Novel chromium system hot die steel and thermal treatment process thereof

A technology of hot work die steel and chromium series, which is applied in the field of hot work die steel, can solve the problems of high material cost and achieve the effects of low raw material cost, improved toughness and wear resistance, and increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A novel chromium-based hot work die steel of the present invention comprises:

[0045] Carbon C 0.45%, Silicon Si 0.80%, Manganese Mn 0.80%, Chromium Cr 9.00%,

[0046] Tungsten W 0.60%, Molybdenum Mo 0.60%, Vanadium V 0.50%, Nickel Ni 0.30%,

[0047] Sulfur S≤0.005%, phosphorus P≤0.030%, and the balance is iron Fe.

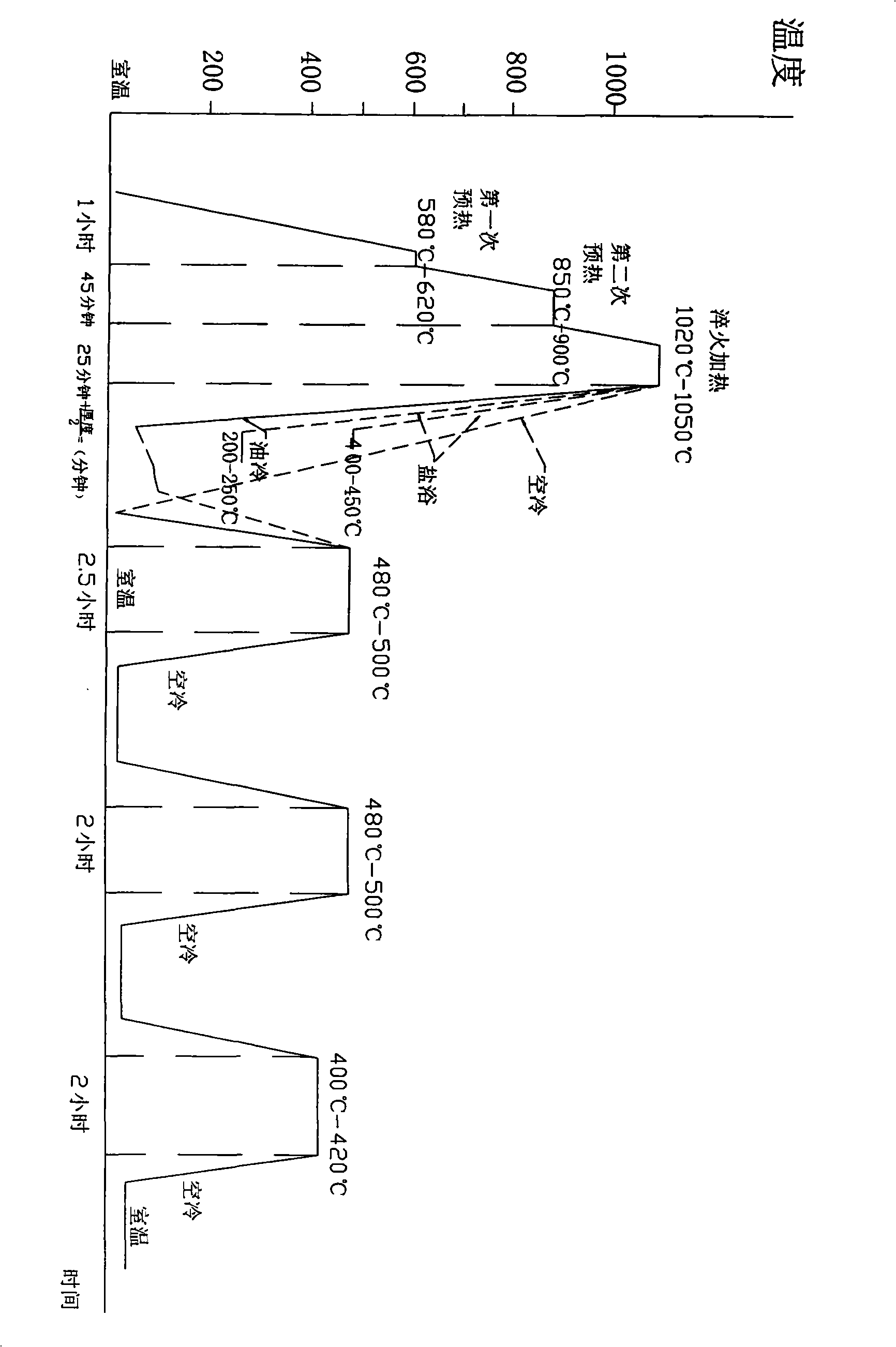

[0048] The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

[0049] (1) Preheating: the preheating temperature is 580°C to 620°C, and the preheating time is 50 to 70 minutes;

[0050] (2) Quenching heating: the quenching heating temperature is 1020°C to 1050°C, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 to 30 minutes;

[0051] (3) Tempering: the tempering temperature is 480°C to 500°C, and then air cooled to room temperature.

Embodiment 2

[0053] A novel chromium-based hot work die steel of the present invention comprises:

[0054] Carbon C 0.35%, Silicon Si 0.30%, Manganese Mn 0.30%, Chromium Cr 7.00%,

[0055] Tungsten W 0.40%, Molybdenum Mo 0.40%, Vanadium V 0.40%, Nickel Ni 0.10%,

[0056] Sulfur S≤0.005%, Phosphorus P≤0.030%, Niobium Nb0.30%, Titanium Ti0.30%,

[0057] Boron B 0.03%, the rest is iron Fe.

[0058] The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

[0059] (1), the first preheating: the preheating temperature of all raw materials is 580C ~ 620C, and the preheating time is 50 ~ 70 minutes;

[0060] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 850 ℃ ~ 900 ℃, the second preheating time is 40 ~ 50 minute.

[0061] (3) Quenching heating: the quenching heating temperature is 1020°C to 1050°C, oil cooling or air cooling or salt bath coo...

Embodiment 3

[0065] A novel chromium-based hot work die steel of the present invention comprises:

[0066] Carbon C 0.70%, Silicon Si1.30%, Manganese Mn 1.30%, Chromium Cr11.00%,

[0067] Tungsten W 1.20%, Molybdenum Mo 1.20%, Vanadium V 1.00%, Nickel Ni1.00%,

[0068] Sulfur S≤0.005%, Phosphorus P≤0.030%, Niobium Nb0.30%, Titanium Ti0.30%,

[0069] Rare earth element 0.05%, nitrogen N 0.02%, nitride 0.02%, nitride is BN, and the rest is iron Fe. The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

[0070] (1), the first preheating: the preheating temperature of all raw materials is 580 ℃ ~ 620 ℃, and the preheating time is 50 ~ 70 minutes;

[0071] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 850 ℃ ~ 900 ℃, the second preheating time is 40 ~ 50 minute.

[0072] (3) Quenching heating: the quenching heating temperature is 1020°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com