Alloying hot galvanizing dual-phase steel and preparation method thereof

An alloying and hot-dip galvanizing technology is applied in the field of cold-rolled hot-dip galvanized steel, which can solve the problems of reducing the cooling rate, hindering the cooling process of strip steel, and unable to obtain martensite equality, so as to improve hardenability and bendability. , the effect of improving elongation and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention solves the defects of the existing hot-dip galvanized dual-phase steel in mechanical properties and preparation methods by providing an alloyed hot-dip galvanized dual-phase steel and a preparation method thereof.

[0034] In order to solve the above problems, the main ideas of the embodiments of the present invention are:

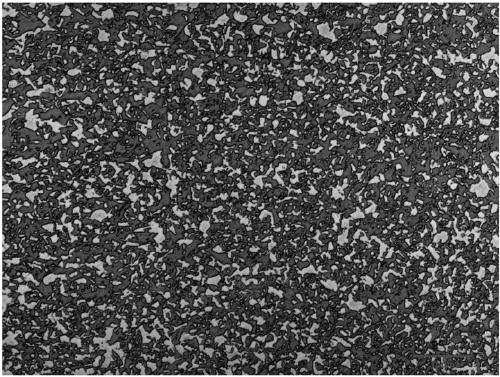

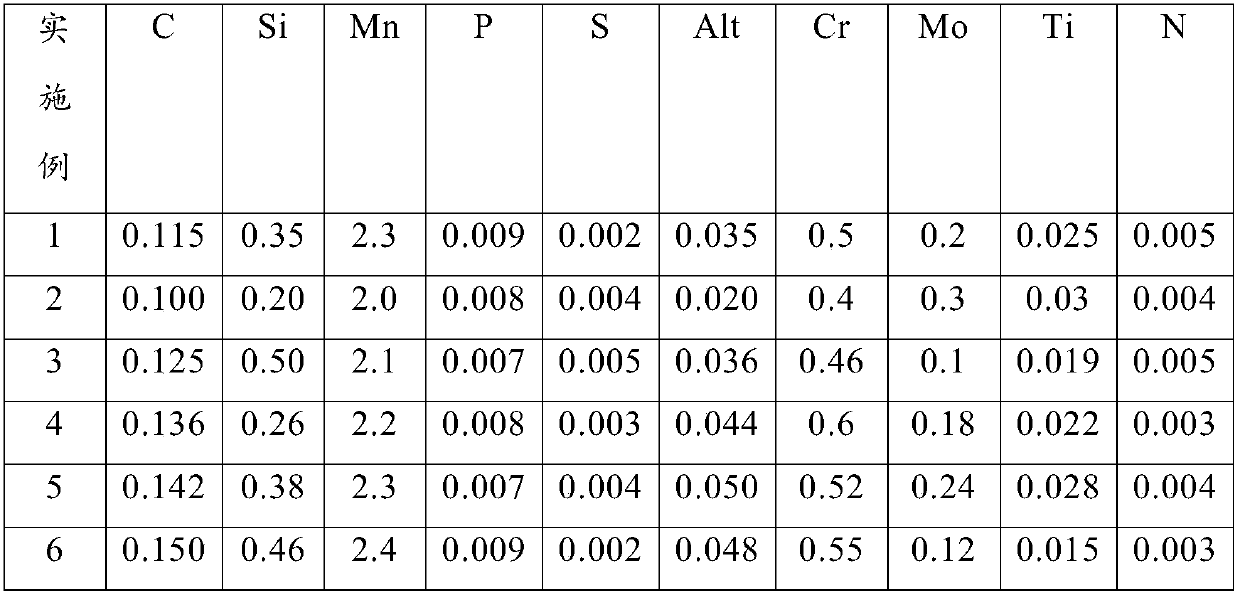

[0035] The alloyed hot-dip galvanized dual-phase steel in the embodiment of the present invention includes the following chemical components in weight percent:

[0036] C: 0.10% to 0.15%, Si: 0.2% to 0.5%, Mn: 2.0% to 2.4%, Alt: 0.02% to 0.05%, Ti: 0.015% to 0.03%, Cr: 0.4% to 0.6%, Mo: 0.1%~0.3%, P≤0.01%, S≤0.01%, N≤0.005%, the balance is Fe and trace elements.

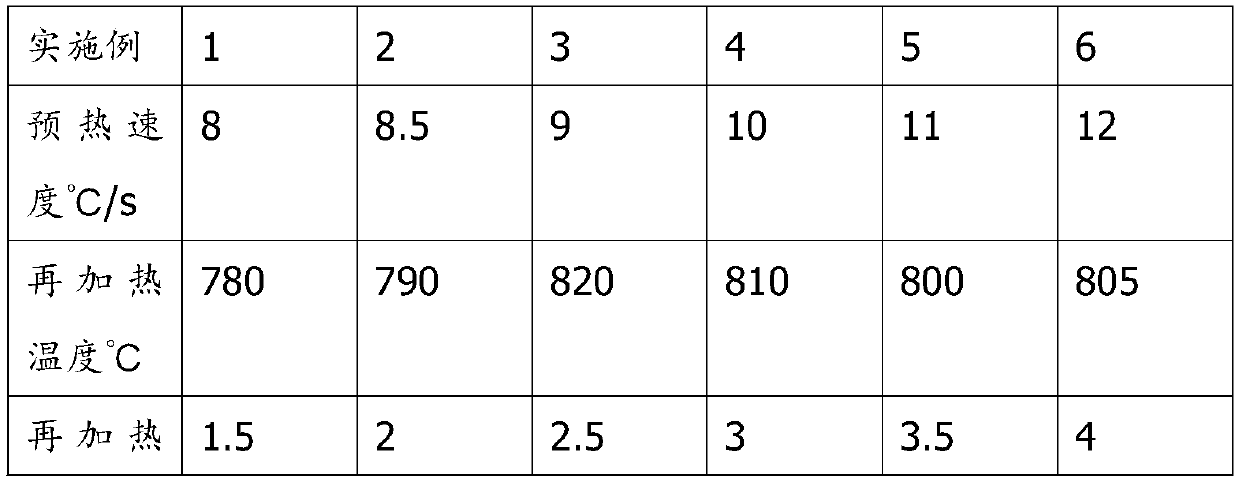

[0037] The embodiment of the present invention can prepare alloyed hot-dip galvanized dual-phase steel through a conventional continuous annealing production line, for example, including the following steps:

[0038] After the molten steel is smelted in a converter, a slab ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com