Dual phase steel with tensile strength of 1000 MPa and production method thereof

A technology of tensile strength and production method, applied in the field of steel materials, to achieve the effects of preventing hydrogen embrittlement, reducing alloy cost, improving hole expansion performance and delayed fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In order to solve the technical problem in the prior art that the steel strength requirements and the material's hole expansion performance and delayed fracture resistance cannot be satisfied at the same time, the application provides a dual-phase steel with a tensile strength of 1000 MPa.

[0036] The chemical composition of the dual-phase steel is by weight percentage:

[0037] C: 0.08% to 0.11%; Si: 0.2% to 0.6%; Mn: 2.0% to 2.5%; P: ≤0.01%; S: ≤0.01%; Al: 0.02% to 0.06%; Cr: 0.4% to 0.6 %; Ti: 0.02%-0.05%; N: ≤0.003%, the rest is Fe and unavoidable impurities.

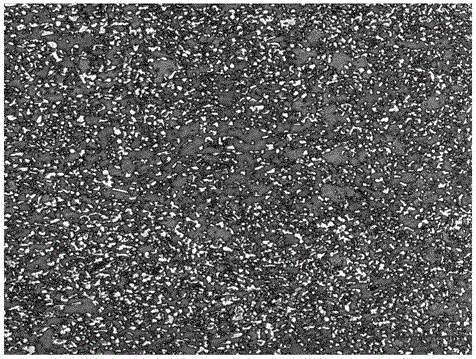

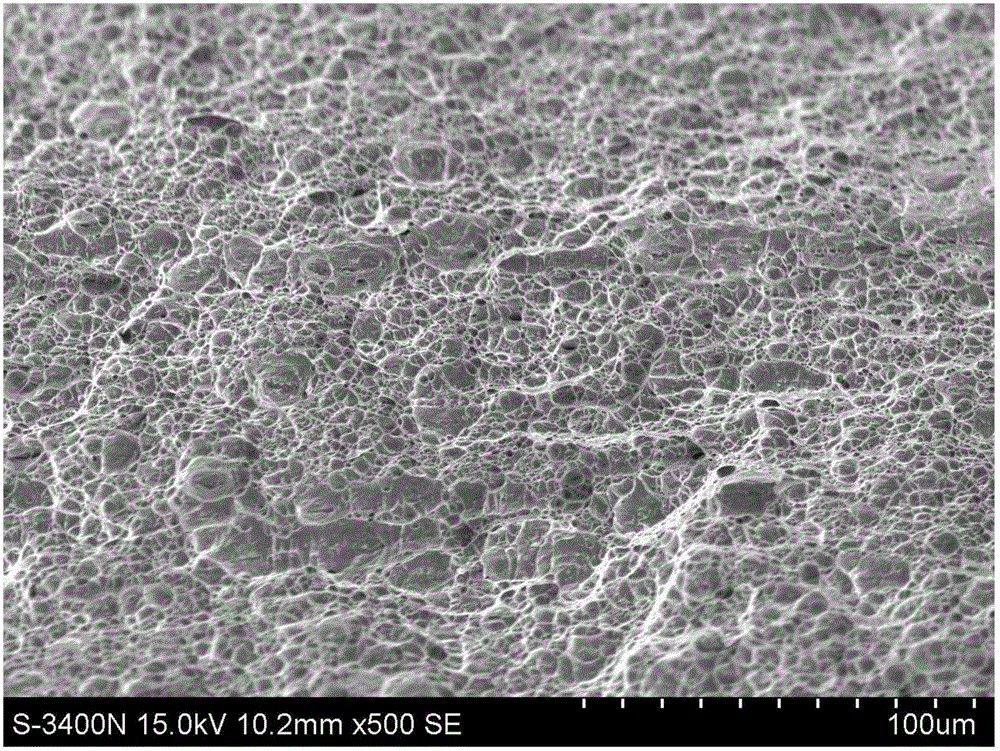

[0038] The metallographic structure diagram of the dual-phase steel with a tensile strength of 1000MPa and the metallographic structure diagram of the TiC nano-precipitated phase of the dual-phase steel sample with a tensile strength of 1000MPa, such as figure 1 and Figure 4 shown.

[0039] The functions and limits of the above-mentioned main alloying elements are as follows:

[0040] Carbon C: Carbon i...

Embodiment 2

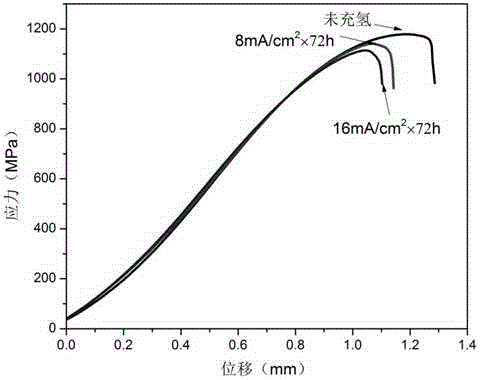

[0058] Based on the same inventive concept, the present application also provides a method for producing a dual-phase steel with a tensile strength of 1000 MPa, which is used to produce the dual-phase steel with a tensile strength of 1000 MPa in Example 1. Such as Figure 5 As shown, the production method of the dual-phase steel with a tensile strength of 1000MPa, please refer to Figure 5 , the production method comprises the following steps:

[0059] In step 110, the molten steel is smelted and cast into continuous casting slabs.

[0060] Specifically, the molten steel is smelted and cast into a continuous casting slab, specifically, the molten steel is smelted in a converter, and the steel is cast in a continuous casting manner. The molten steel is the above-mentioned molten steel of the dual-phase steel with a tensile strength of 1000 MPa.

[0061] Step 120, hot rolling the continuous cast slab to obtain a hot rolled plate.

[0062] Specifically, the heating temperatur...

example 1

[0075] In Example 1, a 220-ton converter is used for smelting. The target thickness of the hot-rolled steel plate is 4 mm, and the cold-rolled thickness is 1.5 mm. The specific steps of smelting are:

[0076] S1: Smelt molten steel and cast it into continuous casting slabs; strictly control the content of P and S during the smelting process to ensure the quality of casting slabs. The chemical composition of the slab is as follows: calculated by mass percentage C: 0.095wt%; Si: 0.35wt%; Mn: 2.3wt%; P: 0.007wt%; S: 0.005wt%; Al: 0.0035wt%; wt%; Ti: 0.027wt%; N: 0.0027wt%, the rest is Fe and unavoidable impurities.

[0077] S2: Hot rolling the continuous casting slab to obtain a hot rolled plate; the heating temperature of the hot rolling is 1250°C, the finishing temperature of the hot rolling is 873°C, and the coiling temperature of the hot rolling is 669°C. The thickness of the steel plate after hot rolling was 4 mm.

[0078] S3: cold-rolling the hot-rolled sheet to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com