Process for producing high-strength hot-dip galvanized steel sheet with excellent material-quality stability, processability, and deposit appearance

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of chemical instruments and methods, manufacturing tools, metal material coating technology, etc., which can solve problems such as increased deviation, decreased mass production efficiency, and poor shape, and achieves high ductility , The effect of high utilization value and high hole expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

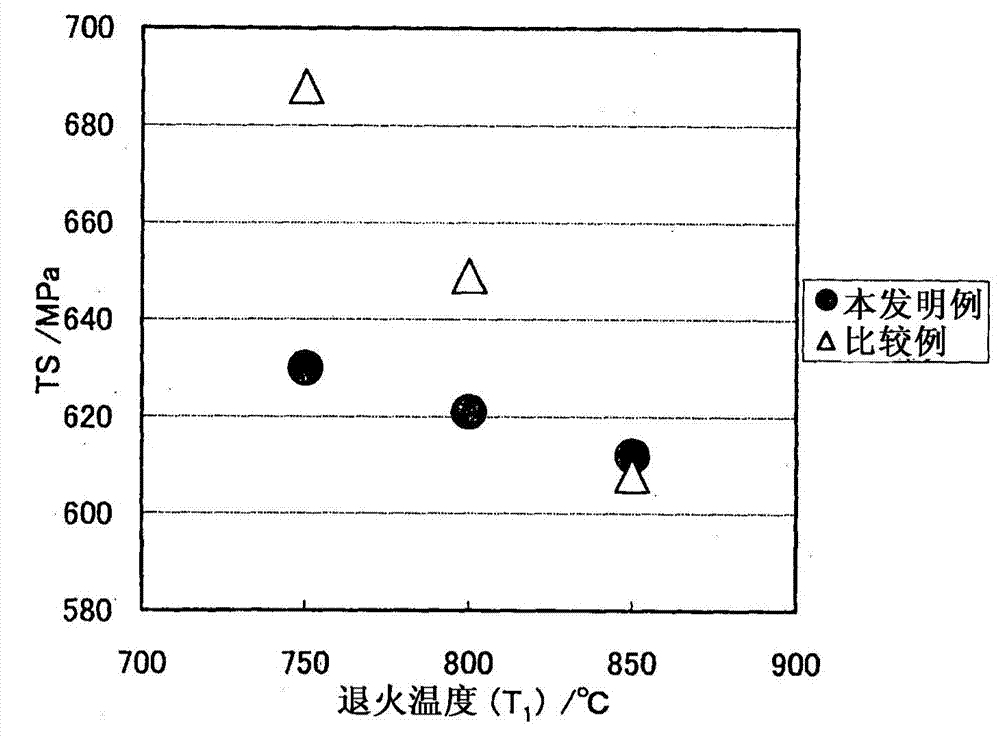

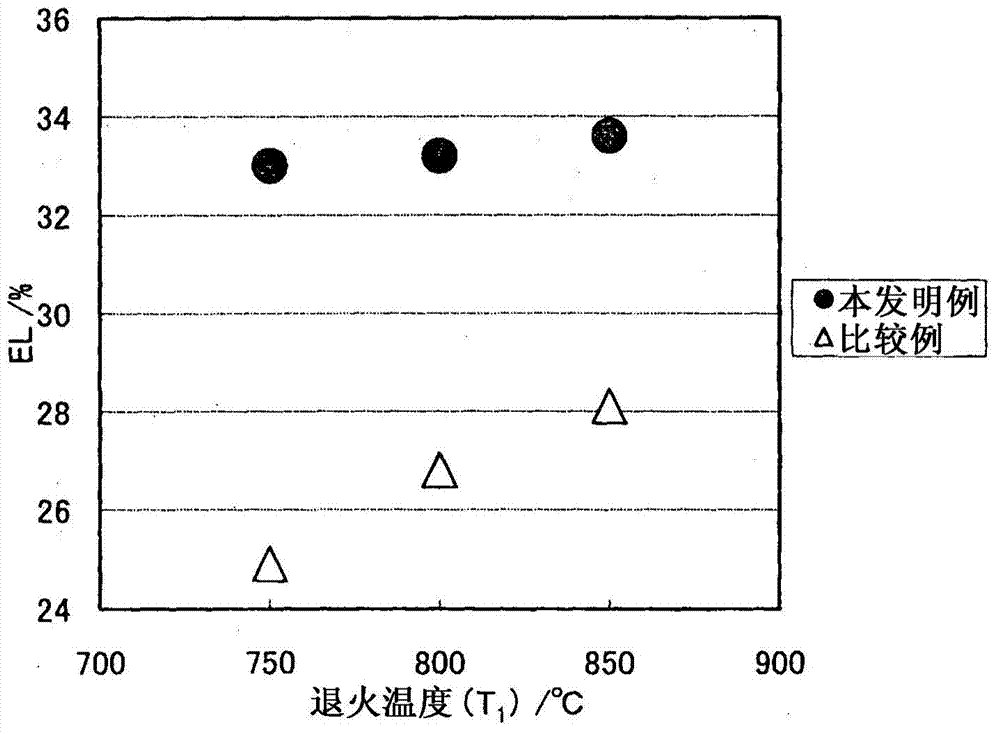

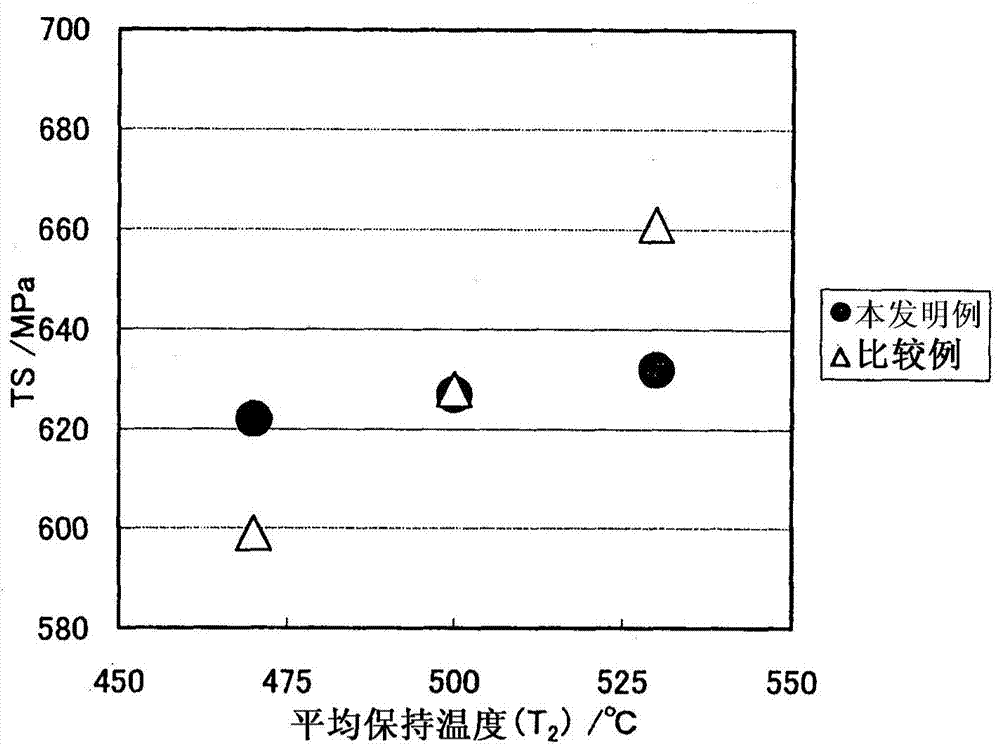

[0119] Steel having the composition shown in Table 1 with the balance consisting of Fe and unavoidable impurities was melted in a converter and cast into billets by continuous casting. The obtained slab was heated to 1200°C, hot rolled at a finish rolling temperature of 870 to 920°C to a plate thickness of 3.2 mm, and coiled at 520°C. Next, the obtained hot-rolled sheet is pickled to produce a hot-rolled steel sheet. A part is directly made into hot-rolled steel plate after pickling, and the rest is further subjected to cold rolling to be made into cold-rolled steel plate. Next, using a continuous hot-dip galvanizing line, under the manufacturing conditions shown in Tables 2 to 4, the pickled hot-rolled steel sheet and cold-rolled steel sheet obtained above are annealed, hot-dip galvanized, and then coated. Alloying treatment to obtain hot-dip galvanized steel sheets (hot-dip galvanized materials for cold-rolled steel sheet substrates: No. 1 to 90, hot-dip galvanized material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com