickel and incidental impurities.

Owner:HUNTINGTON ALLOYS CORP (US)

High-boron high-speed steel composite roller and manufacturing method thereof

ActiveCN103866200AEnergy savingHas the advantage of material savingRollsMetal rolling arrangementsAfter treatmentChemical composition

The invention discloses a high-boron high-speed steel composite roller and a manufacturing method thereof, belonging to the technical field of rollers. A roller shaft and a high-boron high-speed steel composite roller sleeve are combined together through hot charging; the outer layer of the composite roller sleeve is wear-resistant high-boron high-speed steel, and the inner layer is a steel pipe; the roller shaft is arranged in the steel pipe and coaxially penetrates through the steel pipe; the molten steel of the wear-resistant high-boron high-speed steel at the outer layer comprises the following chemical components in percentage by mass: 1.25-1.80% of C, 1.25-1.60% of B, 5.5-8.0% of Cr, 1.0-1.5% of W, 2.5-3.0% of Mo, 0.3-0.6% of V, 0.6-1.2% of Ni, 0.3-0.9% of Si, 0.30-0.55% of Mn, less than 0.04% of S, less than 0.05% of P and the balance of Fe and unavoidable impurities; the molten steel is prepared by casting and combination with the steel pipe after treatment outside the furnace. The composite roller disclosed by the invention has the advantages of high hardness, good wear resistance and low production cost, and brings good benefits in application.

Owner:娄底市巨能高新耐磨材料有限公司

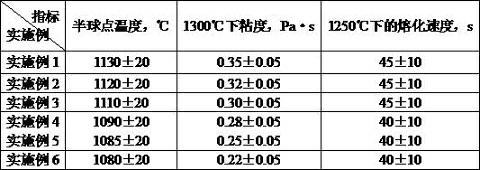

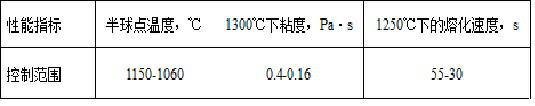

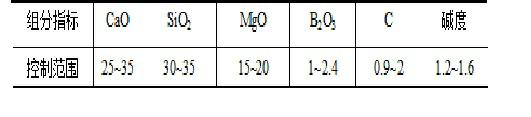

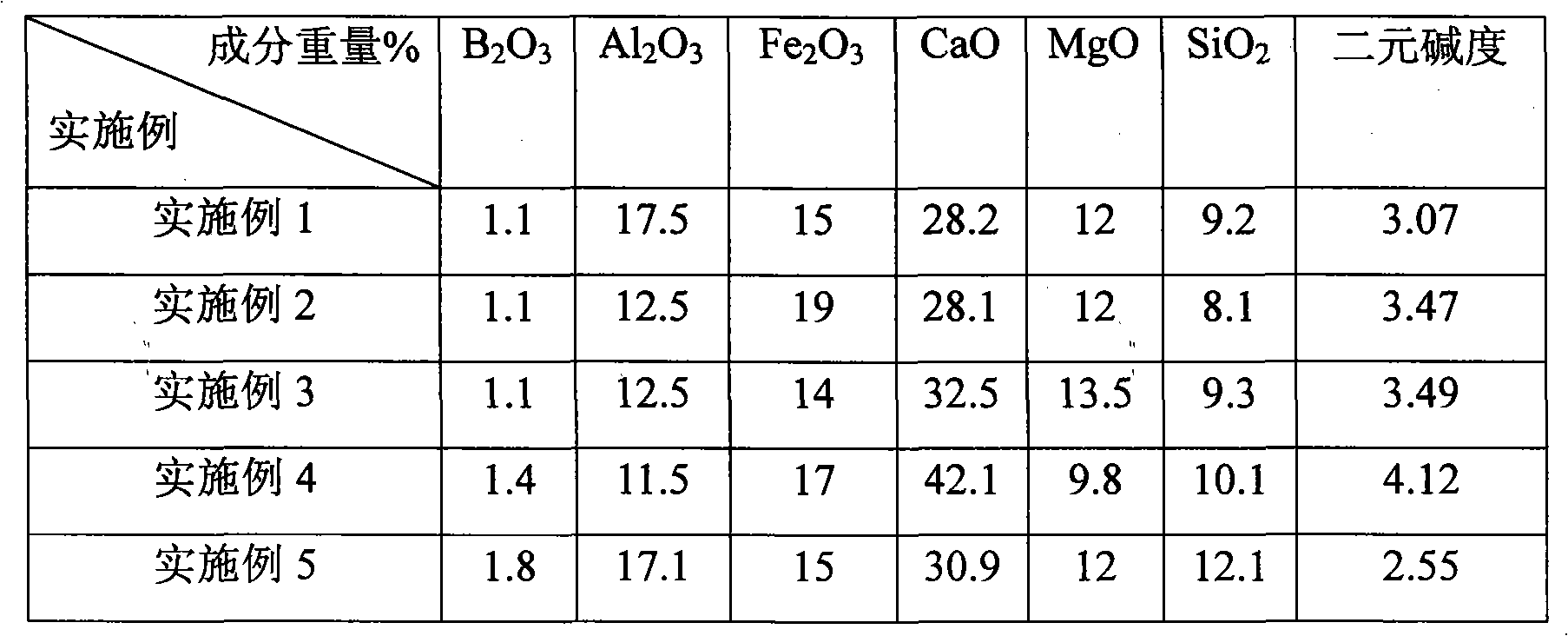

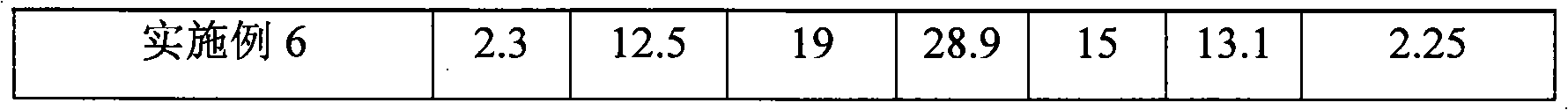

Boron-containing fluoride-free covering slag for steel continuous-casting crystallizer and preparation method thereof

The invention belongs to the technical field of steel smelting continuous casting production and in particular relates to boron-containing fluoride-free covering slag for a steel continuous-casting crystallizer and a preparation method thereof. The boron-containing fluoride-free covering slag is characterized by being prepared form the following raw materials in percentage by weight: 50-60 percent of boric sludge powder, 20-30 percent of wollastonite powder, 10-20 percent of lime powder and 1-2 percent of coke powder. The preparation method comprises the steps of: fully drying and dewatering the raw materials, weighing and burdening the raw materials according to weight fractions, levigating, uniformly mixing, and preparing the levigated materials into granular finished products of slag by adopting a traditional covering slag preparing and forming process. The covering slag has better melting property and absorption and entrapment capability, and particularly, boron is used to replacefluoride to realize the fluoride-free property of the covering slag and the recycling of the waste boric sludge, therefore, the advantages of cost reduction, environment friendliness and obvious economic and social benefits are achieved.

Owner:JIANGSU UNIV

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

Manufacturing method of high-strength high-tenacity alloy steel

The invention discloses a manufacturing method of high-strength high-tenacity alloy steel. The high-strength high-tenacity alloy steel is prepared from the following chemical components by weight percent: 0.3-0.58% of carbon, 0.25-1.38% of silicon, 0.55-1.55% of manganese, 0.025% or less of phosphorus, 0.02-0.025% of sulphur, 0.09-1.32% of chromium, 0.28-0.62% of nickel, 0.02-0.035% of molybdenum, 0.18-0.20% of titanium, 0.2-0.5% of vanadium, 0.4-0.9% of tungsten, 0.3-0.6% of niobium, 0.11-0.15% of cobalt, 0.2-0.8% of copper, 0.2% or less of aluminum, 0.15% or less of boron, 0.3% or less of nitrogen and unavoidable impurities. According to the manufacturing method, medium carbon steel is adopted to produce the high-strength high-tenacity alloy steel, the production cost is relatively low, the tensile strength, the yield strength and the hardness are relatively high, and a wide application prospect is ensured.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

A high-boron cast alloy guide and its heat treatment method

InactiveCN101549360AGood resistance to shock and heatReduce carbon contentGuiding/positioning/aligning arrangementsQuenching agentsChemical compositionAlloy

A high-boron cast alloy guide and its heat treatment method pertain to the technical field of steel rolling. The chemical composition of the guide provided by the present invention (mass fraction, %): C 0.25-0.45, Cr 12.0-15.0, B 1.0-2.5, Mo 0.5-0.8, Mn 1.8-2.5, Al 0.10-0.30, Re 0.08-0.20, Mg 0.04-0.08, V 0.05-0.10, N 0.01-0.03, Ti 0.10-0.20, Nb 0.10-0.20, 0.25<=Ti+Nb<=0.35, Si<1.0, S<0.05, P<0.05, and Fe as the rest. Through smelting, casting, oil quenching, tempering and other steps, the present invention prepares a high-boron cast alloy guide with high hardness and strength, desirable tenacity and wear resistance, and low cost.

Owner:BEIJING UNIV OF TECH

Boron-containing fluorine-free fluxing slag-melting agent for electric steelmaking

The invention provides a boron-containing fluorine-free fluxing slag-melting agent for electric steelmaking, belonging to the technical field of steelmaking. The slag-melting agent is made from the following components in parts of by weight: 30-50 parts of boron sludge, 20-40 parts of laterite, 20-40 parts of quicklime and 5-15 parts of ferric oxide. The preparation method of the slag-melting agent comprises the following steps: sufficiently drying and dehydrating the raw materials, and weighting and proportioning based on weight parts; and grinding, evenly mixing, and making block slag by a pelleting-drying-sintering method or premelting-cooling-crushing-sieving method. Compared with the prior art, the invention has the following beneficial effects: the product provided by the invention is used as the fluxing agent instead of fluorite, calcium aluminate and ferriferous oxide, thereby eliminating fluorine pollution and relieving the corrosion action of the slag-melting agent on the furnace lining; and particularly, the waste boron sludge are recycled, and high-cost calcium aluminate is replaced with low-cost laterite with abundant reserves, thus the boron-containing fluorine-free fluxing slag-melting agent provided by the invention has important meanings for reasonably and comprehensively utilizing mineral resources, lowering the steelmaking cost, and realizing high-efficiency low-cost low-pollution green steelmaking.

Owner:JIANGSU UNIV

High-strength steel plate for light goods shelves and forging process thereof

The invention discloses a high-strength steel plate for light goods shelves and a forging process thereof. The high-strength steel plate for the light goods shelves is composed of, by weight percentage, 0.22-0.24% of carbon, 0.32-0.38% of boron, 0.52-0.54% of palladium, 0.02-0.04% of selenium, 0.02-0.04% of arsenic, 3.23-3.25% of rubidium, 0.45-0.48% of vanadium, 5.36-5.39% of titanium, 6.63-6.67% of copper, 4.57-4.59% of tin, 8.7-8.9% of chromium, 0.06-0.08% of molybdenum, 8.78-8.79% of nickel, 0.36-0.38% of barium, 3.42-3.44% of magnesium, 3.21-3.23% of neodymium, 0.25-0.35% of promethium, 0.45-0.48% of praseodymium, 1.2-1.5% of holmium, 0.04-0.06% of dysprosium, balancing Fe and inevitable impurities.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Hypereutectic white iron alloys comprising chromium, boron and nitrogen and articles made therefrom

Disclosed are a hypereutectic white iron alloy and articles such as pump components made therefrom. Besides iron and unavoidable impurities the alloy comprises, in weight percent based on the total weight of the alloy, from 3 to 6 C, from 0.01 to 1.2 N, from 0.1 to 4 B, from 3 to 48 Cr, from 0.1 to 7.5 Ni and from 0.1 to 4 Si and, optionally, one or more of Mn, Co, Cu, Mo, W, V, Mg, Ca, rare earth elements, Nb, Ta, Ti, Zr, Hf, Al.

Owner:RADON ROMAN +1

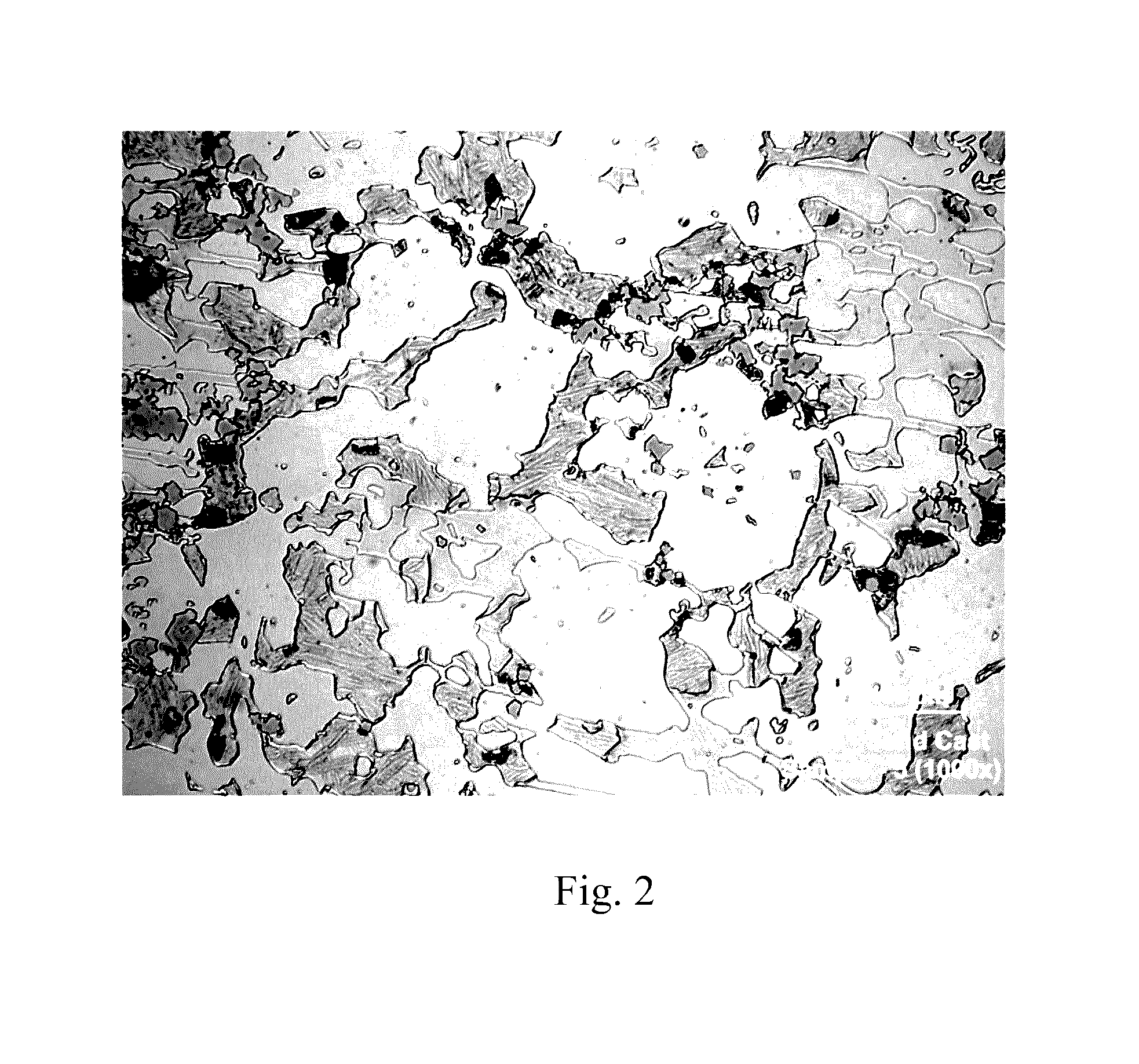

Ferrite-free heavy caliber thick-wall heat resistant steel pipe material

Owner:CENT IRON & STEEL RES INST

Laser remanufacturing and reinforcing method of mine car wheel set

InactiveCN104878380AExtended service lifeHigh bonding strengthMetallic material coating processesManganeseFerrochrome

The invention relates to a laser remanufacturing and reinforcing method of a mine car wheel set. The laser remanufacturing and reinforcing method is characterized in that nickel-based alloy powder is adopted for a fusion covering middle buffer layer, and the nickel-based alloy powder comprises the following chemical components in percentage by weight: 0.33%-0.50% of carbon, 0.32%-3.8% of silicon, 0.65%-7.5% of chromium, 0.25%-3.5% of iron, 0.10%-1.5% of boron, 0.10%-0.2% of vanadium and the balance of nickel and inevitable impurities; iron-based alloy powder is adopted for a fusion covering strengthening layer, and the iron-based alloy powder comprises the following components in percentage by weight: 0.10%-1.5% of carbon, 0.22%-2.8% of silicon, 4.5%-6.0% of chromium, 4.5%-5.0% of molybdenum, 1.5%-2.0% of boron, 3.0%-3.5% of manganese, 2.0%-2.5% of vanadium, 6.5%-7.5% of tungsten and the balance of iron and inevitable impurities. Thus, the laser remanufacturing and reinforcing method disclosed by the invention can be used for effectively prolonging the service life of the mine car wheel set and reducing the replacement frequency of the mine car wheel set.

Owner:辽宁思达思克控股有限公司

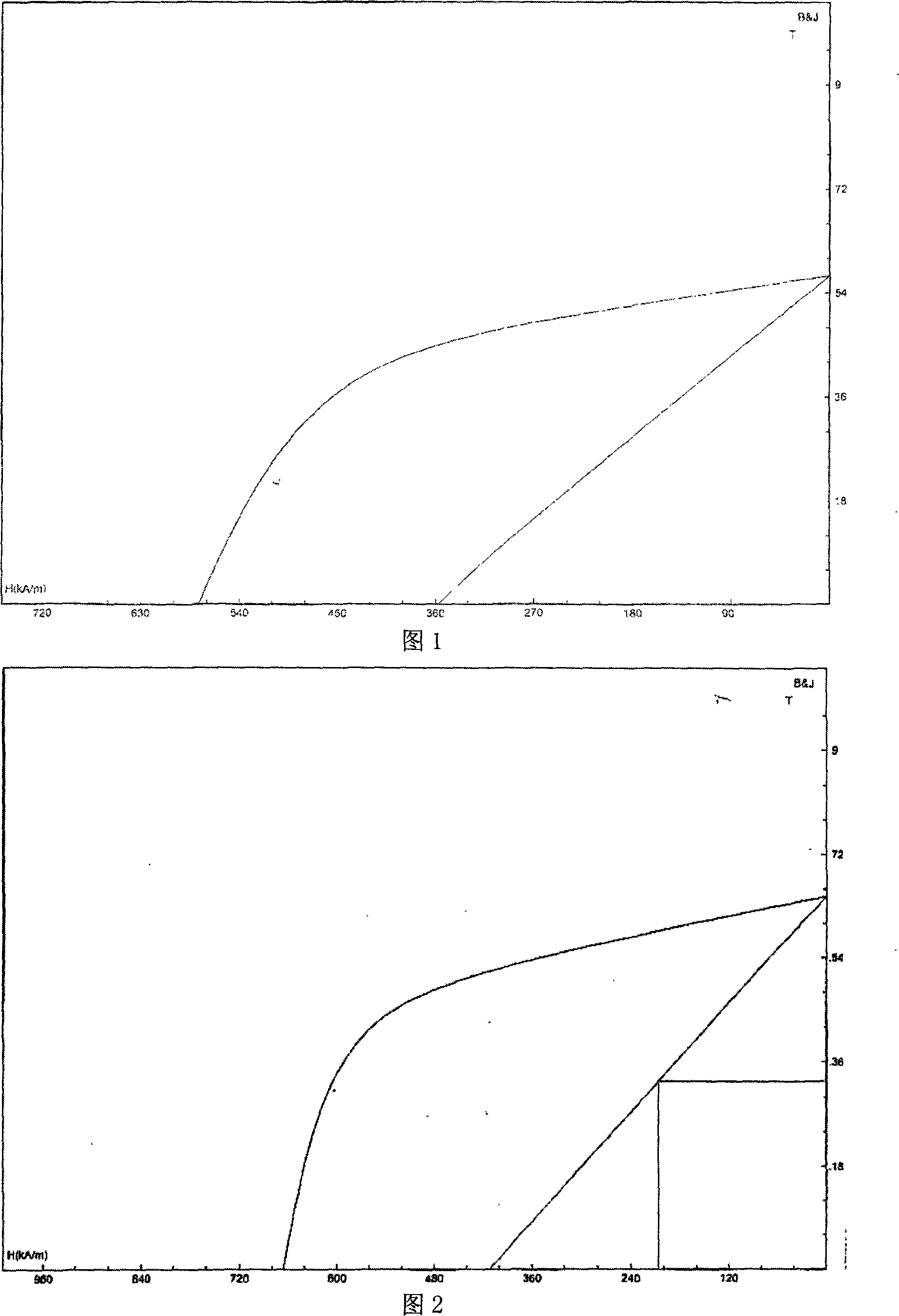

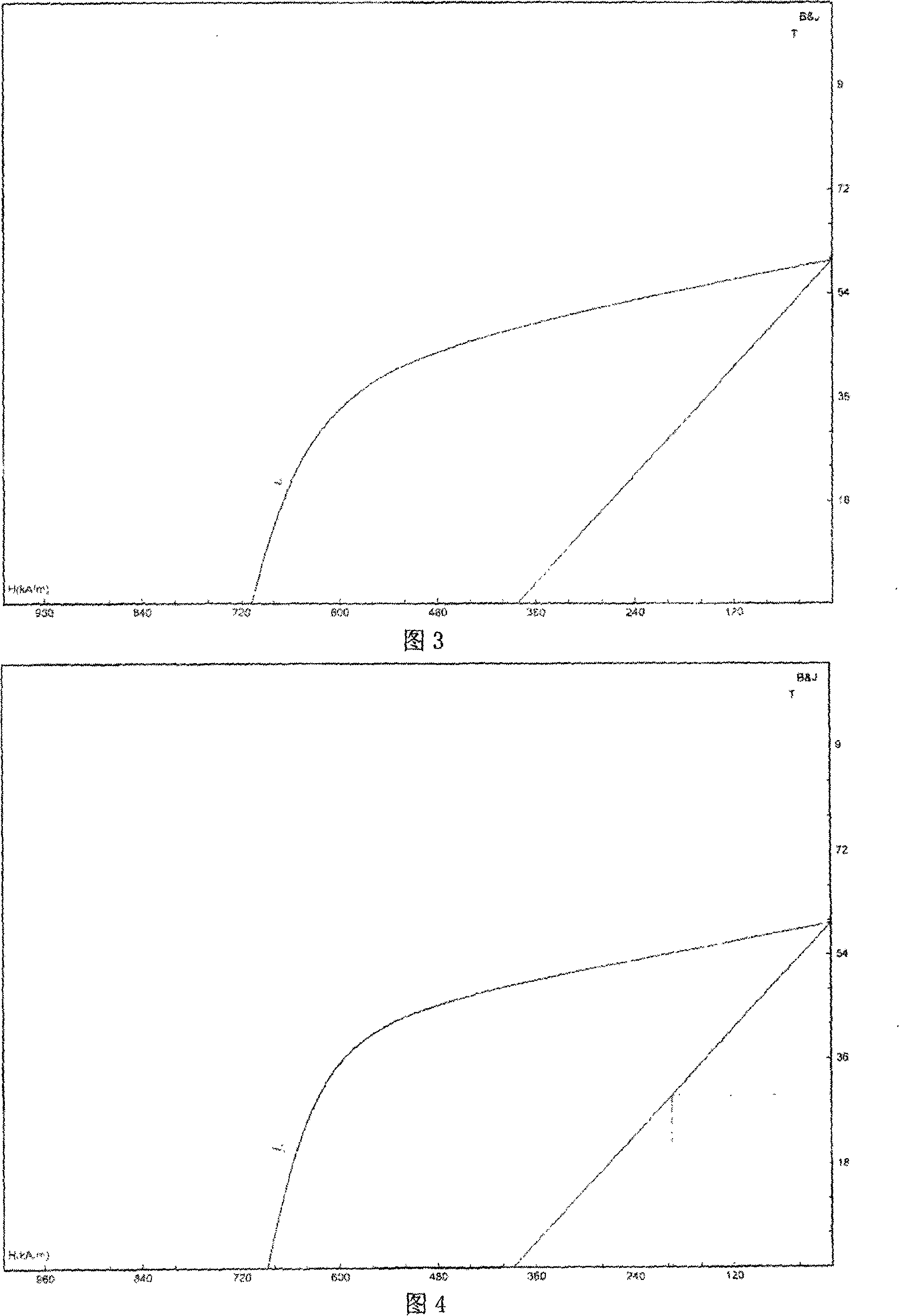

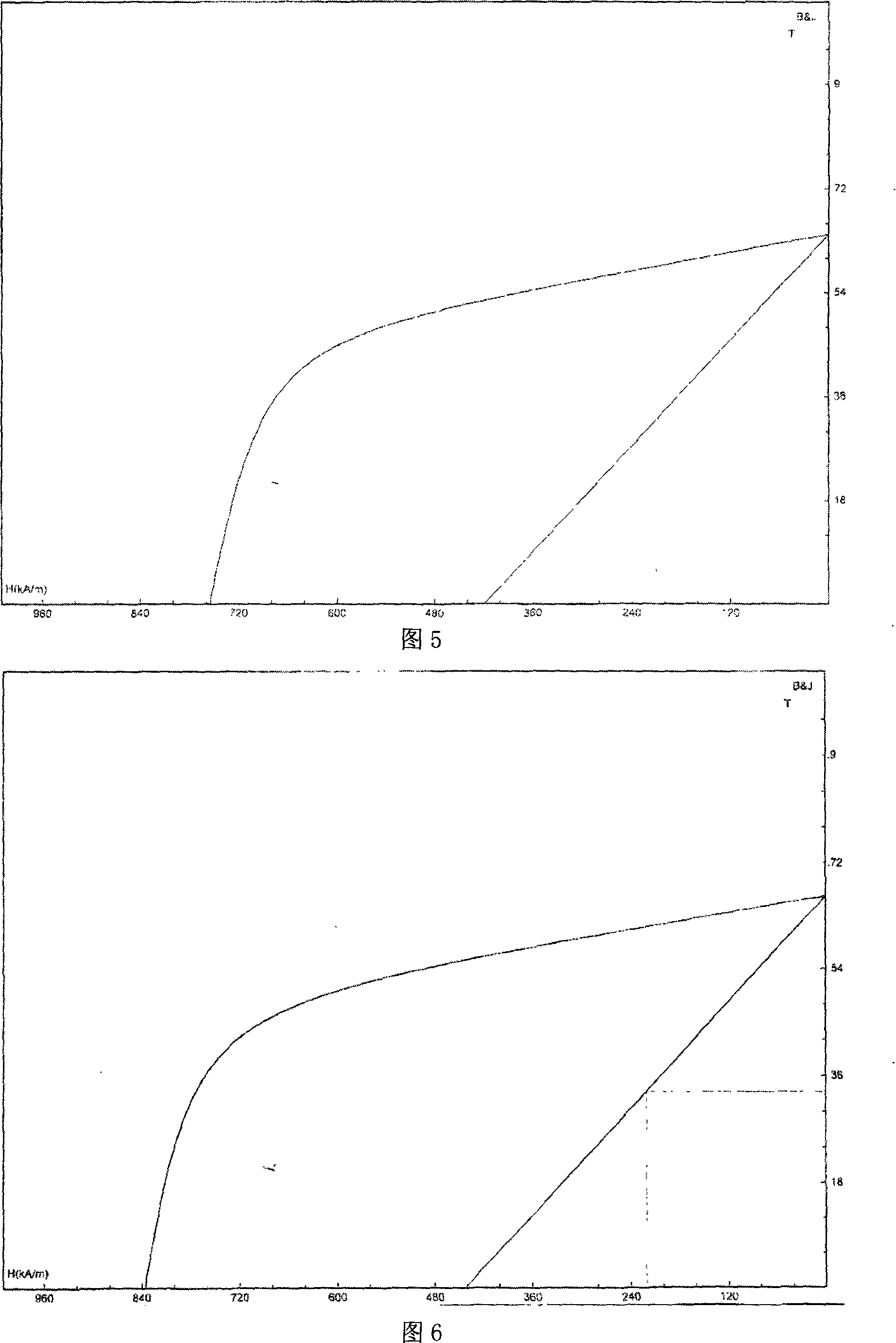

A lanthanon permanent magnetic powder and its making method

InactiveCN101241789AImprove stabilityImprove coercive forceInorganic material magnetismMetal alloyRare earth

The present invention provides a rare-earth permanent-magnetic powder and the preparing method thereof. The basic representation of the rare-earth permanent-magnetic powder is as follows: (R<1-a>La)uFe<100-u-x-y>MxBy, wherein R is Nd, Pr or NdPr or the mixed rare earth metal alloy which is mainly La, Ce and Nd. La is metal lanthanum element. Fe is metal iron element. M is metal Zr, Hf, Nb, V or the alloy. B is boron element. The rare-earth permanent-magnetic powder of the invention can be prepared with arc remelting fast quenching method or induction remelting fast quenching method. Under the condition that the Nd content is reduced greatly, the invention keeps higher synthetic magnetic character and has better temperature stability. After the 150 DEG C high temperature aging experiment, the irreversible flux loss is only 3to 5 The performance-price ratio of the rare-earth permanent-magnetic powder of the invention is higher and the invention has better market applying prospect.

Owner:绵阳西磁科技开发公司

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20120138194A1Good energyGood formabilityHot-dipping/immersion processesThin material handlingNiobiumManganese

A galvanized dual phase steel sheet with a martensite phase and a ferrite phase and a composition containing within the following ranges by weight: carbon from about 0.01% to about 0.18%; manganese from about 0.2% to about 3%; silicon≦about 1.2%; aluminum from about 0.01% to about 0.1%; one or both of chromium and nickel from about 0.1% to about 3.5%; calcium from about 0.0003% to about 0.01%; phosphorus≦about 0.1%; sulfur≦about 0.03%; nitrogen≦about 0.02%; molybdenum≦about 1%; one or more of niobium and titanium≦about 1%; and boron≦about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. The steel sheet may be both galvanized and galvannealed.

Owner:NUCOR CORP

Method and fixture for welding high temperature alloy and cupronickel

ActiveCN101983819AHigh strengthImprove corrosion resistanceSoldering auxillary devicesCupronickelManganese

The invention discloses a method and fixture for welding high temperature alloy and cupronickel. A brazing filler metal consisting of powdery gold 20, nickel, chromium, iron, silicon and boron, or consisting of platinoid copper, manganese, cobalt and nickel is used for welding. The brazing filler metal is coated or arranged between a cupronickel piece and high temperature alloy, and the peripheryof the bonding surface of the cupronickel piece and the high temperature alloy is coated with a red stop-off agent and is pressed tightly by a fixture. A brazing filler metal welding piece which is pressed tightly by the fixture is put in a vacuum furnace, and then the processes of vacuumizing, heating and brazing are performed. Since the brazing filler metal consisting of copper, manganese, cobalt and nickel has the characteristics of high strength, good corrosion resistance, low price and high weld joint quality, and the brazing filler metal consisting of gold 20, nickel, chromium, iron, silicon and boron has the characteristics of good ductility and strong wetting function, respective pressing is omitted the process of brazing, thereby achieving good molding quality of the weld joint. Since the brazing elements of the two brazing filler metals used in the brazing process have the alloying effect on the two materials to be connected, the brazing joint has large spreading area, the joint is high in strength, and the quality of the brazing joint meets the requirement.

Owner:AECC AVIATION POWER CO LTD

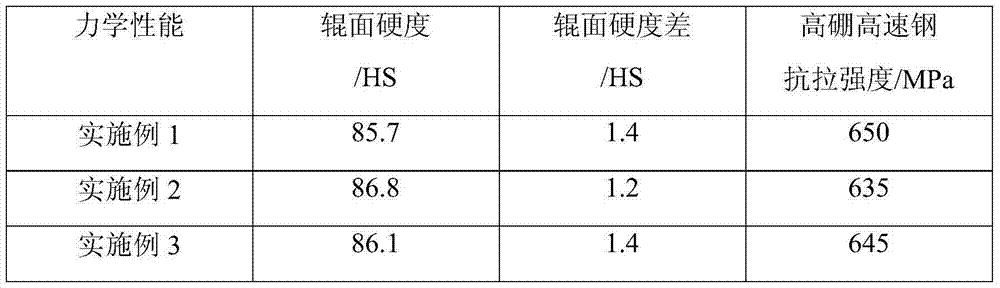

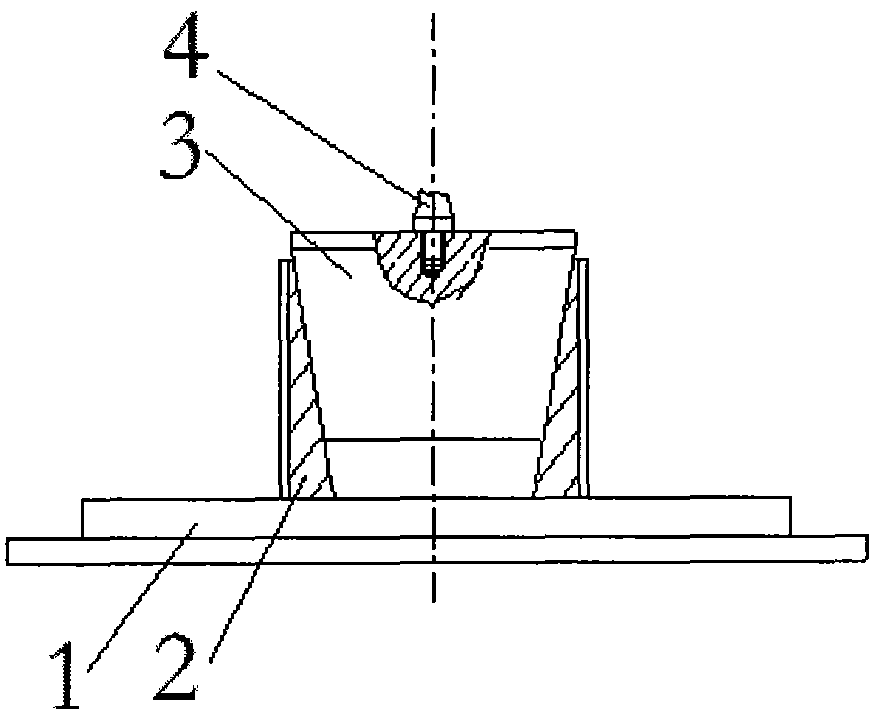

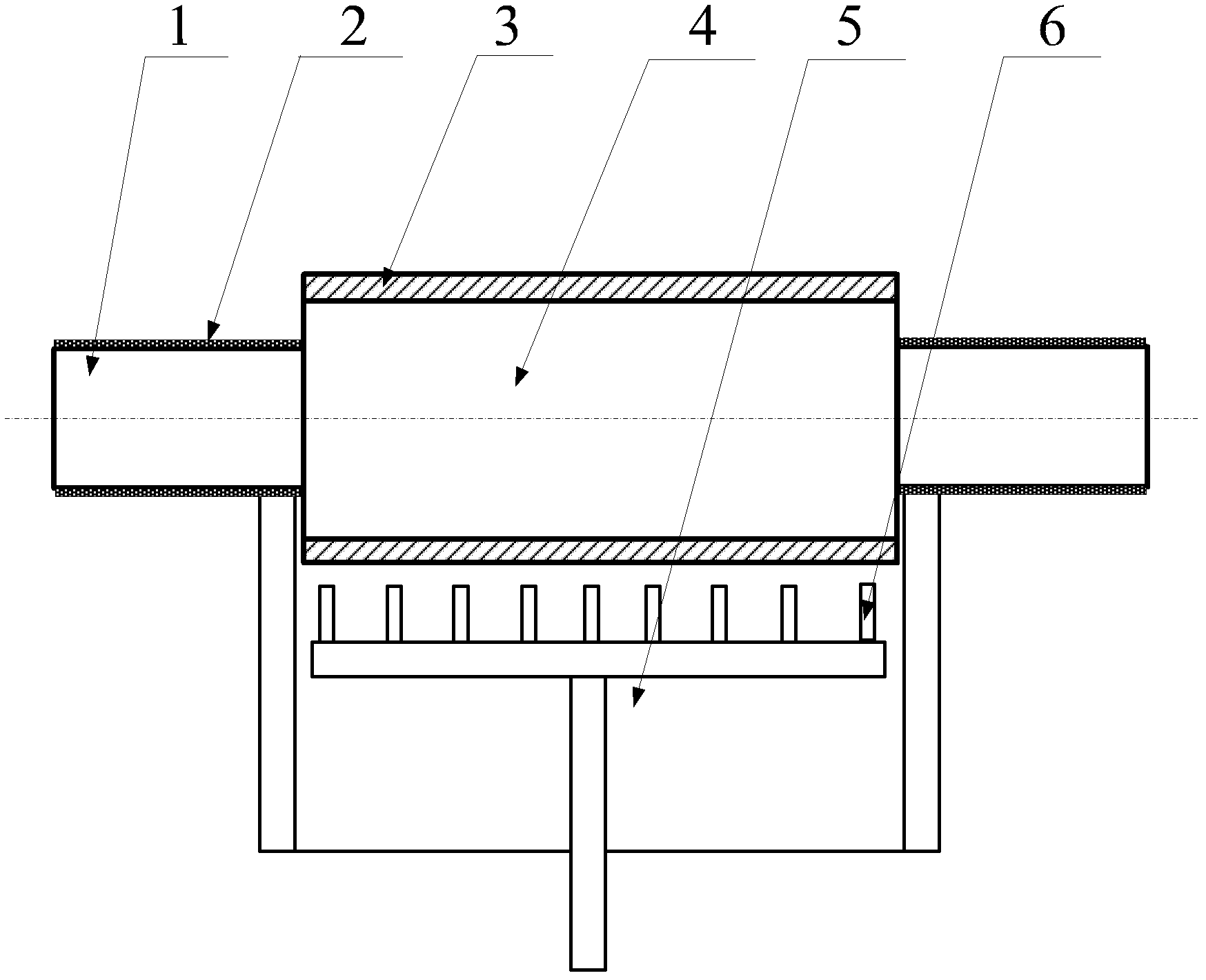

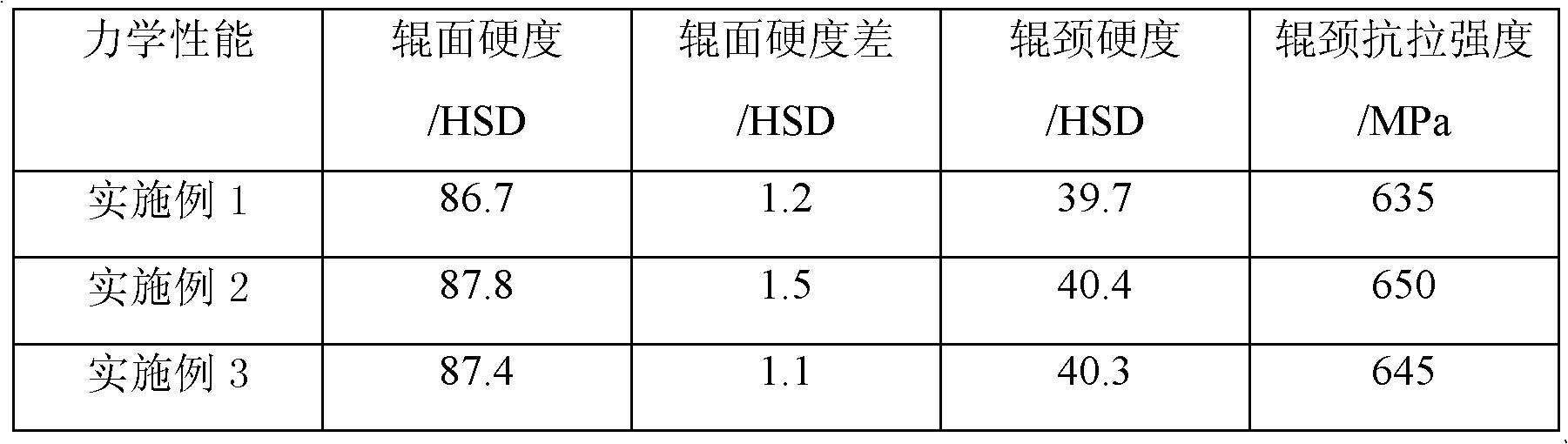

Composite roll having uniform roll surface hardness and made of high-speed steel containing boron and method for manufacturing composite roll

InactiveCN102634733AHigh roller surface hardnessHigh hardnessFurnace typesRollsDuctile ironLanthanum

A composite roll having uniform roll surface hardness and made of high-speed steel containing boron and a method for manufacturing the composite roll belong to the technical field of manufacture of rolls. A roll body is made of the high-speed steel containing boron, a roll core is made of spheroidal graphite cast iron, the roll body and the roll core are centrifugally cast in a compounded manner,and metallurgical bonding is realized. On the basis of high-tungsten high-speed steel, the chromium content of the roll body is reduced, and the boron and a proper quantity of trace alloying elementssuch as potassium, sodium, calcium, barium, zinc, magnesium, lanthanum, cerium and the like aer added into the roll body. The roll body is heated in a heating furnace, stays warm and then is placed in a cooling control device, a roll neck is coated with a heat-insulating material and is placed outside the cooling control device, the roll body is in spray cooling according to a spray quenching process 1, then is in spray cooling according to a spray quenching process 2 until the temperature of the roll body is lower than 160 DEG C, and is in natural air cooling, when the temperature of the roll surface rises to 300 DEG C, the roll body is in spray cooling according to the spray quenching process 2 again, spray cooling is performed repeatedly until the rising temperature of the roll surfacedoes not exceed 300 DEG C, and then the roll body is in air cooling to the room temperature. The roll surface hardness of the composite roll is high, hardness uniformity of the roll surface is good, wear resistance of the roll is fine, and the service life of the composite roll is long.

Owner:BEIJING UNIV OF TECH

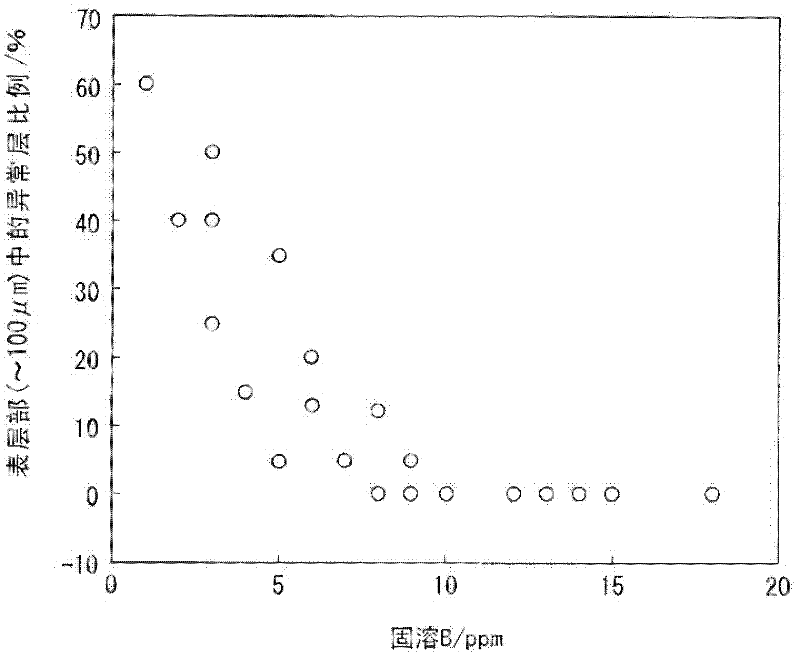

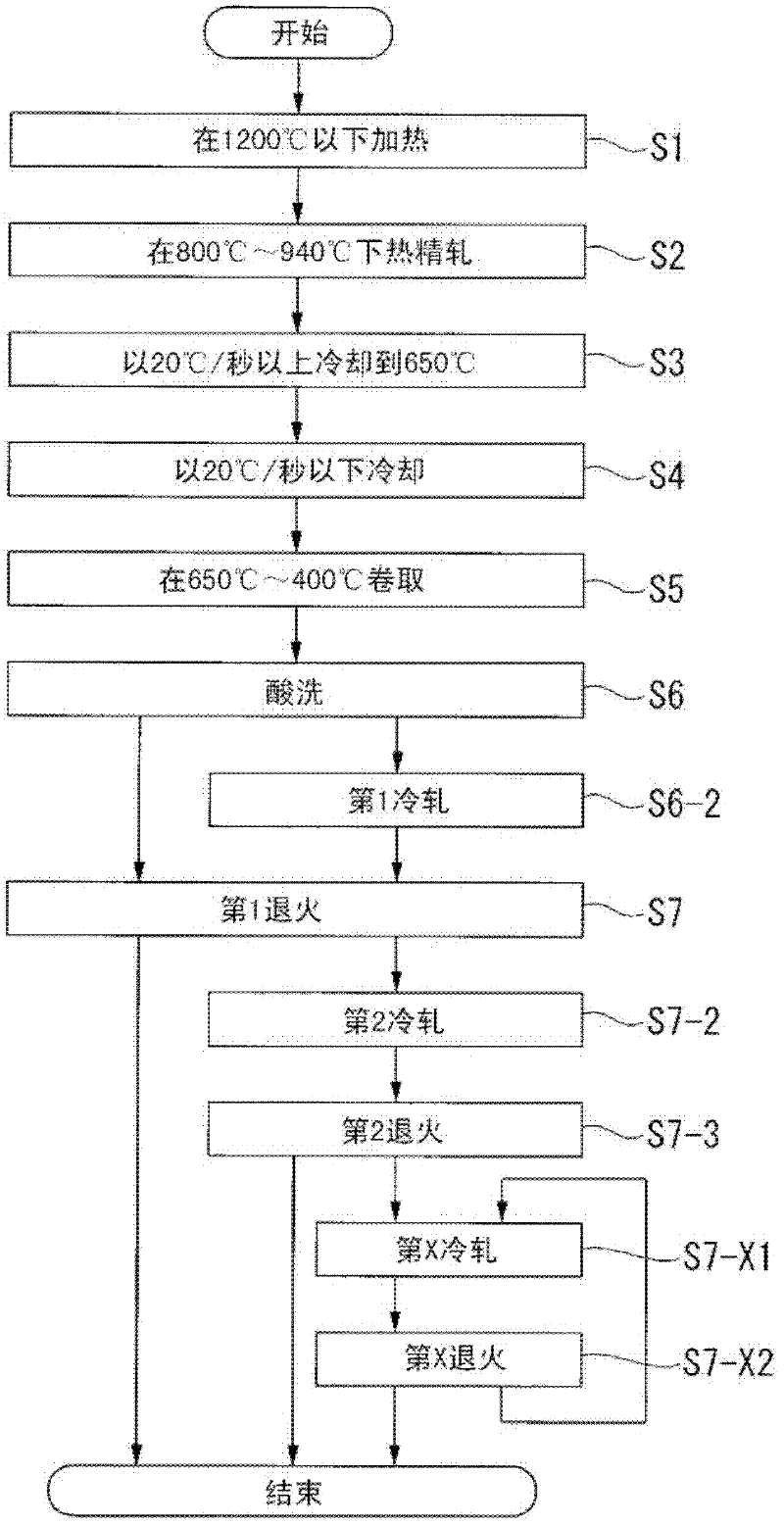

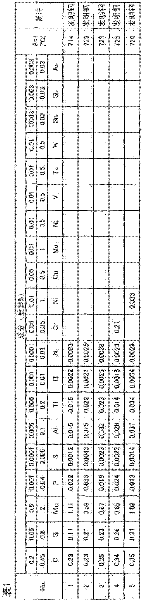

Boron-containing steel sheet with excellent hardenability and method of manufacturing same

InactiveCN102348822AImprove hardenabilityEasy to processFurnace typesHeat treatment furnacesMetallurgyBoron containing

The present invention provides a boron steel sheet including components of C: 0.20 mass% or more and 0.45 mass% or less, Si: 0.05 mass% or more and 0.8 mass% or less, Mn: 0.5 mass% or more and 2.0 mass% or less, P: 0.001 mass% or more and 0.04 mass% or less, S: 0.0001 mass% or more and 0.006 mass% or less, Al: 0.005 mass% or more and 0.1 mass% or less, Ti: 0.005 mass% or more and 0.2 mass% or less, B: 0.001 mass% or more and 0.01 mass% or less, N: 0.0001 mass% or more and 0.01 mass% or less, and the balance including Fe and inevitable impurities, wherein a mean concentration of solid B in an area from a surface to a depth of 100 [mu] m is 10 ppm or more.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Reduced Cost Steel for Hydrogen Technology with High Resistance to Hydrogen-Induced Embrittlement

An austenitic steel for hydrogen technology has the following composition:0.01 to 0.4 percent by mass of carbon,≦5 percent by mass of silicon,0.3 to 30 percent by mass of manganese,10.5 to 30 percent by mass of chromium,4 to 12.5 percent by mass of nickel,≦3 percent by mass of molybdenum,≦0.2 percent by mass of nitrogen,≦5 percent by mass of aluminum,≦5 percent by mass of copper,≦5 percent by mass of tungsten,≦0.1 percent by mass of boron,≦3 percent by mass of cobalt,≦0.5 percent by mass of tantalum,≦2.0 percent by mass of at least one of the elements: niobium, titanium, vanadium, hafnium and zirconium,≦0.3 percent by mass of at least one of the elements: yttrium, scandium, lanthanum, cerium and neodymium, the remainder being iron and smelting-related steel companion elements.

Owner:BAYERISCHE MOTOREN WERKE AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com