Surface treatment method for solid carbon-boron complex penetration of low-carbon alloy steel part

A low-carbon alloy steel and low-carbon alloy technology, applied in heat treatment equipment, solid-state diffusion coating, metal material coating technology, etc., can solve the problems of boronizing layer brittleness, peeling, etc., and achieve improved corrosion resistance and low equipment requirements , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

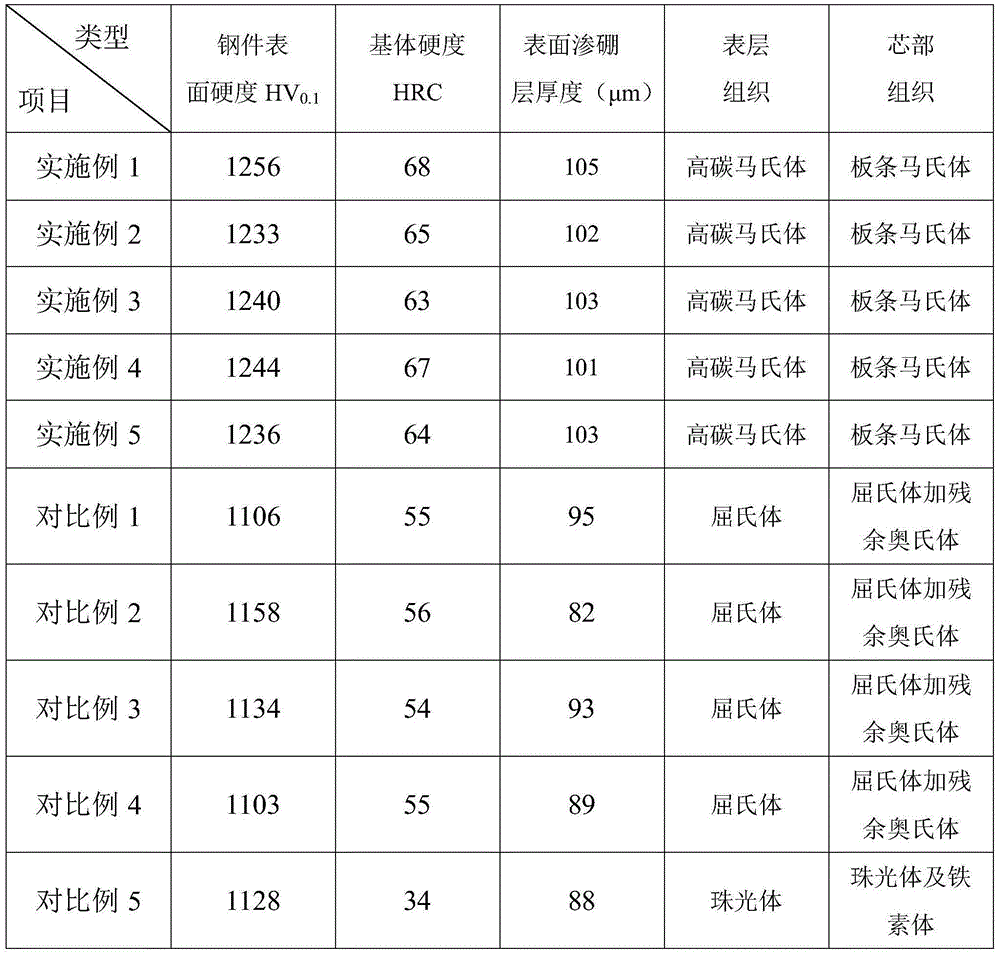

Examples

Embodiment 1

[0028] A surface treatment method for solid carbon-boron compound infiltration of low-carbon alloy steel parts, comprising the following steps:

[0029] a. The carburizing agent and carburizing box are dried at 200°C for 3 hours respectively; the low-carbon alloy steel parts are placed in anhydrous ethanol solution and ultrasonicated for 20 minutes to clean the surface of the workpiece and remove oil stains;

[0030] b. After the treatment in step a, put the carburizing agent in the bottom of the carburizing box, then put the low-carbon alloy steel parts into the carburizing box, and then put the carburizing agent again to make the carburizing agent Cover the workpiece by 5mm; cover the upper cover of the carburizing box, and use water glass mud prepared from water glass and refractory mud to coat the joint surface between the edge of the upper cover and the inner wall of the infiltration box, and then seal the upper cover; Put the carburizing box into the resistance furnace f...

Embodiment 2

[0038] A surface treatment method for solid carbon-boron compound infiltration of low-carbon alloy steel parts, comprising the following steps:

[0039] a. The carburizing agent and carburizing box are dried at 190°C for 4 hours respectively; the low-carbon alloy steel parts are placed in anhydrous ethanol solution and ultrasonicated for 30 minutes to clean the surface of the workpiece and remove oil stains;

[0040] b. After the treatment in step a, pour the carburizing agent into the bottom of the carburizing box, then put the low-carbon alloy steel parts into the carburizing box, and then put in the carburizing agent again to make the carburizing Cover the workpiece with 6mm of agent; cover the upper cover of the carburizing box, and use water glass mud prepared from water glass and refractory mud to coat the joint surface between the edge of the upper cover and the inner wall of the infiltration box, and then seal the upper cover; Put the carburizing box into the resistanc...

Embodiment 3

[0048] A surface treatment method for solid carbon-boron compound infiltration of low-carbon alloy steel parts, comprising the following steps:

[0049] a. The carburizing agent and carburizing box are dried at 210°C for 2 hours respectively; the low-carbon alloy steel parts are placed in anhydrous ethanol solution and ultrasonicated for 10 minutes to clean the surface of the workpiece and remove oil stains;

[0050] b. After the treatment in step a, put the carburizing agent in the bottom of the carburizing box, then put the low-carbon alloy steel parts into the carburizing box, and then put the carburizing agent again to make the carburizing agent Cover the workpiece by 5mm; cover the upper cover of the carburizing box, and use water glass mud prepared from water glass and refractory mud to coat the joint surface between the edge of the upper cover and the inner wall of the infiltration box, and then seal the upper cover; Put the carburizing box into the resistance furnace f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com