Disk-shaped roller cutter ring and manufacture method thereof

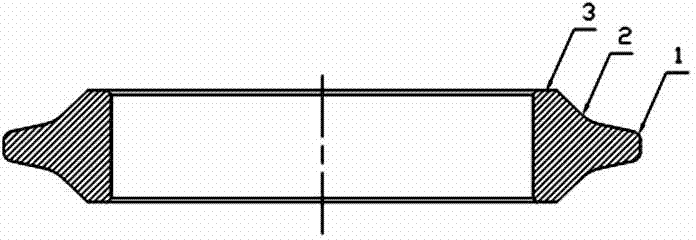

A disc-shaped hob and knife ring technology, which is applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of easy fracture and poor wear resistance, and achieve the goal of improving hardenability, reducing temper brittleness, and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The main components of the material for manufacturing disc-shaped hob cutter rings are (wt.%): C 0.5, Si 0.93, Mn 0.43, Cr 5.43, Mo 1.31, V 1.0, Fe balance; impurities (wt.%) : P 0.011, S 0.004.

[0021] The above materials are smelted in an electric furnace and electroslag remelted to make ingots, and then heated to make round bars, which are pre-forged at a forging ratio of 4 to 6 to make the material rough, and then according to the required shape of the knife ring, use a mold to The material is forged into a knife ring blank. Slowly cool after forging and anneal immediately. The annealing process heats up at a rate of 60-80°C / h, heats it at 900°C for 5-6 hours, cools at a rate of 40-60°C / h to 750°C and holds it for 4 hours, and then Cool at a rate of 40-60°C / h, take out the furnace at 500°C, and air-cool.

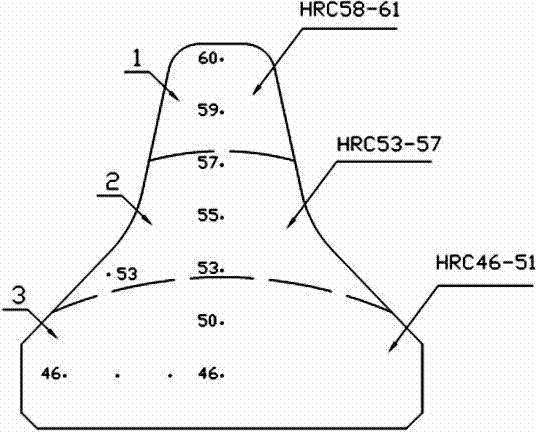

[0022] After cooling, the cutter ring blank is turned according to the required cross-sectional shape, and the hardness is tested, which is required...

Embodiment 2

[0026] Embodiment 2: The main components, smelting, forging, and annealing processes of the materials for manufacturing the disc-shaped hob cutter ring are all the same as in Embodiment 1, and the cutter ring blank is obtained.

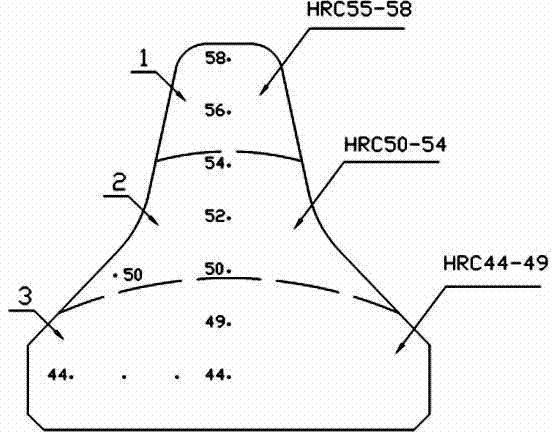

[0027] Quench the blank of the knife ring through a vacuum quenching furnace. First, the blank is heated from room temperature to 700°C at a speed of <200°C / h, and kept for 2h. Then, the blank is heated to 870°C at a speed of <180°C / h, and kept for 1.5h. Then Continue to heat up to 1030°C, keep it warm for 1h, and finally carry out oil quenching, and then tempering can be carried out after cooling to below 60°C.

[0028] Tempering at 530°C for the first time (3h holding time), and tempering at 520°C for the second time (2h holding time). Check the knife ring, the overall surface hardness HRC55-58 is a qualified knife ring. This disc hob cutter ring is suitable for tunneling in hard rock formations.

[0029] Configure a rotary platform on the medium ...

Embodiment 3

[0031] Example 3: The main components of the material for manufacturing the disc-shaped hob cutter ring are (wt.%): C 0.48, Si 0.97, Mn 0.40, Cr 5.30, Mo 1.28, V 0.97, Fe balance, impurities: P 0.02, S 0.003.

[0032]The above materials are smelted in an electric furnace and electroslag remelted to make ingots, and then heated to make round bars. The materials are forged at a forging ratio of 4 to 6, and then the materials are forged with molds according to the desired shape of the knife ring. Into a knife ring blank. Slowly cool after forging and anneal immediately. The annealing process is to raise the temperature at a rate of 60-80°C / h, keep it at 890°C for 5-6 hours, cool at a rate of 40-60°C / h to 740°C and hold it for 4 hours, and then Cool at a rate of 40-60°C / h, take out the furnace at 500°C, and air-cool.

[0033] After cooling, the cutter ring blank is turned according to the required cross-sectional shape, and the hardness is tested, which is required to be lower t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com