Novel chromium system hot die steel and thermal treatment process thereof

A technology of hot work die steel and chromium series, which is applied in the field of hot work die steel to achieve the effect of increasing toughness and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A novel chromium-based hot work die steel of the present invention comprises:

[0048] Carbon C 0.65%, Silicon Si 0.30%, Manganese Mn 0.30%, Chromium Cr 7.00%,

[0049] Tungsten W 1.80%, Molybdenum Mo 1.40%, Vanadium V 0.50%, Cobalt Co 0.50%,

[0050] Nickel Ni 0.50%, sulfur S≤0.005%, phosphorus P≤0.030%, the rest is iron Fe,

[0051] The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

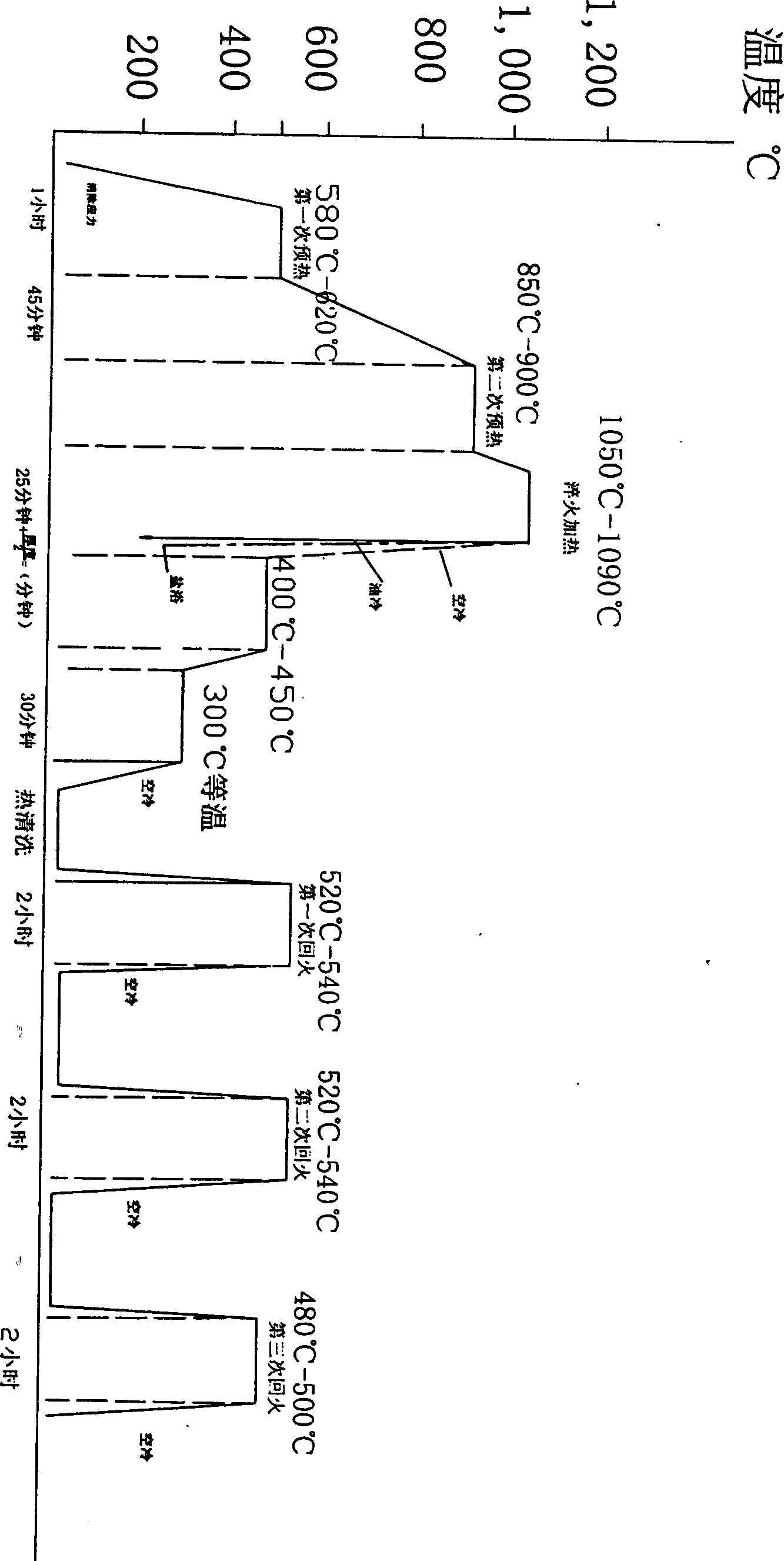

[0052] (1), preheating: preheating temperature of all raw materials is 580 ℃ ~ 620 ℃, preheating time is 50 ~ 70 minutes;

[0053] (2) Quenching heating: the quenching heating temperature is 1050°C to 1090°C, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 to 30 minutes;

[0054] (3) Tempering: the tempering temperature is 520°C to 540°C, and then air cooled to room temperature.

Embodiment 2

[0056] A novel chromium-based hot work die steel of the present invention comprises:

[0057] Carbon C 0.65%, Silicon Si 0.30%, Manganese Mn 0.30%, Chromium Cr 6.50%,

[0058] Tungsten W 1.80%, Molybdenum Mo 1.40%, Vanadium V 0.50%, Cobalt Co 0.50%,

[0059] Nickel Ni 0.50%, sulfur S≤0.005%, phosphorus P≤0.030%, niobium Nb0.30%,

[0060] Titanium Ti0.30%, rare earth elements 0.05%, boron B 0.04%, and the balance is iron Fe.

[0061] The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

[0062] (1), the first preheating: the preheating temperature of all raw materials is 580 ℃ ~ 620 ℃, and the preheating time is 50 ~ 70 minutes;

[0063] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 850 ℃ ~ 900 ℃, the second preheating time is 40 ~ 50 minute.

[0064] (3) Quenching heating: the quenching heating temperature is 1050°C t...

Embodiment 3

[0068] A novel chromium-based hot work die steel of the present invention comprises:

[0069] Carbon C 0.65%, Silicon Si 0.30%, Manganese Mn 0.30%, Chromium Cr 6.50%,

[0070] Tungsten W 1.80%, Molybdenum Mo 1.40%, Vanadium V 0.50%, Cobalt Co 0.50%,

[0071] Nickel Ni 0.50%, Sulfur S≤0.005%, Phosphorus P≤0.030%, Niobium Nb0.30%,

[0072] Titanium Ti0.30%, rare earth element 0.05%, boron B 0.08%, boron nitride BN 0.02%, and the balance is iron Fe.

[0073] The steps of the heat treatment process for the above-mentioned novel chromium-based hot work die steel are as follows:

[0074] (1), the first preheating: the preheating temperature of all raw materials is 580 ℃ ~ 620 ℃, and the preheating time is 50 ~ 70 minutes;

[0075] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 850 ℃ ~ 900 ℃, the second preheating time is 40 ~ 50 minute.

[0076] (3) Quenching heating: the quenching heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com