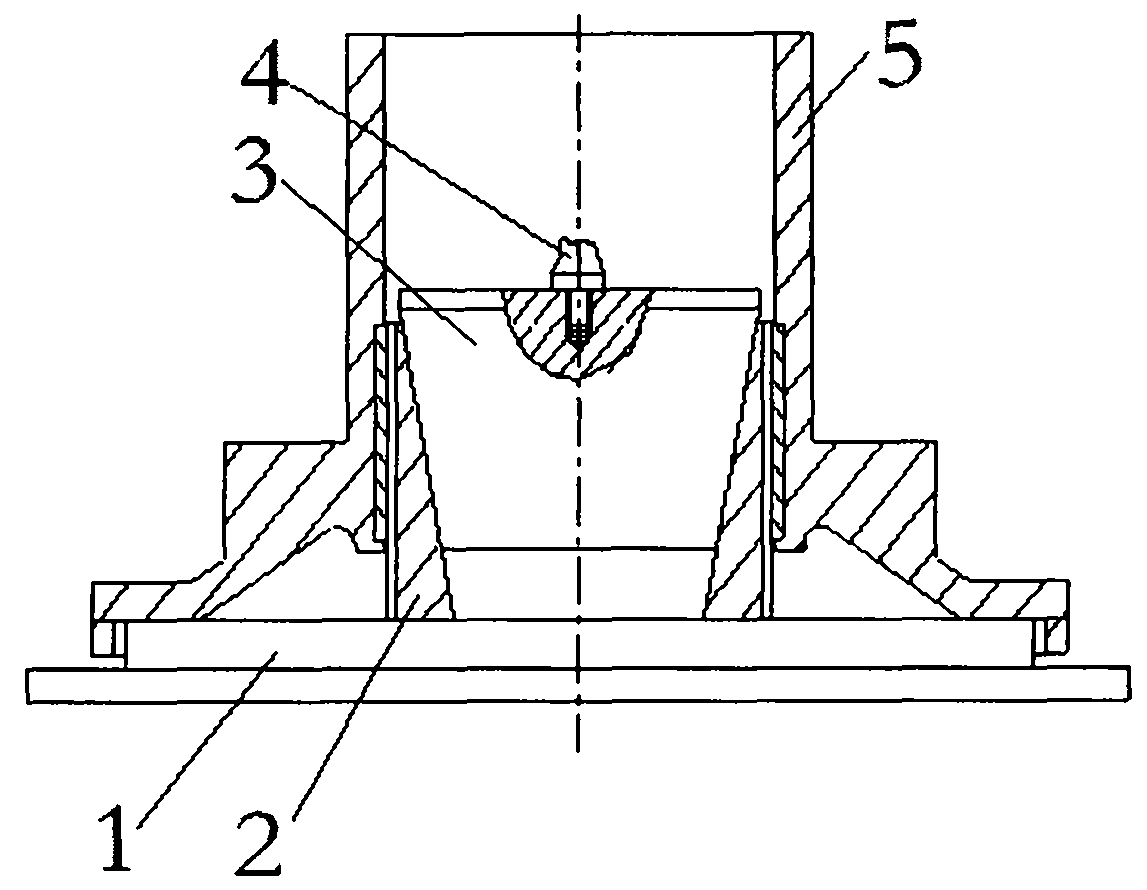

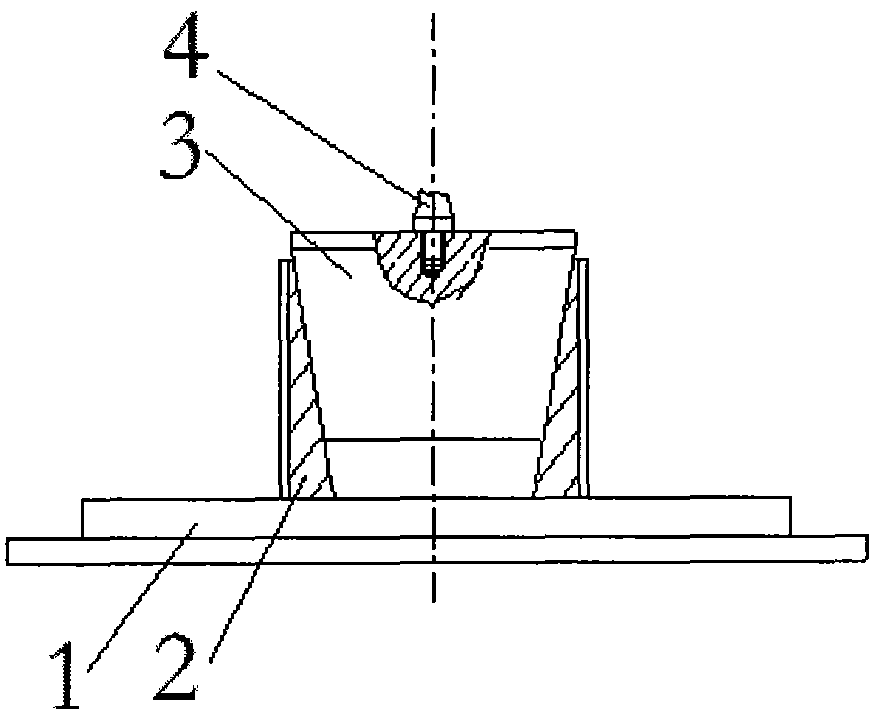

Method and fixture for welding high temperature alloy and cupronickel

A high-temperature alloy, cupronickel technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of the growth of the grain size of the base metal, the deformation of the parts, the performance of the base metal, etc., and achieve high cost and corrosion resistance. Good, good auxiliary development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, B19 cupronickel is welded on the engine shaft made of GQGH4169 superalloy.

[0037] The solder used in this embodiment is powdered gold 20 nickel chromium iron silicon boron, and the particle size of the solder is -150 mesh.

[0038] When welding, the specific process includes the following steps:

[0039] Step 1. Clean the surface of the welded parts; clean the surface of the welded parts with acetone and alcohol in sequence;

[0040] Step 2, configure the adhesive; the adhesive used includes 500g trichloroethylene and 50g polystyrene; pour the two into clean glassware, mix well, and cover for use;

[0041] Step 3. Solder configuration; mix 100g of powdered gold 20 nickel chromium iron silicon boron with 100g of binder. The specific process is to pour the powdered solder into a clean beaker, and then add 100g of binder. Dilute and stir evenly with a glass rod to form a paste solder; the viscosity of the paste solder is that when the glass rod is used to lift...

Embodiment 2

[0045] In this embodiment, B19 copper-nickel alloy is welded on the bearing seat made of GQGH4169 high-temperature alloy.

[0046] The solder used in this embodiment is powdered gold 20 nickel chromium iron silicon boron, and the particle size of the solder is -150 mesh.

[0047] When implementing welding, the specific process includes the following steps:

[0048] Step 1. Clean the surface of the welded parts; clean the surface of the welded parts with acetone and alcohol in sequence;

[0049] Step 2, configure the adhesive; the adhesive used includes 500g trichloroethylene and 50g polystyrene; pour the two into clean glassware, mix well, and cover for use;

[0050] Step 3. Solder configuration; mix 100g of powdered gold 20 nickel chromium iron silicon boron with 100g of binder. The specific process is to pour the powdered solder into a clean beaker, and then add 100g of binder. Dilute and stir evenly with a glass rod to form a paste solder; the viscosity of the paste solder is that w...

Embodiment 3

[0054] In this embodiment, B19 cupronickel is welded on the sealing ring made of GQGH4169 superalloy.

[0055] The solder used in this embodiment is powdered gold 20 nickel chromium iron silicon boron, and the particle size of the solder is -150 mesh.

[0056] When implementing welding, the specific process includes the following steps:

[0057] Step 1. Clean the surface of the welded parts; clean the surface of the welded parts with acetone and alcohol in sequence;

[0058] Step 2, configure the adhesive; the adhesive used includes 500g trichloroethylene and 50g polystyrene; pour the two into clean glassware, mix well, and cover for use;

[0059] Step 3. Solder configuration; mix 100g of powdered gold 20 nickel chromium iron silicon boron with 100g of binder. The specific process is to pour the powdered solder into a clean beaker, and then add 100g of binder. Dilute and stir evenly with a glass rod to form a paste solder; the viscosity of the paste solder is that when the glass rod is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com