Manufacturing method of seamless steel pipe for long pipe trailer gas cylinder with diameter of 920mm

A technology of seamless steel pipes and manufacturing methods, which is applied in the field of manufacturing large-diameter seamless steel pipes, can solve the problems of unguaranteed comprehensive mechanical properties, low material utilization rate, and high manufacturing costs, so as to improve manufacturing precision and product pass rate, The effect of reducing monomer weight, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate understanding of the present invention, the present invention enumerates the following examples.

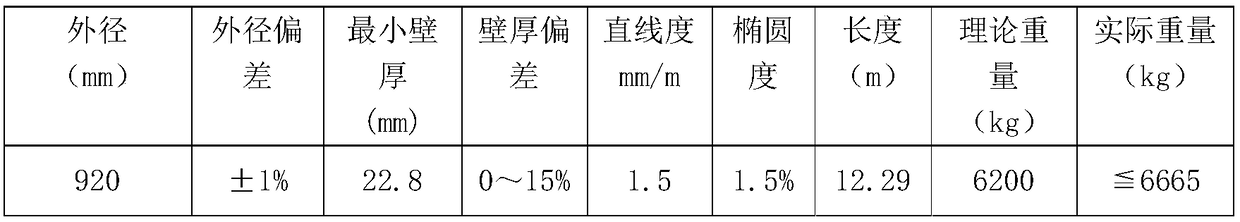

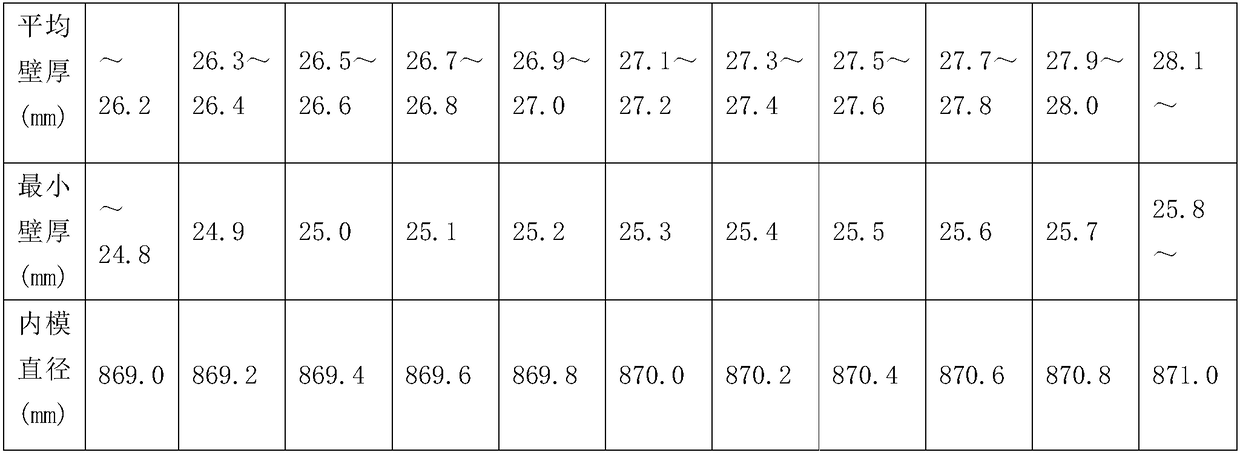

[0041] In this example, a method for manufacturing a seamless steel pipe for a long-tube trailer gas cylinder with a diameter of 920mm, the product specification is: 920x22.8x12290mm seamless steel pipe, the material of the steel pipe is 4130X, and the size and weight requirements of the product are as follows surface:

[0042]

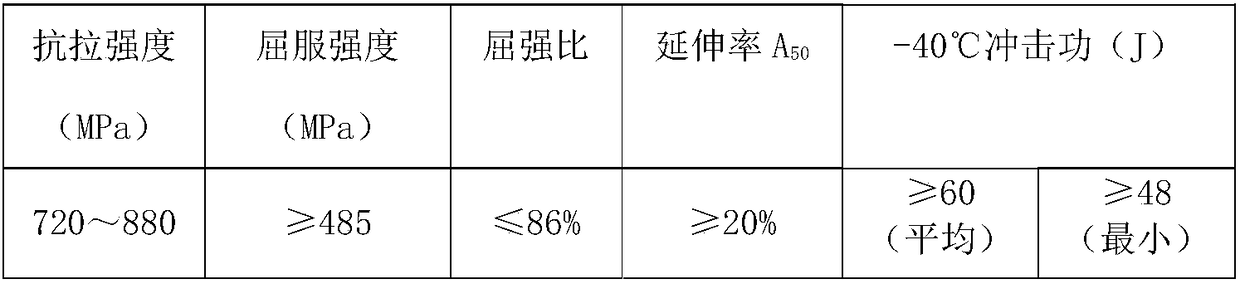

[0043] The mechanical performance requirements of the product are shown in the table below:

[0044]

[0045] The specific manufacturing process of the seamless steel pipe for long-tube trailer gas cylinders with a diameter of 920 mm is as follows:

[0046] Step a: The continuous casting slab with a diameter of 600mm is heated to 1250°C-1280°C in an annular heating furnace, and the temperature of the continuous casting slab is 1250°C;

[0047] In terms of mass percentage, the chemical composition of the continuous ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com