Patents

Literature

104results about How to "Reduce hardness difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

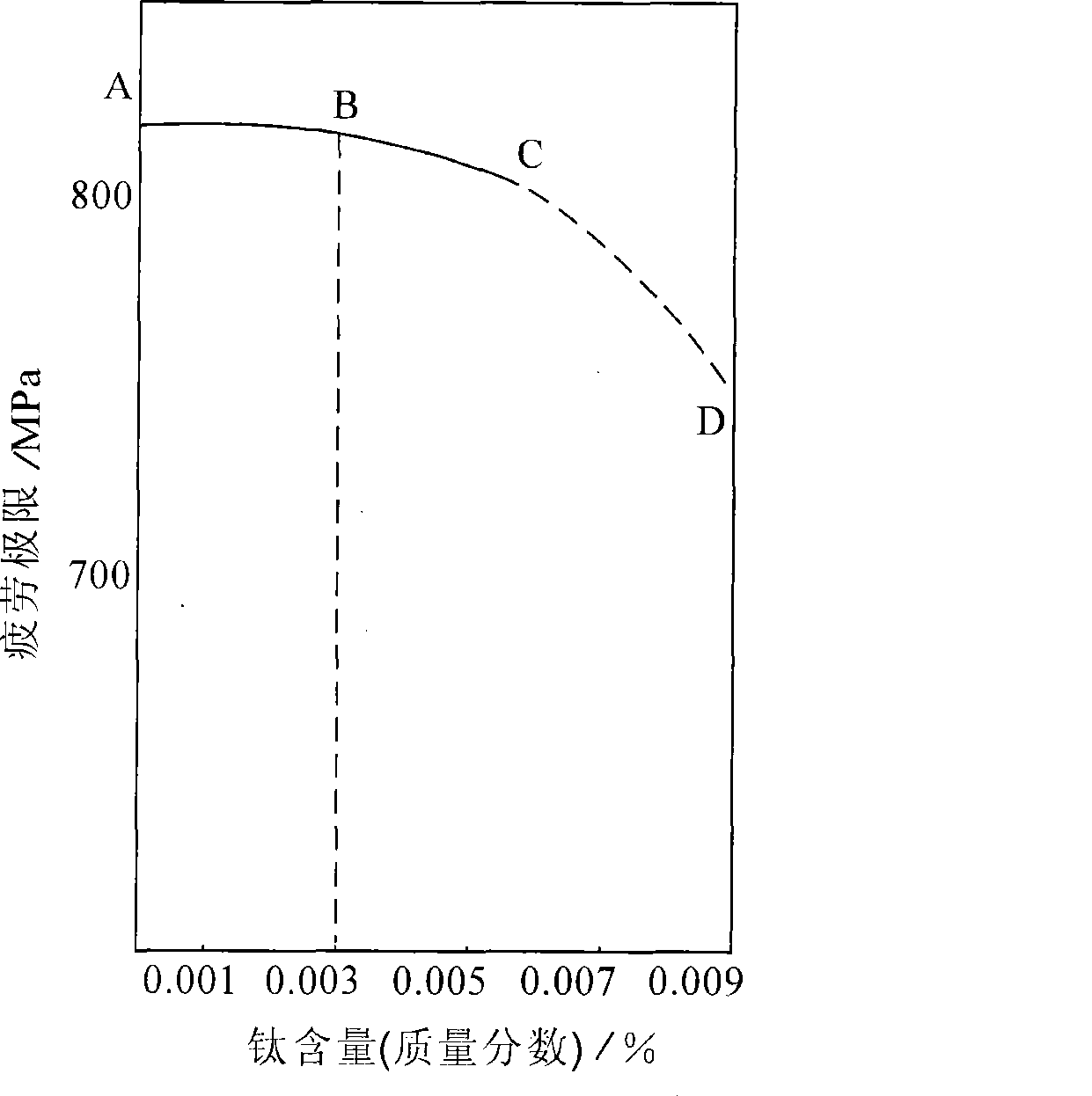

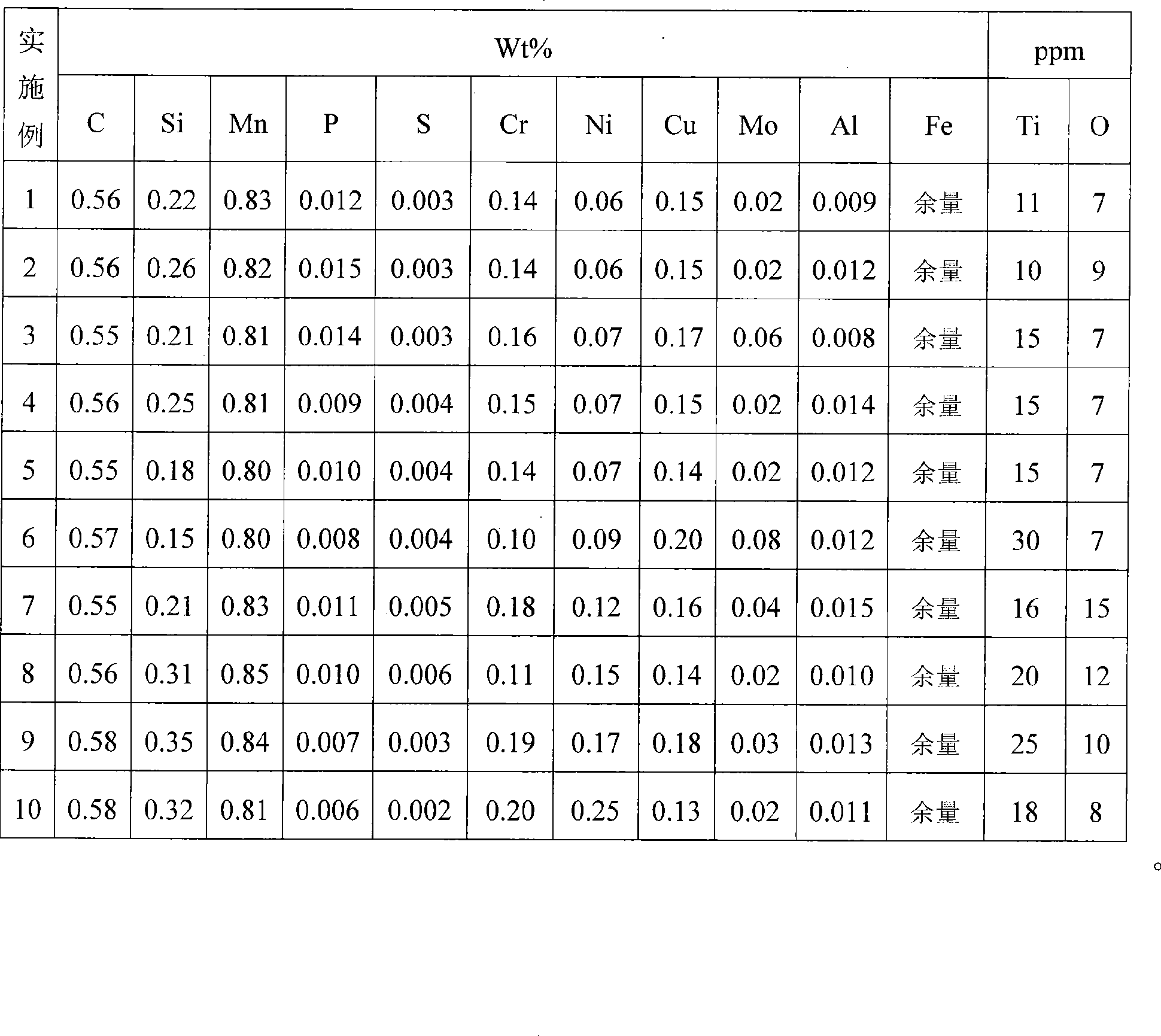

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

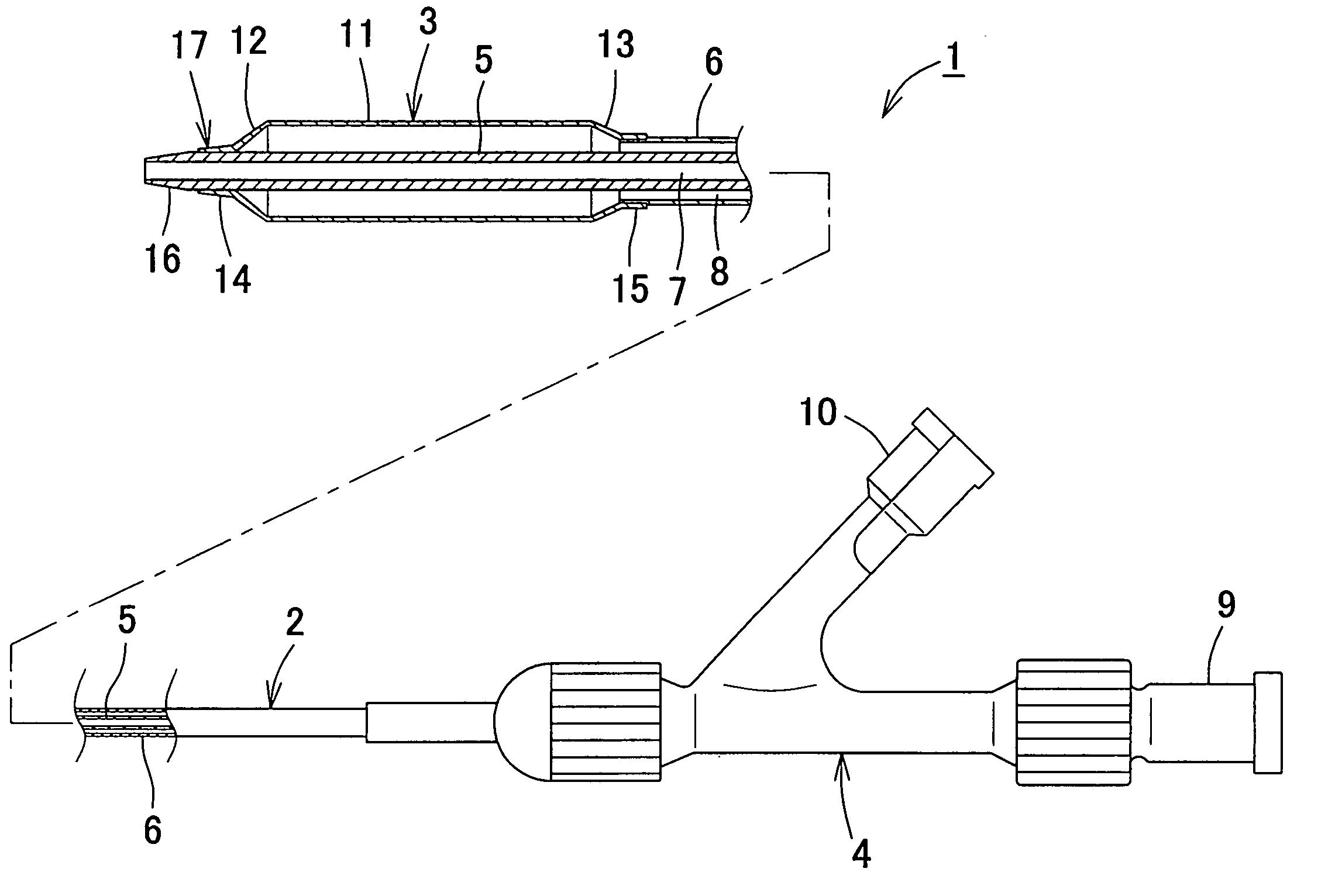

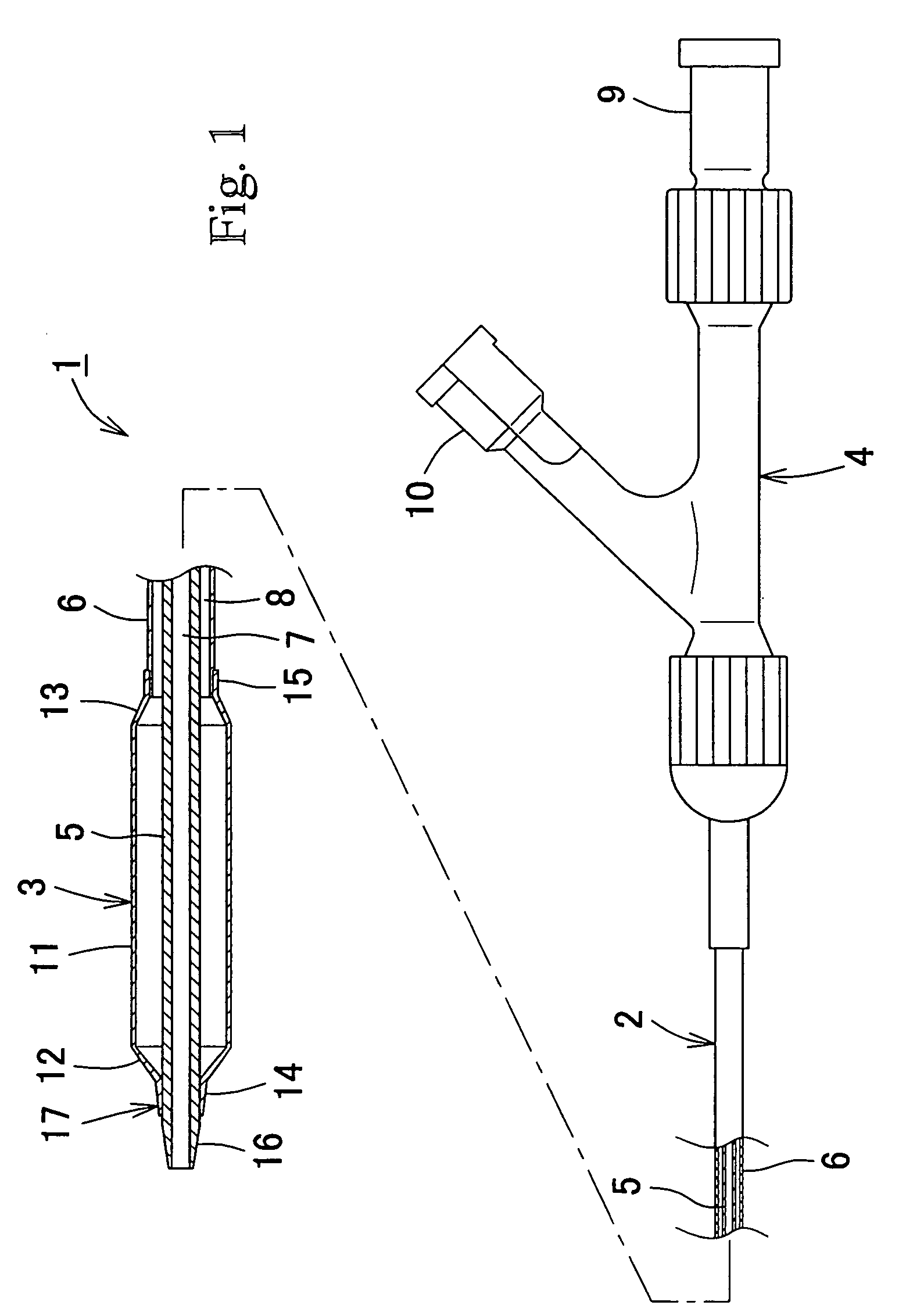

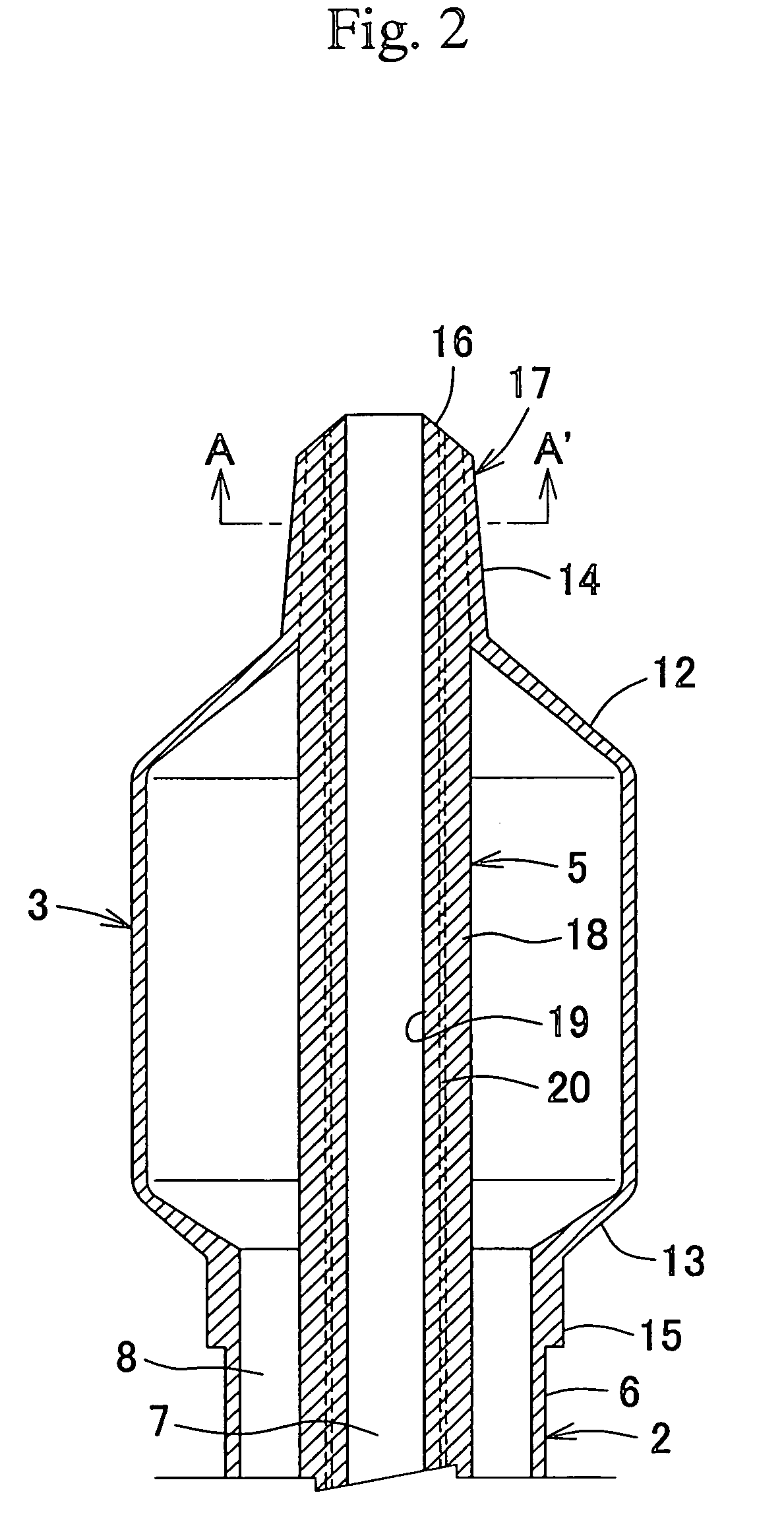

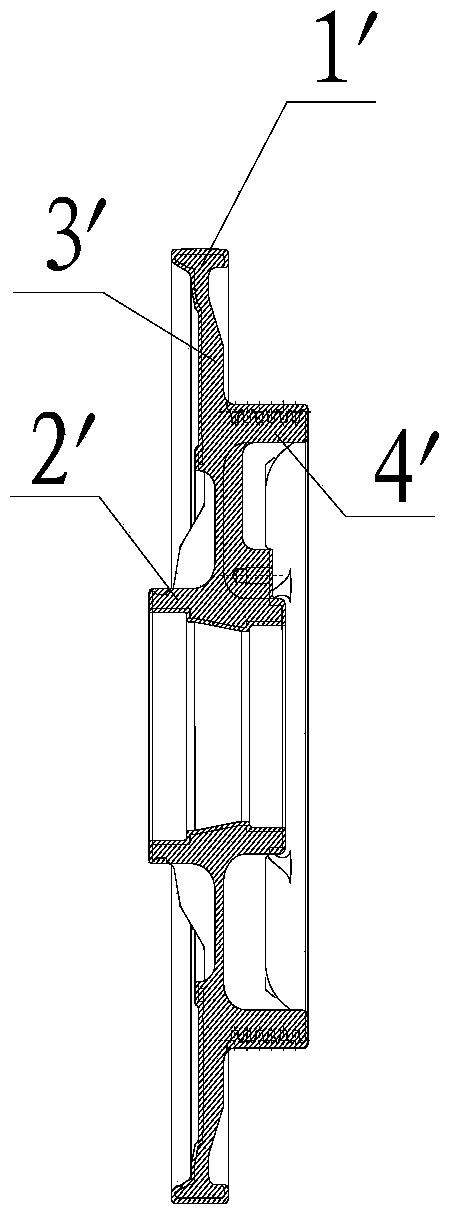

Balloon catheter

InactiveUS6960186B1Outstanding controllabilityIncrease flexibilityStentsBalloon catheterHuman bodyBalloon catheter

The present invention is a balloon catheter used primarily in treatment and surgery for the purpose of dilating lesion sites such as strictures or blockages in passages in the human body. The balloon catheter of the present invention has a structure wherein a guide wire passing tubular member is deployed passing through the interior of the expansion body, and the outer surface of the tubular member and the expansion body are concentrically fused near the distal end of the catheter. This is a balloon catheter that is characterized by the fact that the Shore hardness of the material configuring the outermost surface of the tubular member is smaller than the Shore hardness of the material configuring the expansion body. It is therefore possible to flexibly adjust the tip portion formed by securing the expansion body and the guide wire passing tubular member.

Owner:KANEKA CORP

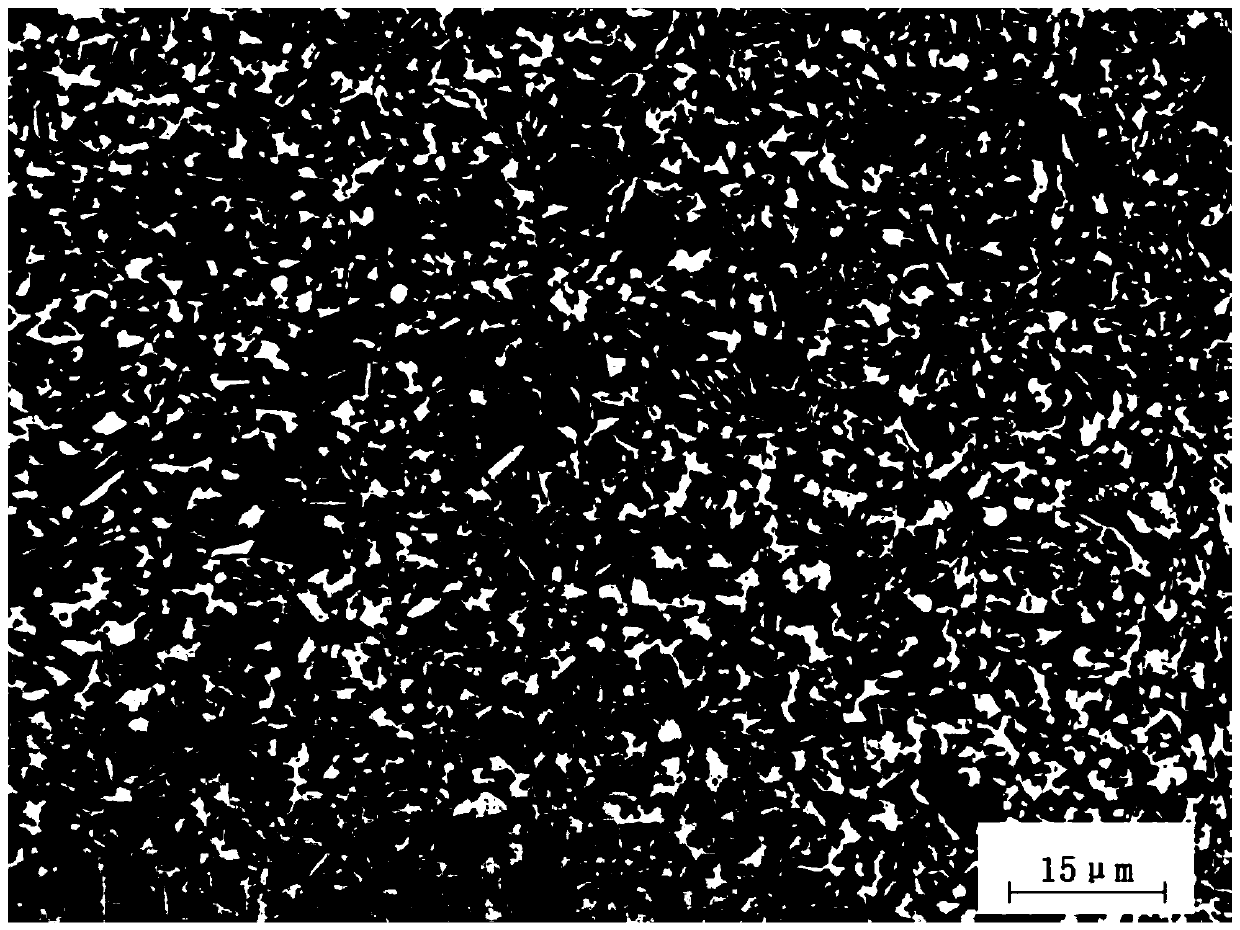

Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

The invention relates to a cold-rolled hot-galvanized dual-phase steel plate with a flanging property and a manufacturing method thereof. The steel plate comprises the following chemical components by weight percent: 0.06% to 0.095% of C, 0.3% to 0.6% of Si, 1.4% to 1.8% of Mn, greater than 0% and less than or equal to 0.02% of P, greater than 0% and less than or equal to 0.01% of S, 0.02% to 0.05% of Al, 0.35% to 0.55% of Cr, 0.02% to 0.04% of Nb, greater than 0% and less than or equal to 0.005% of N and the balance of Fe. According to the steel plate provided by the invention, the austenite is dispersedly distributed in a ferrite matrix via the refining of austenite grains by adding the Nb element and controlling temperatures during hot rolling and finish rolling and a rolling temperature; the amount of the austenite after annealing is increased by limiting the content of C and carrying out high-temperature annealing in a continuous hot-galvanized annealing furnace, so that tissues in low-C martensite are obtained after quenching. Thus, the hardness of the martensite is decreased. As a result, a hardness difference between the martensite phase and the ferrite phase is reduced.

Owner:ANSC TKS GALVANIZING

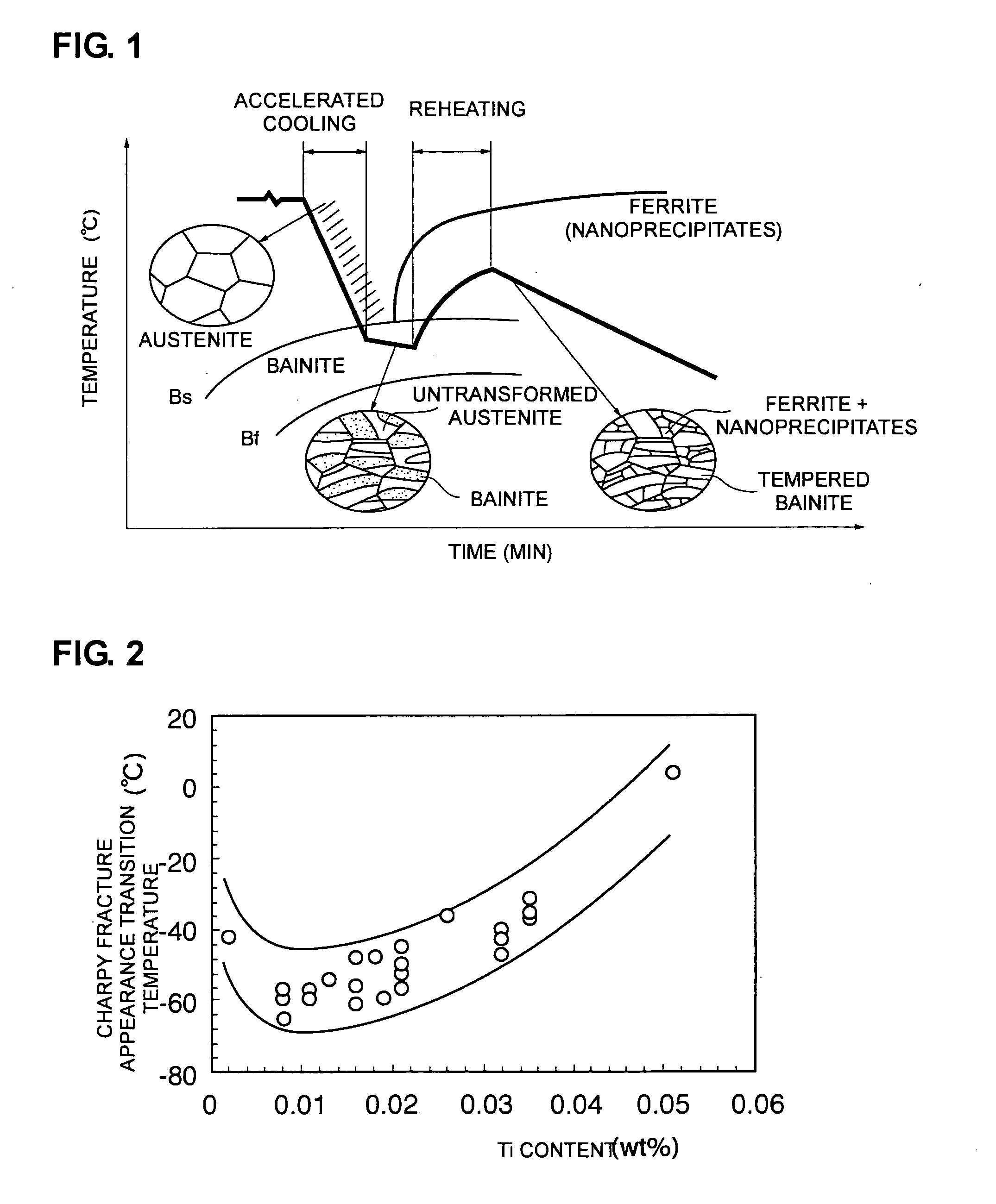

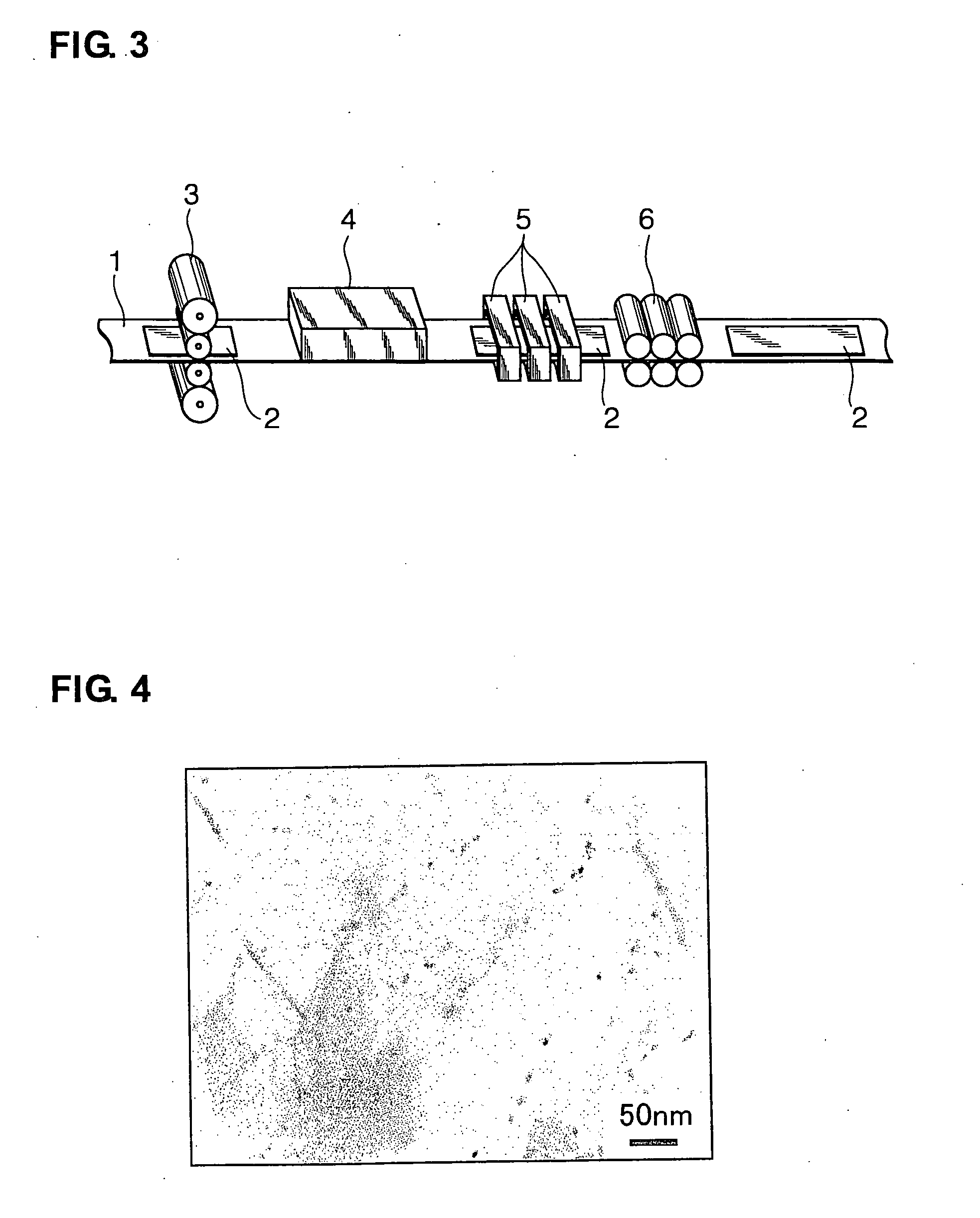

High strength steel plate and method for production thereof

InactiveUS20050106411A1High strengthIncrease resistanceThin material handlingMetal layered productsHigh intensityUltimate tensile strength

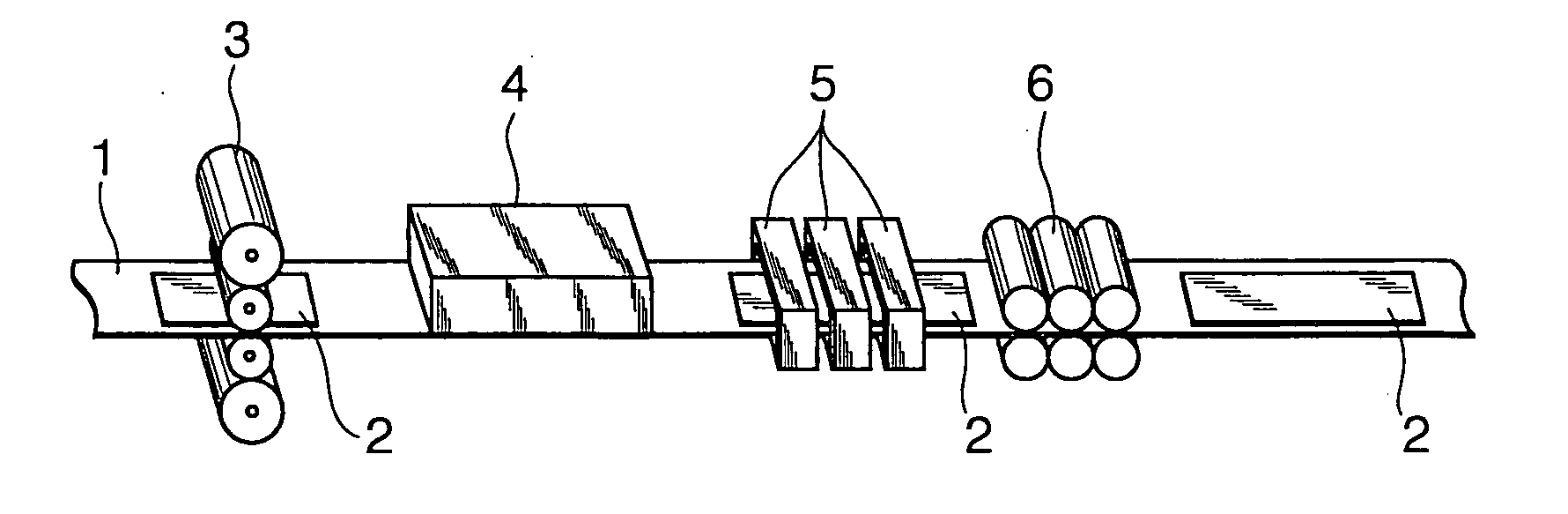

The high strength steel plate according to the present invention contains 0.02 to 0.08% C, by mass, and has substantially a two phase microstructure of ferrite and bainite. The ferrite contains precipitates having particle size of 30 nm or smaller grain size. The steel plate has yield strength of 448 MPa or higher. The method for manufacturing the high strength steel plate comprises the steps of hot rolling, accelerated cooling, and reheating. The accelerated cooling is conducted down to the temperature of 300 to 600° C. at a cooling rate of 5° C. / s or higher. The reheating is conducted up to temperature of 550 to 700° C. at a heating rate of 0.5° C. / s or higher.

Owner:JFE STEEL CORP

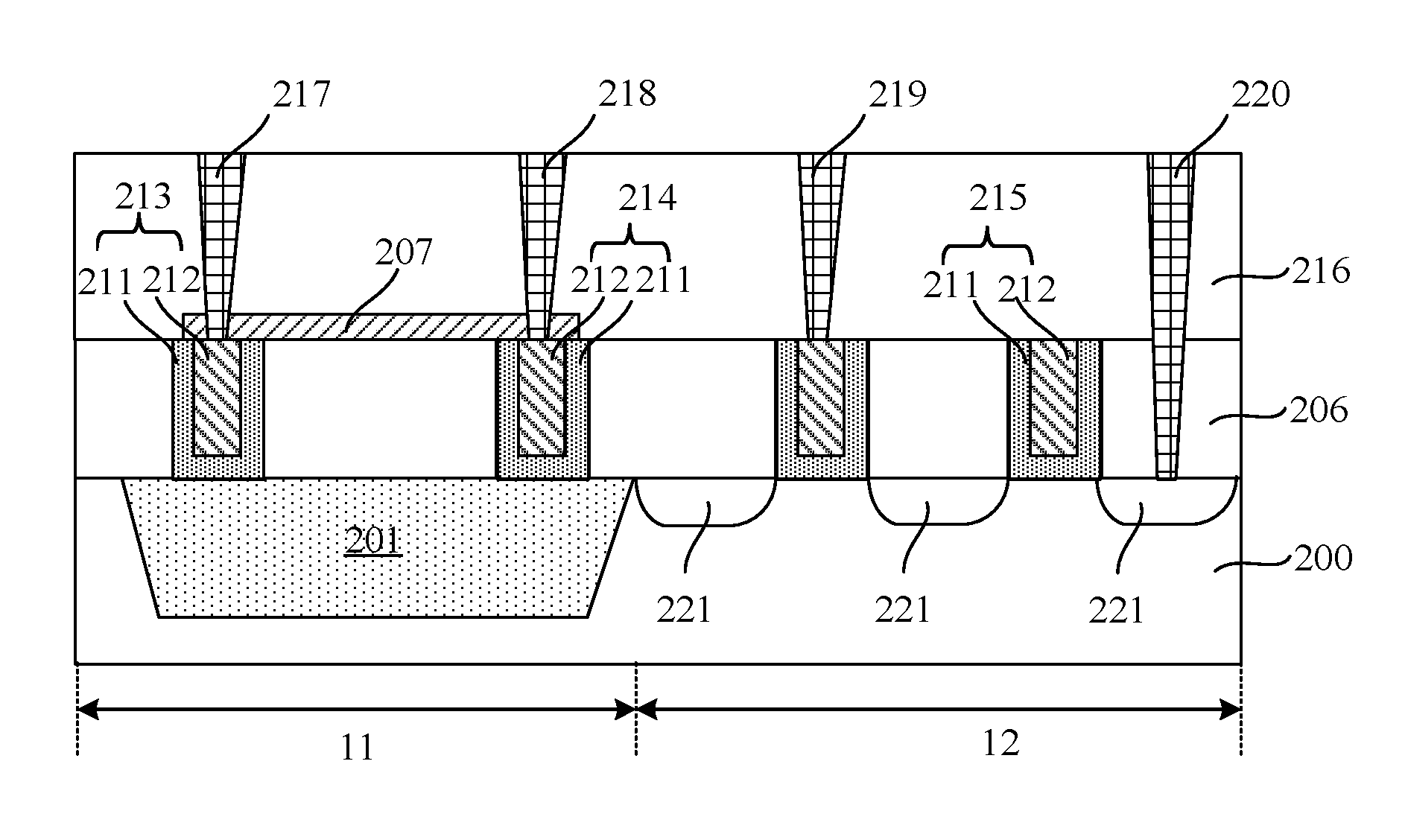

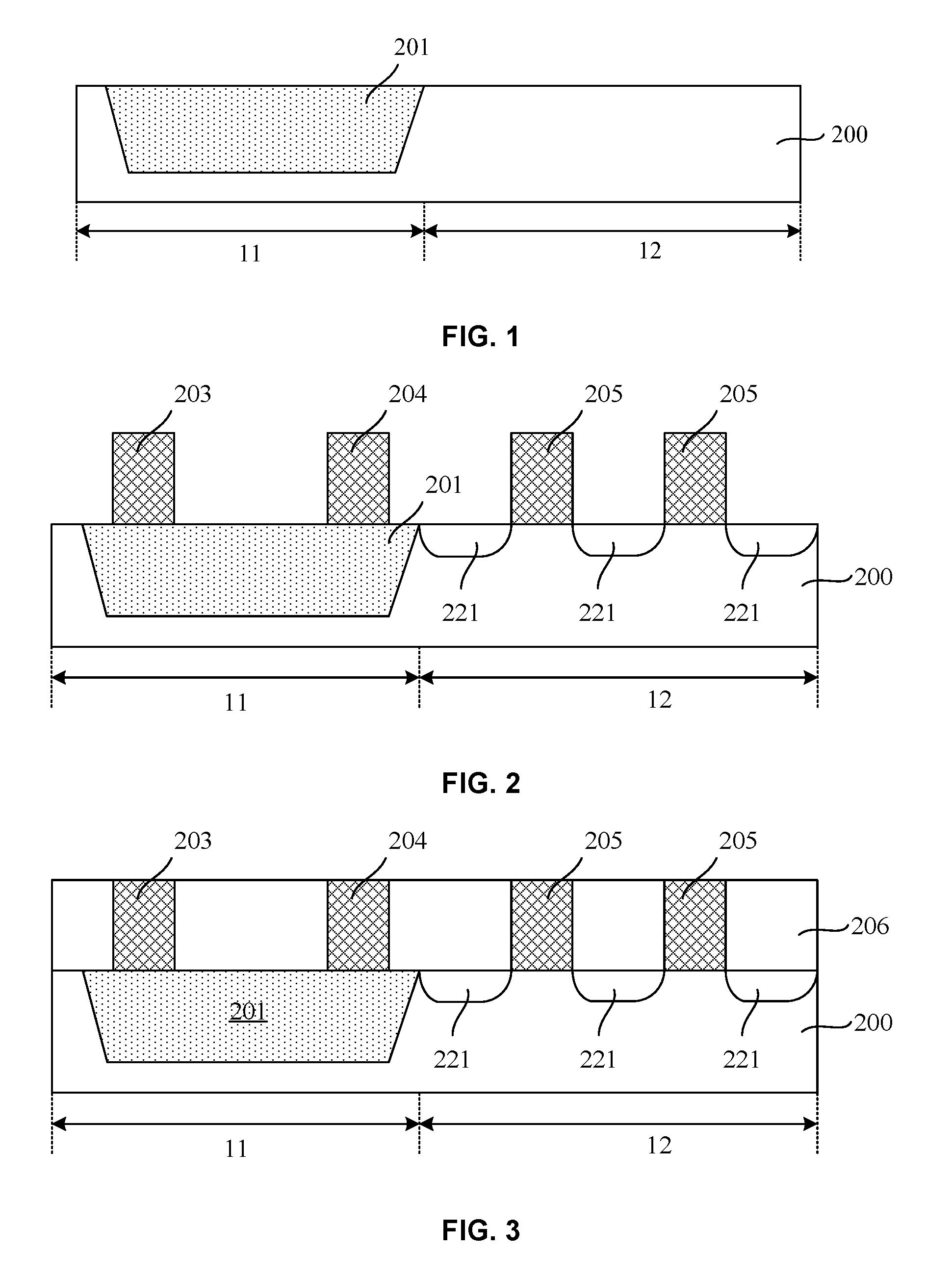

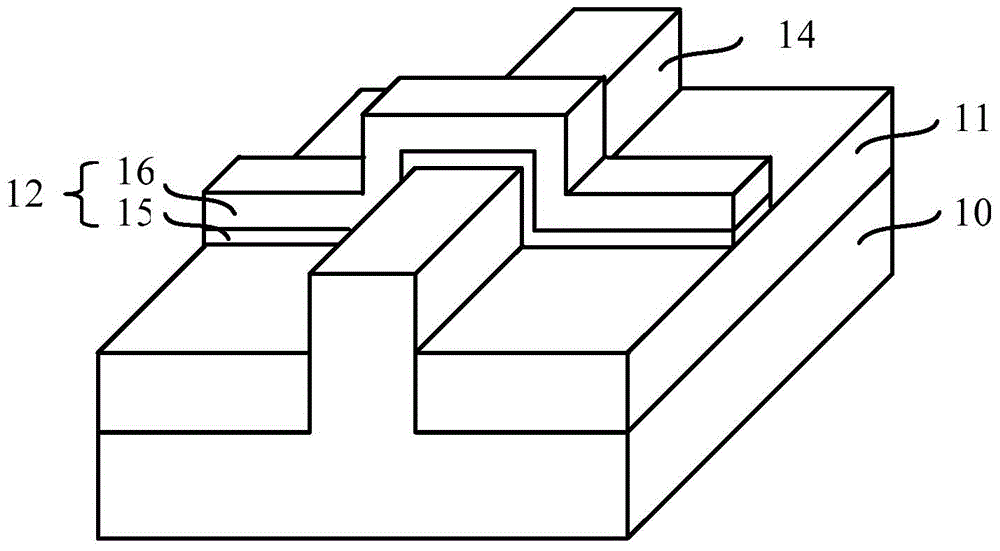

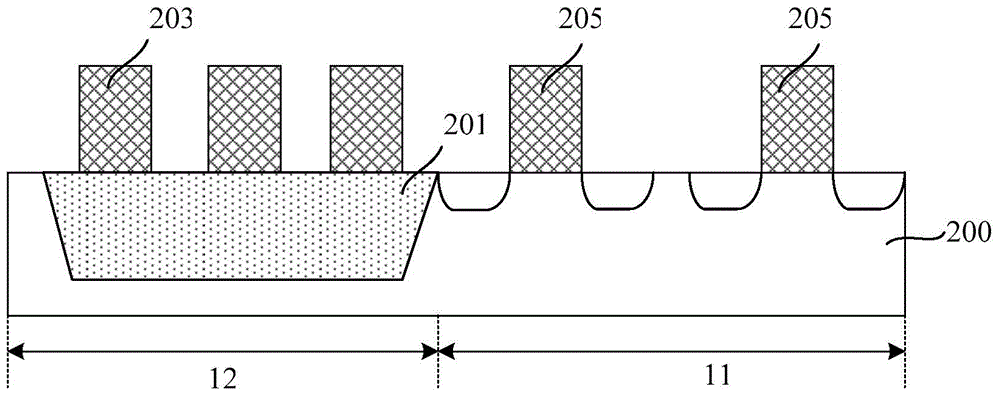

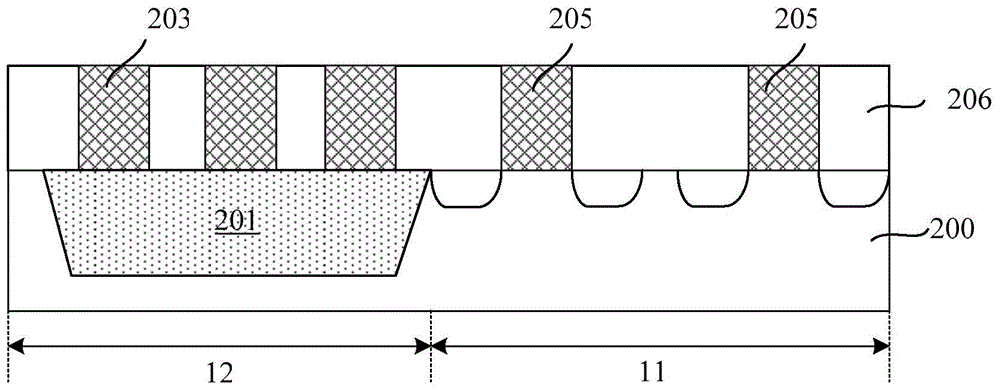

Semiconductor device and formation method thereof

ActiveUS20160204100A1Reduce hardness differenceAvoid formingTransistorSemiconductor/solid-state device detailsEngineeringDielectric layer

The present disclosure provides a semiconductor device and formation method thereof. A shallow trench isolation structure is formed in a semiconductor substrate. A first dielectric layer is formed on the semiconductor substrate. First and second dummy gate structures are formed on the shallow trench isolation structure and through the first dielectric layer. A resistive material layer is formed on the first and second dummy gate structures and on the first dielectric layer between the first and second dummy gate structures. A second dielectric layer is formed on the first dielectric layer and the resistive material layer. A first plug is formed in the second dielectric layer and the resistive material layer and on the first dummy gate structure. A second plug is formed in the second dielectric layer and the resistive material layer and on the second dummy gate structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

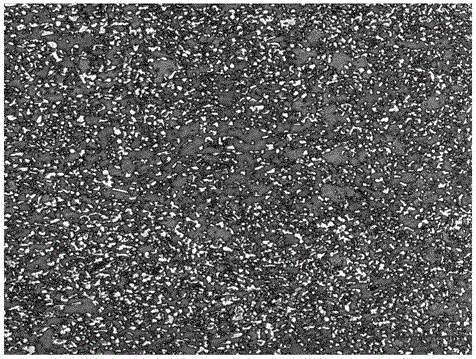

Dual phase steel with tensile strength of 1000 MPa and production method thereof

The invention discloses a dual phase steel with tensile strength of 1000 MPa and a production method thereof. The dual phase steel is composed of the following chemical components in percentage by weight: 0.08%-0.11% of C, 0.2%-0.6% of Si, 2.0%-2.5% of Mn, at most 0.01% of P, at most 0.01% of S, 0.02%-0.06% of Al, 0.4%-0.6% of Cr, 0.02%-0.05% of Ti, at most 0.003% of N, and the balance of Fe and inevitable impurities. The method solves the technical problem of how to lower the alloy cost and enhance the reaming property and delayed fracture resistance of the material on the premise of satisfying the strength requirement.

Owner:SHOUGANG CORPORATION

Method for forming fin field-effect transistors, and method for forming MOS transistors

ActiveCN105225950AHigh densityHigh hardnessSemiconductor/solid-state device manufacturingField-effect transistorDielectric layer

The invention provides a method for forming fin field-effect transistors, and a method for forming MOS transistors. The method for forming fin field-effect transistors comprises the steps of providing a semiconductor substrate provided with a plurality of discrete fin parts; forming a pseudo grid crossing the sidewalls of the fin parts and the top surfaces of the fin parts; forming a dielectric layer covering the pseudo grid and the semiconductor substrate, wherein the surface of the dielectric layer is higher than the top surface of the pseudo grid; implanting first ions and implanting cured ions in the dielectric layer to increase the density of the dielectric layer; planarizing the dielectric layer to expose the surface of the pseudo grid; removing the pseudo grid to form a groove, and forming a metal gate in the groove. According to the invention, the defect of recesses is prevented from occurring in the dielectric layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

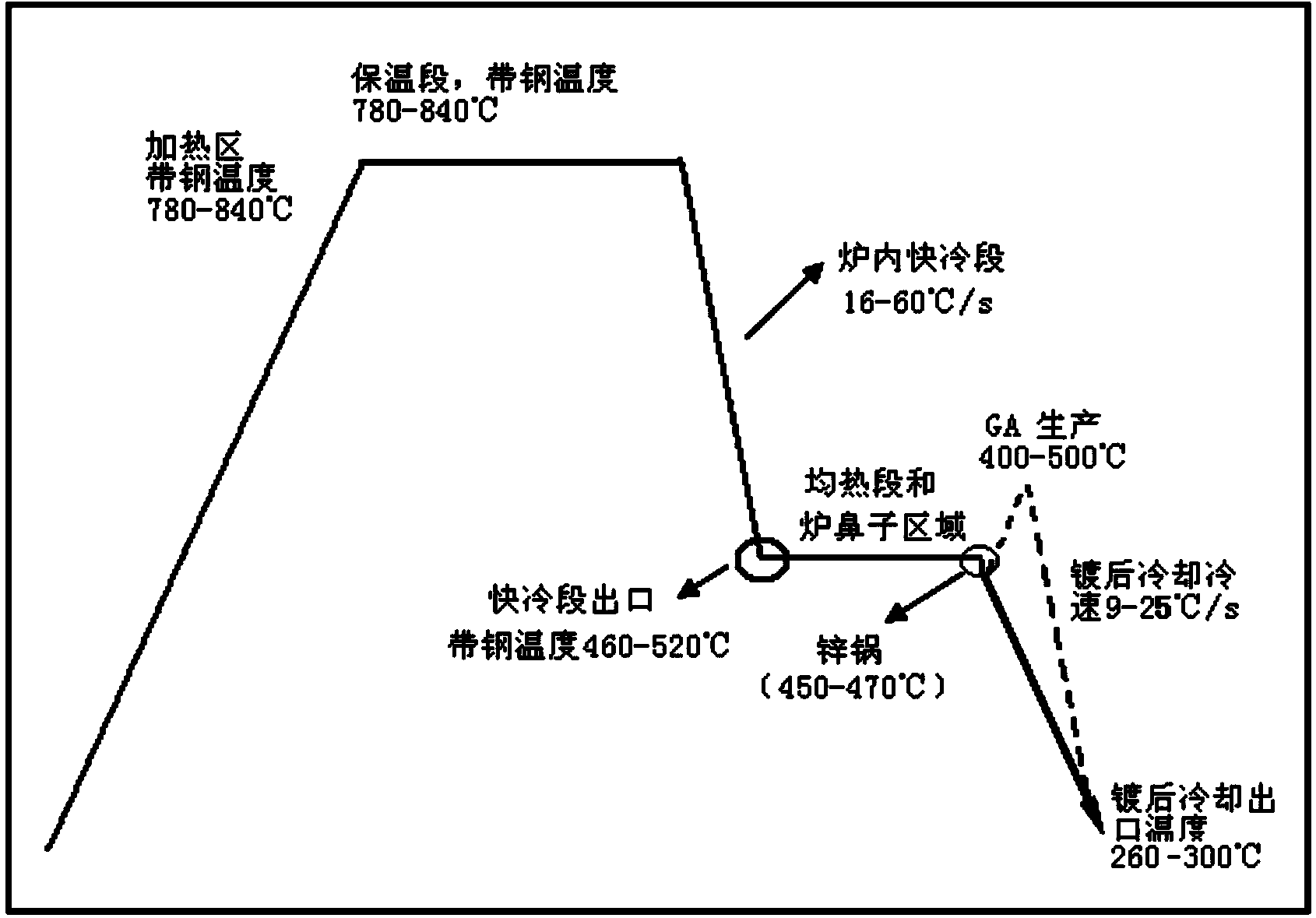

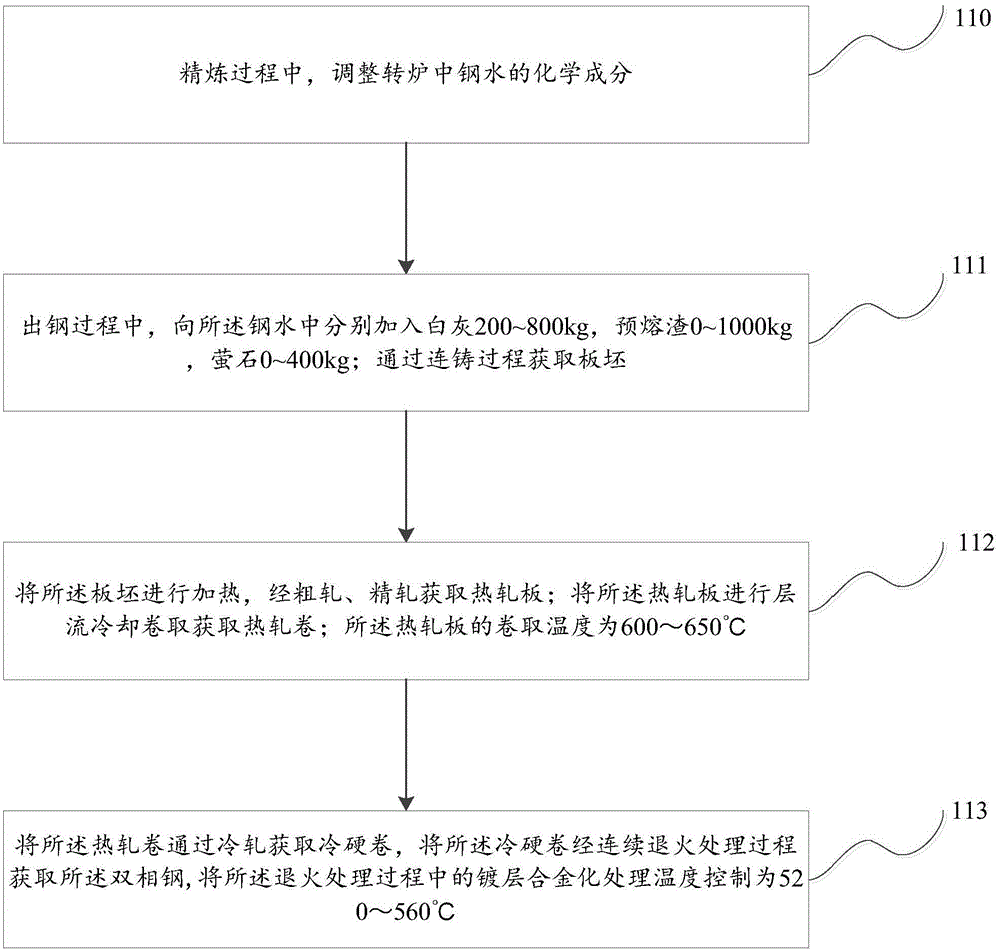

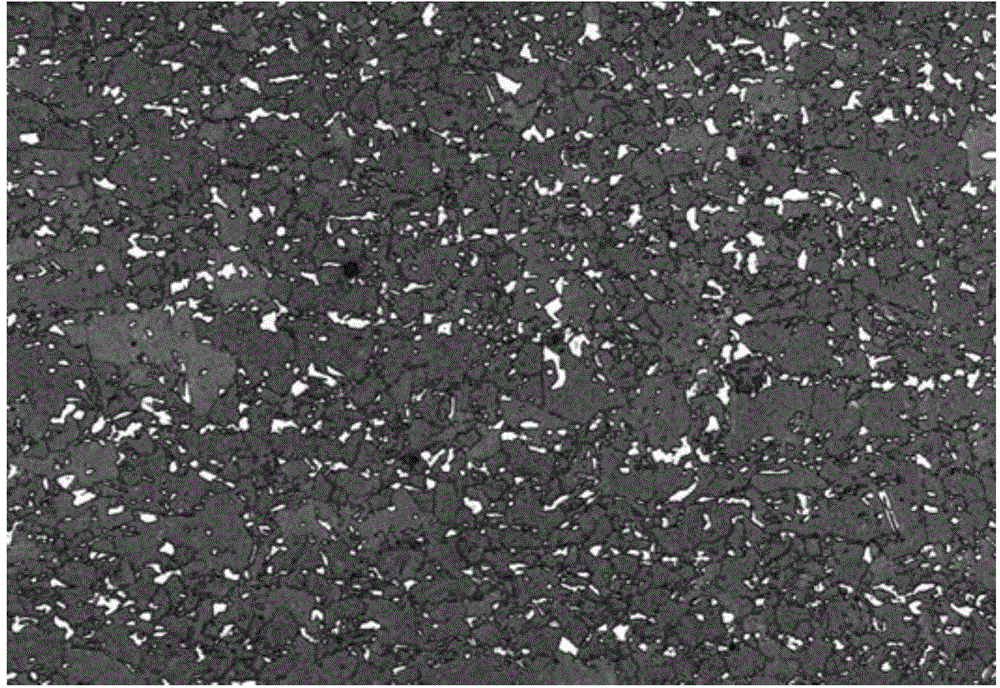

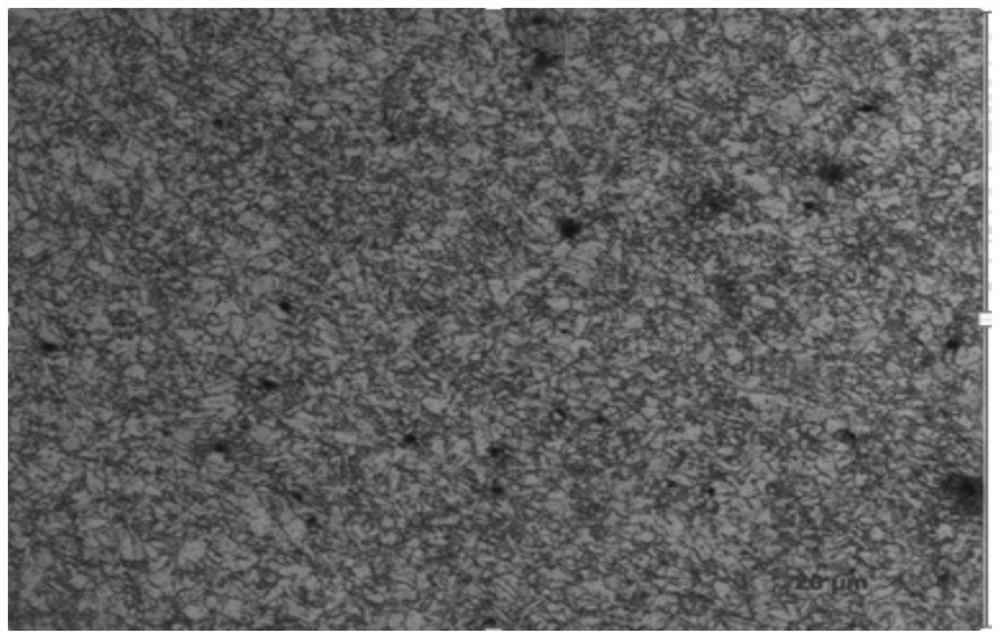

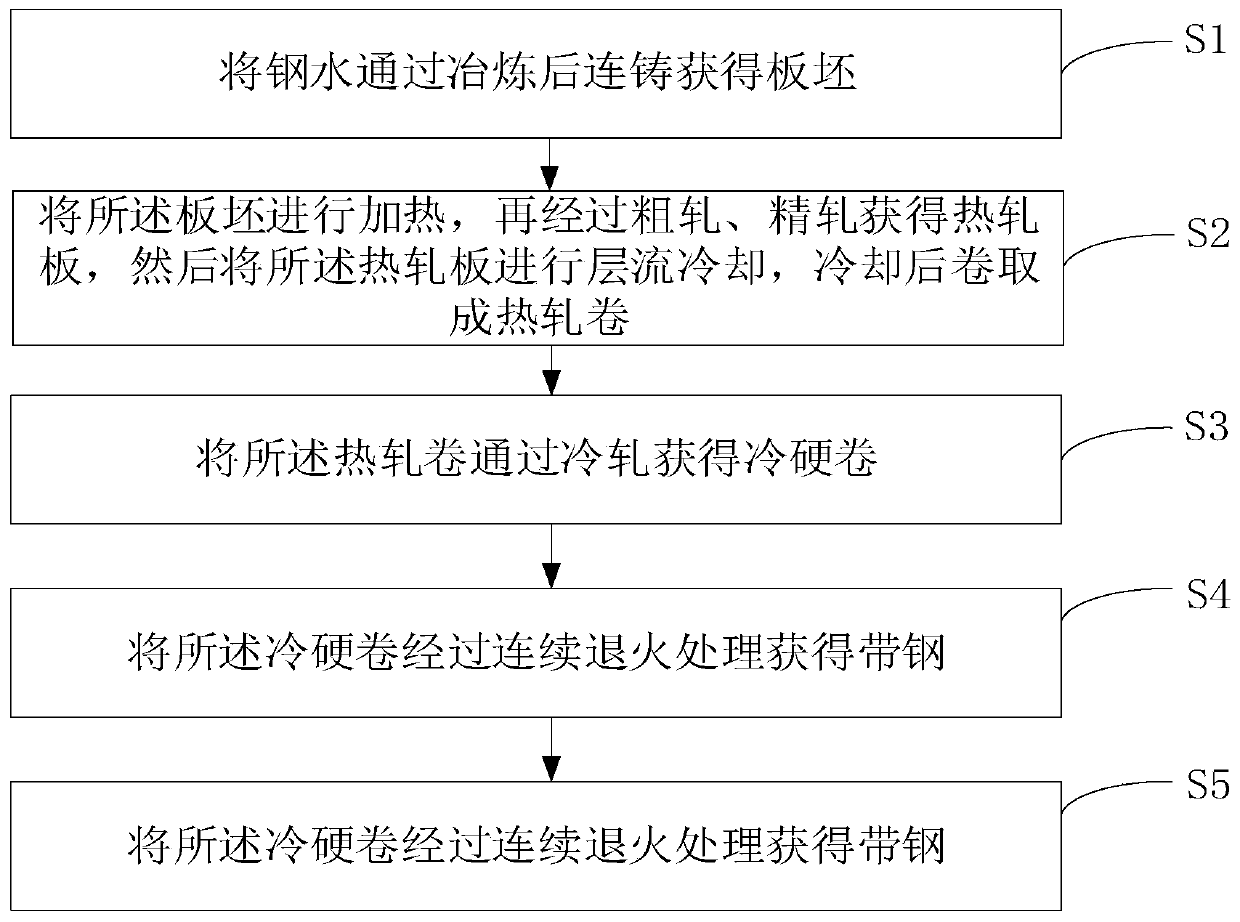

Preparation method of alloyed hot-galvanized dual-phase steel

ActiveCN104593686AReduce hardness differenceImprove hole reaming effectHot-dipping/immersion processesChemical compositionHardness

The invention provides a preparation method of alloyed hot-galvanized dual-phase steel, belonging to the technical field of high-strength cold-rolled hot-galvanized steel. Cold-rolled dual-phase DP steel comprises the following chemical components in percentage by weight: 1.3%-1.7% of Mn, less than or equal to 0.01% of P, 0.15%-0.25% of Mo, 0.15%-0.25% of Cr, 0.02%-0.04% of Nb, 0.07%-0.11% of C, 0.2%-0.5% of Si, 0.02%-0.07% of Als, less than or equal to 0.04% of N, 0.01% of S and the balance of Fe and impurities. According to the preparation method of the alloyed hot-galvanized dual-phase steel with excellent pore broadening performance, by adding a certain amount of Nb, martensite phases are refined and uniformly dispersed in a final microstructure; furthermore, by properly regulating the alloying temperature (520-560 DEG C), a proper amount of intermediate hard phase pearlite is generated, and the hardness difference between the hard martensite phases and a soft ferritic phase is reduced, so that the pore broadening performance of the dual-phase steel is improved.

Owner:SHOUGANG CORPORATION

100-260 mm-thick tempering-state prehardened plastic mold steel plate and manufacturing method thereof

ActiveCN107177796AImprove organizationImprove the quality of flaw detectionSheet steelChemical composition

The invention relates to a 100-260 mm-thick tempering-state prehardened plastic mold steel plate. The steel plate has the following chemical components in percentage by mass: 0.35-0.45 of C, 0.20-0.50 of Si, 0.60-1.00 of Mn, 1.00-2.50 of Cr, 0.20-0.50 of Mo, 0.04-0.15 of V+Ti, 0.01-0.04 of Als, 0.015 or less of P, 0.005 or less of S, and the balance of Fe and inevitable impurities; the steel plate is uniform in performance; the overall hardness difference is not more than 2.0 HRC; and the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection. The overall hardness difference is not more than 2.0 HRC; the steel plate reaches NB / T47013.3 plate part I grade requirements by ultrasonic detection; and the total inclusion grade is not higher than 2.5. The chemical components of the mold steel plate are simplified; the improvement is performed from the production process angle; the difference of the steel plate in the thickness direction is reduced; and in particular, the section hardness uniformity is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

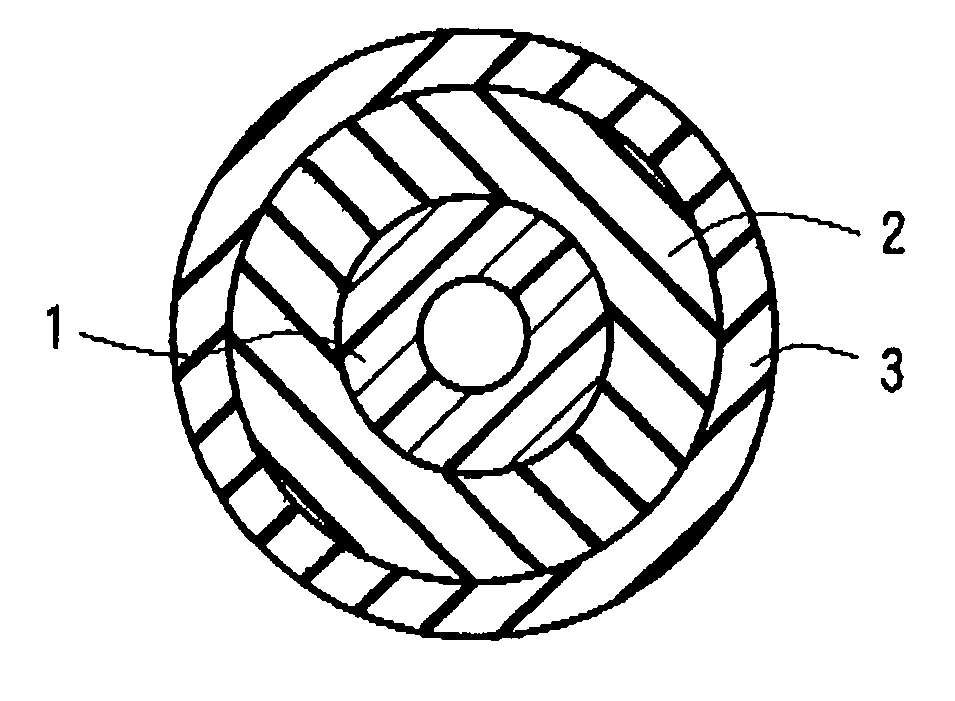

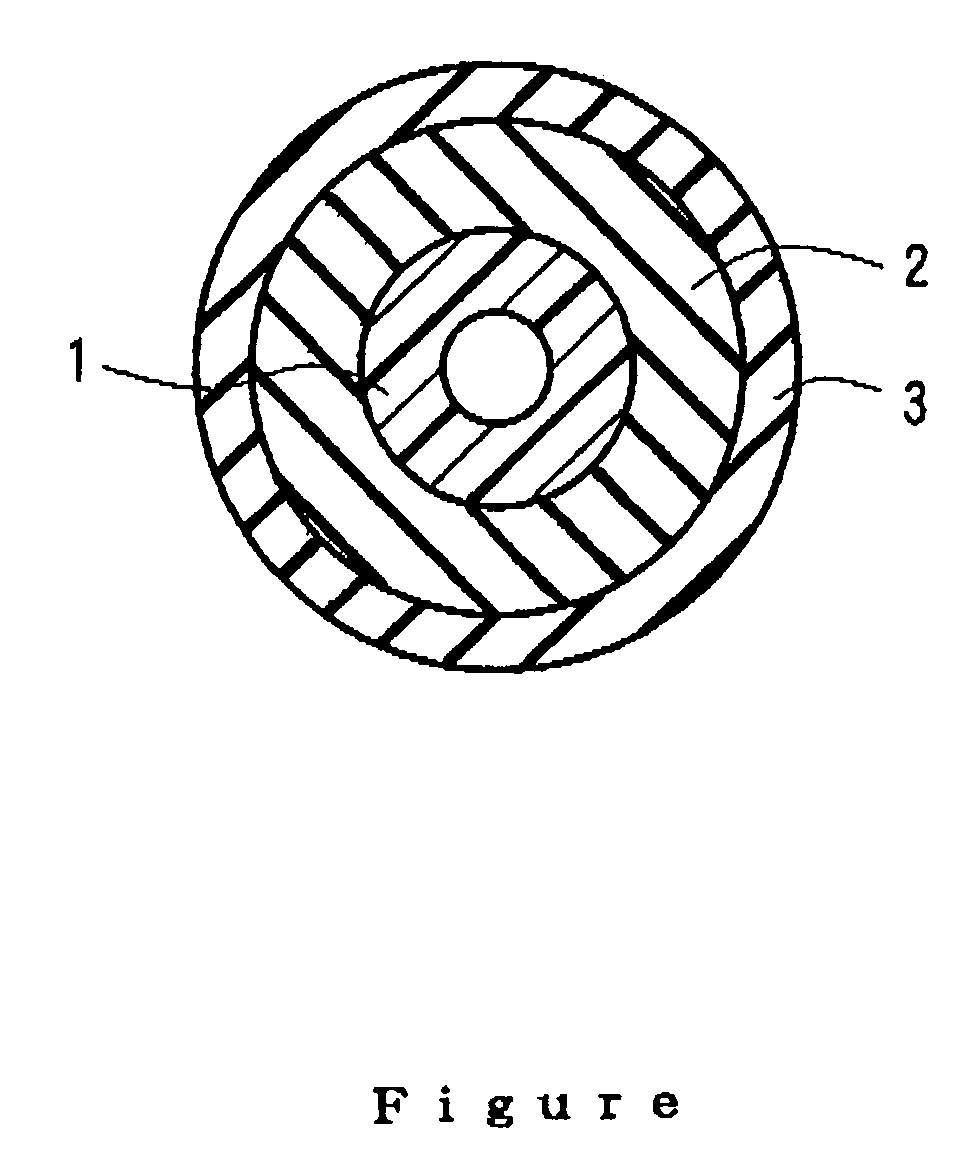

Sheet feeding roller

InactiveUS7284649B2Low production costGood transportabilityShaft and bearingsPortable power-driven toolsHardnessEngineering

A sheet feeding roller, available at a lower cost, having lower hardness with securing both abrasion resistance and sustainability of friction coefficient. The sheet feeding roller comprises a hub, an inner layer provided on an outer peripheral surface of the hub, and an outer layer provided on an outer peripheral surface of the inner layer, the inner layer and the outer layer are formed by an unfoamed cured body of thermosetting urethane rubber wherein the outer layer is harder than the inner layer.

Owner:SUMITOMO RIKO CO LTD

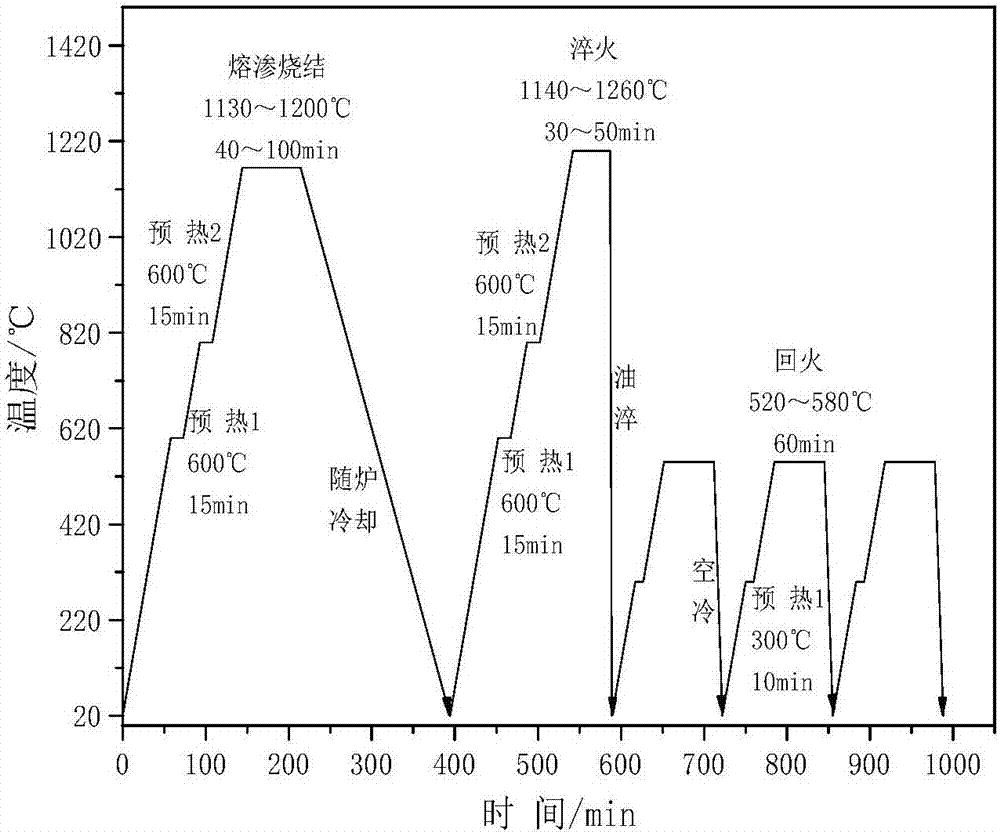

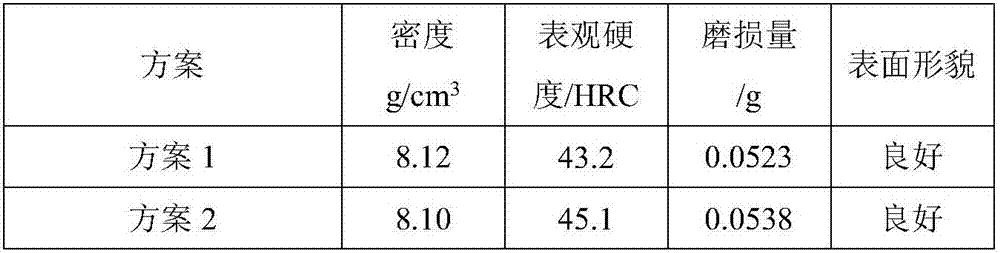

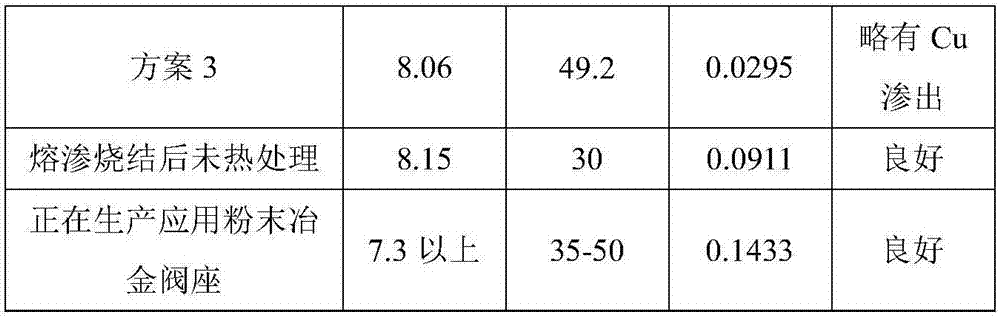

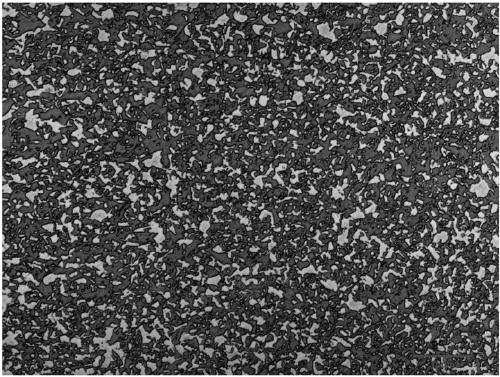

Powder metallurgy high-speed steel valve seat for clean fuel engine and production process of powder metallurgy high-speed steel valve seat

ActiveCN107267877AConvenient sourceReasonable ratio of ingredientsTransportation and packagingMetal-working apparatusCarbideAlloy

The invention discloses a powder metallurgy high-speed steel valve seat for a clean fuel engine and a production process of the powder metallurgy high-speed steel valve seat. With W6Mo5Cr4V2 high-speed steel powder as a base body material, Cu, Co-Cr-Mo and Fe-Mo hard particles are added, and the hard particles comprise, by mass percentage, 45%-57% of W6Mo5Cr4V2, 13%-17% of Co-Cr-Mo, 4%-7% of Fe-Mo, 17%-22% of Cu and 2%-3% of a solid lubricant and easy-to-cut components. According to the powder metallurgy high-speed steel valve seat, by the adoption of an infiltration sintering and heat treatment technology, the density of the powder metallurgy high-speed steel valve seat is increased, the hardness, wear resistance and the like of the powder metallurgy high-speed steel valve seat are improved; and on the one hand, stable alloy tempered martensite and fine dispersed secondary alloy carbide can be obtained, and on the other hand, the bonding of a base body and the hard particles is firmer, and the hard particles are not likely to be peeled off from the base body during frictional wear. By the adoption of the infiltration sintering and heat treatment technology, the density of the material is increased, and the hardness, wear resistance and the like of the material are improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

High-toughness synthetic cast iron cylinder-sleeve material and manufacturing process

The invention discloses a manufacturing process of a high-toughness synthetic cast iron cylinder-sleeve material. The method comprises the following steps: using low-carbon steel scrap as a raw material, carrying out recarburization by adding a carburant, adding ferroalloy and fusing to obtain high-carbon high-silicon molten iron; adding a high-silicon silicon steel sheet into the surface of the molten iron to carry out silicon-increasing and carbon-reduction processing; and adding an instantaneous inoculant into the molten iron to carry out secondary instantaneous compound inoculation treatment, and pouring a blank to prepare the high-toughness synthetic cast iron cylinder-sleeve material. Casting costs of the high-toughness synthetic cast iron provided by the invention are 15-20% lower than casting costs of general alloy cast iron. Tensile strength of the prepared high-toughness synthetic cast iron cylinder-sleeve is 80-130MPa higher than tensile strength of an alloy cast iron cylinder-sleeve, and the tensile strength of the prepared high-toughness synthetic cast iron cylinder-sleeve can reach 350-420 MPa. Hardness can be controlled to 190-240, and hardness difference of the high-toughness synthetic cast iron cylinder-sleeve is shortened by 20HB in comparison with hardness difference of the alloy cast iron cylinder-sleeve and can shortened to delta HB being less than or equal to 10. Elasticity modulus E is greater than or equal to 140GPA. High-toughness synthetic cast iron can be used to reduce wall thickness of the cylinder sleeve and raise power of an engine. In addition, the elasticity modulus is high, hardness is low and processability is good, clearance between a piston and a cylinder can be decreased; noise can be reduced; and power can be increased.

Owner:FUJIAN LONGSHENG MACHINERY

Cold milling two-phase steel and preparation method thereof

Owner:SHOUGANG CORPORATION

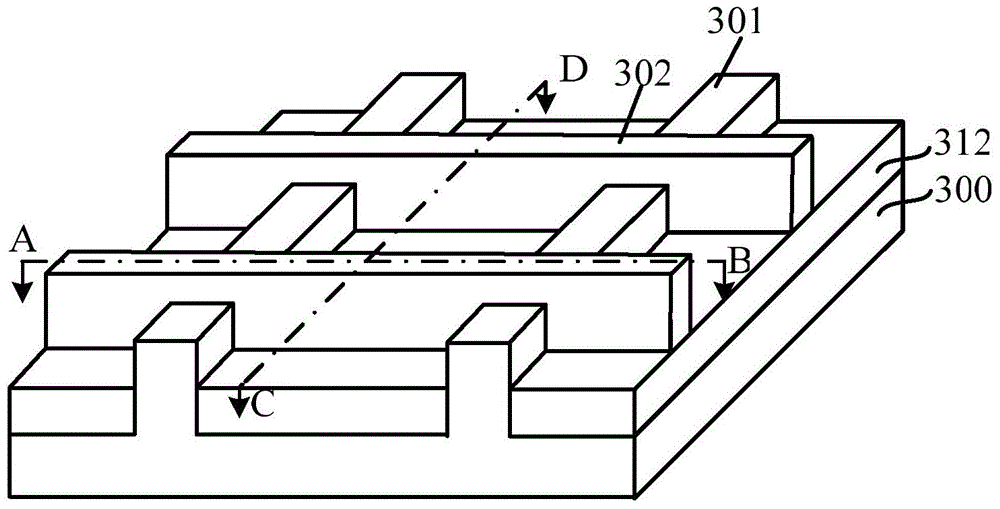

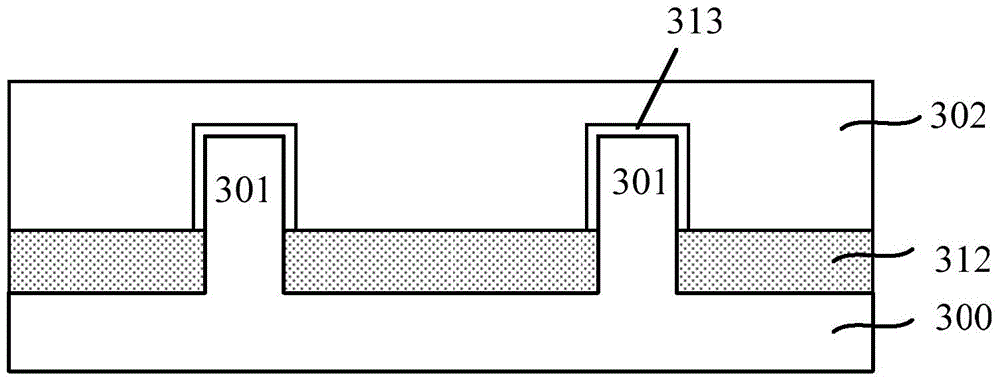

Formation method for semiconductor structure

ActiveCN106206271ARealize integrated process productionSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureDielectric layer

Disclosed is a formation method for a semiconductor structure. The formation method comprises the steps of providing a semiconductor substrate, wherein the semiconductor substrate comprises one or more first regions and one or more second regions; multiple first pseudo-gage structures are formed on the first regions of the semiconductor substrate; multiple second pseudo-gage structures are formed on the second regions of the semiconductor substrate; forming a first dielectric layer which covers the semiconductor substrate; forming a mask layer which covers the second pseudo-gage structures; removing the first pseudo-gage structures from the first regions to form a groove; forming a metal gate electrode in the groove; forming a thin film resistor which covers the second pseudo-gage structures, wherein a first contact region and a second contact region are arranged at the two ends of the thin film resistor respectively; and the first contact region and the second contact region are correspondingly positioned on one second pseudo-gage structure. By adoption of the formation method, the performance of the formed thin film resistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Steel for large-sized wind power fastener and manufacturing method of steel

ActiveCN110643881AAvoid performance fluctuationsReduce hardness differenceTemperature control deviceWork heating devicesUltimate tensile strengthWind power

The invention discloses steel for a large-sized wind power fastener. The steel is prepared from the element components in percentage by mass: 0.38-0.45% of C, 0.20-0.35% of Si, 0.60-0.80% of Mn, lessthan or equal to 0.015% of P, less than or equal to 0.010% of S, 0.95-1.20% of Cr, 0.18-0.30% of Mo, 0.10-0.25% of Ni, 0.02-0.08% of Nb, 0.020-0.050% of Al, less than or equal to 0.008% of N, and thebalance of Fe and inevitable impurities. After heat treatment, the core part of the steel is provided with 90% or above of a martensitic structure, the surface hardness difference of the core part isless, especially the low-temperature impact property is excellent, the good mechanical properties are achieved, the tensile property meets the 10.9-grade strength requirements, and the machining usingrequirements for the steel for 48-65 mm of the large-sized wind power fastener by a user can be met.

Owner:NANJING IRON & STEEL CO LTD

Wear-resistant alloy steel, alloy grinding ball and preparation method of wear-resistant alloy steel

The invention discloses wear-resistant alloy steel, an alloy grinding ball and a preparation method of the wear-resistant alloy steel, and relates to the technical field of metallurgy, aiming at solving the problem that an alloy grinding ball which is good in ductility and good in wear resistance cannot be prepared by a rolling process in the prior art. The main technical scheme of the invention is as follows: the wear-resistant alloy steel consists of the following substances in percentage by weight: 0.90-1.00% of carbon, 0.35-0.45% of silicon, 0.50-0.60% of manganese, 1.1-1.3% of chromium, 0.25-0.35% of molybdenum, 0.07-0.09% of boron, 0.3-0.5% of rare earth, 0-0.016% of sulfur, 0-0.015% of phosphor, 0-0.06% of copper and the balance of iron and inevitable impurities. The invention prepares the wear-resistant alloy steel and the alloy grinding ball which are high in ductility and wear-resistant mainly by virtue of a rolling process.

Owner:清原满族自治县三方耐磨材料有限公司

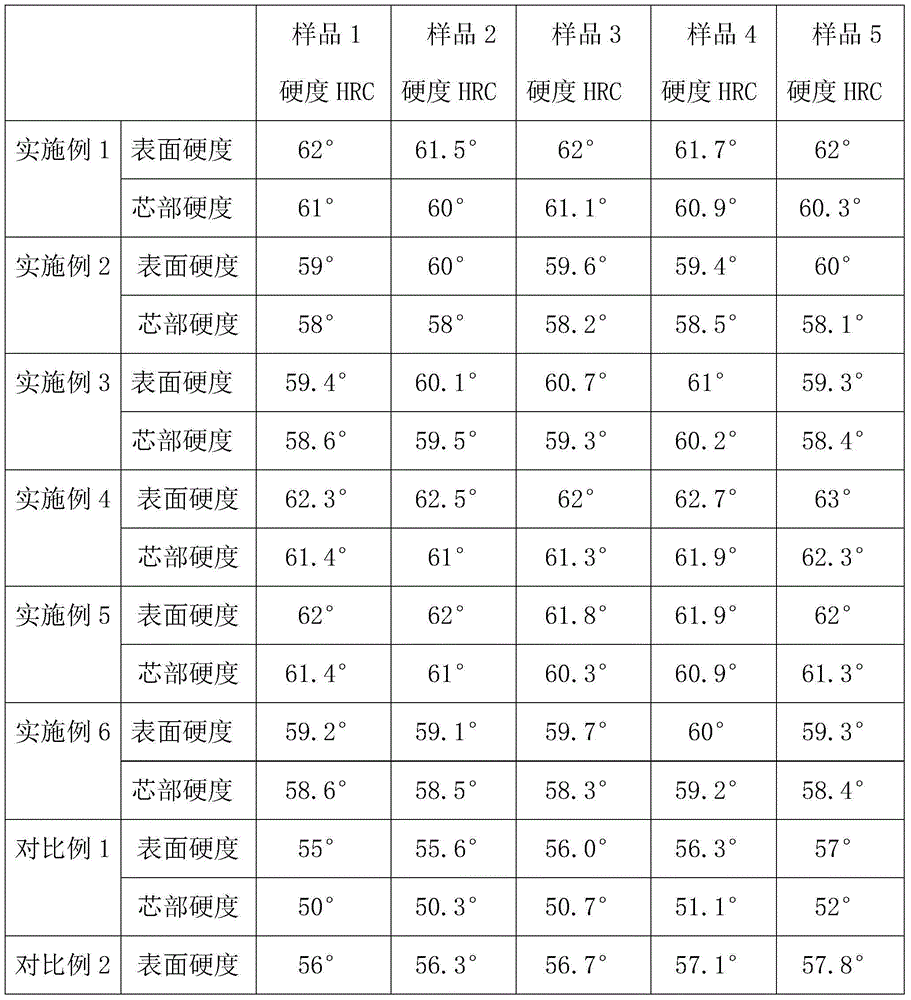

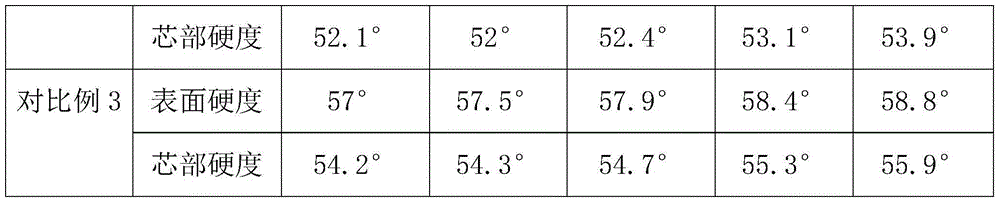

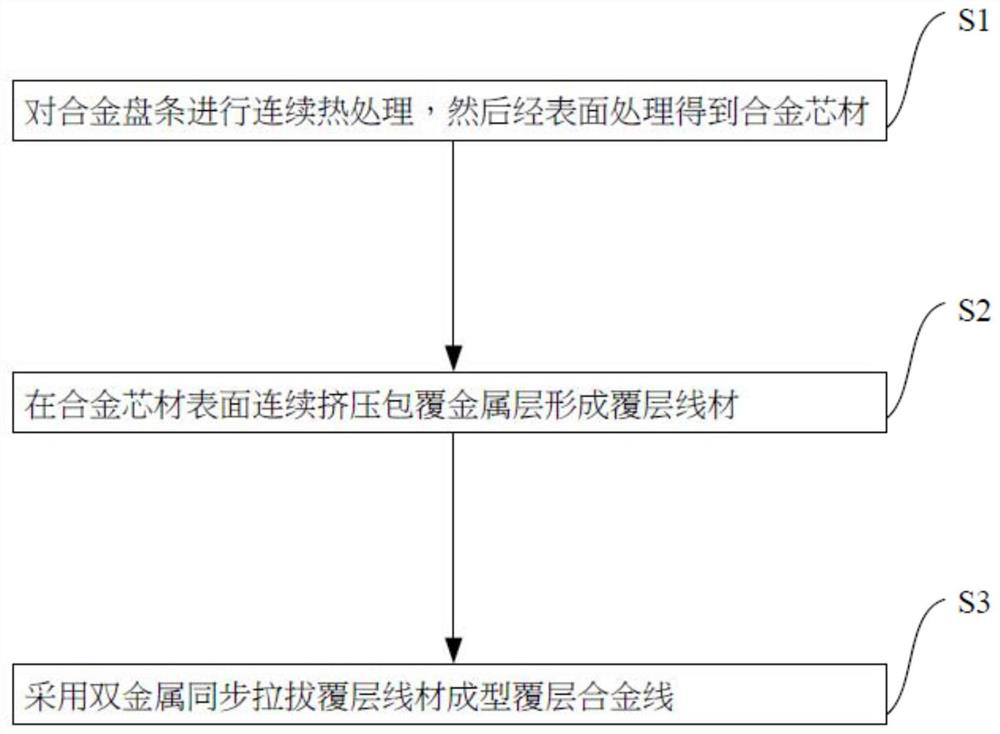

Preparation method of coated alloy wire

ActiveCN111687236AImprove elongationReduce hardness differenceRevolution surface grinding machinesBelt grinding machinesAlloy steelSurface preparation

The invention provides a preparation method of a coated alloy wire. The preparation method comprises the following steps that an alloy steel wire rod is subjected to continuous heat treatment, and then surface treatment is carried out to obtain an alloy core material; the surface of the alloy core material is subjected to continuous extrusion coating to form the coated wire rod; and double metal is adopted to synchronously pull the coated wire rod to form the coated alloy wire. According to the preparation method of the coated alloy wire, a continuous heat treatment furnace is used for treating, the alloy steel wire rod with good matching of strength and elongation is obtained, then the binding force of the alloy core material and a coated material is improved by combining with the surfacetreatment, finally, the elongation of the coated alloy wire is improved by synchronously pulling the double metal, and the hardness difference of the cross section of the coated alloy wire is reduced.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +2

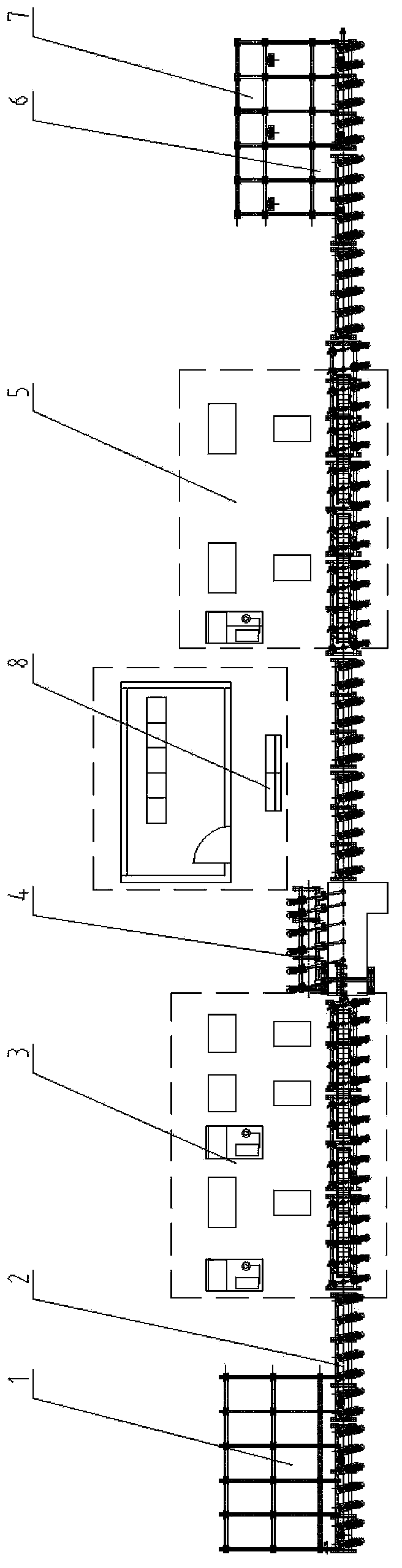

Induction heating quenching and tempering system

InactiveCN103421936ARealize automatic controlEffective controlIncreasing energy efficiencyControl systemElectrical control

The invention discloses an induction heating quenching and tempering system which is used for quenching and tempering heat treatment of car rack blanks or connecting rod rods. The system comprises an adjustable conveying system and an electrical control system which are mutually connected, wherein a feeding mechanism, an induction hardening heating unit, an adjustable spray coil type quenching and cooling mechanism, an induction tempering and heating unit and a discharging structure are sequentially arranged on the adjustable conveying system; the adjustable conveying system is used for advancing and rotating of workpieces connected one after another; the electrical control system is used for controlling the induction heating quenching and tempering system. The system can effectively improve the uniformity and precision of the workpiece heating, and allows the workpiece to be more uniformly cooled and have small, even no, deformation. When the workpiece is subjected to tempering, no deformation is caused during uniform cooling. Due to the adoption of the system, the rigidity difference between the surface and core of the automobile rack blank is small, deformation is small or even can be avoided, and mass and stable continuous production is realized.

Owner:SHANGHAI BEITE TECH

Stainless steel with high content of chromium and middle content of carbon and preparing method thereof

ActiveCN101033527AReduce brittlenessImprove wear resistancePiston ringsShaftsChemical compositionHardness

This invention relates to an alloyed material of high Cr mid-carbon stainless steel including the following chemical components in weight percentages: C 0.45-0.9, Si smaller than or equal to 1.0, Mn smaller than or equal to 0.6, P smaller than or equal to 0.03, S smaller than or equal to 0.03, Cr 16-18, Mo smaller than or equal to 1.2 and V smaller than or equal to 0.6, which reduces C and increases the content of metal so as to reduce brittleness of alloys and increase the performance of anti-corrosion, keep bright for long and meets requirement of hardness of alloyed steel.

Owner:大连环新新材料科技有限公司

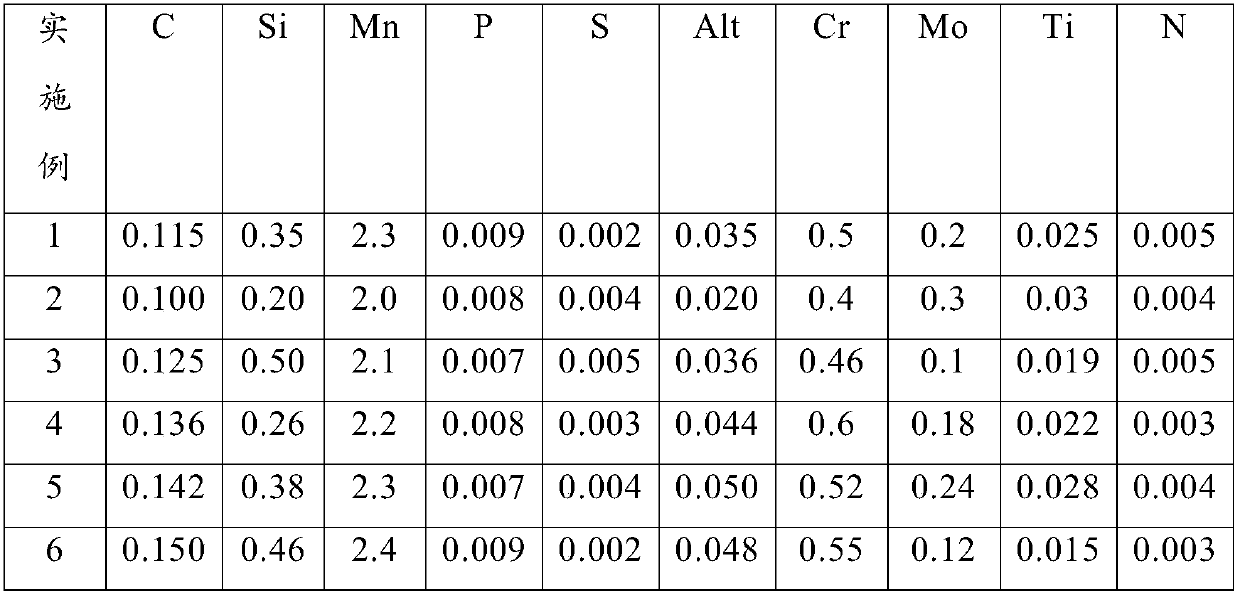

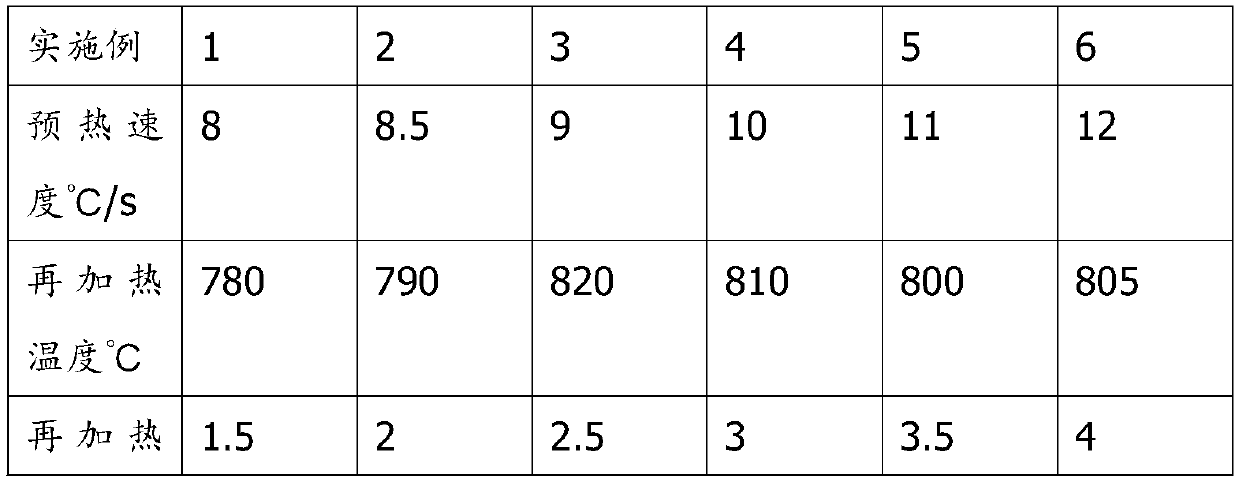

Alloying hot galvanizing dual-phase steel and preparation method thereof

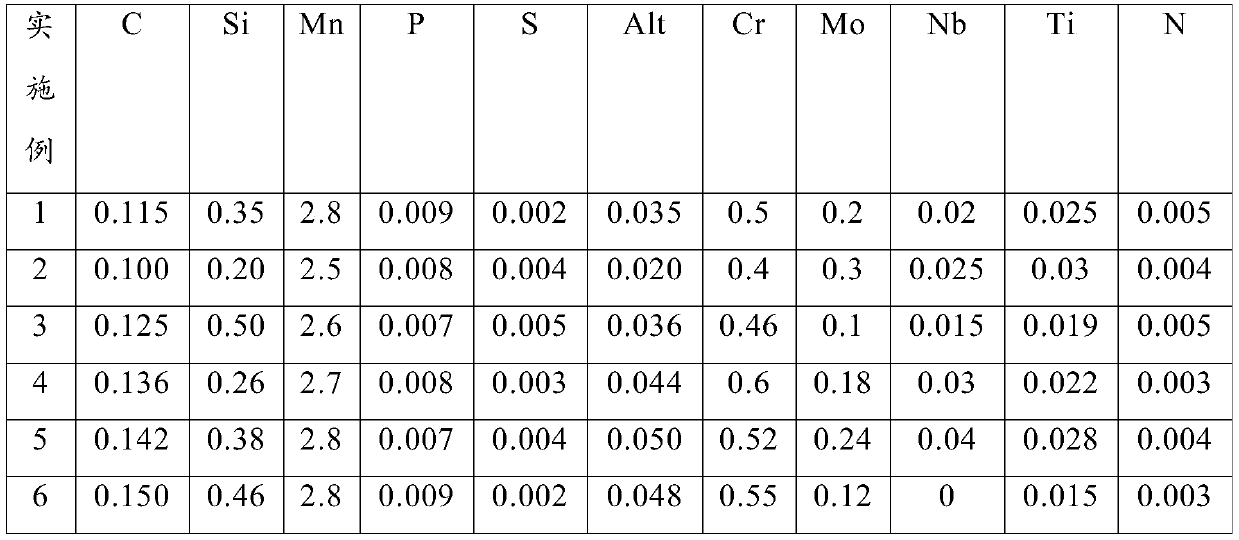

The invention provides alloying hot galvanizing dual-phase steel and a preparation method thereof. The alloying hot galvanizing dual-phase steel comprises, by weight, 0.10%-0.15% of C, 0.2%-0.5% of Si, 2.0%-2.4% of Mn, 0.02%-0.05% of Alt, 0.015%-0.03% of Ti, 0.4%-0.6% of Cr, 0.1%-0.3% of Mo, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.005% of N, andthe balance Fe and microelements. According to the alloying hot galvanizing dual-phase steel, the 980 MPa grade alloying hot galvanizing dual-phase steel is obtained by designing a reasonable alloyingcomponent system and determining a reasonable process method matched with the alloy component system; and the extension ratio and bend property of the alloying hot galvanizing dual-phase steel are improved, and the alloying hot galvanizing dual-phase steel meets the special requirement of automobile parts for processing performance.

Owner:SHOUGANG CORPORATION

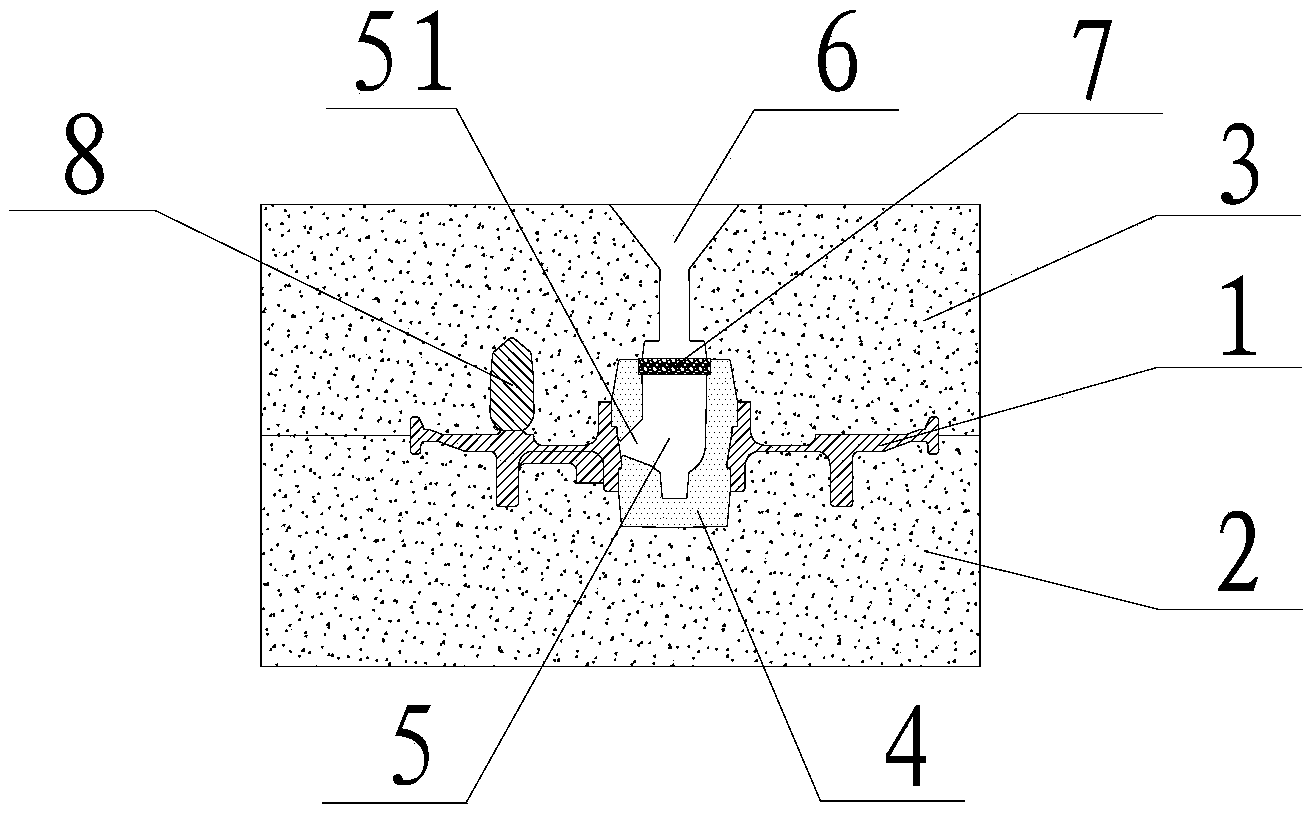

Casting technology capable of reducing hardness difference of traction wheel rope groove face

ActiveCN103464693AReduce hardness differenceLittle difference in temperatureFoundry mouldsFoundry coresHardnessMulti point

The invention relates to a casting technology capable of reducing the hardness difference of a traction wheel rope groove face. The casting technology comprises the following technical steps: manufacturing an upper sand box; manufacturing a lower sand box; making a core; milling a molten iron casting passage; assembling a mould; (f) casting; cleaning. A water inlet is formed in the sand core of an inner cavity in a milling manner, so that a feed head is in multi-point communication with a sand cavity; on one hand, the sand core of the inner cavity is positioned in the center of the cavity, and thus casting molten iron flows in from the middle of the cavity; one the other hand, the feed head is in multi-point communication with a sand cavity, so that the times spent on the molten iron in different directions reaches the same horizontal plane of the rope groove face are the same, the temperatures at the circle of the rope groove face are small in difference and relatively uniform, the subsequent solidification processes are basically the same, the hardness difference of the traction wheel rope groove face is reduced, and the product quality of castings is improved.

Owner:SUZHOU TORIN MACHINERY CASTING

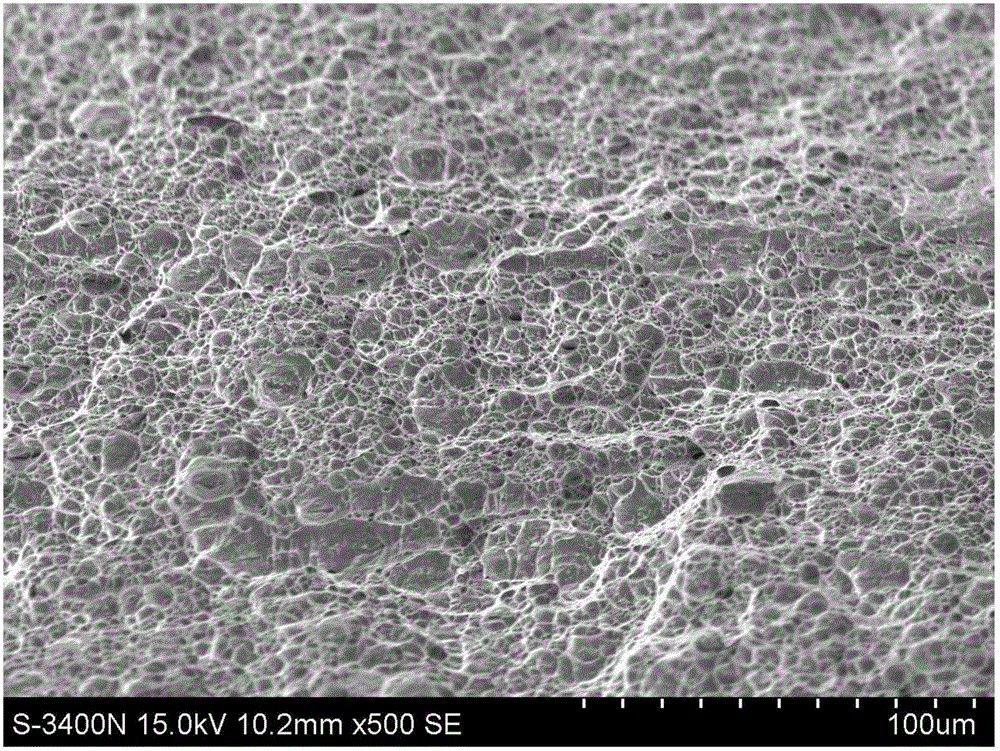

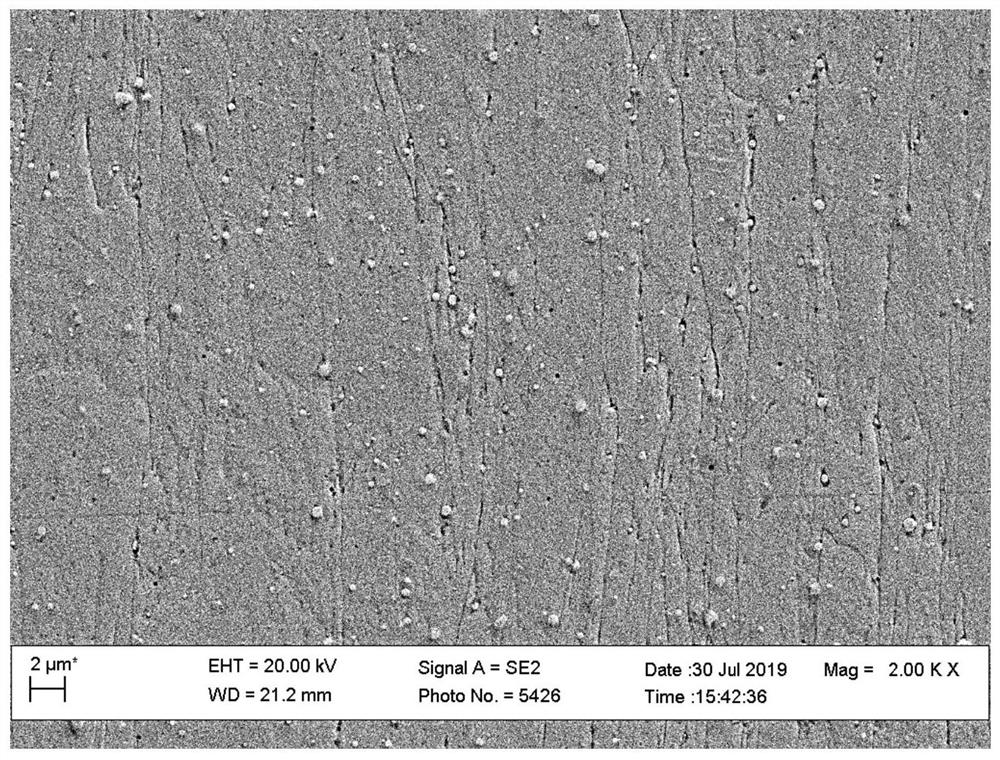

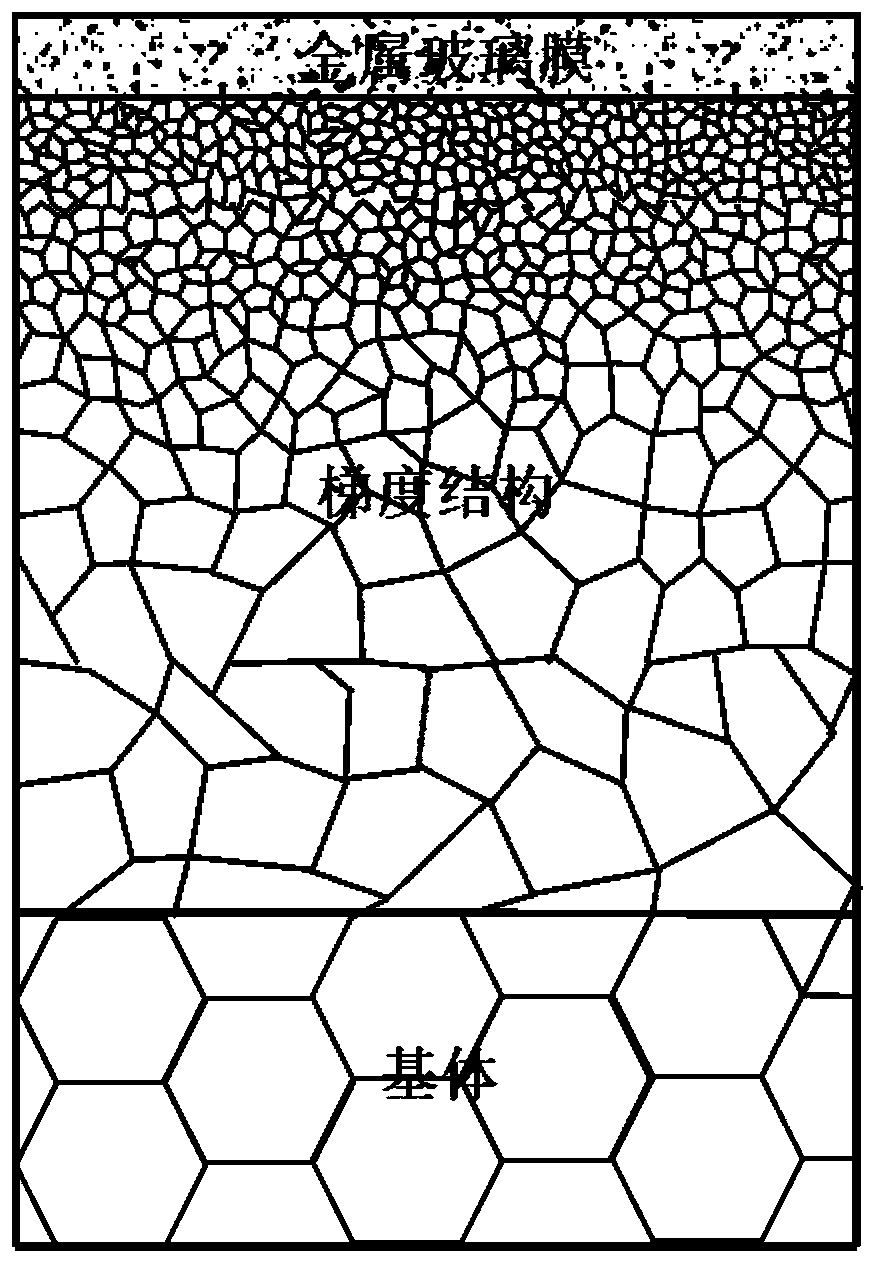

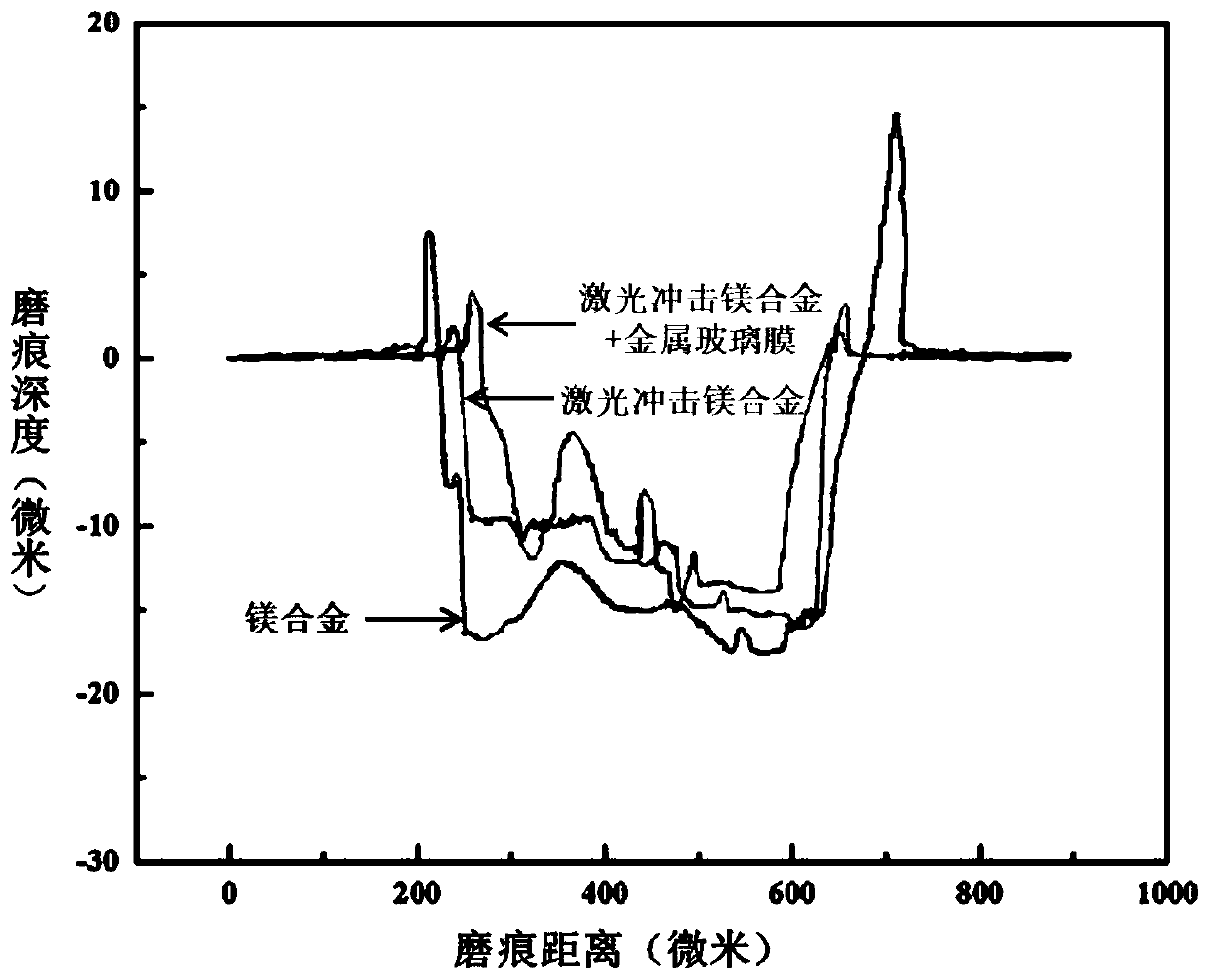

Method for improving corrosion resistance of magnesium alloy through laser shock peening and magnetron sputtering

InactiveCN109750242AImprove wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingShock waveSputtering

The invention relates to the technical field of surface modification of magnesium alloy, in particular to a method for improving the corrosion resistance of magnesium alloy through laser shock peeningand magnetron sputtering. According to the method, the surface of the magnesium alloy is treated through the laser shock peening technique first; after the surface is polished, and a magnesium-based(Mg49Cu33Y18) metallic glass film is deposited on the surface of the magnesium alloy through the magnetron sputtering technique; the surface hardness of the magnesium alloy is greatly improved under the super acting force of laser shock waves, the hardness difference between the magnesium alloy and the metallic glass film is reduced, and the difference between the capacities to bear external forceof the magnesium alloy and the metallic glass film is reduced, so that the binding force between the metallic glass film and the magnesium alloy is improved, and the abrasion resistance of the magnesium alloy is improved; and in addition, because of the amorphous property of the metallic glass film, a corrosive medium can hardly penetrate through the metallic glass film to enter a base body, andthus, the corrosion resistance is improved.

Owner:JIANGSU UNIV

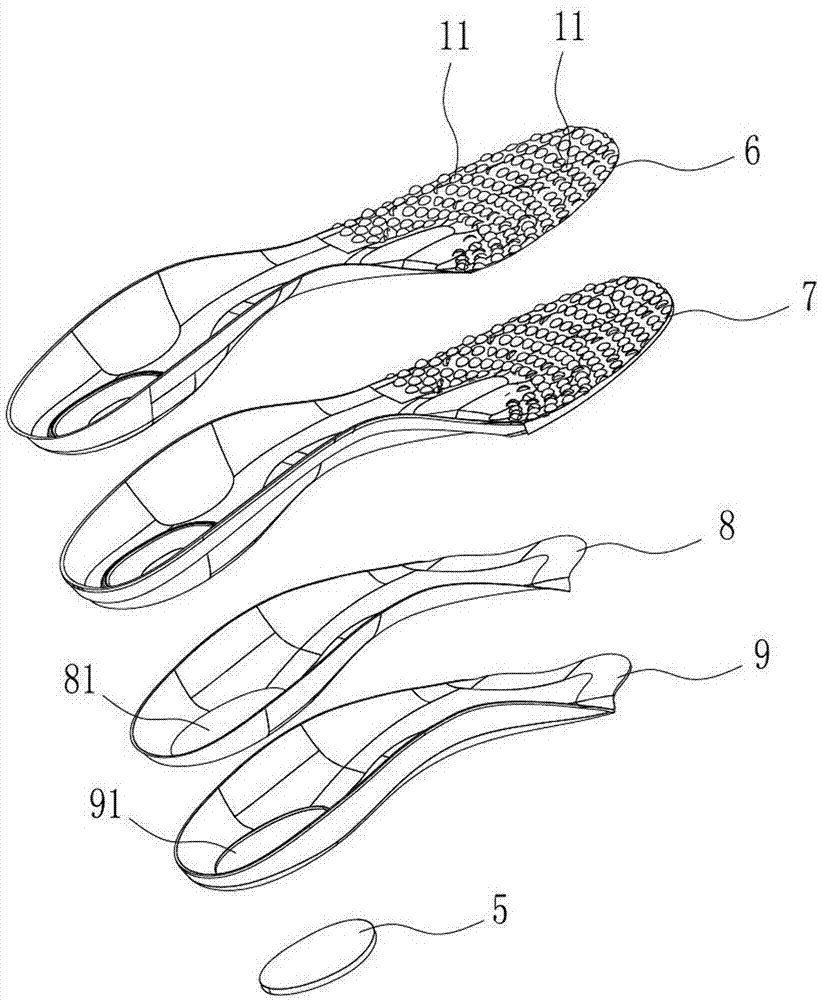

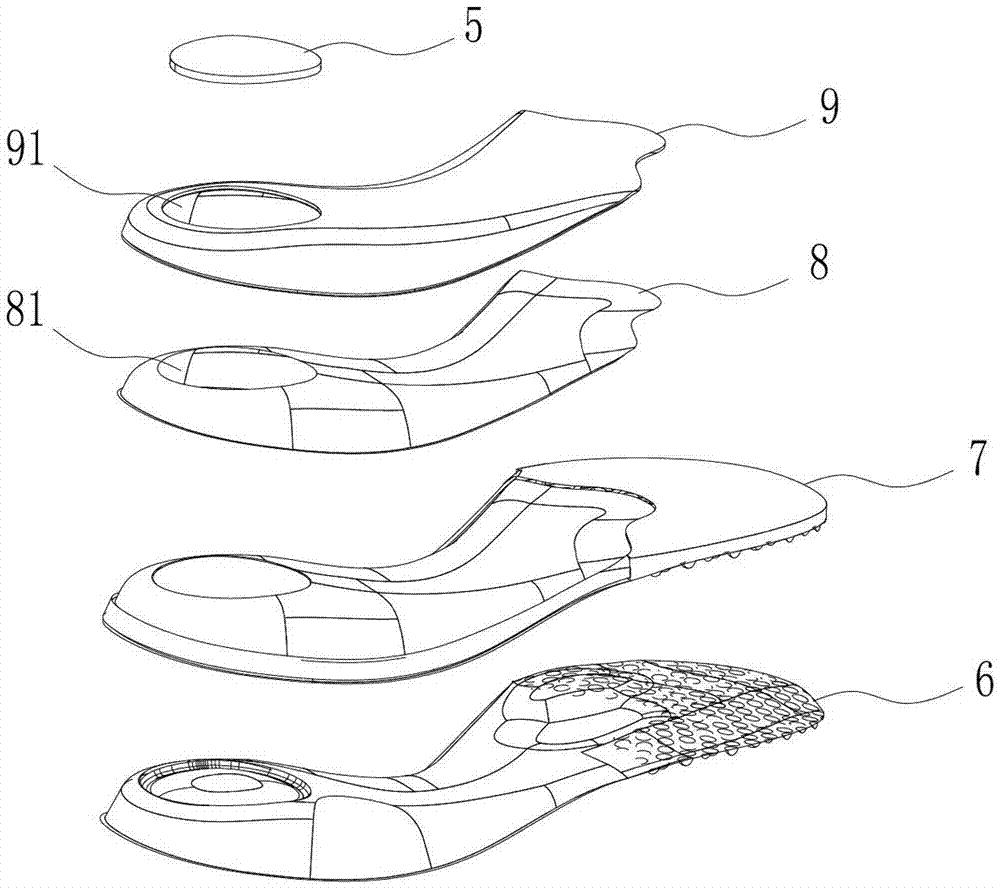

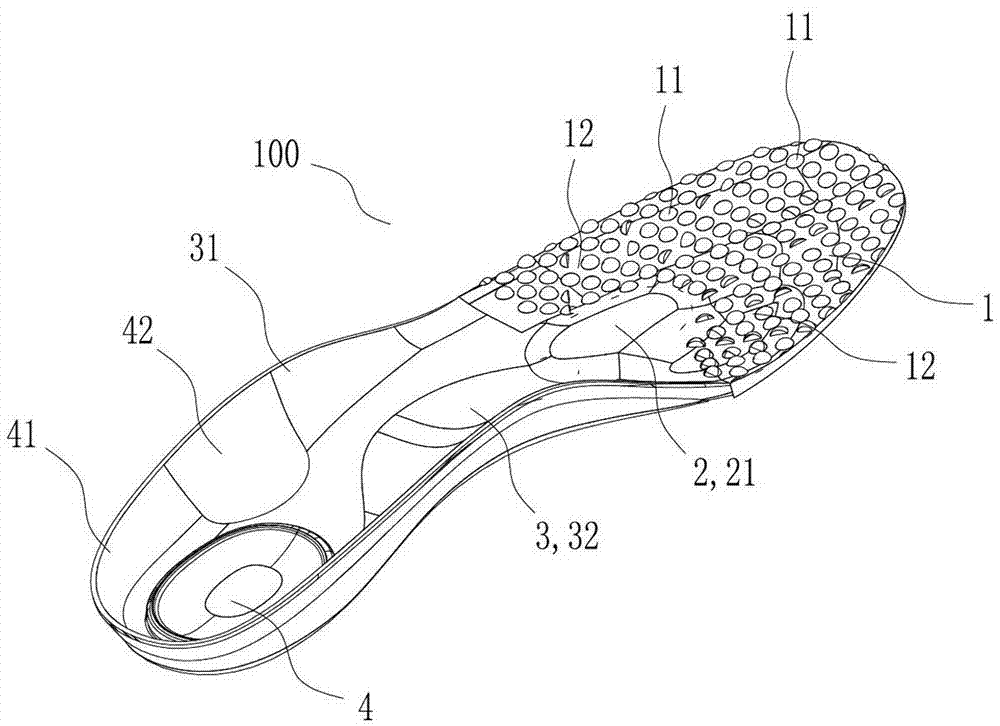

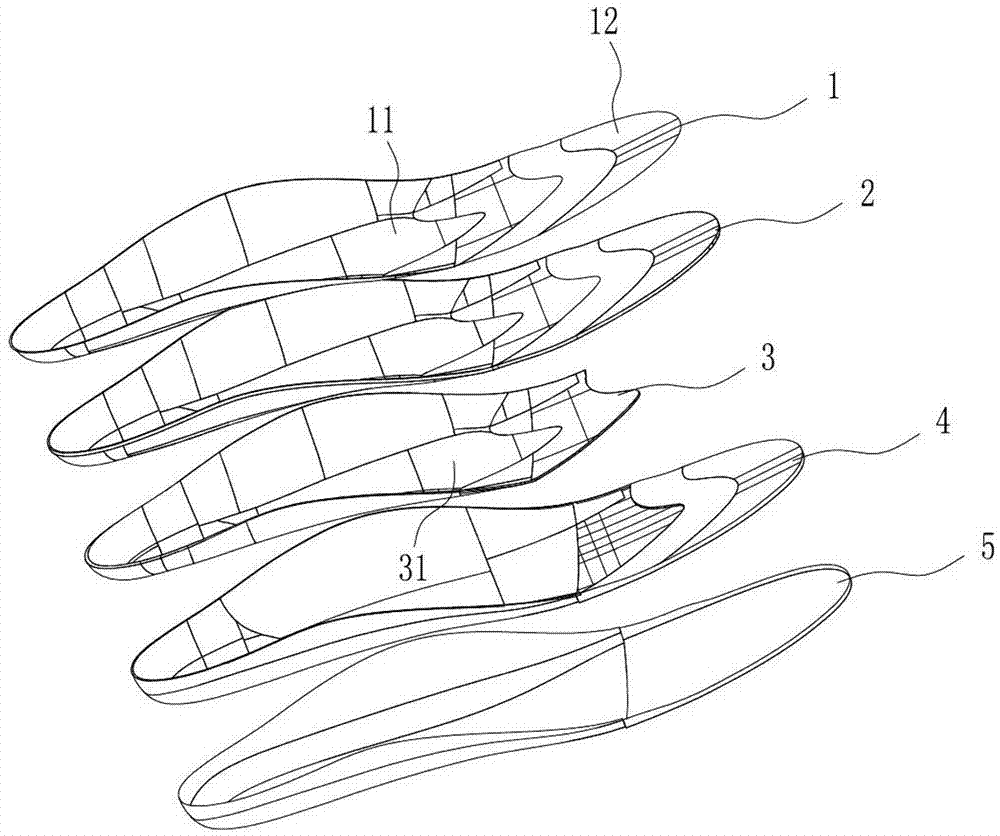

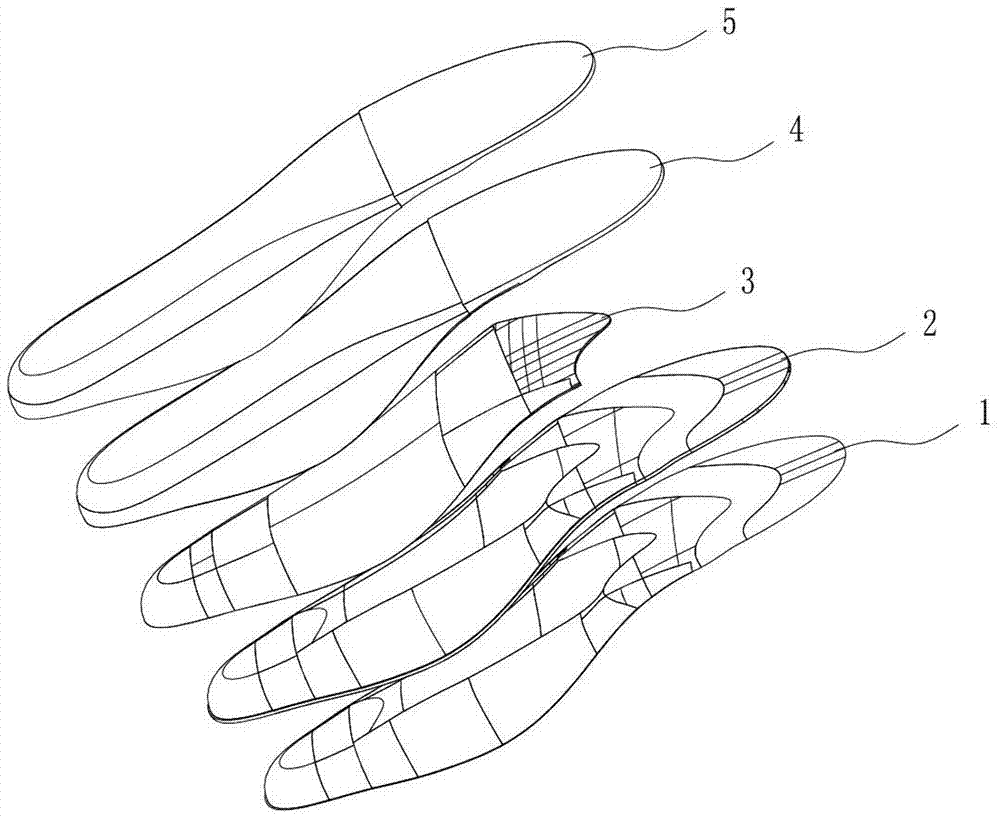

Keep-fit massage sneaker insole

PendingCN107319686AMoisture-absorbing and breathableAntibacterial and antibacterialInsolesMassageEngineering

The invention discloses a keep-fit massage sneaker insole, which comprises an insole main body; the insole main body from a front end to a back end comprises an insole half-sole, an insole center, an insole waist and an insole heel; the upside of the insole half-sole is aligned with 100-200 semispherical convex grains, and the upside of the insole center is provided with an egg type convex body; the outside parts of the insole waist and the insole heel are provided with outer edges warped upwards; the insole waist corresponding to the inside of an arc part of the human body is provided with an arch part; the joint of the insole waist and the insole heel is provided with a bulge part for pressing the outside of the arch part of the human body; the middle lower side of the insole heel is provided with a damping pad. The keep-fit massage sneaker insole has small hardness difference with the sole, is comfortable to wear, strong in damping and foot protecting functions, good in air breathability; the insole has massage and healthcare effects, and can improve flatfoot and straighten sole skeleton; besides, the moulding property is good.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

Low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for kitchen cutter

The invention discloses a low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for a kitchen cutter. The low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is characterized in that the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt comprises the specific components by weight percentage: 0.50-0.60% of C, 0.3-0.7% of Mn, 2.5-3.5% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 9.00-10.00% of Cr, less than or equal to 0.6% of Ni, 0.16-0.32% of V, 0.04-0.08% of N, 0.0008-0.002% of B and the balance of Fe. According to the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for the kitchen cutter, the matrix strength is high; a cutting edge of the cutter has good sharpness, wear resistance and corrosion resistance; and the production cost is low. The low-chromium high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is mainly used for the kitchen cutter and can also be used for the production of shears.

Owner:SHANDONG TAISHAN STEEL GROUP

Alloyed hot dip galvanizing double-phase steel and preparation method thereof

InactiveCN110983198AImprove flexibilityImprove hardenabilityHot-dipping/immersion processesDuctilityTitanium

The embodiment of the invention discloses alloyed hot dip galvanizing double-phase steel. The steel comprises chemical components including, by weight percentage, 0.10%-0.15% of C, 0.2%-0.5% of Si, 2.5%-2.9% of Mn, 0.02%-0.05% of Alt, 0.015%-0.03% of Ti, 0.015%-0.03% of Nb, 0.4%-0.6% of Cr, 0.1%-0.3% of Mo, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of S, smaller than or equal to 0.004% of N, and the balance Fe and inevitable impurity elements. According to the double-phase steel, an alloy component system is designed reasonably, then a reasonable technology method matched with the system is determined, and the 1180MPa-level alloyed hot dip galvanizing double-phase steel is obtained. Ductility and bendability of the alloyed hot dip galvanizing double-phase steel are improved, and thus the steel can meet the special requirement of car parts for machinability.

Owner:SHOUGANG CORPORATION

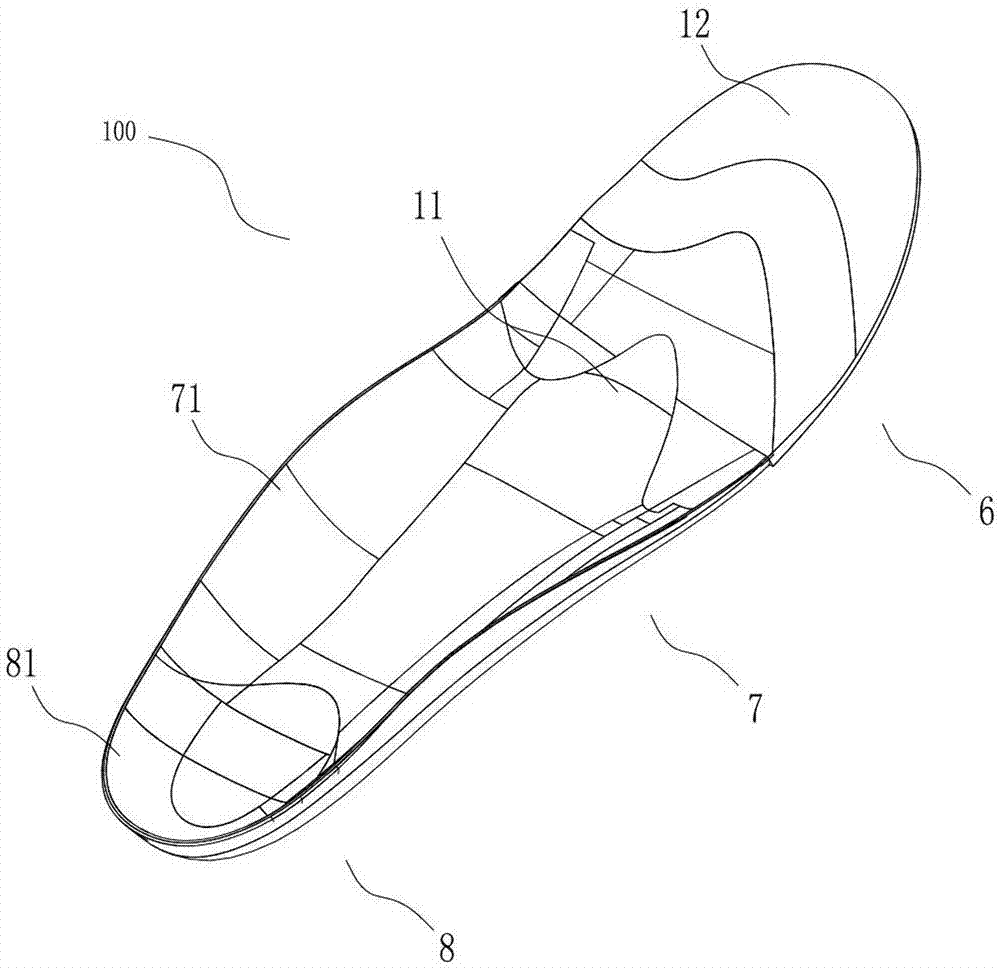

Body shaping insole for smooth and steady growth of teenagers

PendingCN107114860AMoisture-absorbing and breathableAntibacterial and antibacterialInsolesPhysical therapyKnock knees

The invention discloses a body shaping insole for smooth and steady growth of teenagers. The insole comprises an insole body, wherein the insole body comprises a first bamboo charcoal fiber layer, a first polyurethane foamed plastic layer, a cushion pad layer, a second polyurethane foamed plastic layer and a second bamboo charcoal fiber layer from top to bottom sequentially; the cushion pad layer is provided with a bulge part and ejects the first bamboo charcoal fiber layer through the first polyurethane foamed plastic layer, so that an arch bulge area and a toe part recess area are formed on the upper side of the insole body; the insole body comprises an insole forefoot, an insole middle part and an insole heel, and the insole middle part and the insole heel are provided with upwarp outer edges. The difference between hardness of the insole and hardness of sole is small, the insole is beneficial to foot growth of the teenagers, the insole fits a foot stably and is not prone to slip, sports acceleration and shock absorption can be realized, a strong foot protection effect is realized, stress fatigue caused by sports, walking and standing can be relieved, flatfoot can be improved effectively, the sweet and gas discharge effect is good, and knock knees and valgus deformity are prevented and improved effectively.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

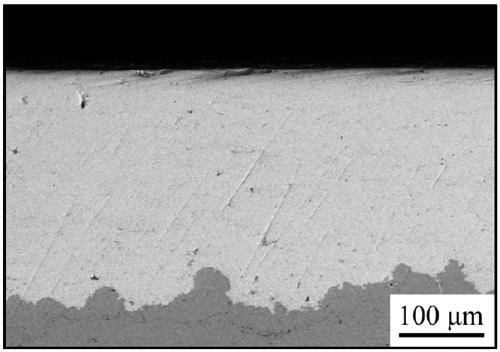

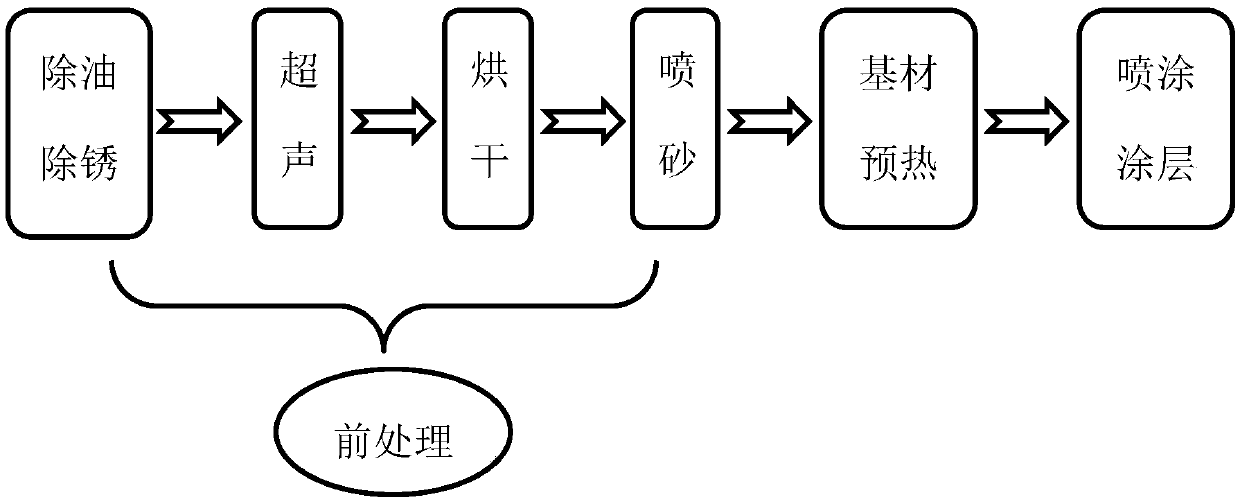

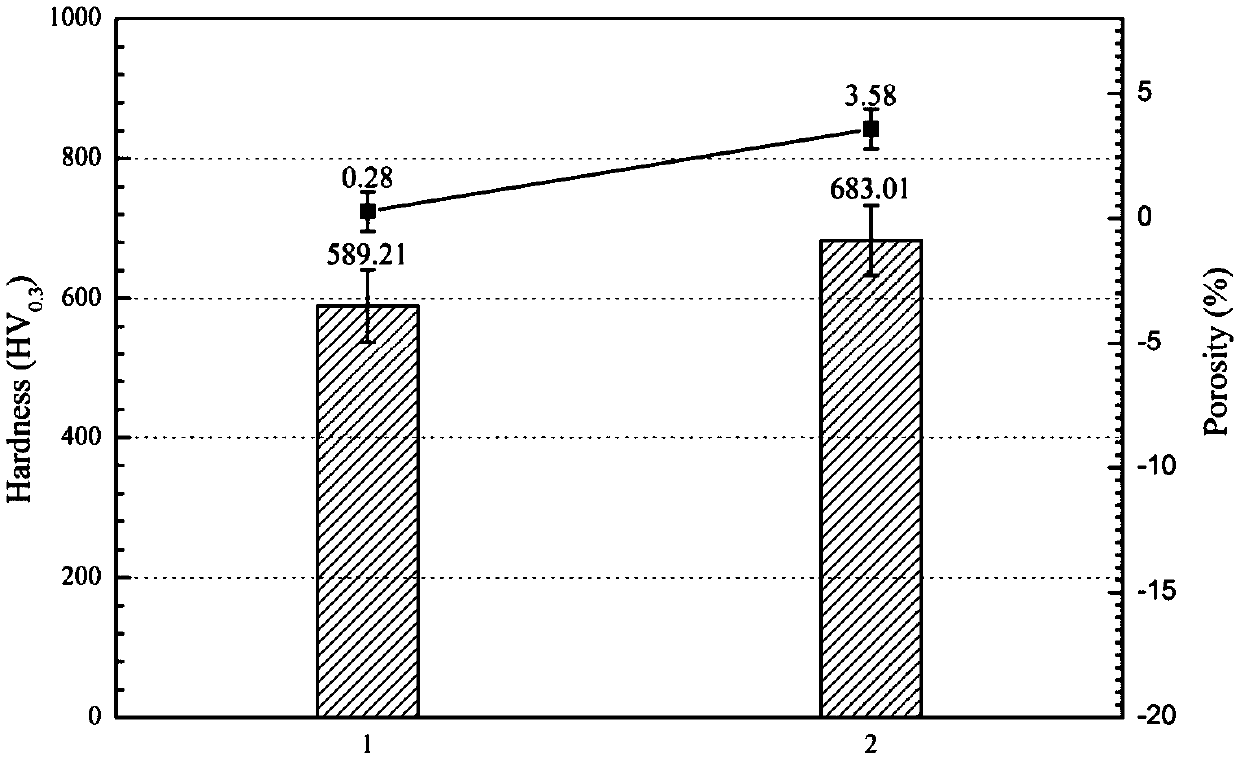

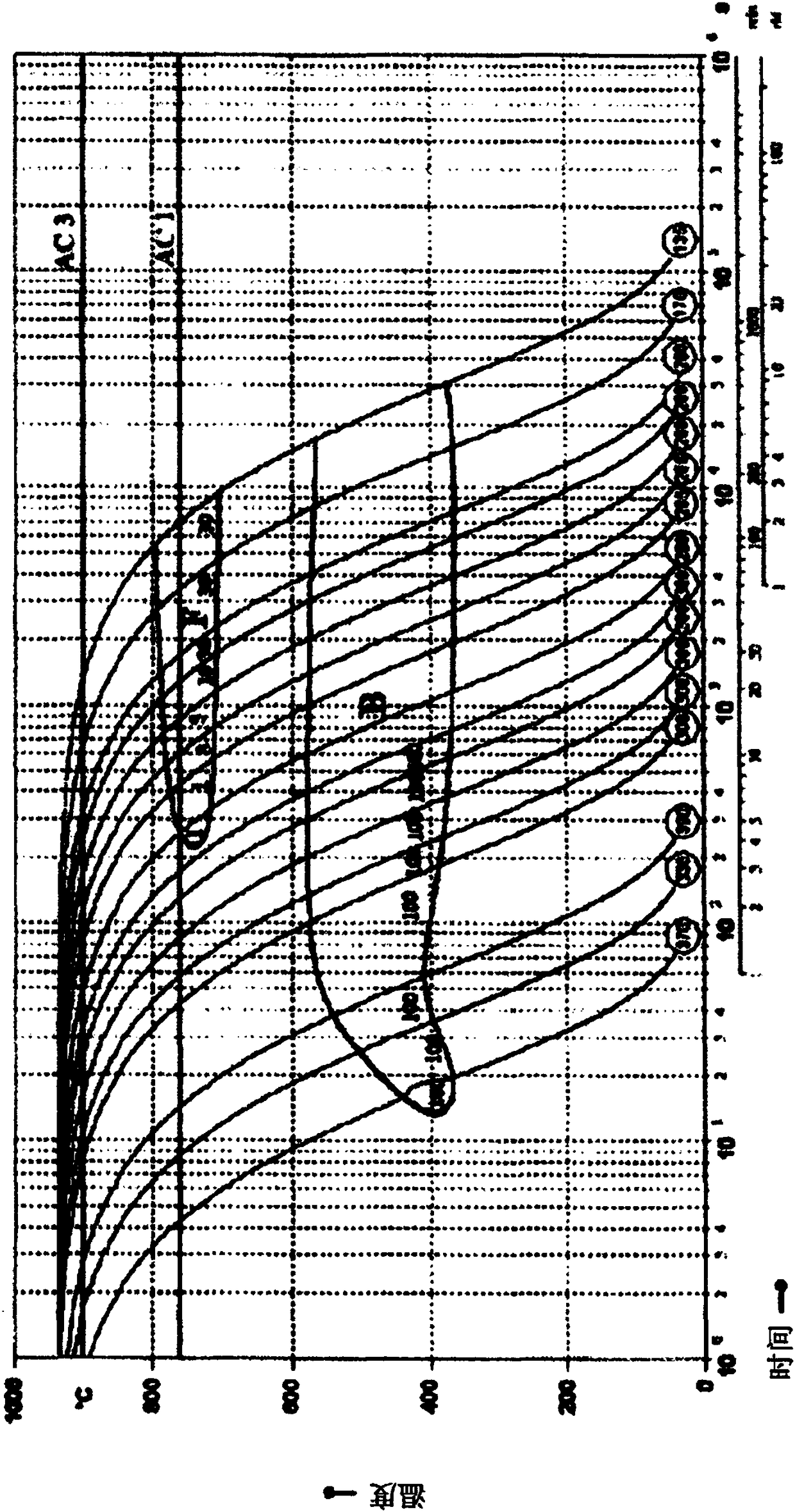

Internal powder feeding type high-energy plasma spraying manufacturing method of refractory metal heavy load wear-proof coating

InactiveCN109518118AImprove densification performanceImprove compactnessMolten spray coatingPorosityThermal spraying

The invention relates to an internal powder feeding type high-energy plasma spraying manufacturing method of a refractory metal heavy load wear-proof coating. Mo powder is used as the raw material ofthe coating, and the coating is obtained on a metal base material by means of an internal powder feeding type high-energy plasma spraying method. By the adoption of the internal powder feeding type high-energy plasma spraying manufacturing method of the refractory metal heavy load wear-proof coating, by means of reasonable thermal spraying technological parameters, the spraying technological process is strictly controlled, so that the porosity of the coating is reduced, the breaking tenacity of the coating is improved, and the comprehensive mechanical property of the coating is greatly improved; the hardness difference between a coated part and a counterpart is small, three-body wear caused under heavy load conditions is avoided, the friction coefficient and wear rate are lowered, the wearresistance is greatly improved, and the service lives of all types of metal parts are effectively prolonged.

Owner:XI AN JIAOTONG UNIV

Transport cylinder and manufacturing method thereof as well as pumping device comprising transport cylinder

ActiveCN102359590AExtended service lifeHigh hardnessCylindersIncreasing energy efficiencyEngineeringHardness

The invention discloses a transport cylinder and a manufacturing method thereof as well as a pumping device comprising the transport cylinder. The manufacturing of the transport cylinder comprises the steps of: forming a first intermediate cylinder block by machining; carrying out high-frequency induction hardening on the internal surface of the first intermediate cylinder block to form a hardening layer on the internal surface of the first intermediate cylinder block so that a second intermediate cylinder block is formed; and plating a chrome coating on the external surface of the hardening layer to form the transport cylinder. By using the method, the hardness of the surface of the cylinder block is improved by high-frequency induction hardening so that the hardness difference between the surface of the cylinder block and the chrome coating plated thereon is diminished, and the thickness of the plated hard chrome coating is diminished simultaneously, thereby lowering interlayer stress between the cylinder block surface and the chrome coating and the innerstress and friability of the plated coating, in turn, lowering the cracking ratio of the chrome coating on the transport cylinder surface and decreasing the abscission of the hard chrome coating so as to prolong the service life of the transport cylinder. Meanwhile, the high-frequency induction hardening process has high efficiency and low cost, and is beneficial to industrial production and environmental conservation; and by adopting the process, the thickness of the hard chrome coating is decreased, and plating cost islowered.

Owner:ZOOMLION HEAVY IND CO LTD

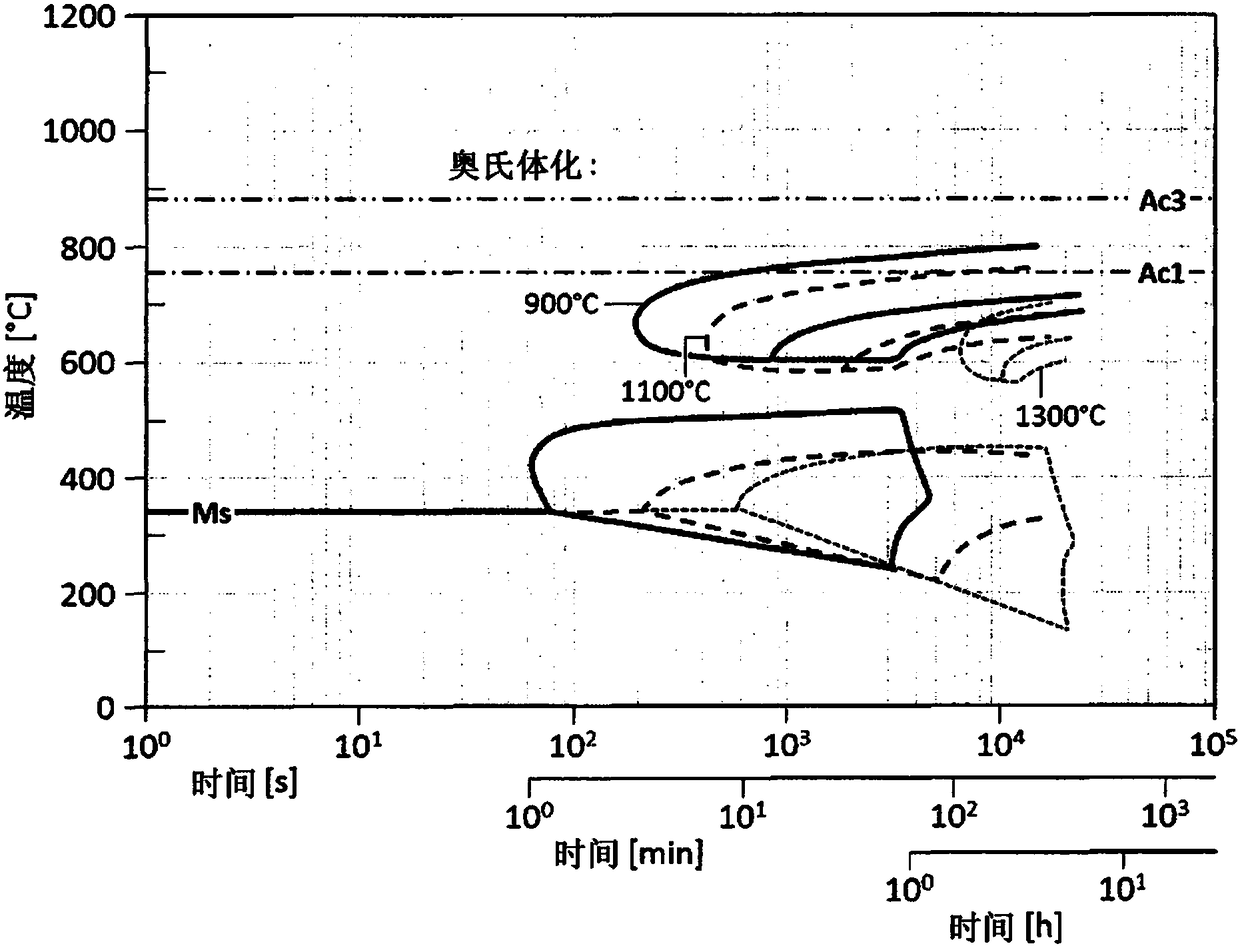

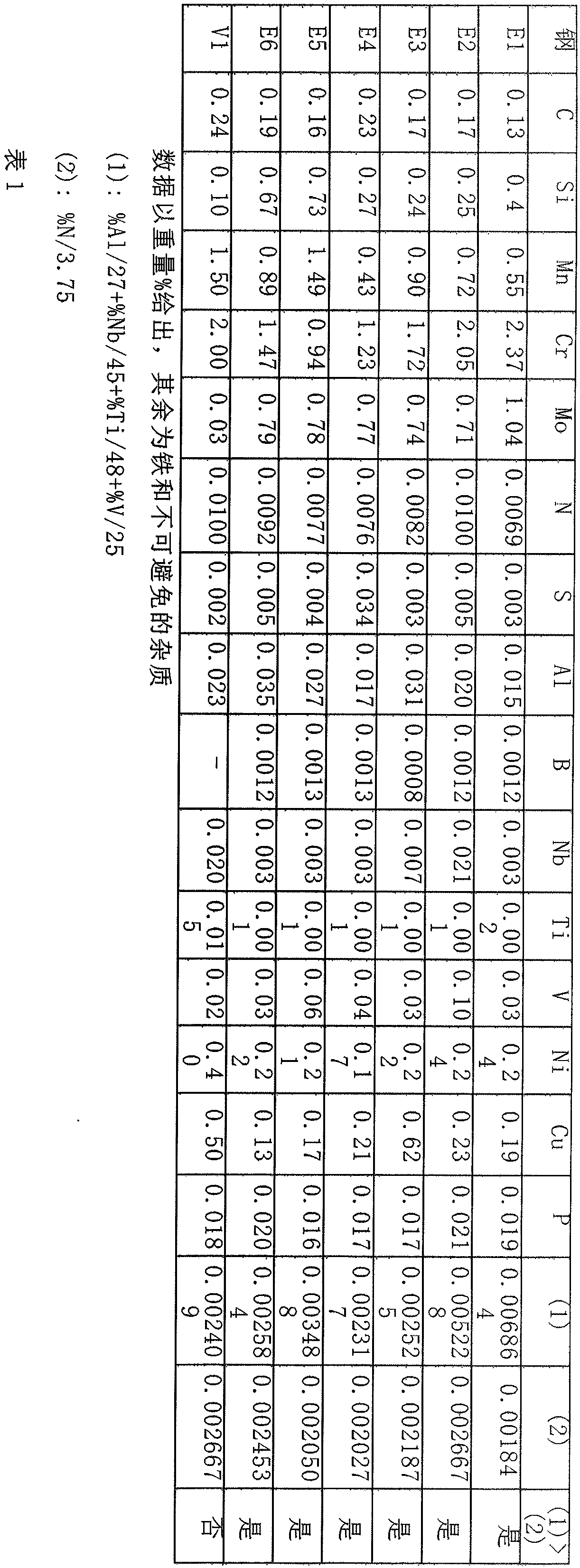

High-grade structural steel with bainitic structure, forged part produced therefrom and method for producing a forged part

The invention provides a steel, which has a high strength, without complex heat treatment processes having to be performed for this purpose, and at the same time has a low tendency to warp. For this purpose, the high-grade structural steel according to the invention consists of (in % by weight) up to 0.25% C, up to 0.45% Si, 0.20-2.00% Mn; up to 4.00% Cr, 0.6-3.0% Mo, 0.004-0.020% N, up to 0.40% S, 0.001-0.035% Al, 0.0005-0.0025% B, up to 0.015% Nb, up to 0.01% Ti, up to 0.10% V, up to 1.5% Ni and up to 2.0% Cu, the remainder iron and unavoidable impurities, wherein the Al content %Al, the Nbcontent %Nb, the Ti content %Ti, the V content %V and the N content %N of the high-grade structural steel respectively meet the following condition: %Al / 27 + %Nb / 45 + %Ti / 48 + %V / 25 > %N / 3.75. The high-grade structural steel according to the invention has a yield strength of at least 750 MPa, a tensile strength of at least 950 MPa and an organization structure which consists at least 80% by volumeof bainite and in total at most 20% by volume of residual austenite, ferrite, pearlite and / or martensite. On account of its combination of properties, the steel according to the invention is suitablein particular for the production of forged parts with great changes in cross section over its length. The invention also discloses a method for producing such forged components.

Owner:DEUTSCHE EDELSTAHLWERKE GMBH

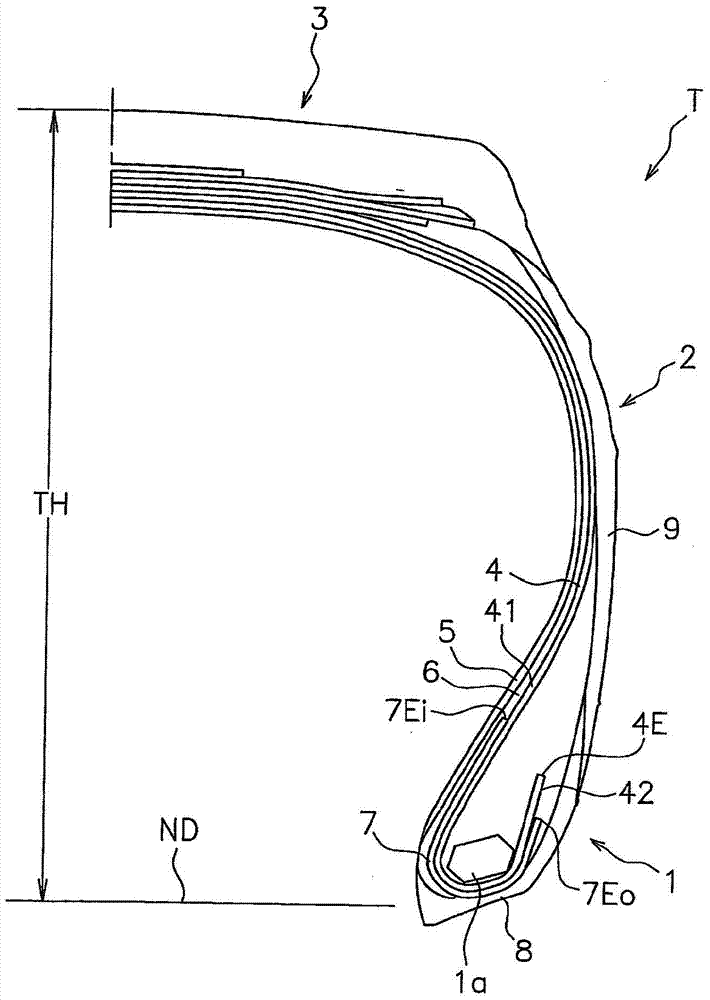

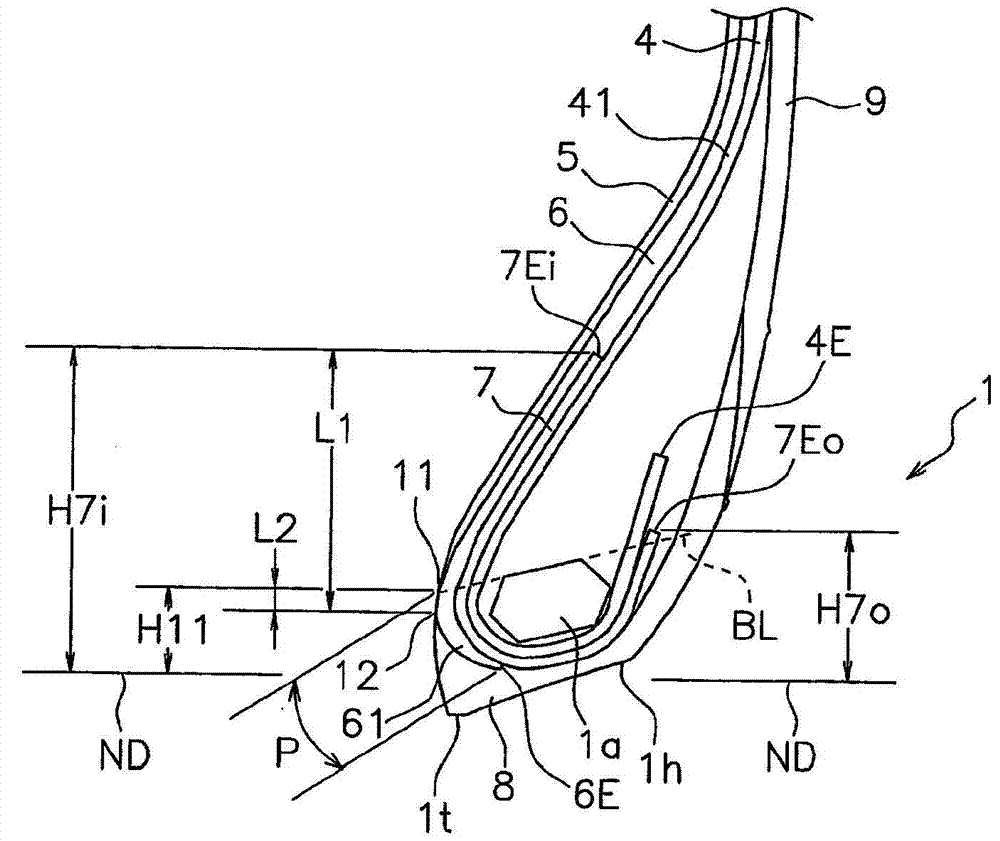

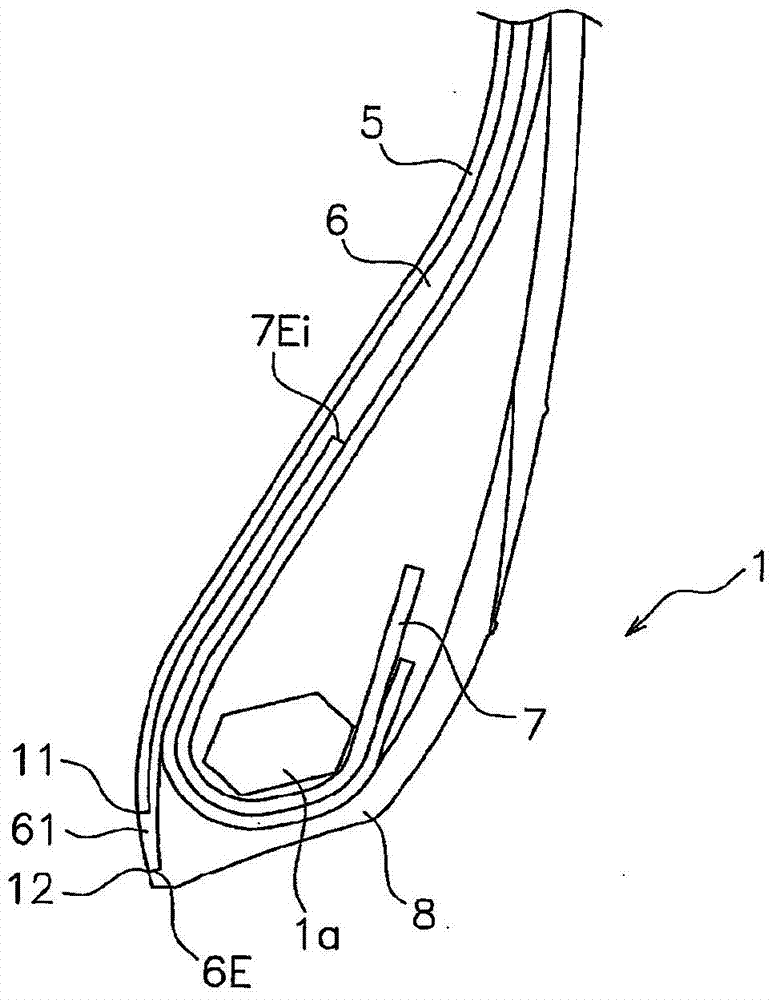

Pneumatic tire

ActiveCN103660807AReduce hardness differenceHigh affinityTyre beadsEngineeringMechanical engineering

The invention provides a pneumatic tire with improved anti-fracturing performance of the tire inner face of a tire ring part. The solution is that isolation glue (6) contacting with the outer surface of the inner bushing rubber (5) is provided with an extending part (61) that is more adjacent to the radial inner V side of the tire than the inner bushing rubber (5) and extends. Cord thread chafer (7) arranged along the cord fabric layer (4) on the periphery of the tire ring core (1a) is provided with an end part (7Ei) between the cord fabric layer (4) and the isolation glue (6). Rigidity difference of the rubber chafer forming the bottom face of the chafer and the isolation glue (6) is within 5 degrees. An interface (11) of the inner bushing rubber (5) and the isolation rubber (6) is exposed out of the tire inner face. An interface (12) of the isolation glue (6) and the rubber chafer (8) is more adjacent to the radial inner side of the tire relative to the end part (7Ei) of the cord thread chafer (7) and is exposed on the inner face of the tire and the extending part (61) is exposed out of the inner face of the tire between the interface (11) and the interface (12).

Owner:TOYO TIRE & RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com