Boron-containing fluoride-free covering slag for steel continuous-casting crystallizer and preparation method thereof

A technology for continuous casting mold and mold slag, which is applied to the field of boron-containing and fluorine-free mold slag for steel continuous casting mold and its preparation field, can solve the problems of high melting point, poor lubrication effect and high crystallization temperature, and achieves the improvement of vitrification. Performance, good use performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

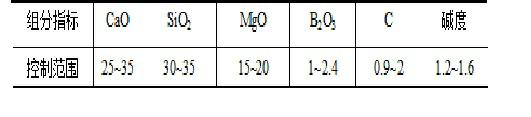

[0042] Ingredients: boron mud powder 50Kg, wollastonite powder 29Kg, lime powder 20Kg, coke powder 1Kg;

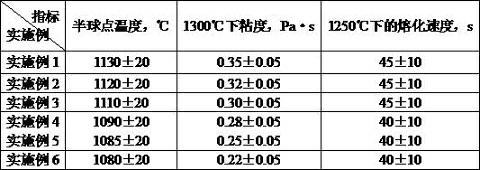

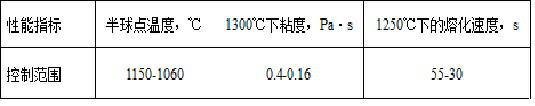

[0043] Preparation process: Mix the materials thoroughly, and use the disc method to make 0.1~0.2mm granular slag. The main composition indexes of mold flux are shown in Table 3, and the main physical and chemical performance indexes are shown in Table 4.

Embodiment 2

[0045] Ingredients: boron mud powder 55Kg, wollastonite powder 25Kg, lime powder 18Kg, coke powder 2Kg;

[0046] Preparation process: Mix the materials thoroughly, and use the disc method to make 0.1~0.2mm granular slag. The main composition indexes of mold flux are shown in Table 3, and the main physical and chemical performance indexes are shown in Table 4.

Embodiment 3

[0048] Fully dry and dehydrate boron mud powder, wollastonite powder, lime powder and coke powder at 200°C, grind them into fine powder and weigh them;

[0049] Ingredients: boron mud powder 60Kg, wollastonite powder 23Kg, lime powder 15Kg, coke powder 2Kg;

[0050] Preparation process: Mix the materials thoroughly, and use the disc method to make granular slag of 0.1~0.2mm. The main composition indicators of mold flux are shown in Table 3, and the main physical and chemical performance indicators are shown in Table 4.

[0051] Second set of examples

[0052] The selected raw materials are as follows:

[0053] The technical index of boron mud powder is: B 2 o 3 4%;

[0054] The chemical composition of wollastonite is (mass%): SiO 2 52, CaO 45, MgO 0.8, S<0.03, P<0.03, the balance of impurities.

[0055] The chemical composition of lime is (mass%): CaO 95.0, MgO 3.0, SiO 2 1.0, the rest are Al 2 o 3 and other trace impurities;

[0056] The technical indicators of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com