Ferrite-free heavy caliber thick-wall heat resistant steel pipe material

A large-diameter, ferritic technology, applied in the field of steel pipes for supercritical thermal power units, can solve the problems of reducing the impact toughness and lasting strength of P92 steel

Inactive Publication Date: 2011-04-13

CENT IRON & STEEL RES INST

View PDF3 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the research also shows that the presence of δ ferr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

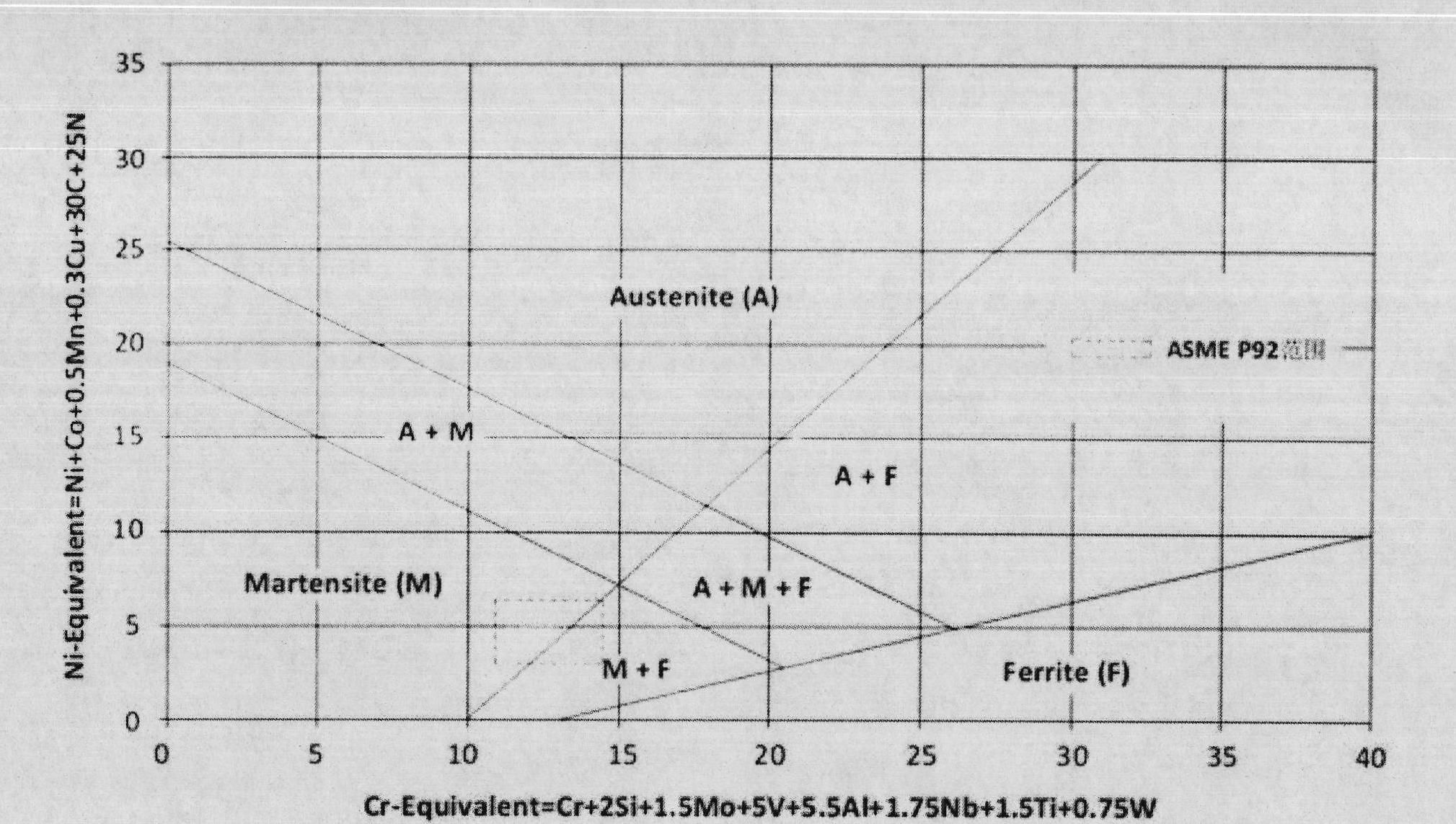

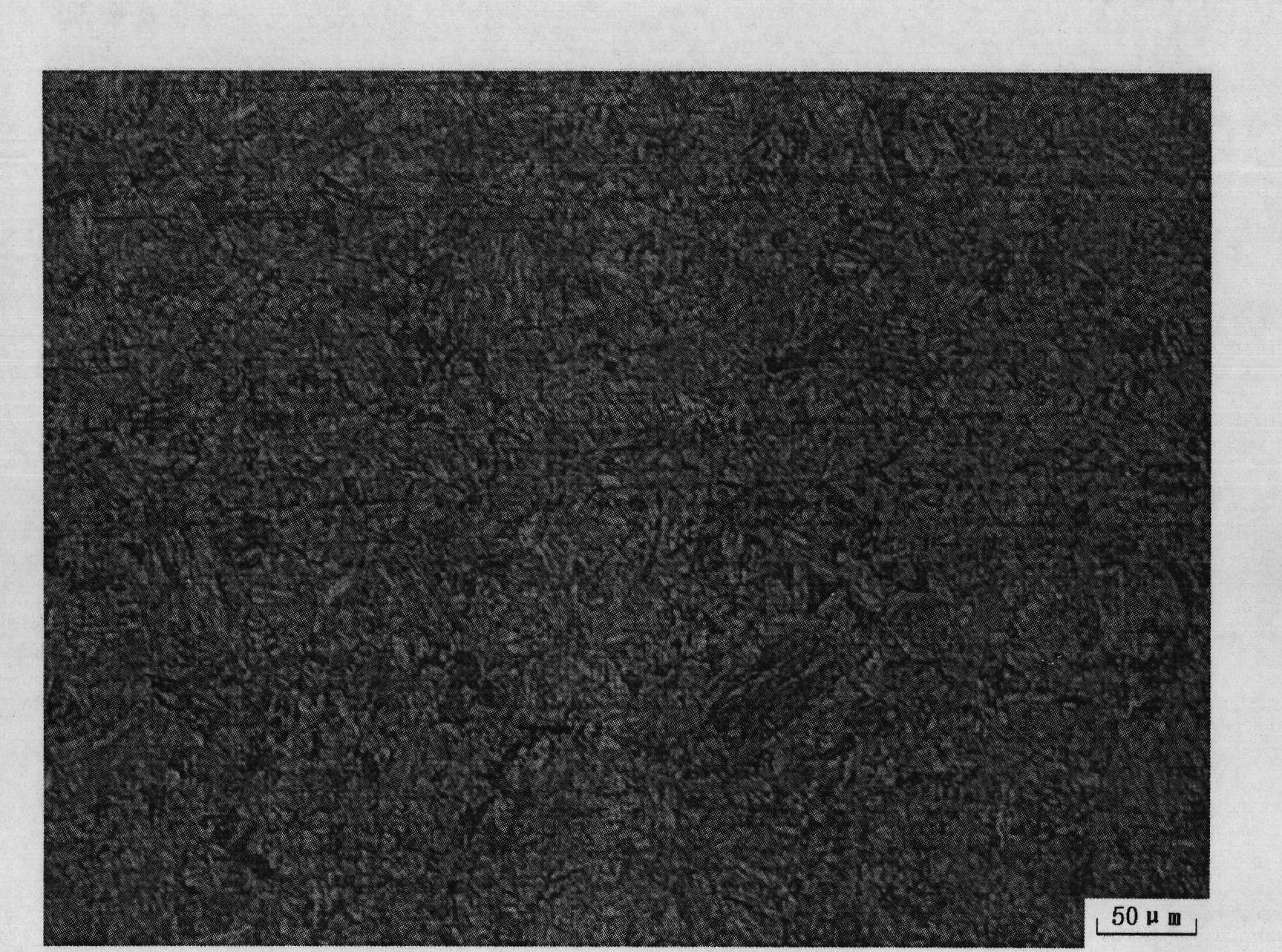

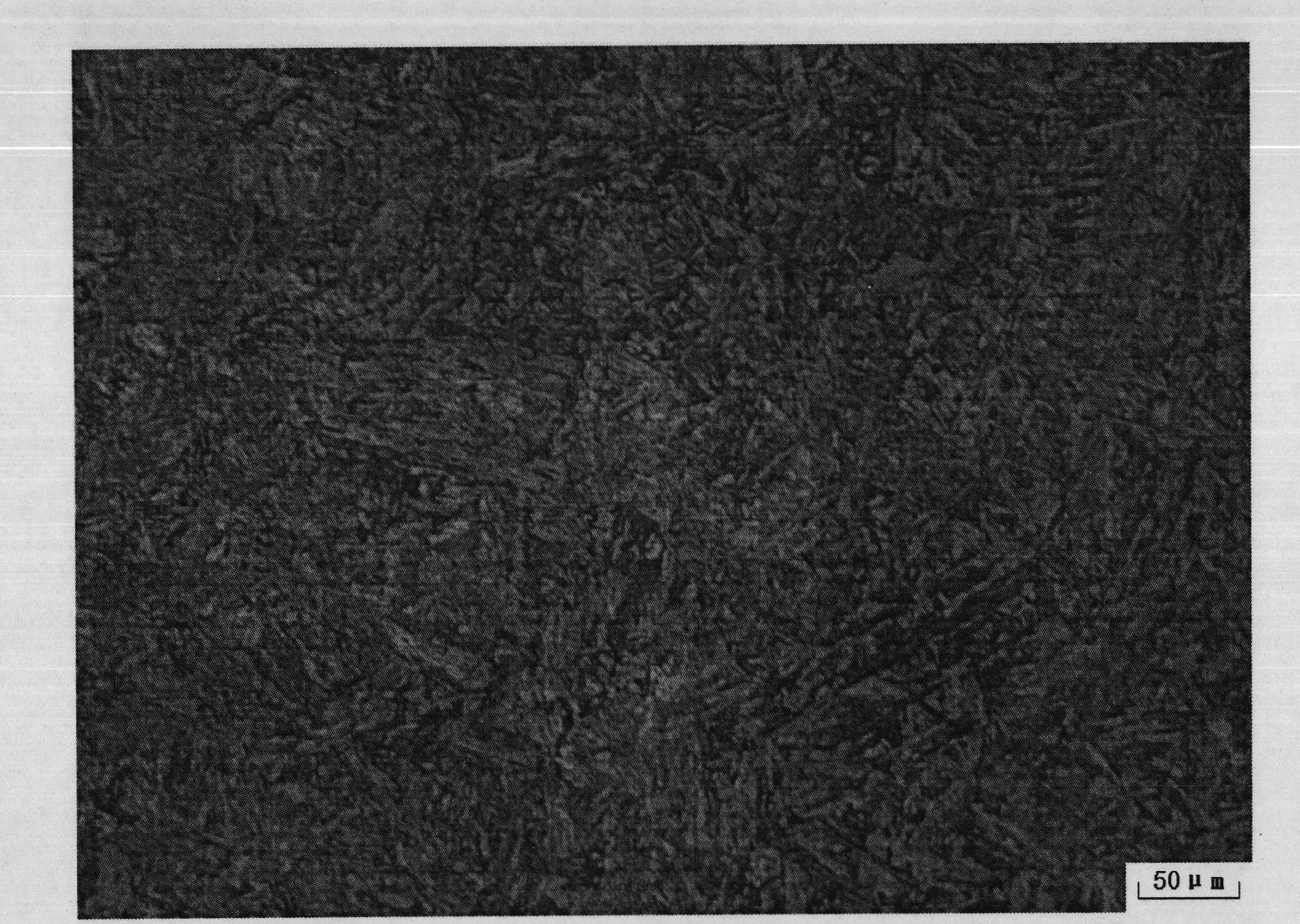

The invention relates to a ferrite-free heavy caliber thick-wall heat resistant steel pipe material which belongs to the technical field of steel tubes for supercritical thermal power generating units and comprises the following components in percent by weight: 0.090-0.12 percent of carbon, less than 0.3 percent of silicon, 0.40-0.6 percent of manganese, not more than 0.020 percent of phosphorus, not more than 0.010 percent of sulfur, 8.5-9.0 percent of chromium, 0.1-0.3 percent of nickel, 1.7-2.0 percent of tungsten, 0.3-0.5 percent of Mo, 0.04-0.07 percent of niobium, 0.15-0.22 percent of vanadium, 0.04-0.07 percent of nitrogen, 0.001-0.004 percent of boron, 0.01-0.03 percent of cobalt, 0.01-0.07 percent of copper, 0-0.01 percent of aluminum and the balance of iron. The invention has the advantages that: based on the P92 steel, through optimizing the component proportion and adding elements Co and Cu, a heavy caliber thick-wall heat resistant steel pipe is in a single martensite structure, has excellent property and meets the requirements on ASME CC2197-6.

Description

technical field [0001] The invention belongs to the technical field of steel pipes for supercritical thermal power units, and in particular provides a ferrite-free large-diameter thick-walled heat-resistant steel pipe material, the optimal chemical composition range of ferrite-free large-diameter thick-walled heat-resistant steel pipes, suitable for It is used in the manufacture of large-diameter thick-walled heat-resistant pipes for large-scale advanced ultra-supercritical thermal power units. Background technique [0002] The higher the steam parameters of thermal power units, the higher the power generation efficiency (see Table 1), thereby reducing resource and energy consumption and greatly reducing greenhouse gas emissions, ensuring national energy security. The key restrictive factor that limits the improvement of steam parameters of thermal power units is the development and application of heat-resistant steel pipes in the high temperature section. my country has ta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/54

Inventor 刘正东程世长石如星包汉生杨钢干勇

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com