High-strength hot-dip galvanized steel sheet and process for producing same

一种热浸镀锌钢板、制造方法的技术,应用在热浸镀工艺、制造工具、化学仪器和方法等方向,能够解决C浓度测定困难等问题,达到耐氢脆性及弯曲性优良、弯曲性优良、耐氢脆性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0057] Hereinafter, the first embodiment of the present invention will be described in detail.

[0058] First, the reason for limiting the composition of the steel sheet will be described. In addition, in this invention, unless otherwise specified, % means mass %.

[0059] (steel plate composition)

[0060] C is an essential element when it is intended to increase the strength of a steel sheet by strengthening the structure of martensite or retained austenite. The reason why the C content is specified as 0.05% or more is because: when C is less than 0.05%, it is difficult to use spray or jet water as a cooling medium to perform rapid cooling from the annealing temperature in a hot-dip galvanizing line, and it is easy to generate bleed. Carbon body or pearlite, it is difficult to ensure the necessary tensile strength. In order to achieve a high strength of 770 MPa or more more stably, it is more preferable to make the amount of C more than 0.08%, and it is more preferable to...

Embodiment 1

[0112] Hereinafter, the present embodiment will be specifically described by way of examples.

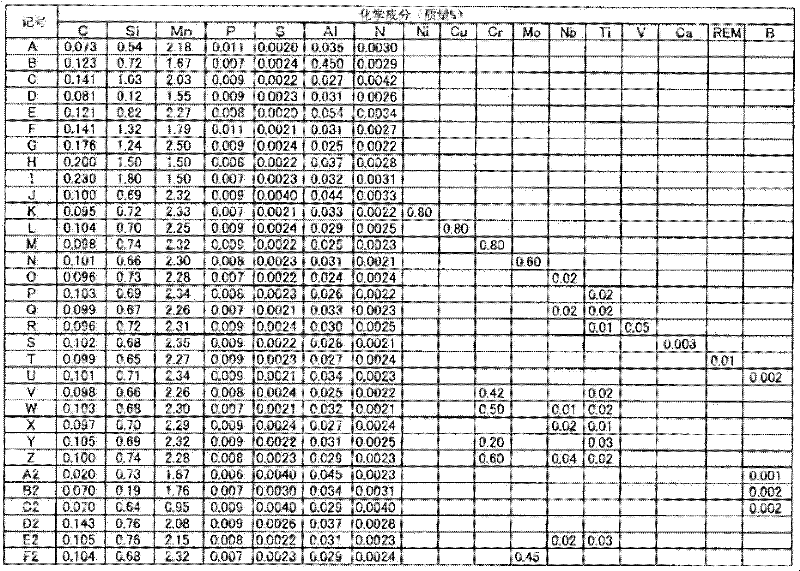

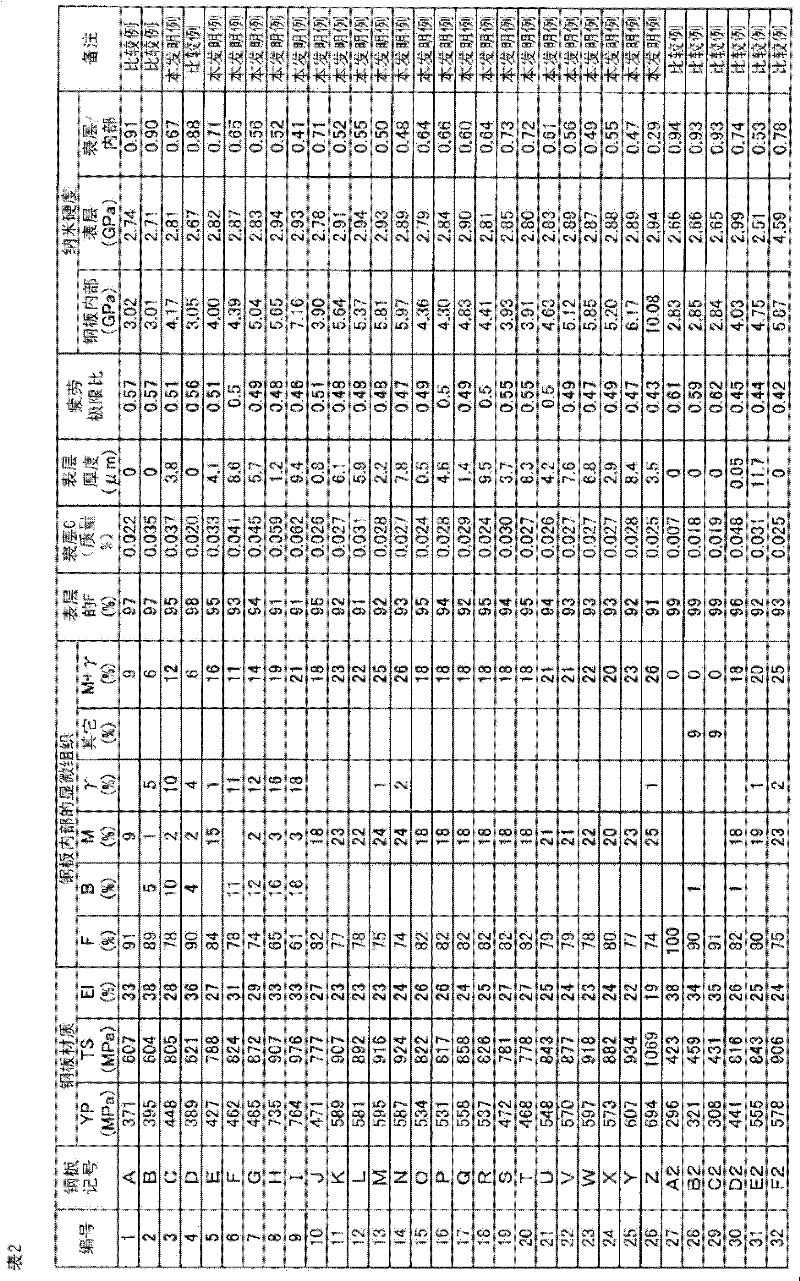

[0113] Continuous casting was carried out using a continuous casting facility equipped with an electromagnetic brake and a wire supply device for alloy addition in the casting mold to obtain steels with the compositions shown in Table 1. The electromagnetic force of the electromagnetic brake is set to 0.1 to 1.0T, and Fe wire is used as the wire. The amount of Fe filament to be added is adjusted according to its cross-sectional area and supply speed.

[0114]Next, the slab obtained by concentrating Fe on the surface portion produced in this way is hot-rolled at a heating temperature of 1080 to 1150°C, a finish rolling finish temperature of 910 to 930°C, and a coiling temperature of 580 to 690°C to reach Plate thickness 4.0mm. In addition, after pickling, it is cold-rolled to 2.0mm, and hot-dip galvanized with continuous hot-dip galvanizing equipment. The maximum reaching point te...

Embodiment 2

[0122] Steel with the composition shown in J in Table 1 was continuously cast using a continuous casting facility equipped with an electromagnetic brake and a wire supply device for alloy addition in the mold section. The electromagnetic force of the electromagnetic brake is set to 0.1 to 1.0T, and Fe wire is used as the wire. The amount of Fe filament added is adjusted according to its thickness and feeding speed.

[0123] Next, the slab obtained by concentrating Fe of various thicknesses in the surface layer produced in this way is subjected to heating temperature of 1080-1150°C, finishing temperature of 910-930°C, and coiling temperature of 580-690°C. Hot-rolled to a plate thickness of 4.0mm. In addition, after pickling, it is cold-rolled to 2.0mm, and hot-dip galvanized with continuous hot-dip galvanizing equipment. The maximum reaching point temperature of the continuous hot dip galvanizing equipment is 800°C, the average cooling rate from the maximum reaching point tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com