Carbon-manganese composite microalloyed steel for engineering machinery and preparation method thereof

A technology of construction machinery and micro-alloying, applied in the direction of temperature control, furnace type, furnace, etc., to reduce center porosity and segregation, stabilize hardenability, and increase equiaxed crystals of billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: 15B36Cr steel

[0039] 1. The weight percent of the chemical composition of the steel is: C0.37 Si0.22 Mn1.25 P0.014 S0.009 B0.0014 Al0.025Ti0.03Ti / N=3.5; the balance is Fe and trace impurities.

[0040] 2. The process route is:

[0041] Batching→electric furnace smelting→tapping from eccentric furnace bottom→deoxidation and alloying in LF furnace→adding iron boron to adjust boron composition→vacuum refining furnace degassing→full protection casting of billet continuous casting machine→rolled product specification Φ70mm→inspection and storage.

[0042] 3. The main process measures of the preparation method

[0043] (1) The proportion of molten iron in the furnace steel material structure reaches 40-60%; no high-phosphorus and sulfur scrap steel such as slag steel and tank side iron are added to the batching.

[0044] (2) The smelting process creates good foam slag, uniform decarburization, and reduces nitrogen absorption.

[0045] (3) The goal of the melti...

Embodiment 2

[0053] Example 2: 15B36Cr steel

[0054] 1. The weight percent of the chemical composition of steel is: C0.35 Si0.20 Mn1.35 P0.016 S0.001 B0.0029 Cr0.20Al0.023 Ti0.05 Ti / N=5; the balance is Fe and trace impurities .

Embodiment 3

[0055] Example 3: 15B36Cr steel

[0056] The chemical composition weight percent of the steel is: C0.33 Si0.23 Mn1.35 P0.012 S0.005 B0.0016 Al0.035Ti0.03 Ti / N=4; the balance is Fe and trace impurities.

[0057] The preparation method is the same as in Example 1.

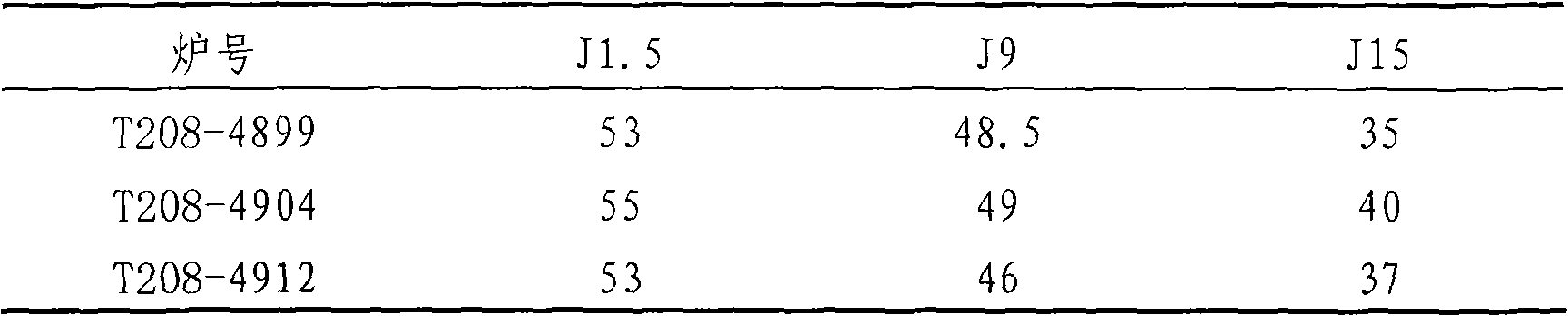

[0058] The furnace numbers of Example 1, Example 2, and Example 3 are T208-4899, T208-4904, and T208-4912 respectively, and the mechanical properties and end hardenability of the rolled materials are shown in Table 1 and Table 2 below.

[0059] Table 1 Mechanical properties of rolled products

[0060] furnace number

Rm(MPa)

tensile strength

ReL(MPa)

Yield Strength

A(%)

Elongation

Z(%)

Shrinkage

Aku(J)

Impact energy

T208-4899

1075 / 1070

940 / 930

16 / 15

52 / 53

110 / 115

T208-4904

1060 / 1065

965 / 965

14 / 15

53 / 52

112 / 97

T208-4912

1055 / 1045 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com