Patents

Literature

62results about How to "Reduce NVH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

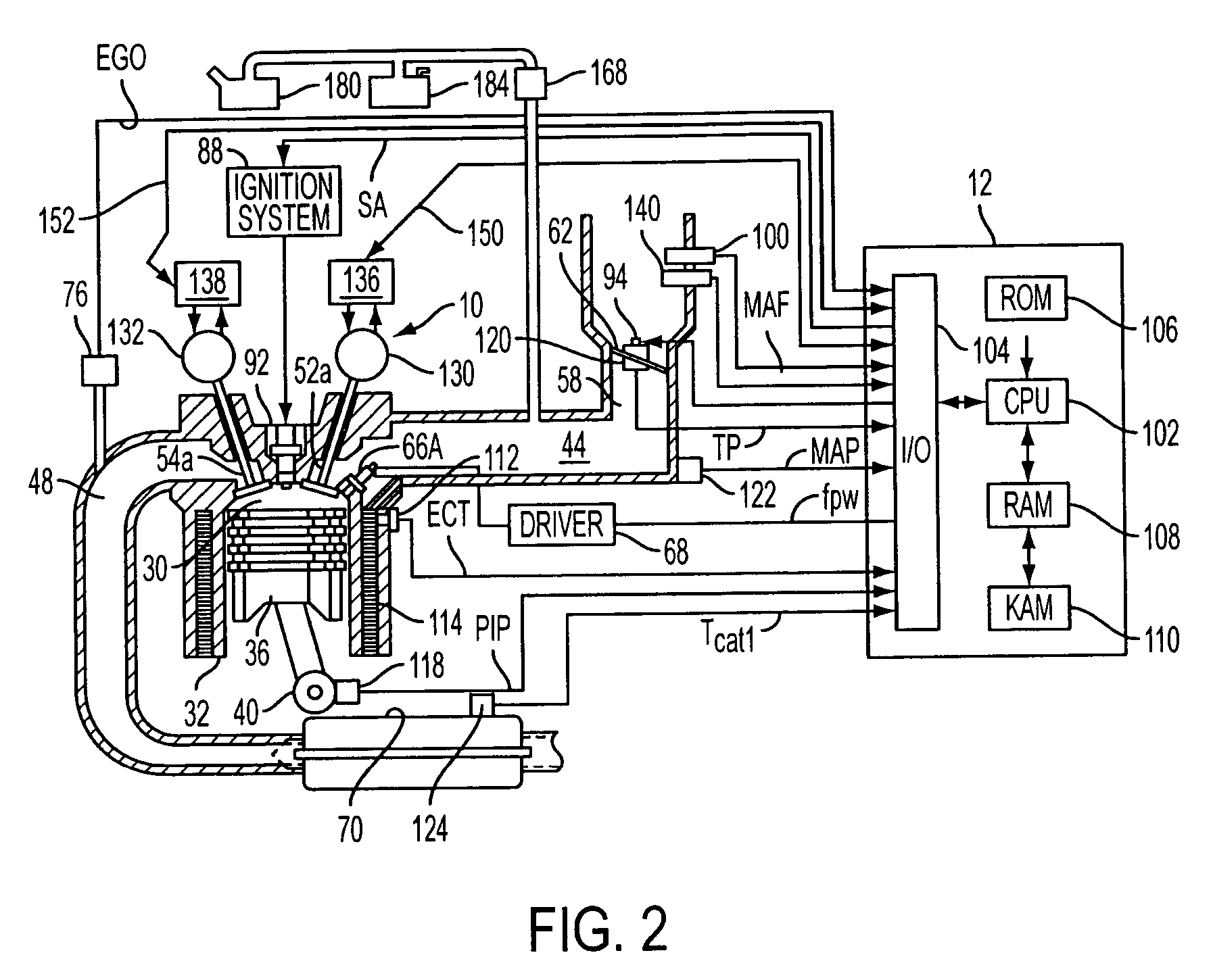

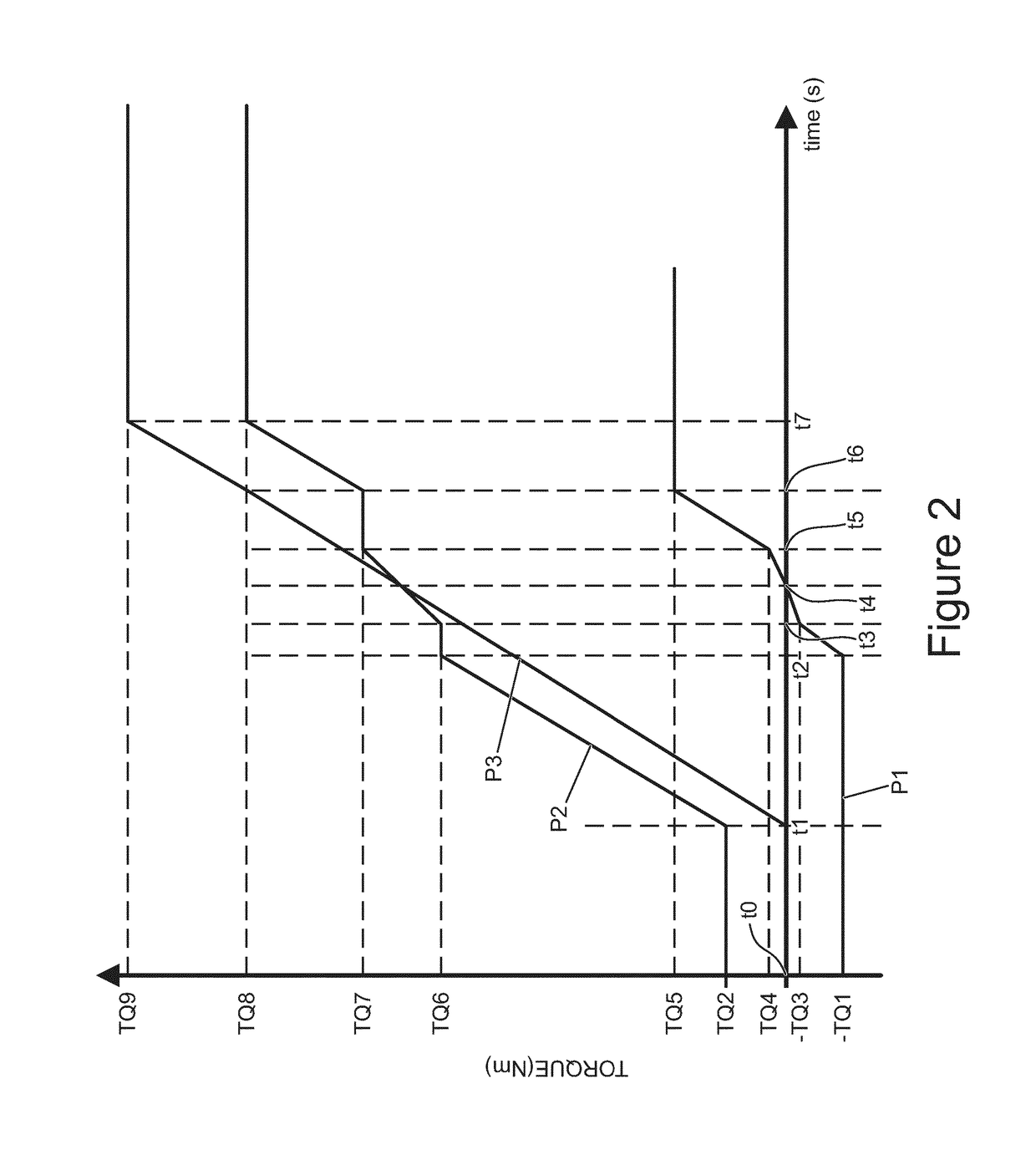

Differential torque operation for internal combustion engine

InactiveUS7503312B2Improve internal efficiencyImprove fuel efficiencyElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

A method of operating an internal combustion engine having a plurality of cylinders including at least a first cylinder and a second cylinder, the method comprising firing the first cylinder and the second cylinder in an alternating sequence; during a first mode, adjusting an operating parameter of the engine to produce a first difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; during a second mode, adjusting the operating parameter of the engine to produce a second difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; and performing the first mode at a higher engine speed than the second mode; wherein the first difference is greater than the second difference.

Owner:FORD GLOBAL TECH LLC

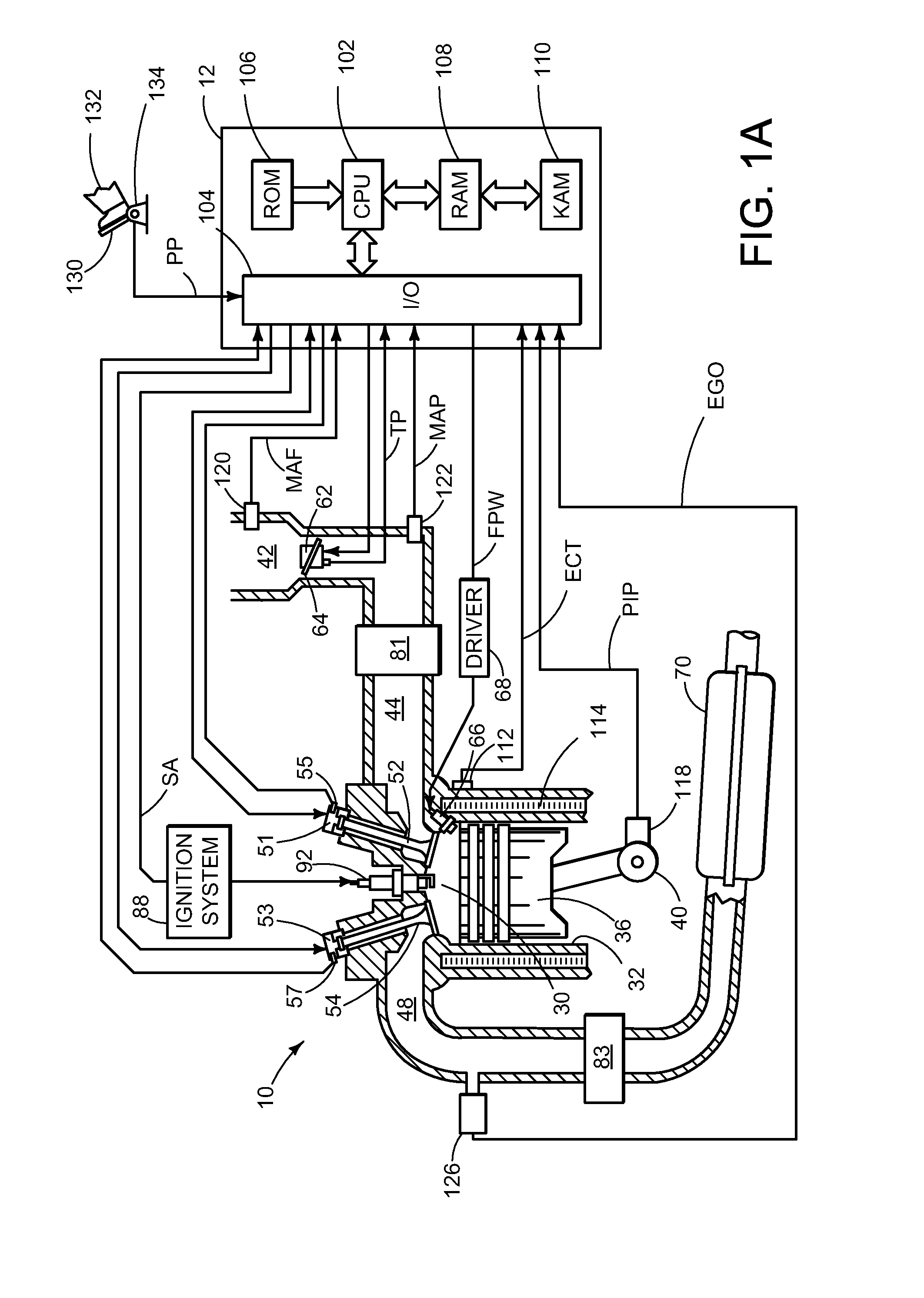

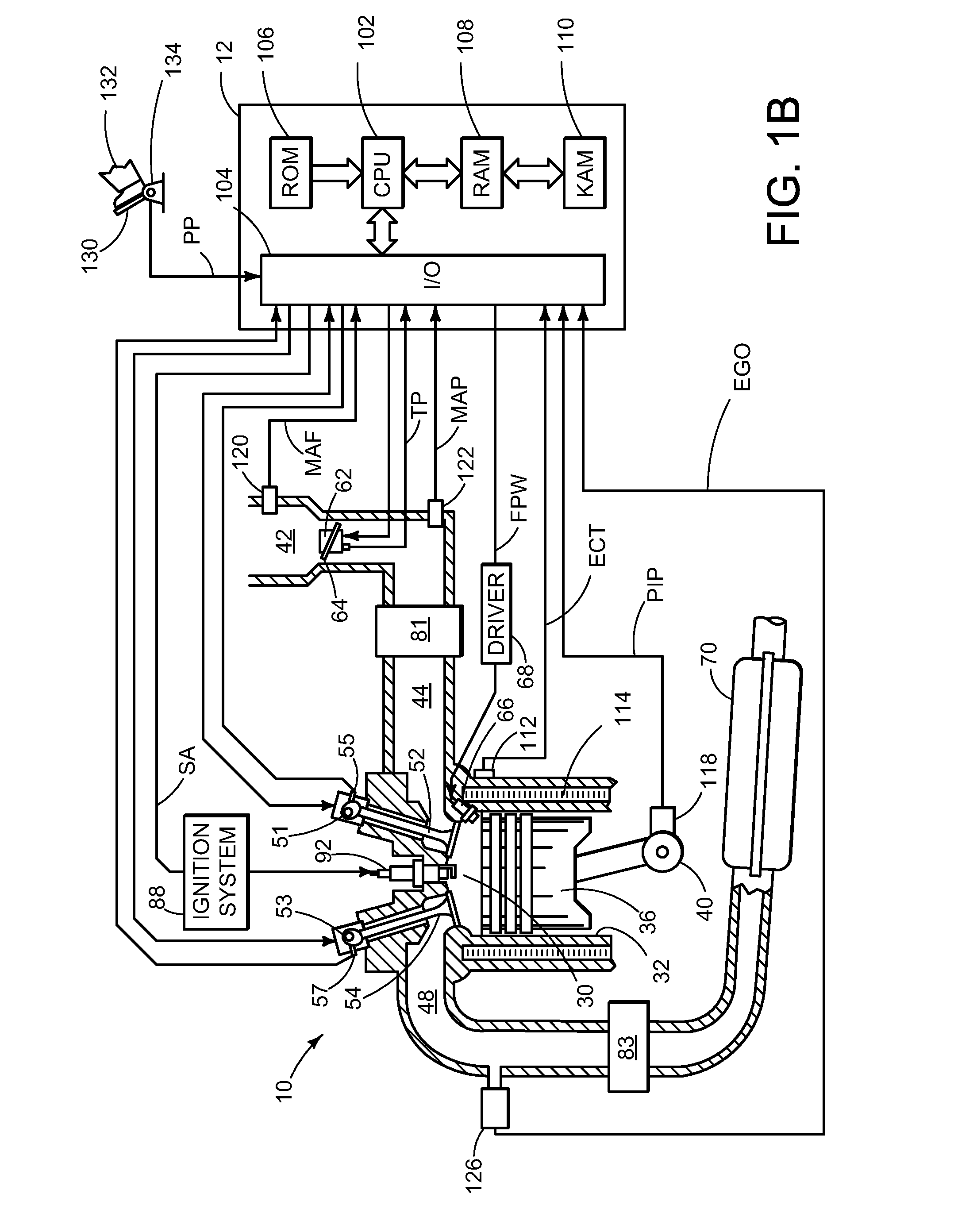

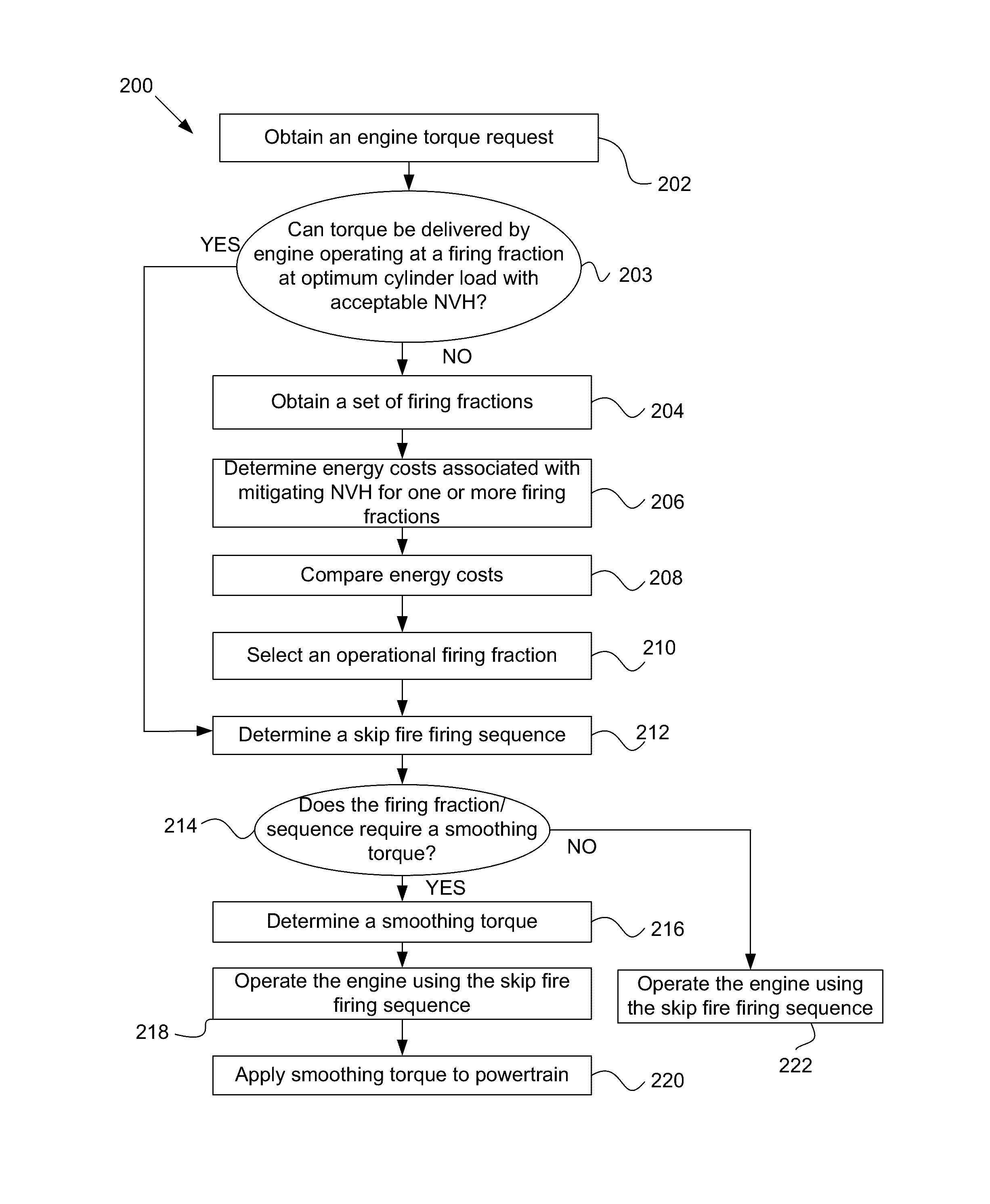

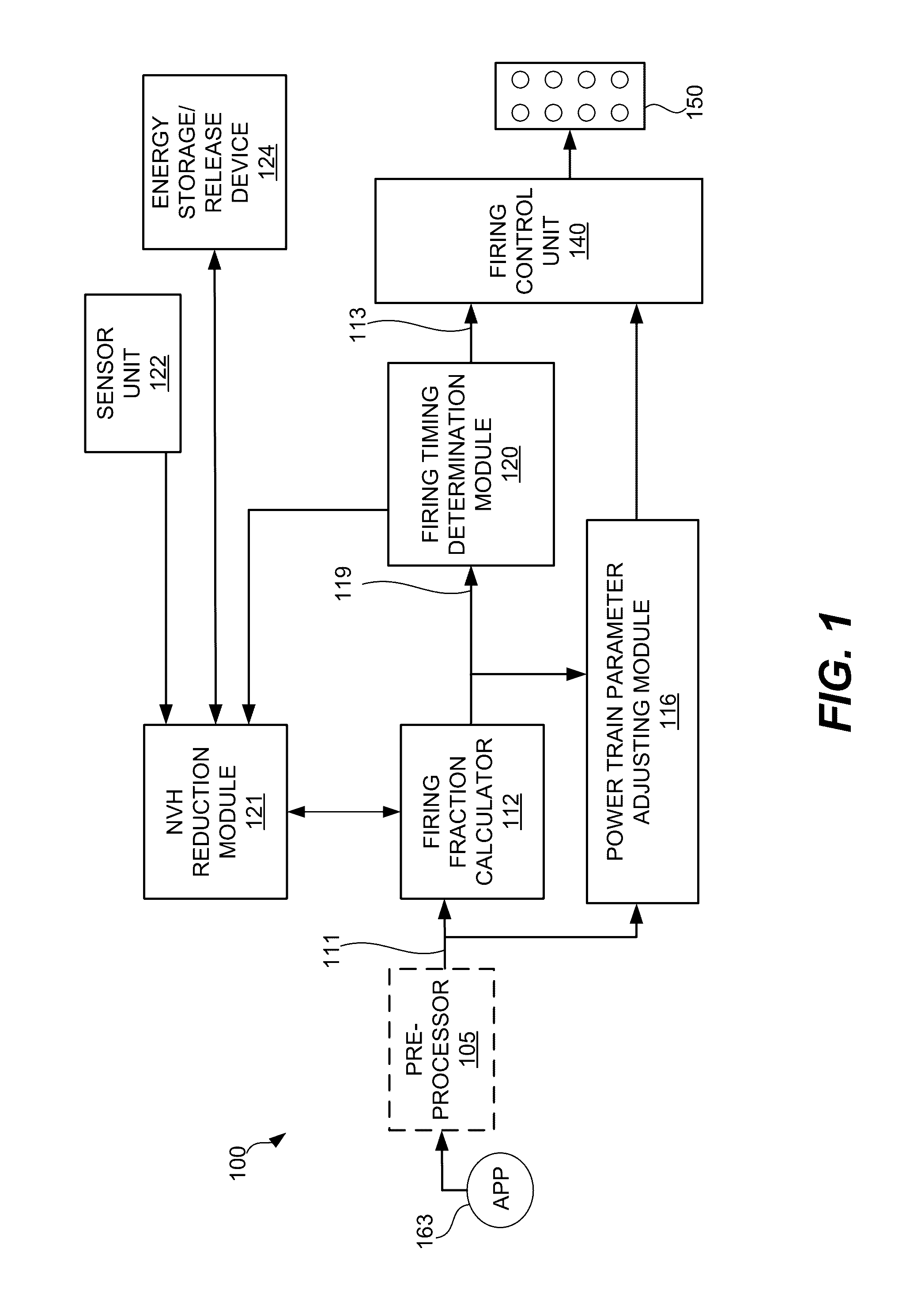

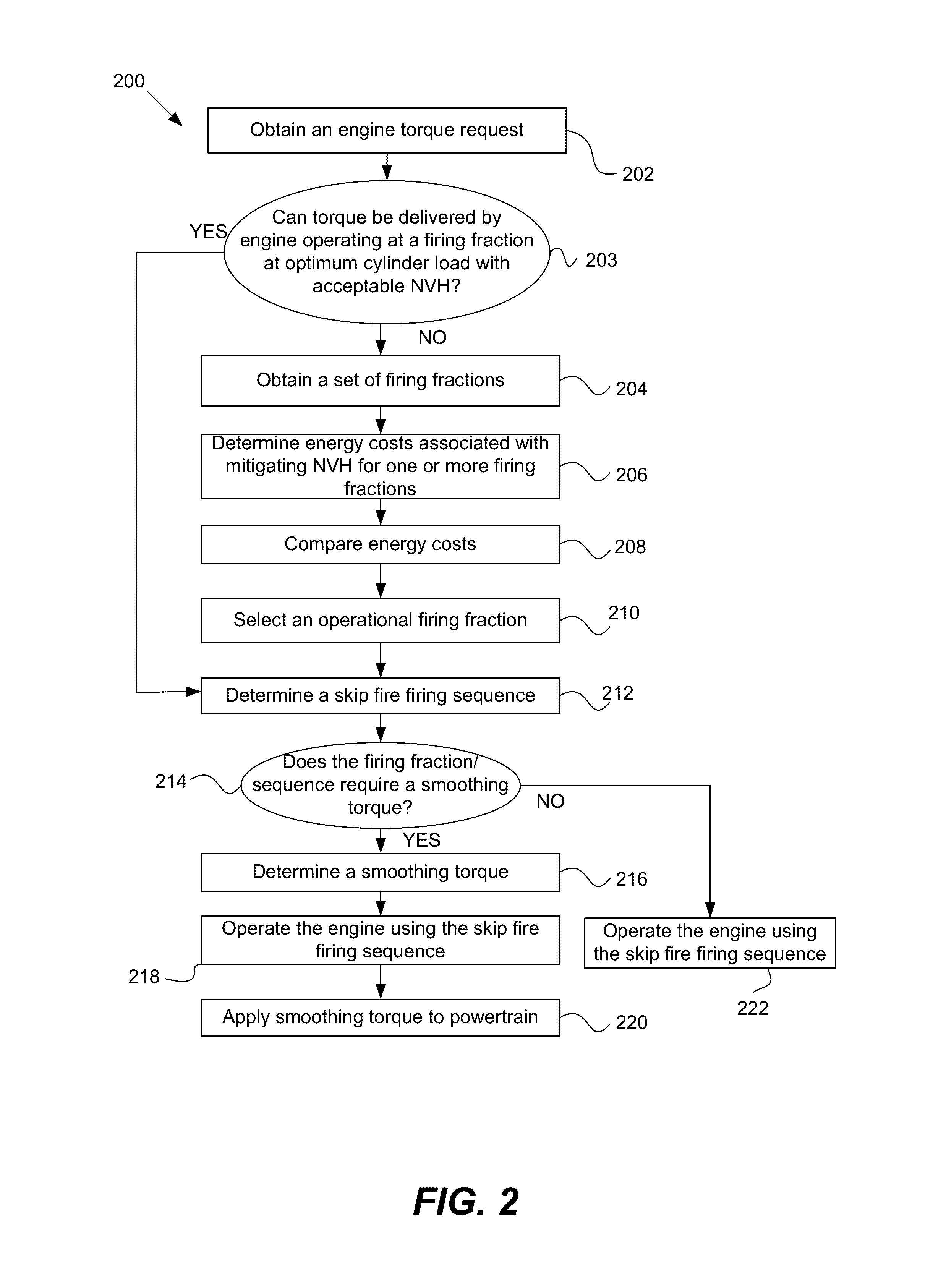

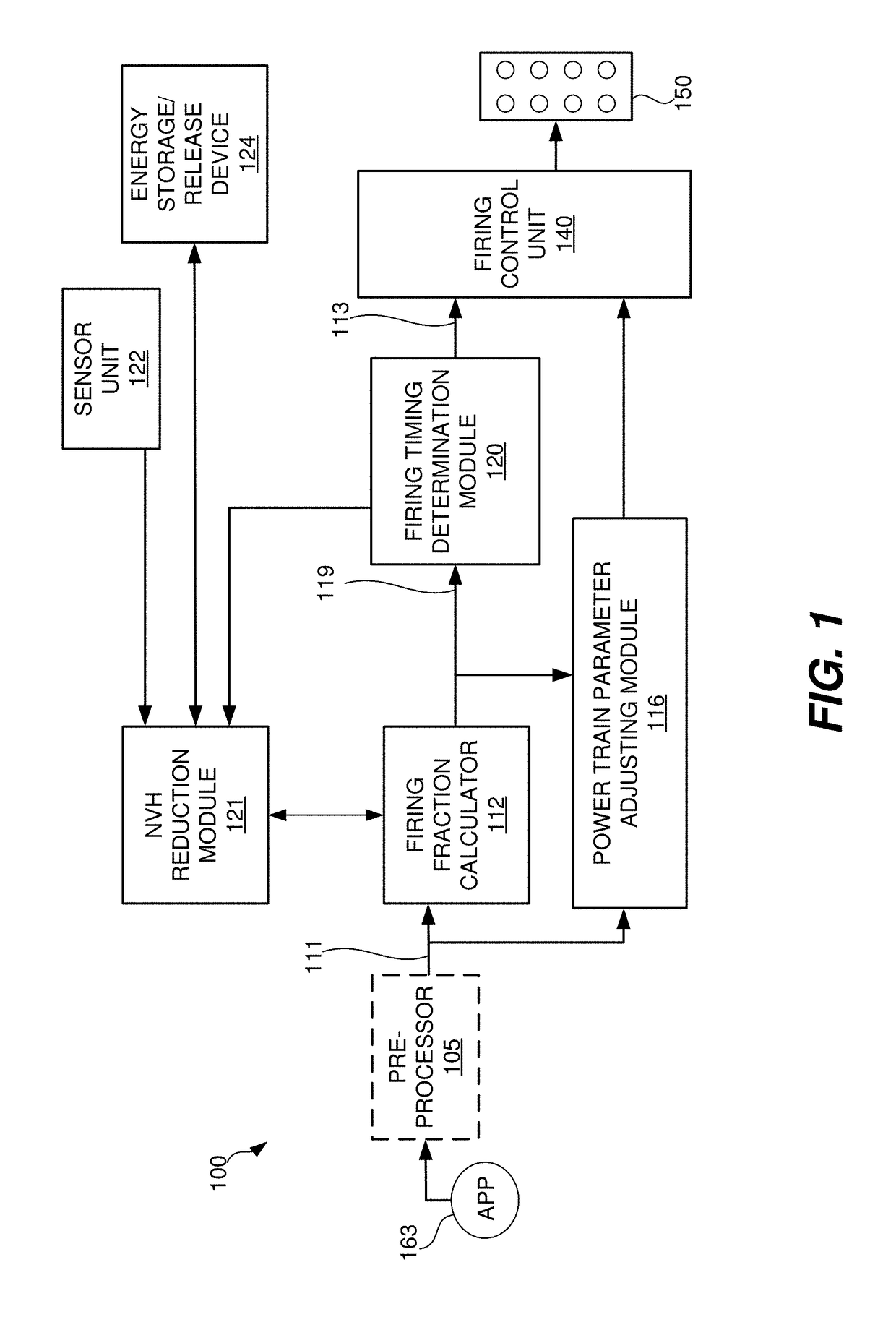

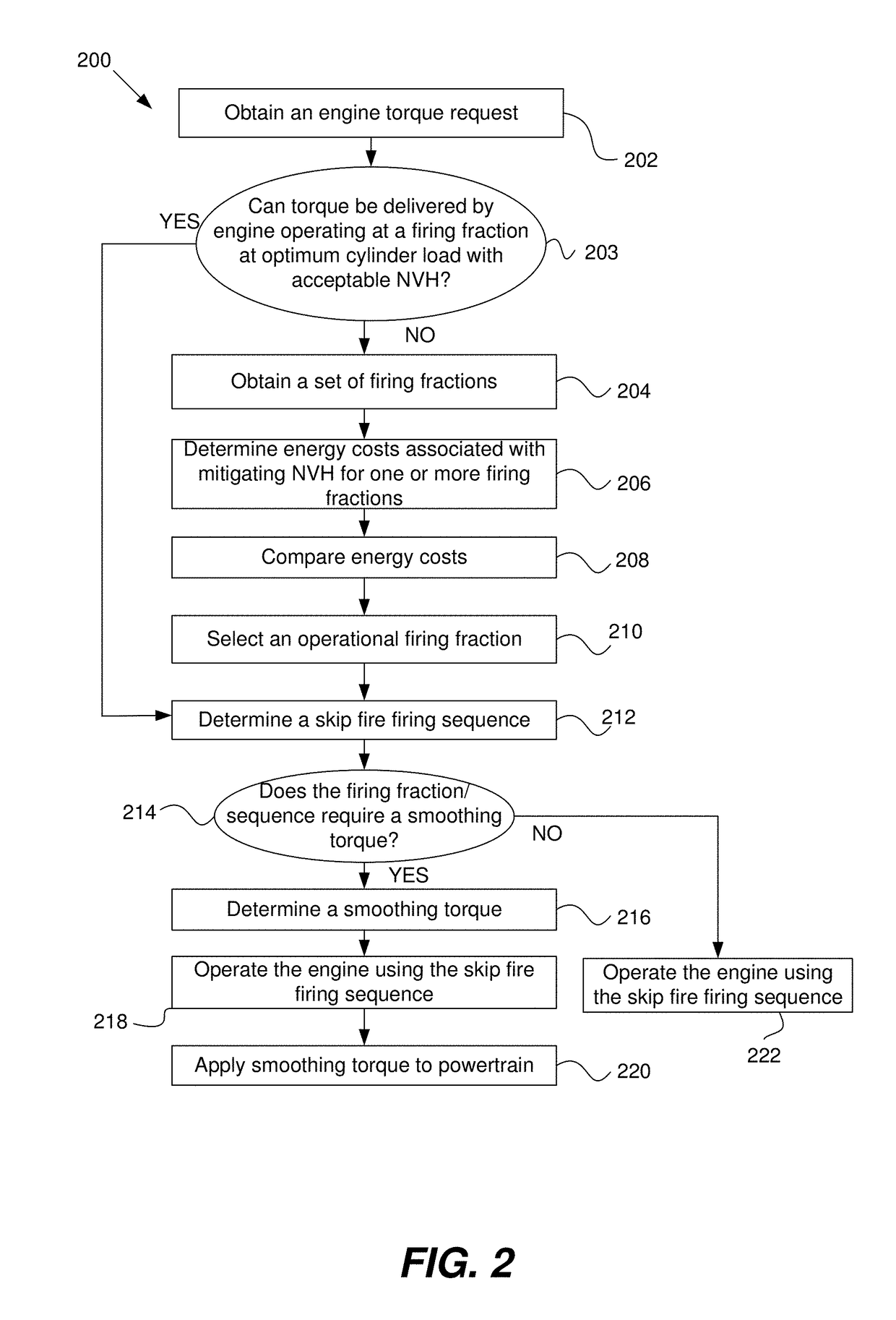

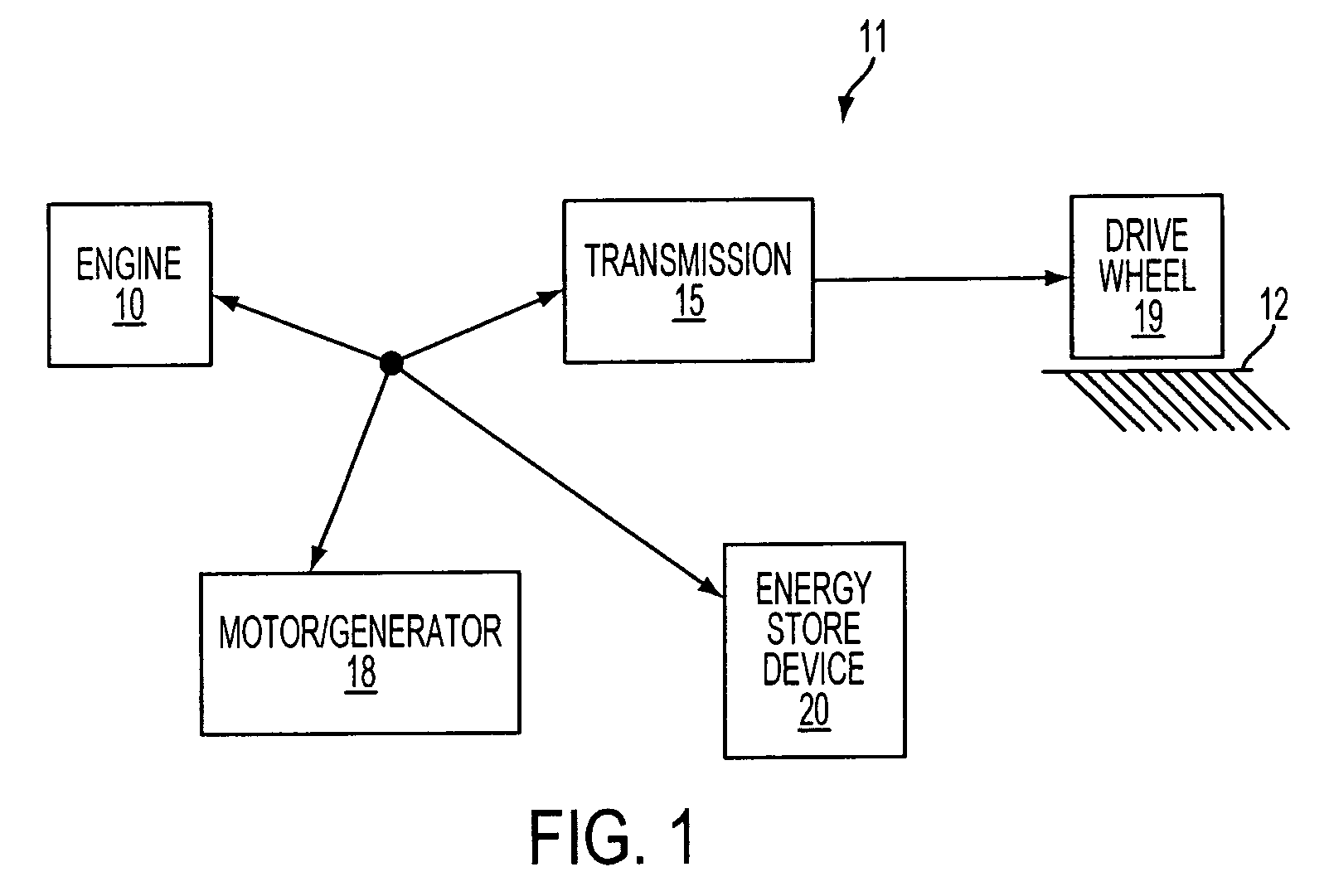

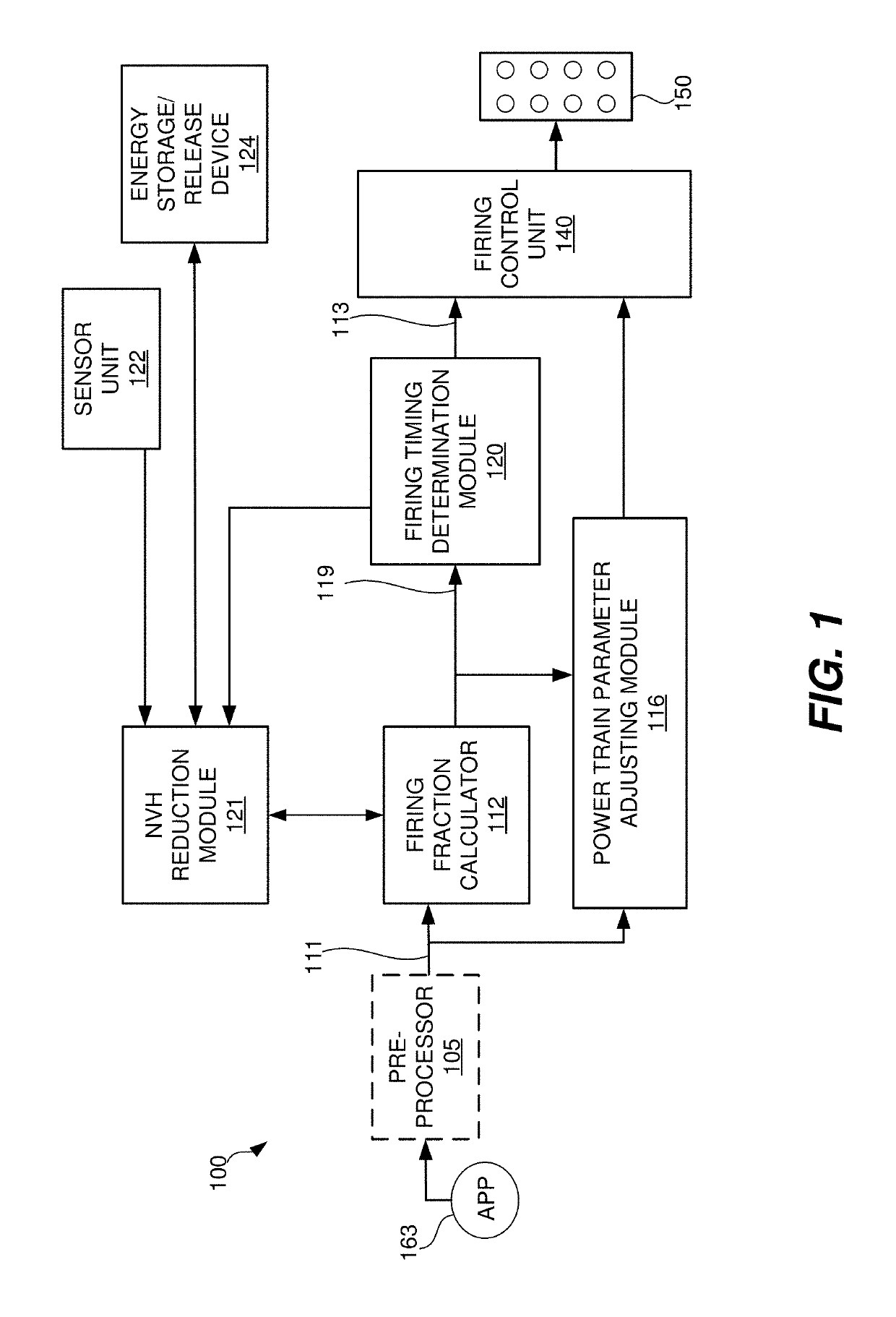

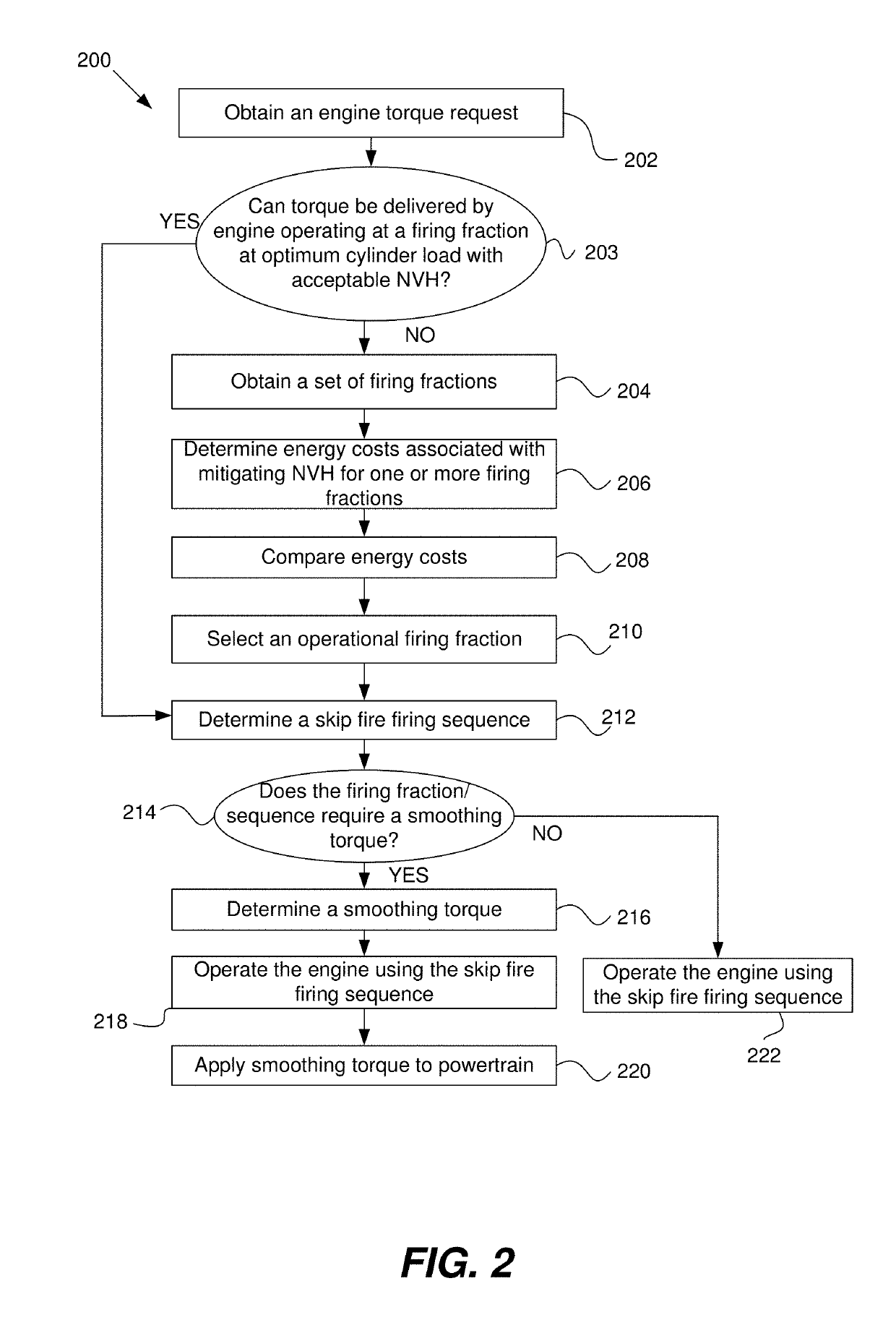

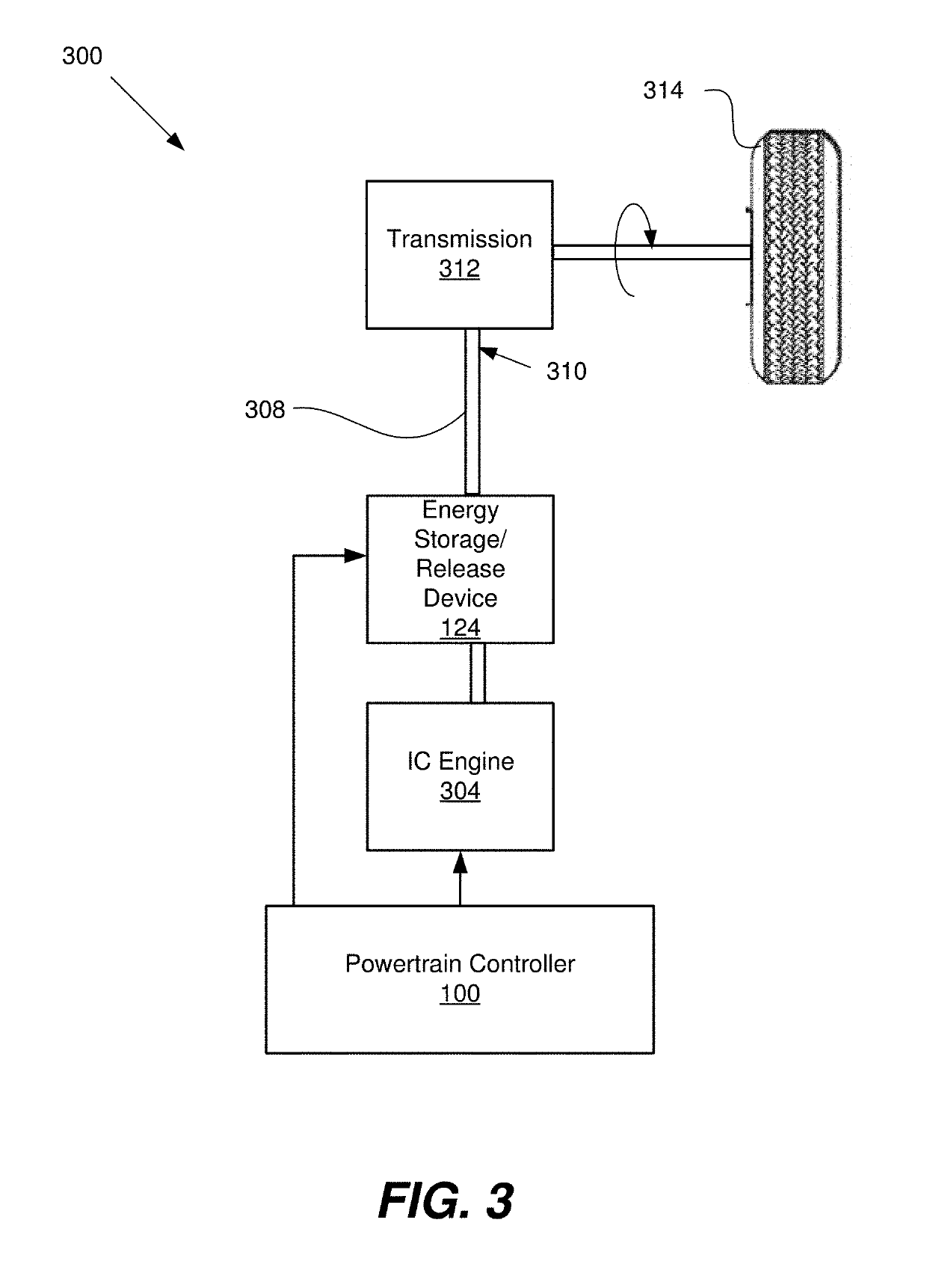

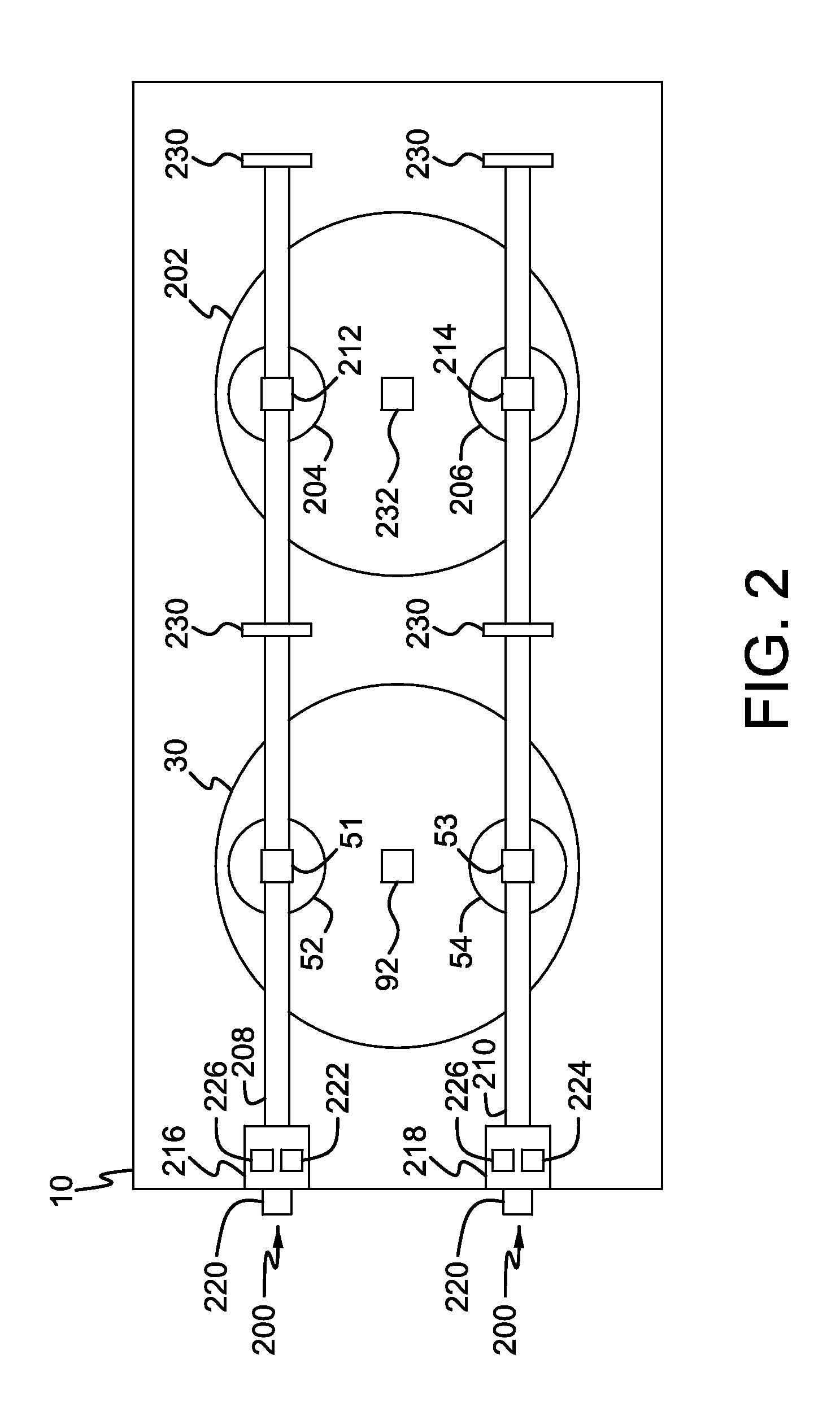

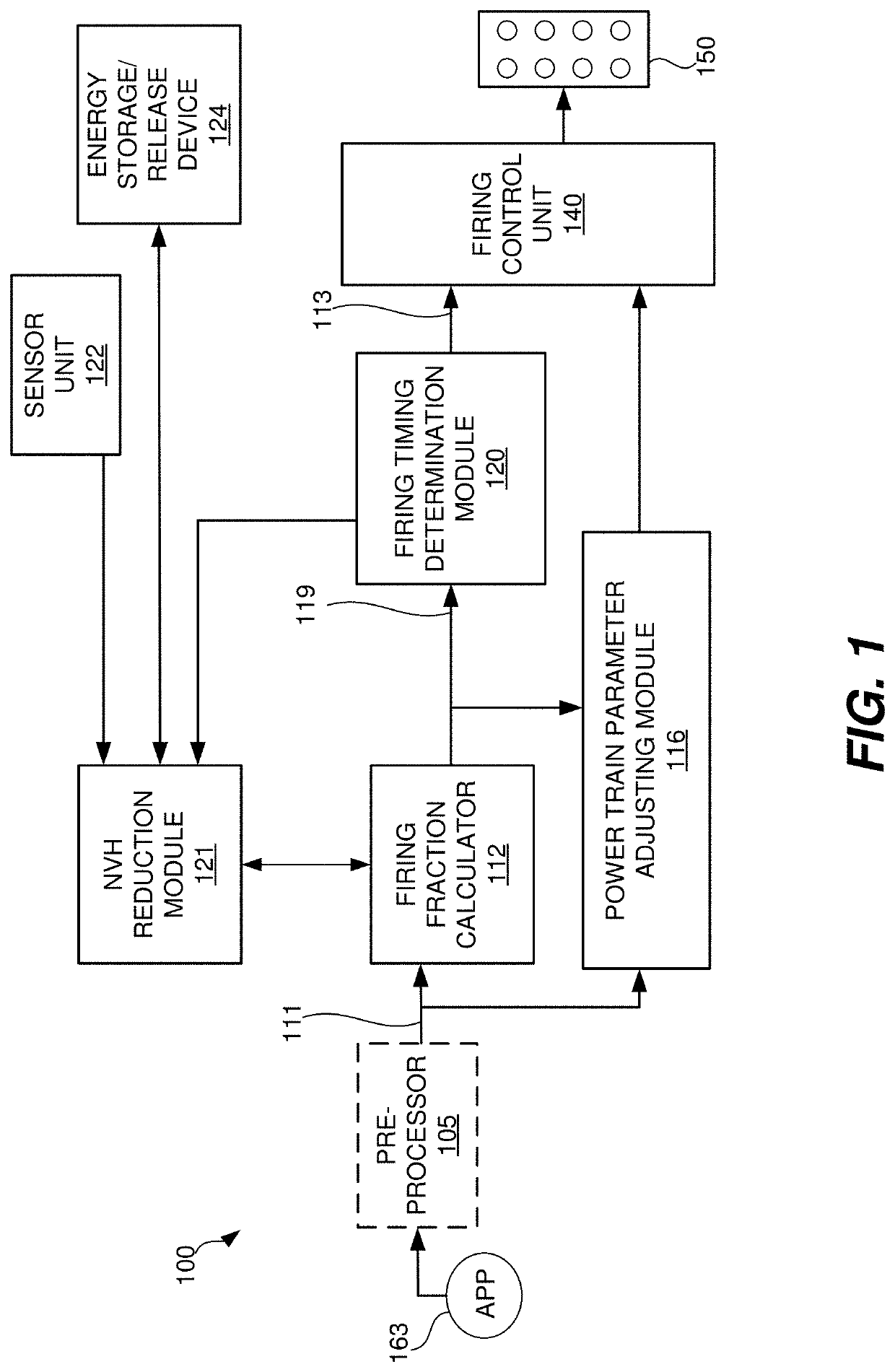

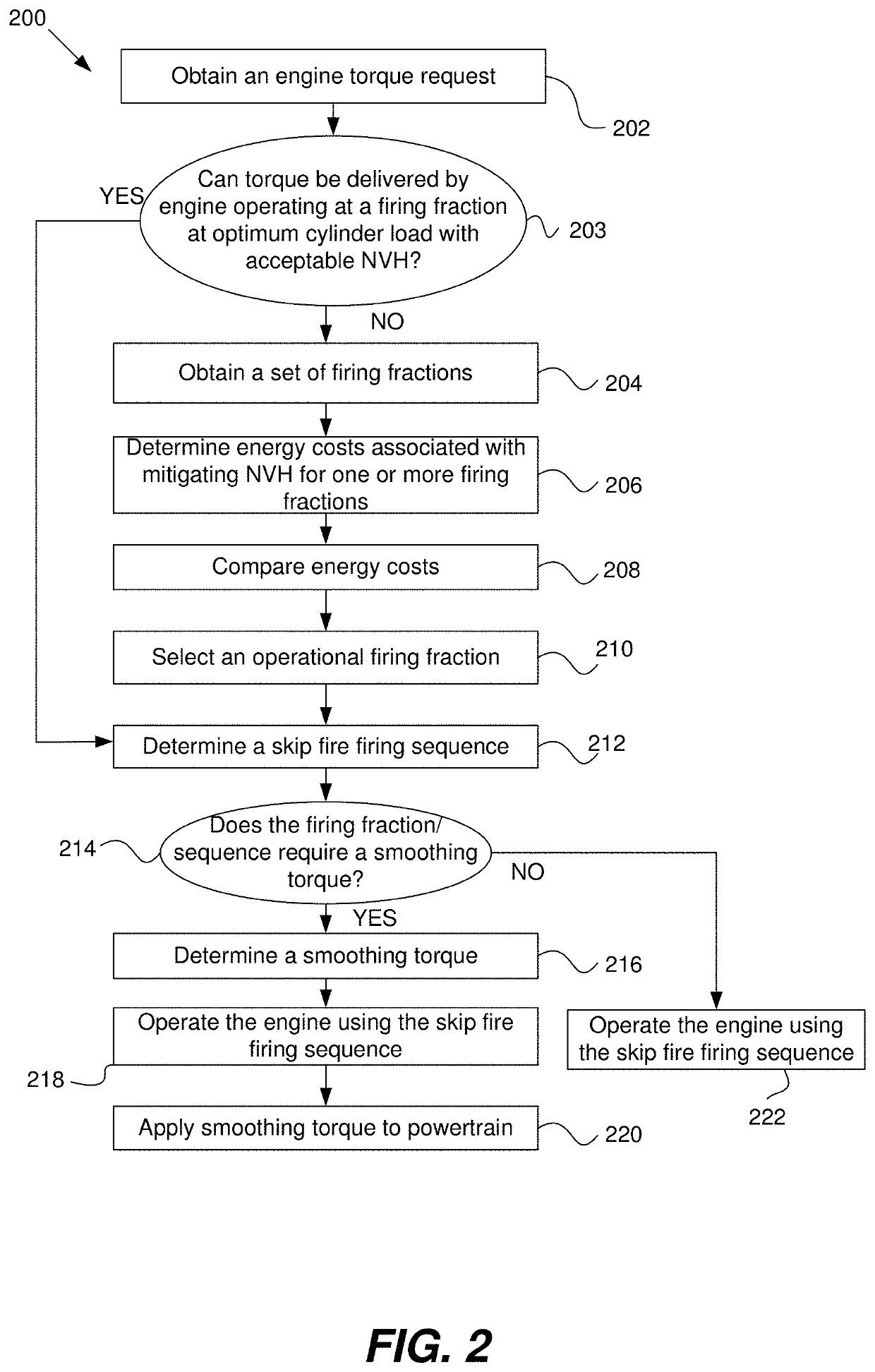

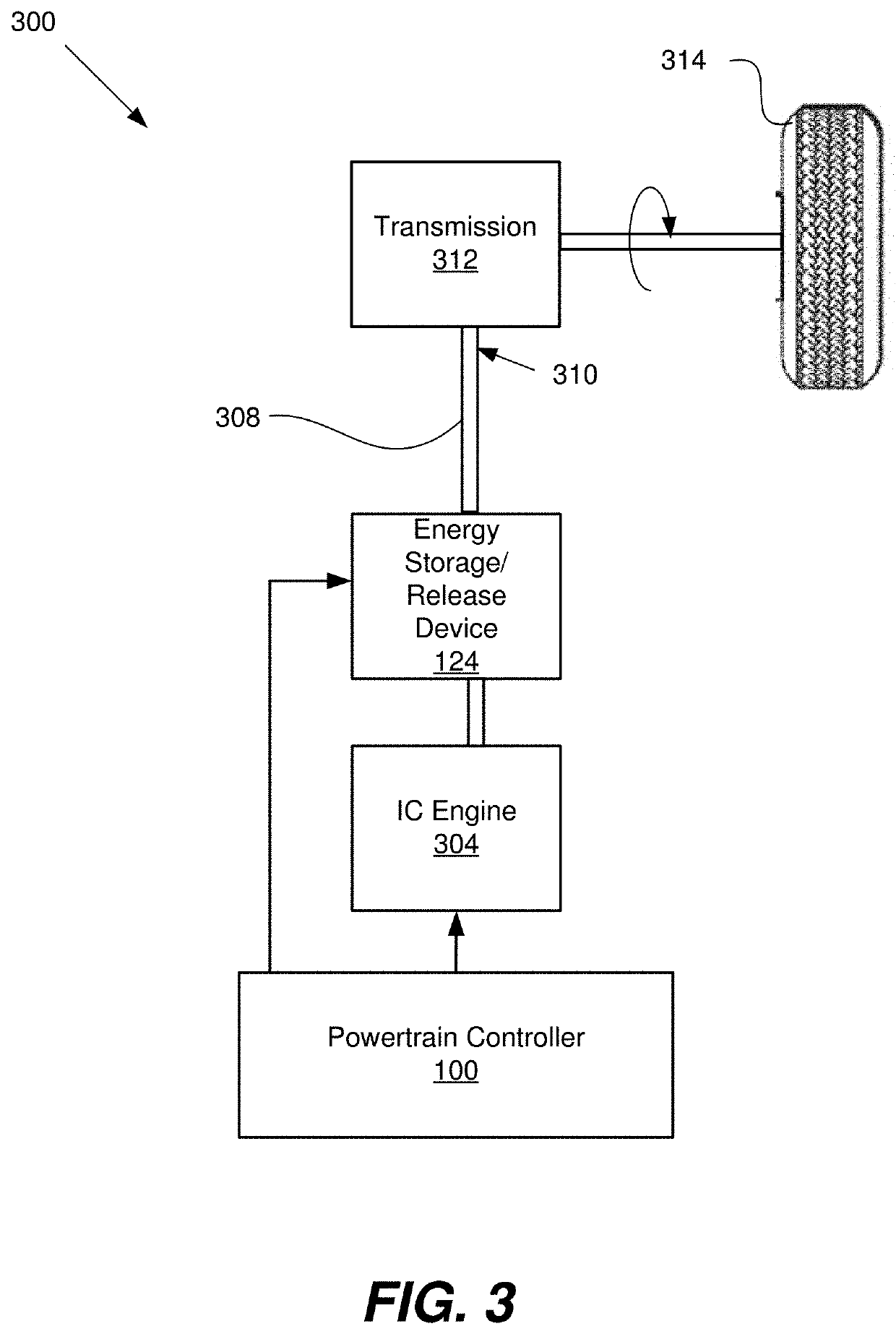

Noise, vibration and harshness reduction in a skip fire engine control system

A variety of methods and arrangements for reducing noise, vibration and harshness (NVH) in a skip fire engine control system are described. In one aspect, a firing sequence is used to operate the engine in a skip fire manner. A smoothing torque is determined that is applied to a powertrain by an energy storage / release device. The smoothing torque is arranged to at least partially cancel out variation in torque generated by the skip fire firing sequence. Various methods, powertrain controllers, arrangements and computer software related to the above operations are also described.

Owner:TULA TECH INC

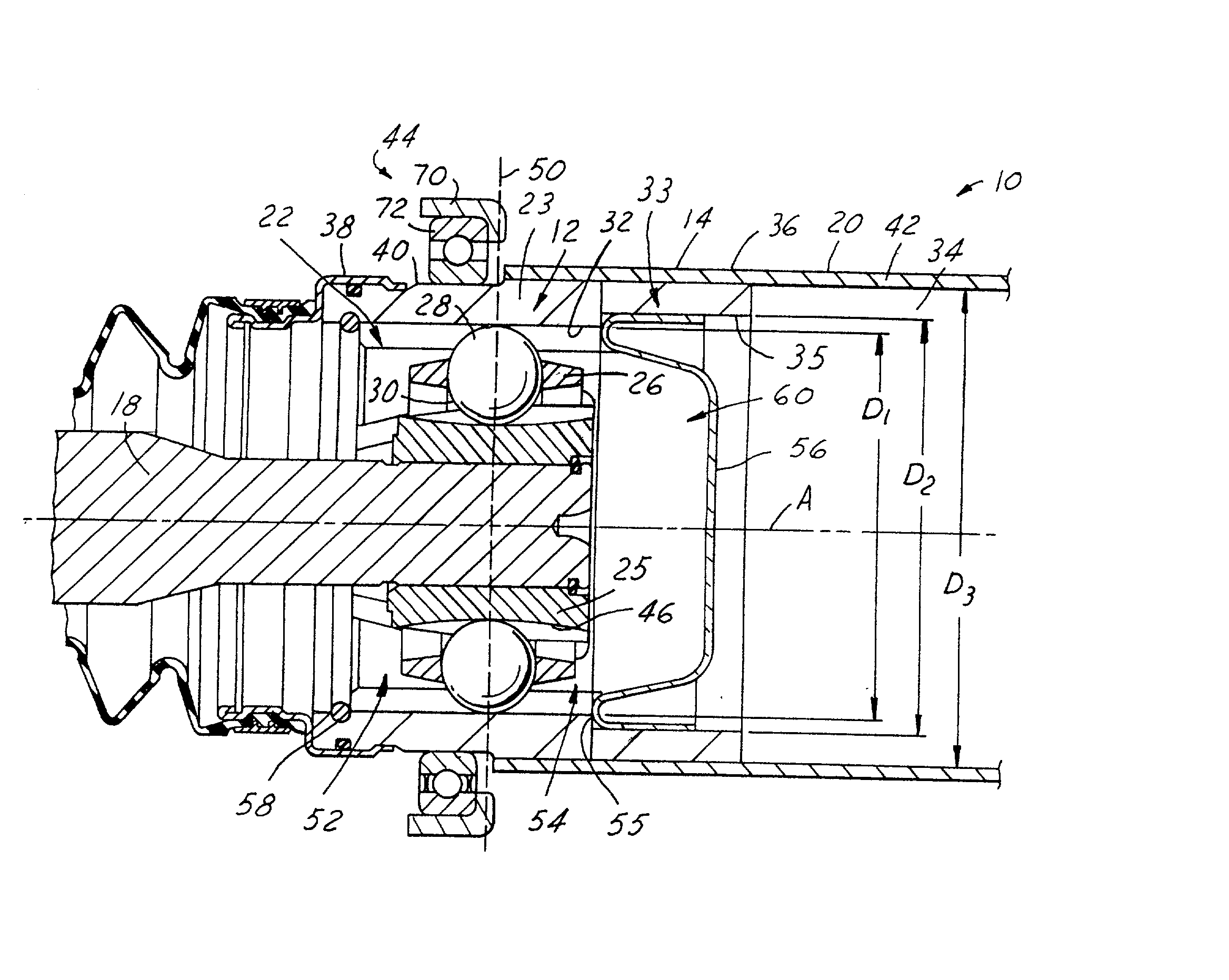

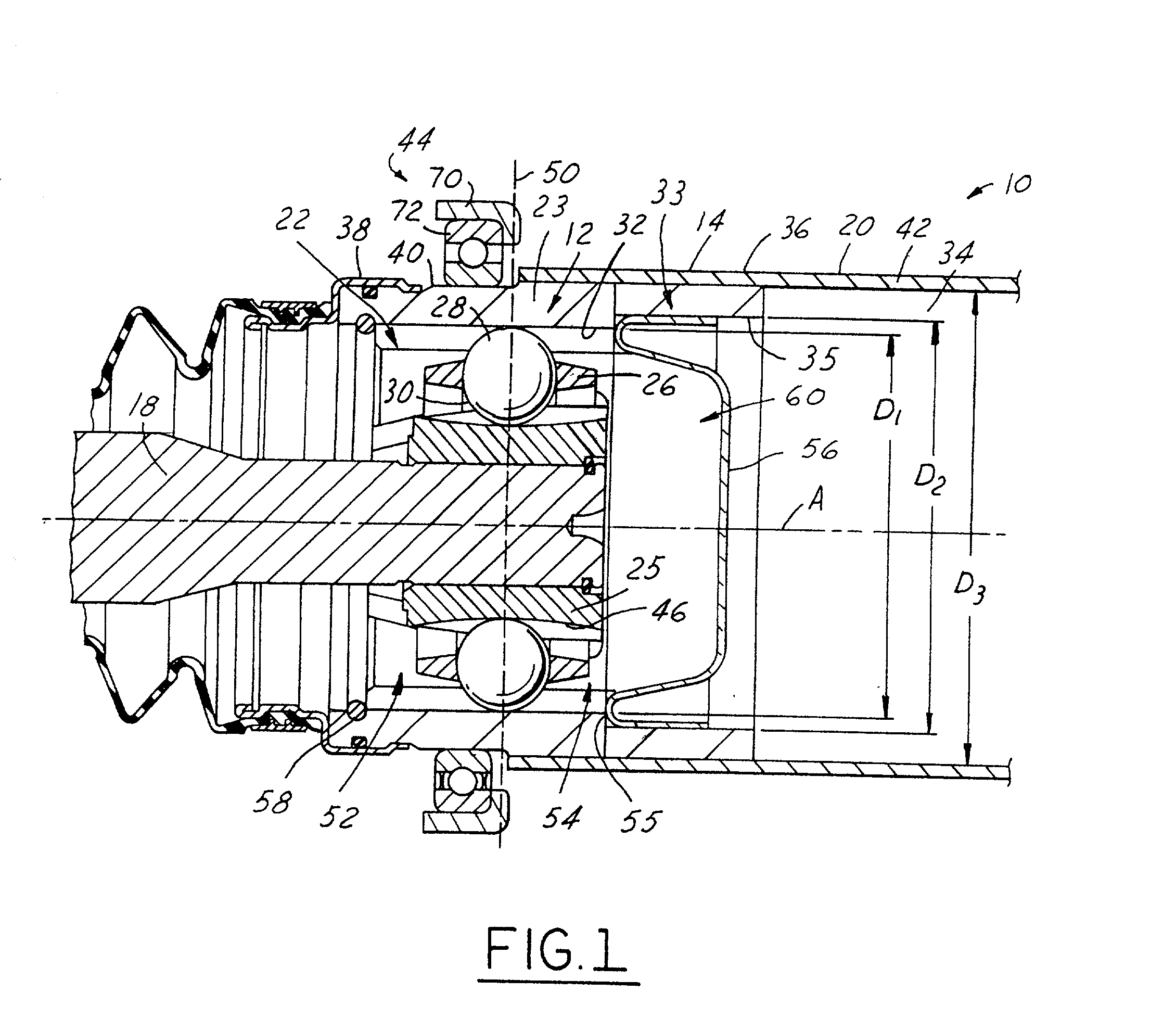

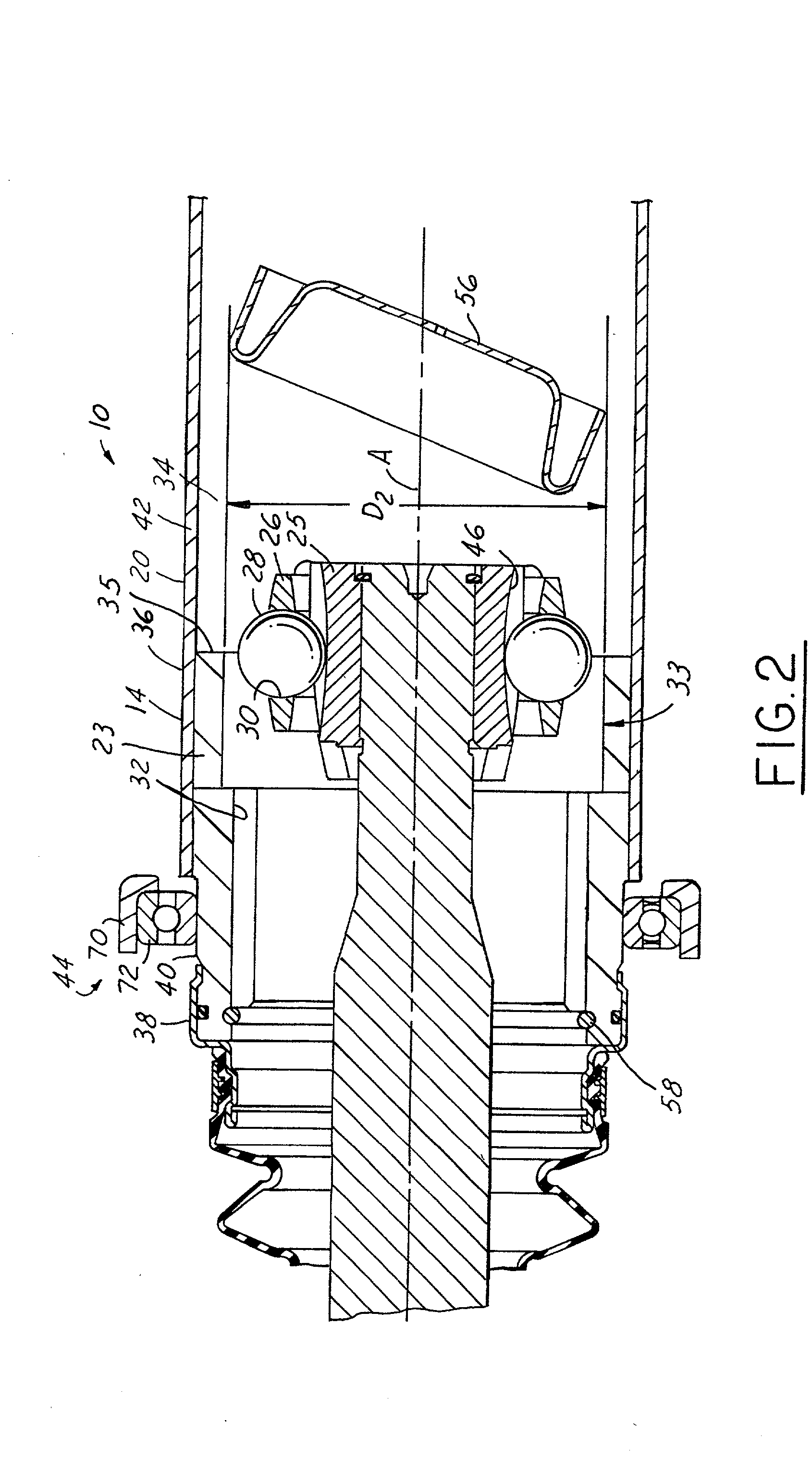

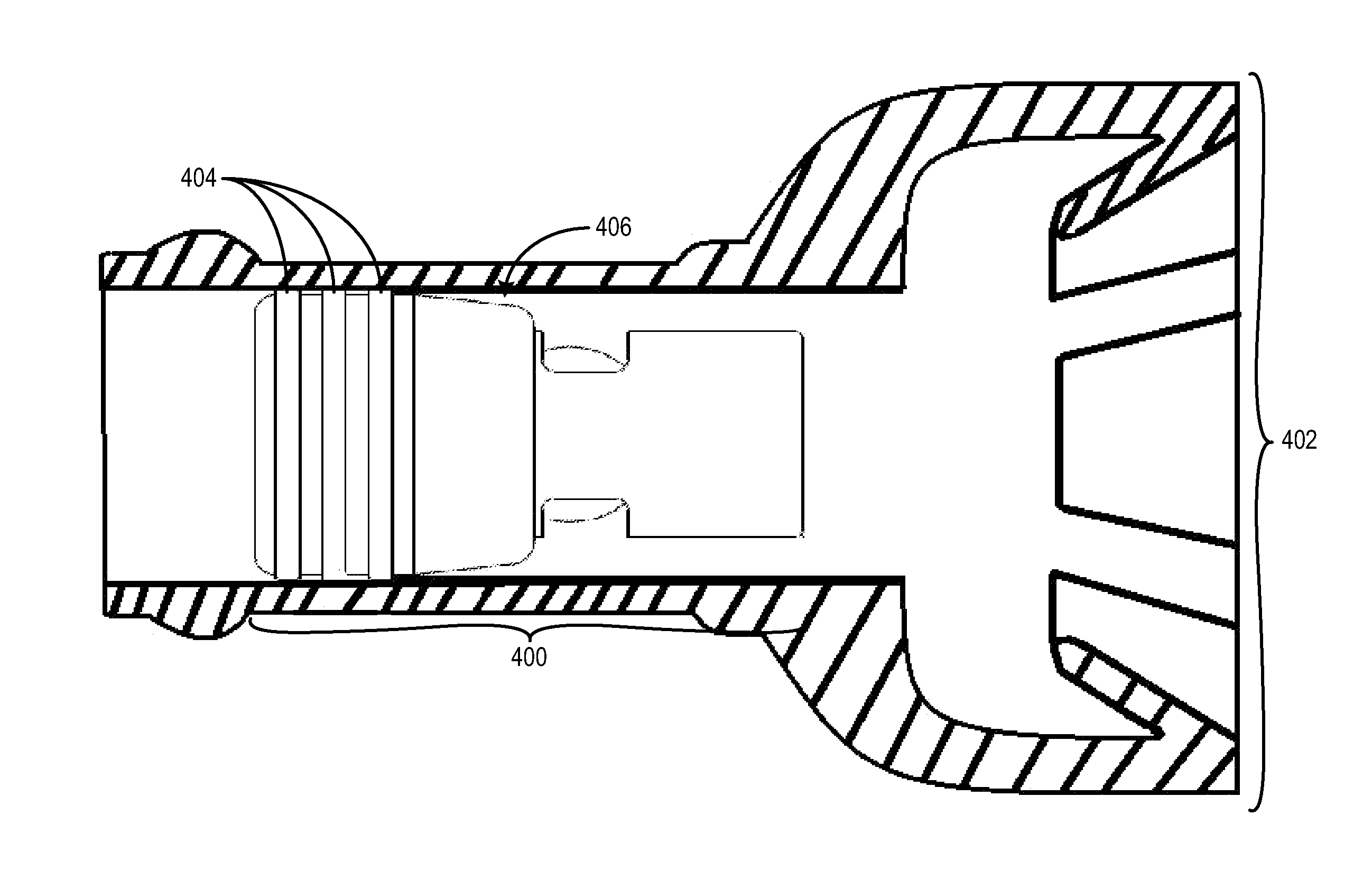

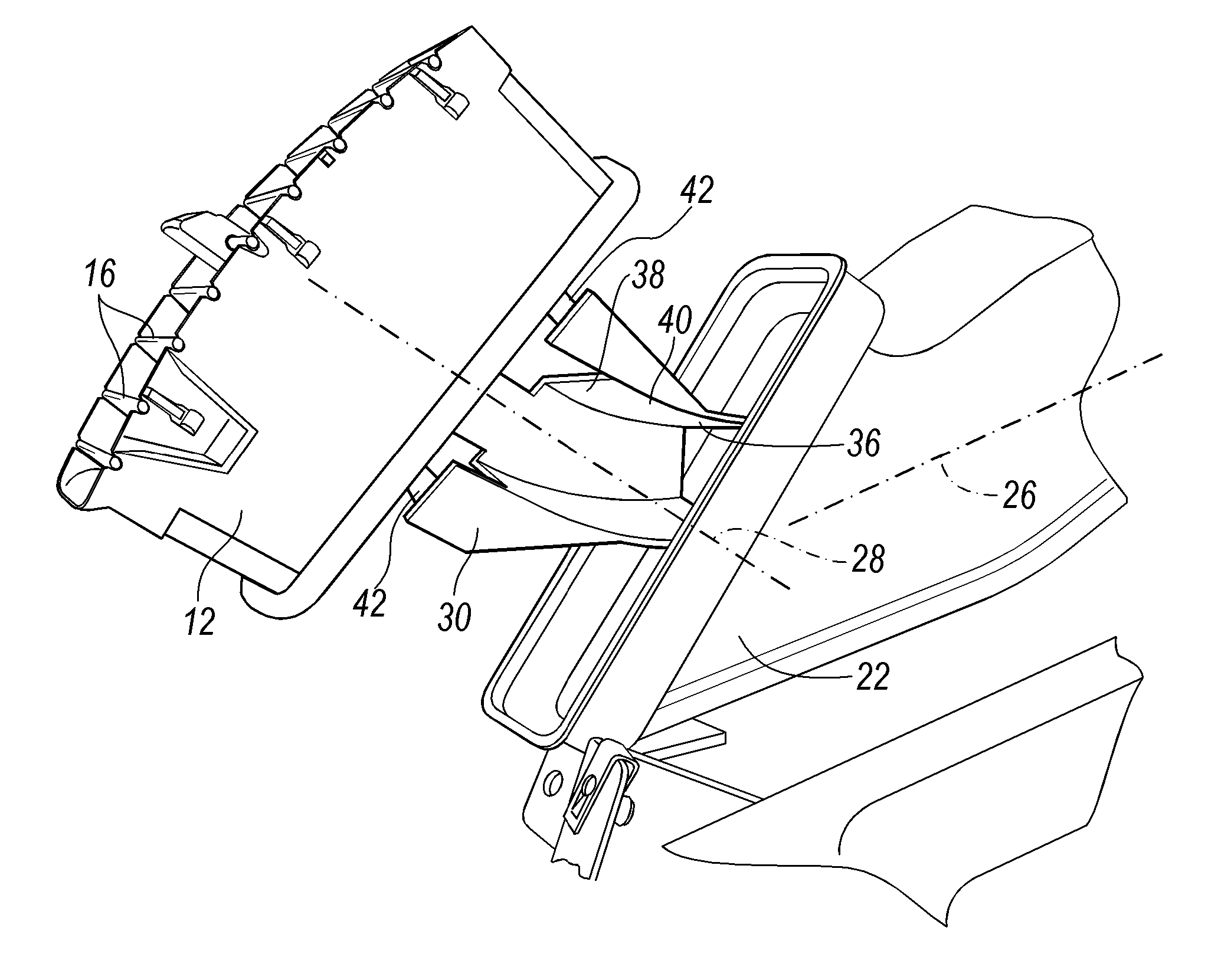

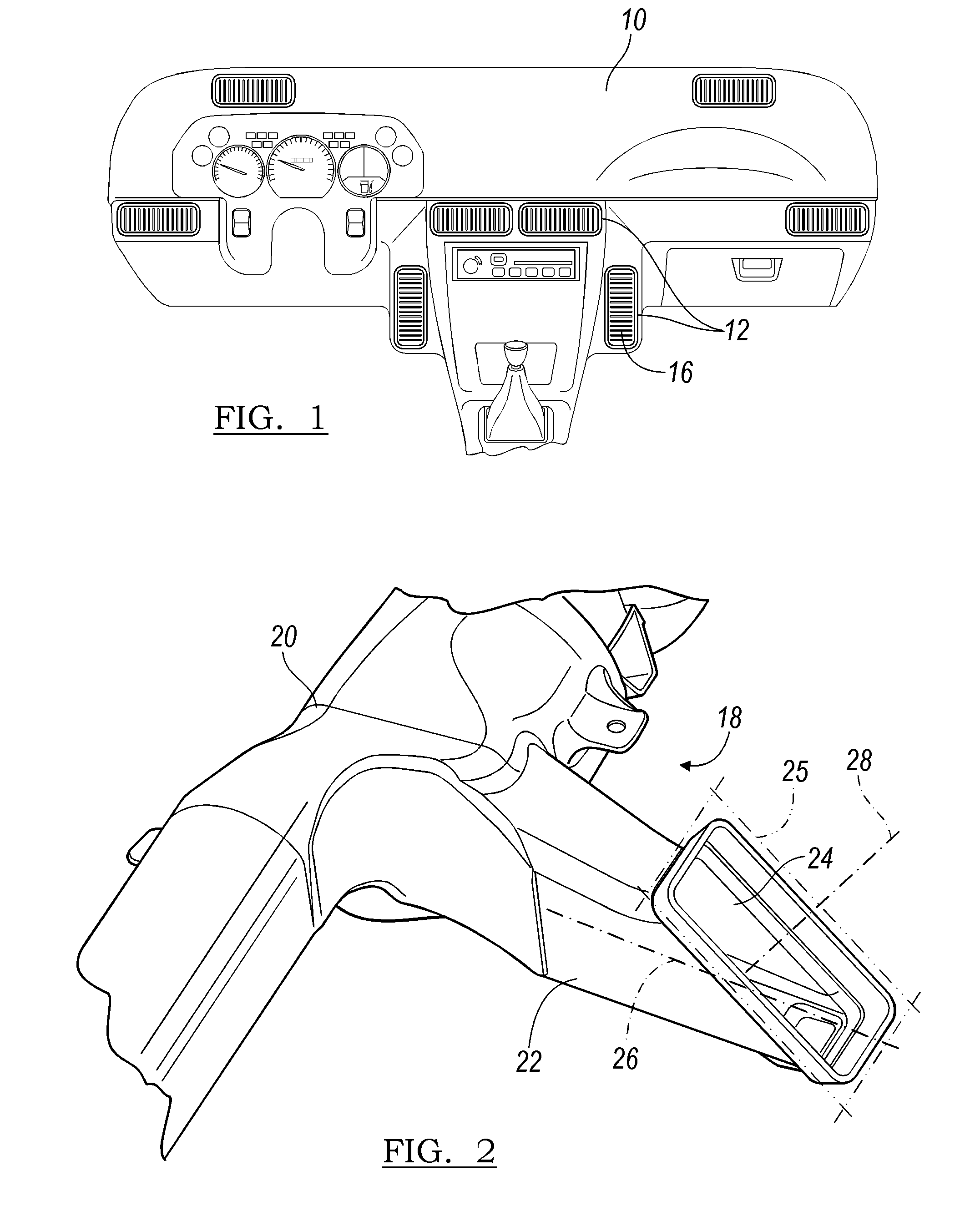

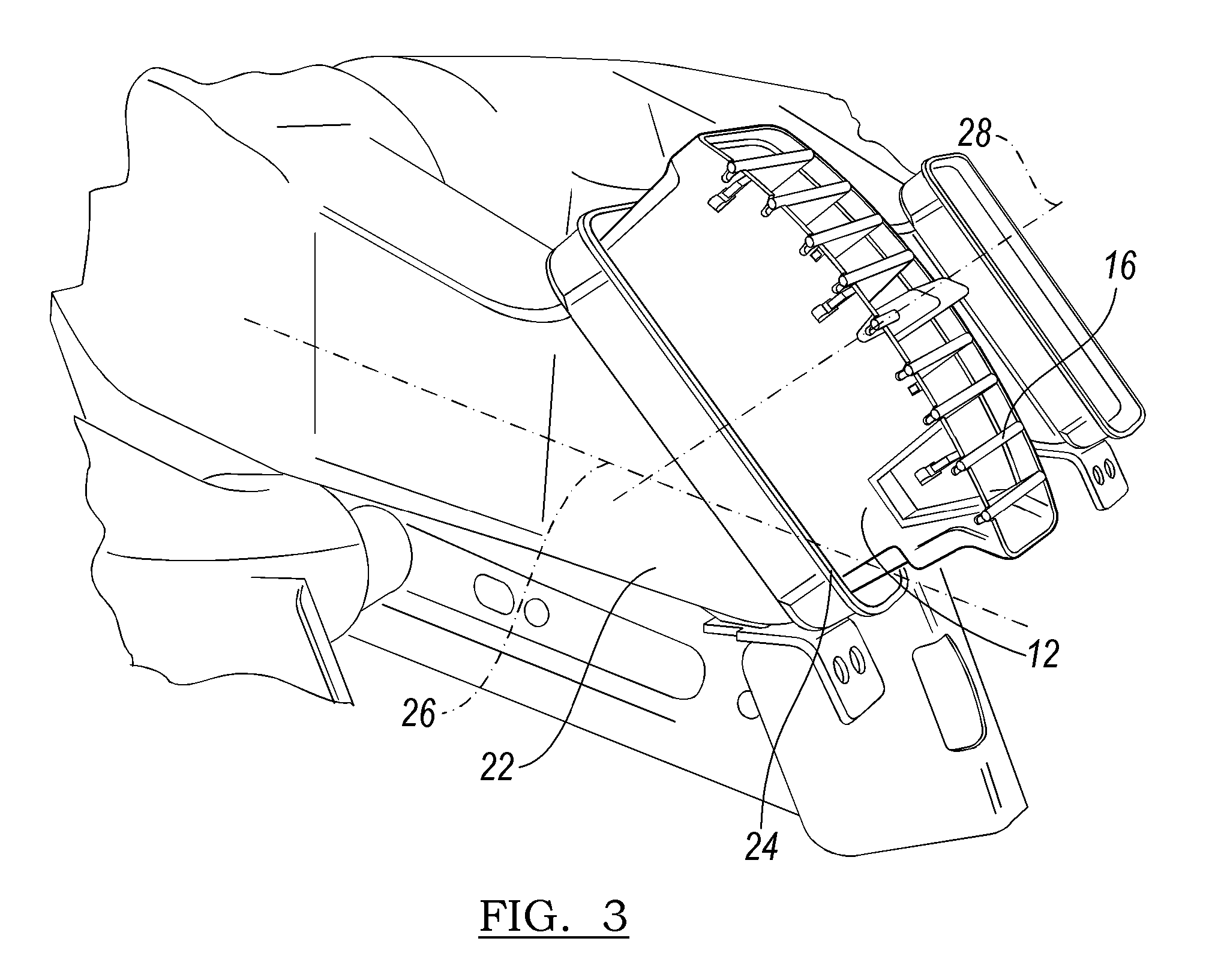

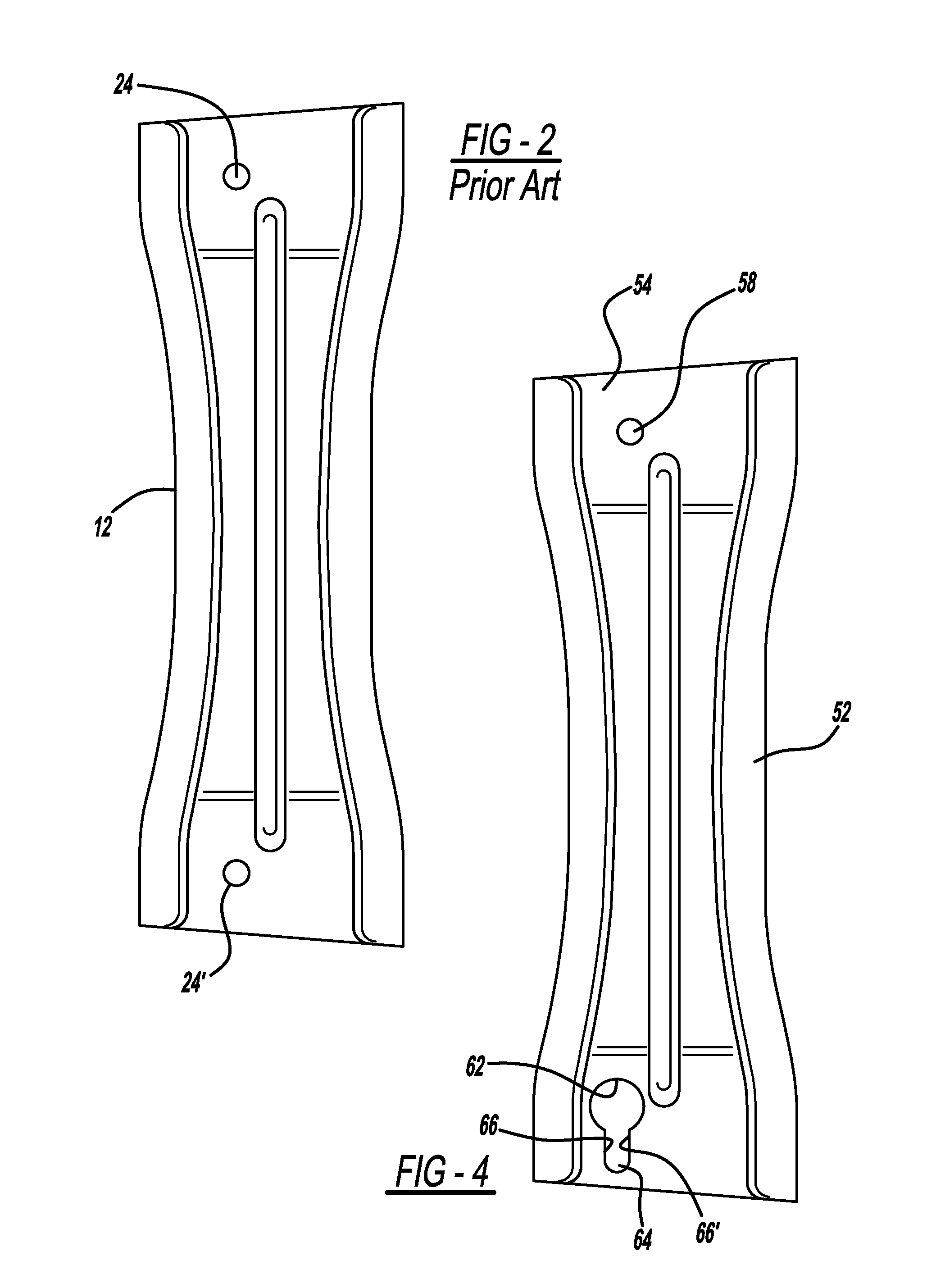

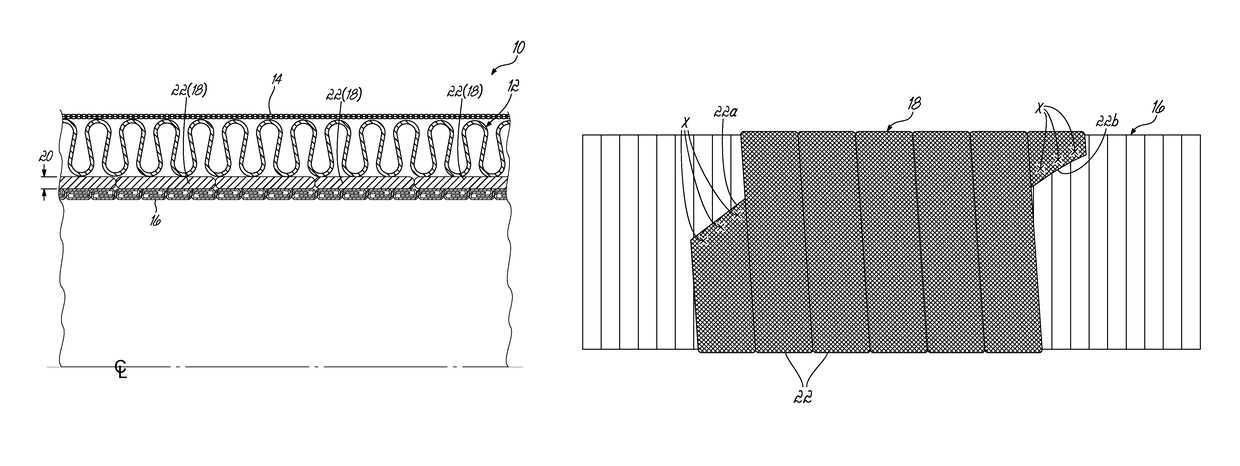

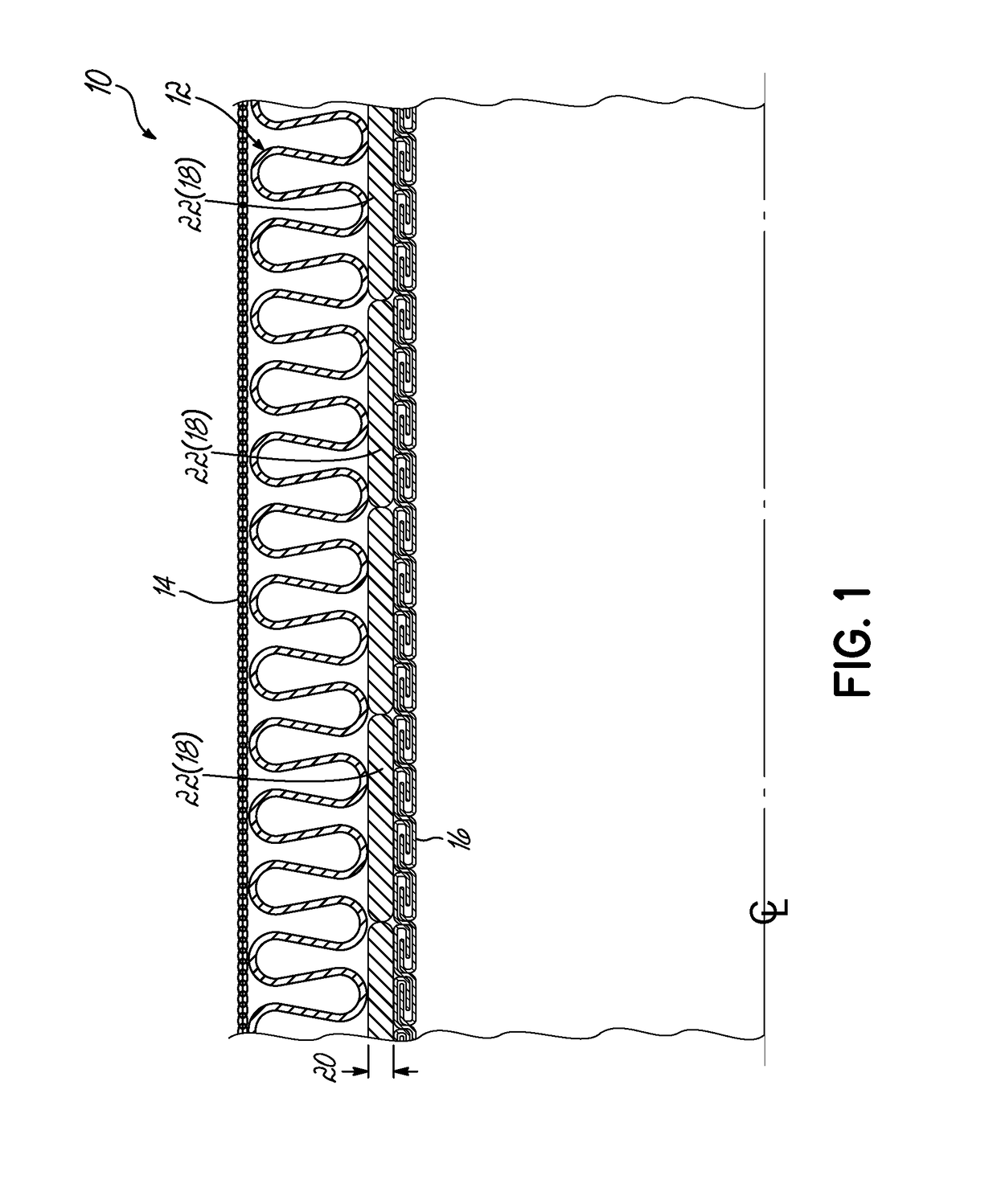

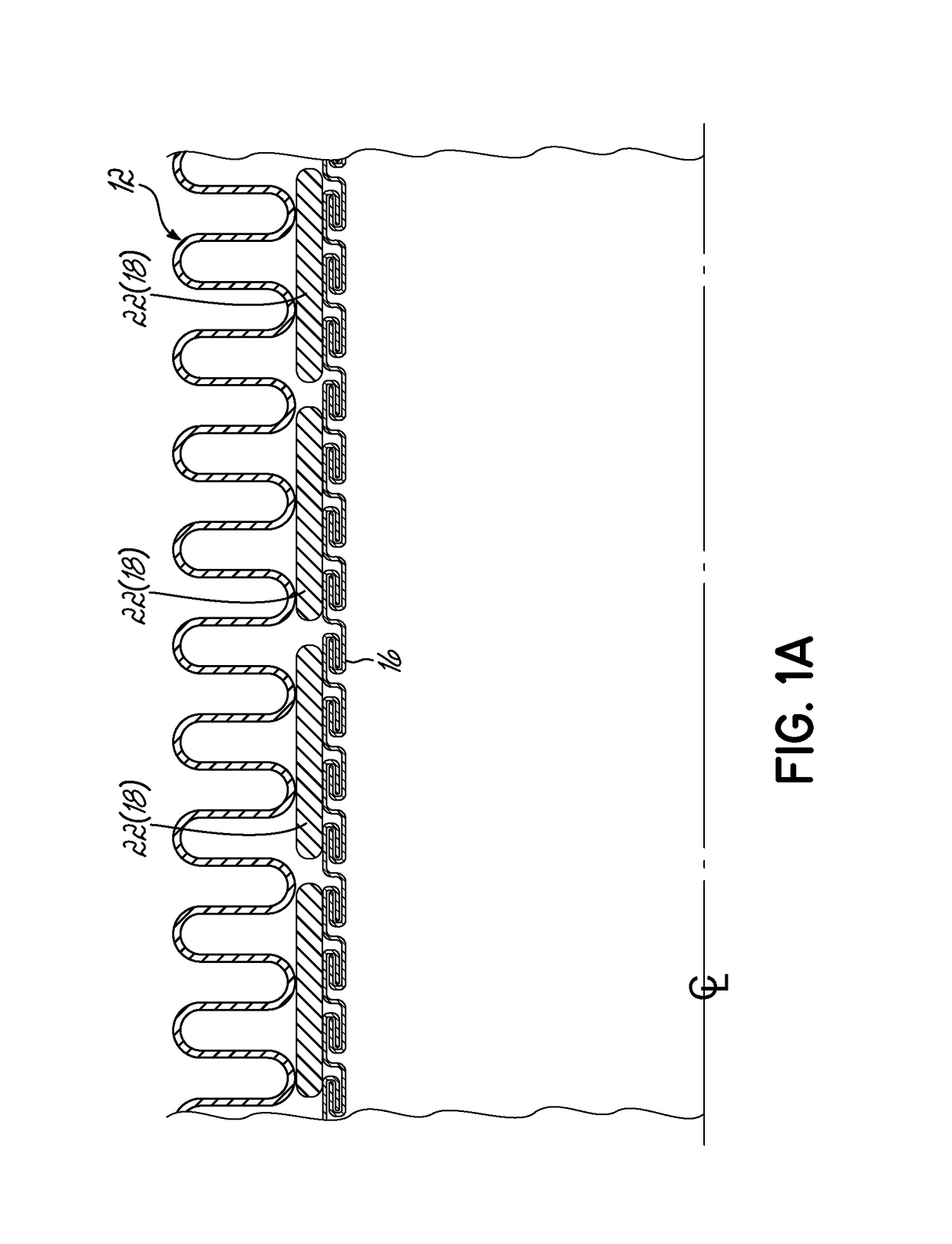

Crash optimized plunging CV joint

InactiveUS20030008716A1Minimize the number of componentsReduce the total massClutchesYielding couplingDrive shaftUniversal joint

A propeller shaft assembly (10) comprising a constant velocity universal joint (12) including a hollow shaft (20) and a connecting shaft (18) is provided. The hollow shaft (20) includes an aft open area (34) and is connected to an outer joint part (23) that has outer ball tracks (32). The connecting shaft (18) is connected to an inner joint part (25) that has inner ball tracks (46). A ball cage (26) that has a plurality of balls (28) is included. A standard plunge (22) that has an aft plunge portion (54) is also included. The aft plunge portion (54) and the aft open area (34) having inner diameters that are greater then or equal to an inner diameter D.sub.1 of the outer joint part (23). A first stop (55) limits the ball movement of travel in the aft direction. The first stop (55) is forcibly dispensable such that the connecting shaft (18) may release the first stop (55) and intrude significantly within the aft open area (34) which is outside a normal operating range (24).

Owner:GKN AUTOMOTIVE INC

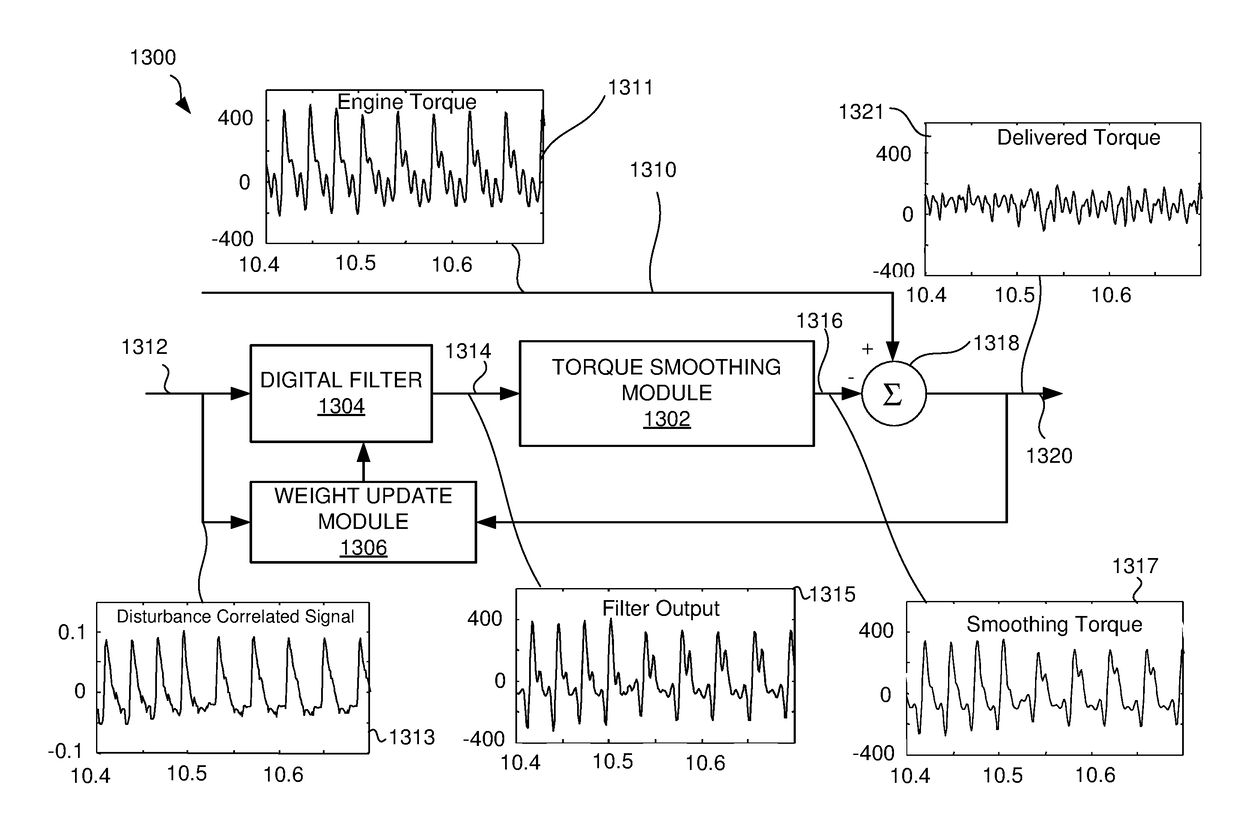

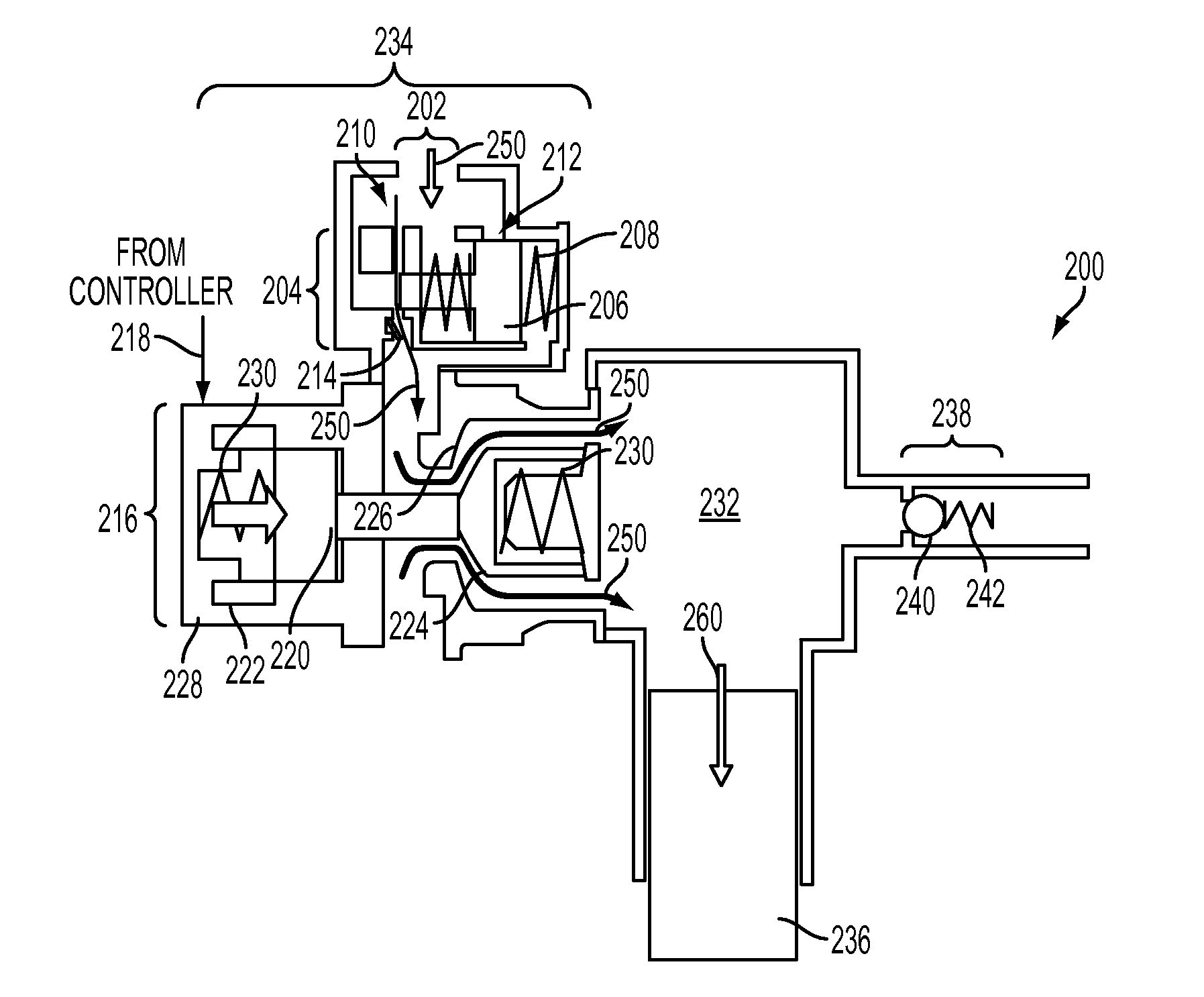

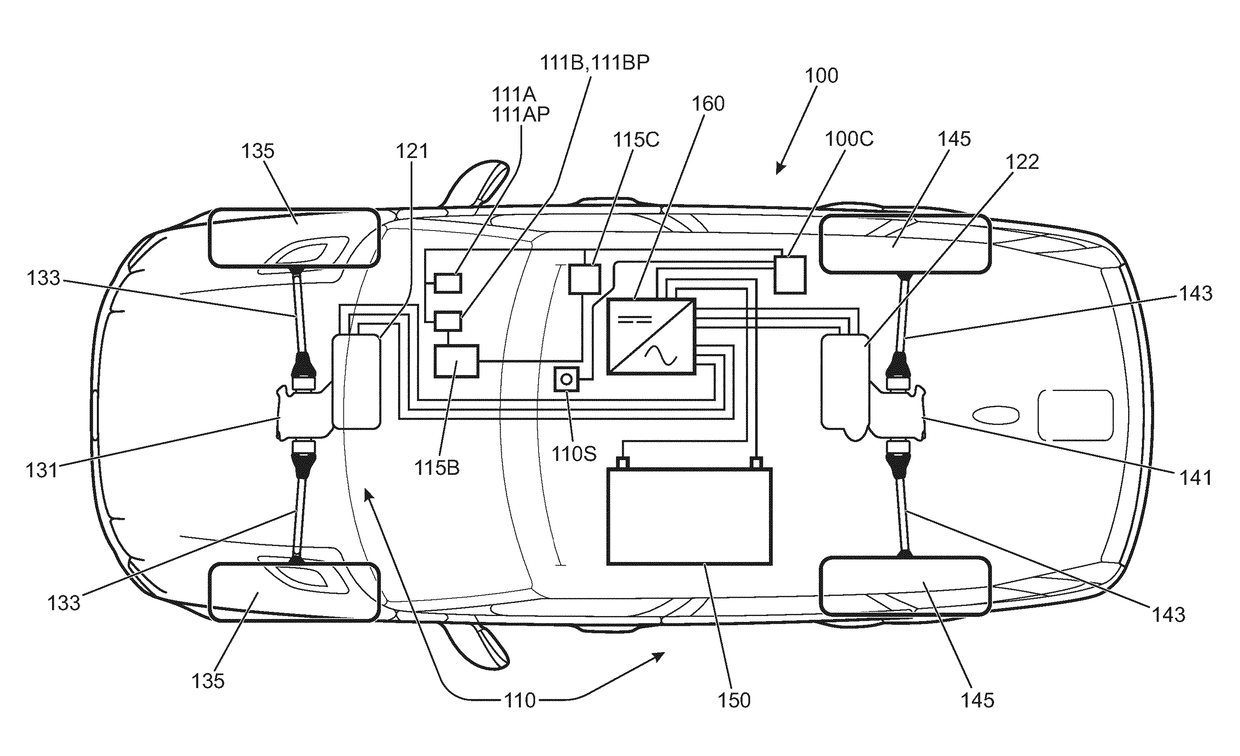

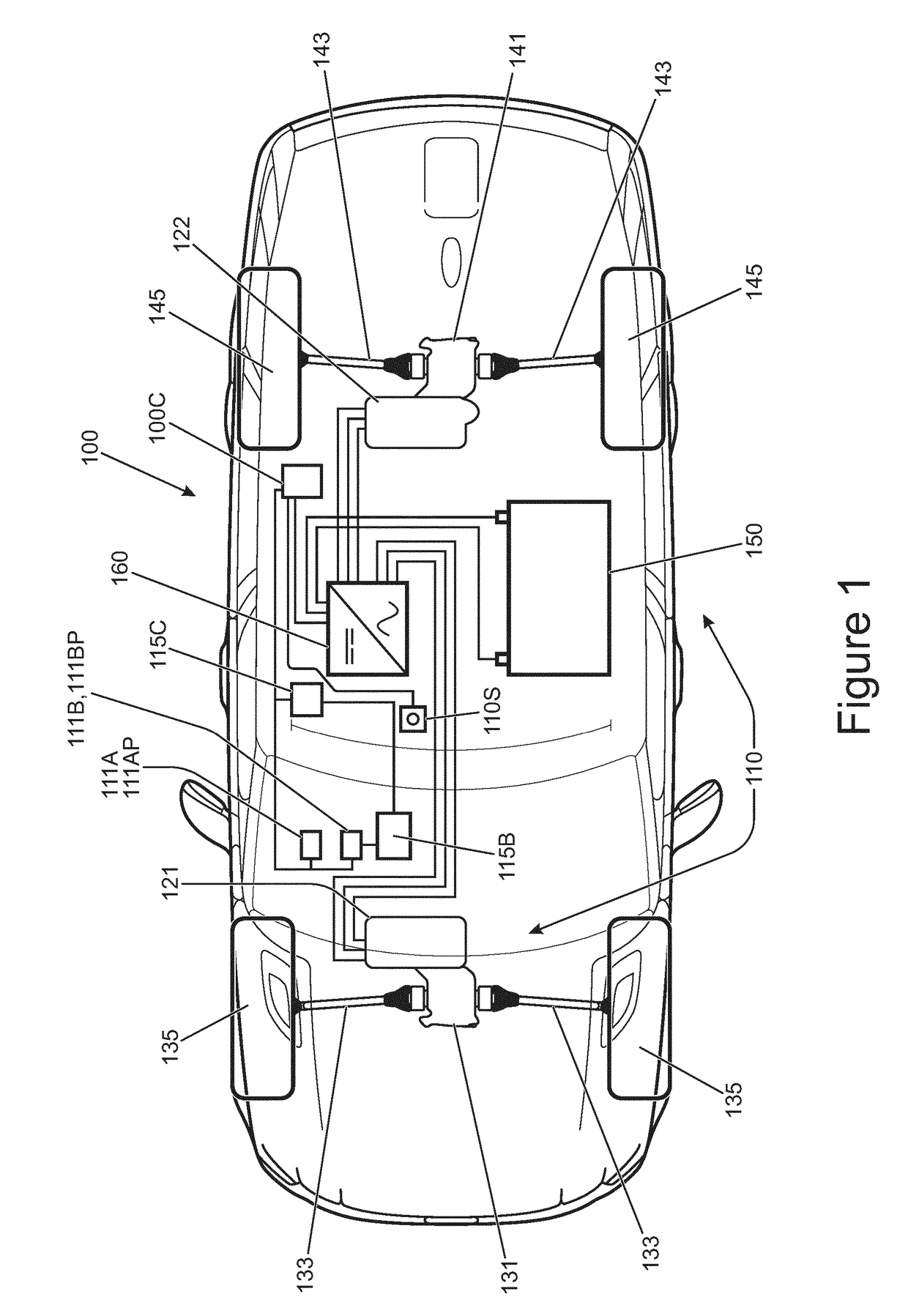

Adaptive torque mitigation by micro-hybrid system

ActiveUS20180230919A1Minimize consumptionAcceptable vibrationElectrical controlMachines/enginesHybrid systemControl system

A variety of methods and arrangements for reducing noise, vibration and harshness (NVH) in a skip fire engine control system are described. In one aspect, a firing sequence is used to operate the engine in a dynamic firing level modulation manner. A smoothing torque is determined by adaptive control that is applied to a powertrain by an energy storage / release device. The smoothing torque is arranged to at least partially cancel out variation in torque generated by the firing sequence. Various methods, powertrain controllers, arrangements and computer software related to the above operations are also described.

Owner:TULA TECH INC

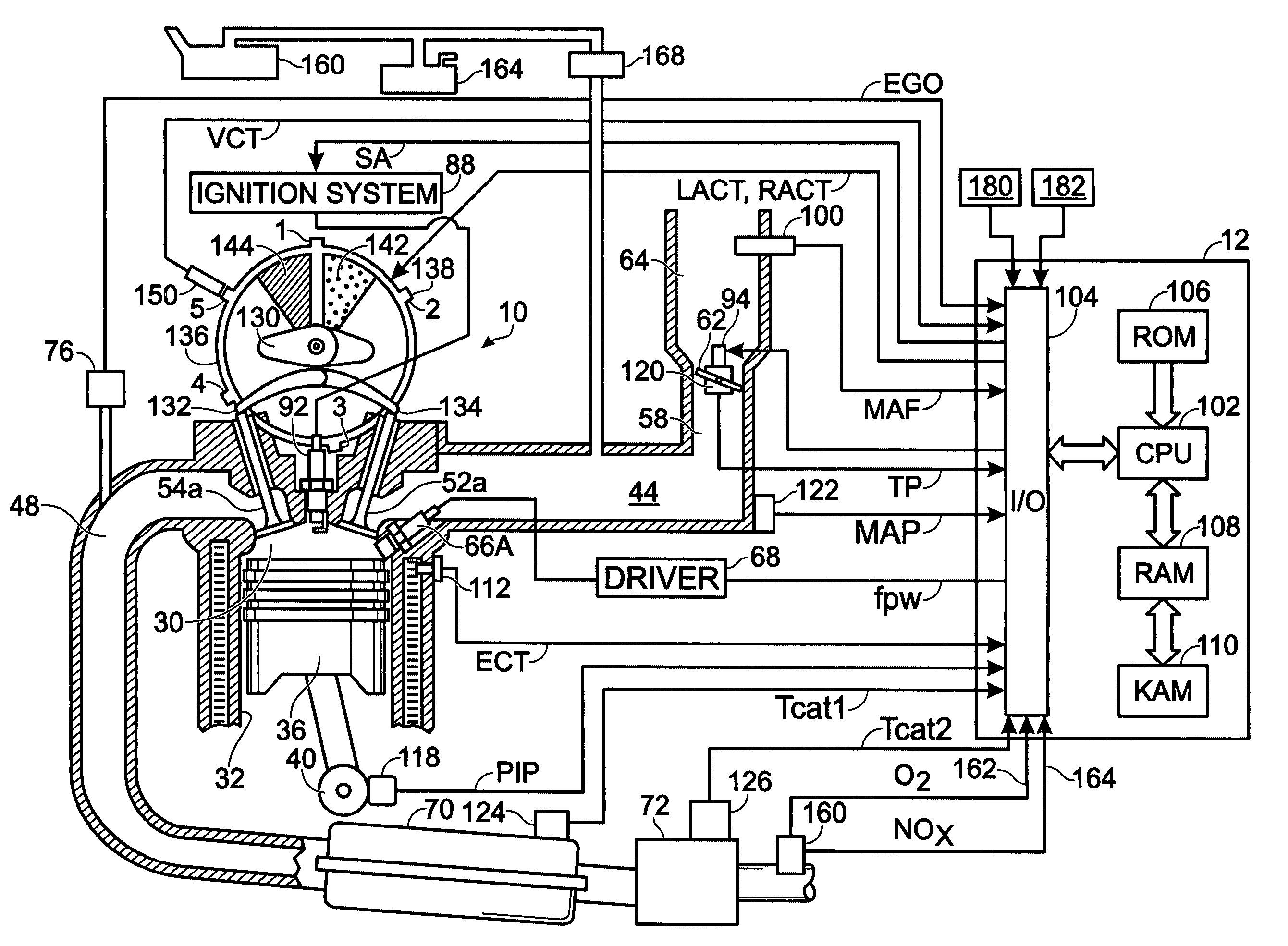

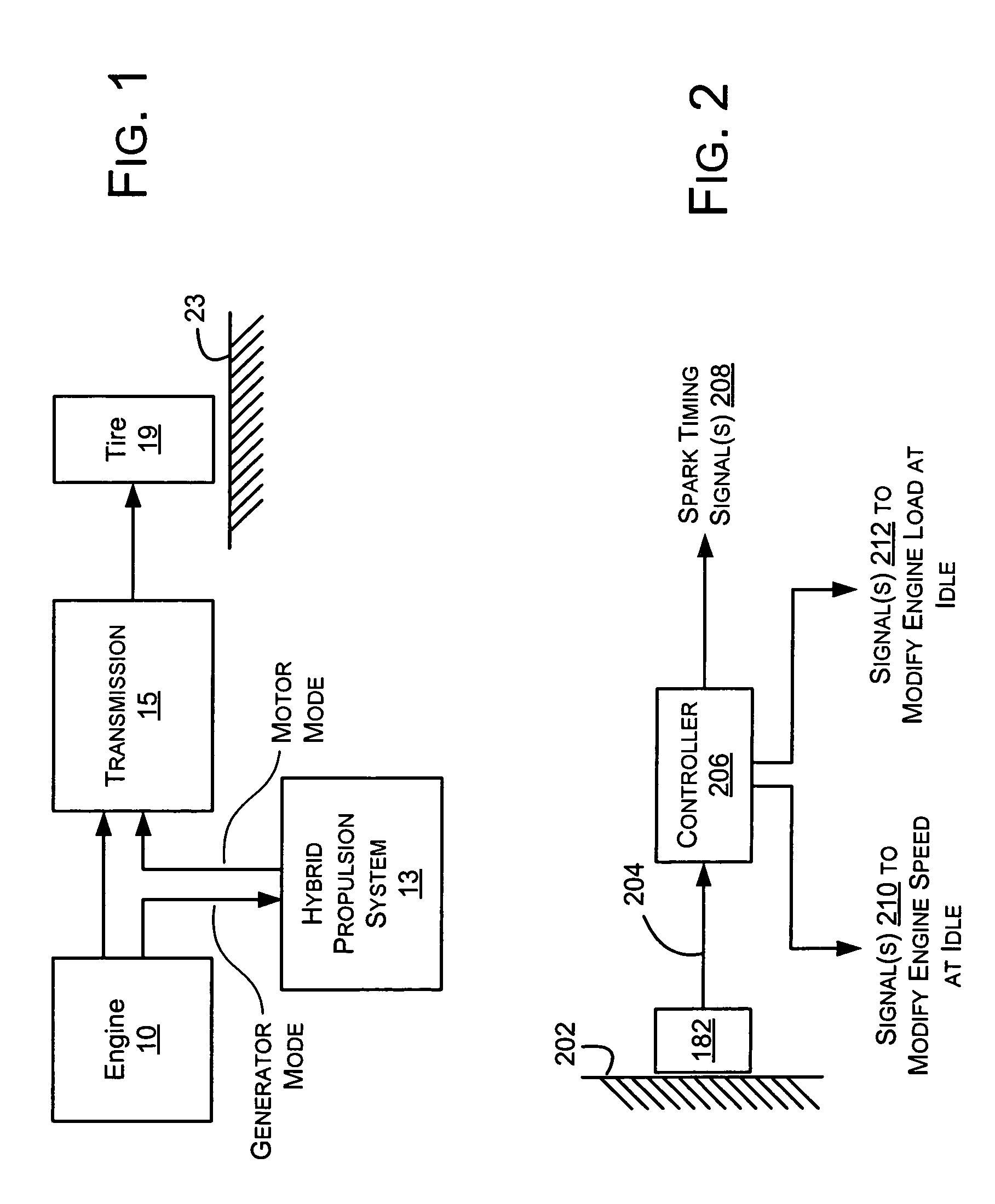

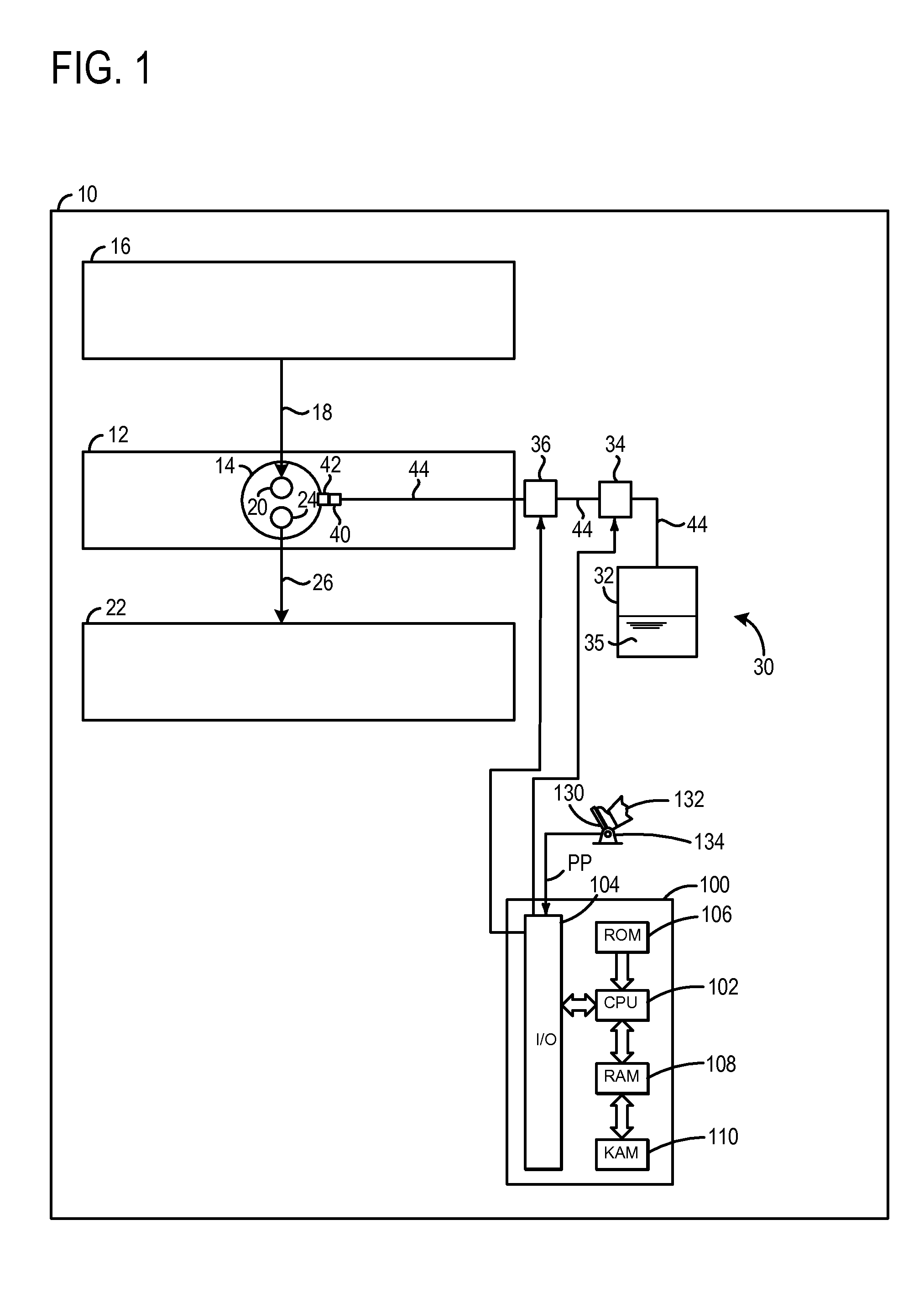

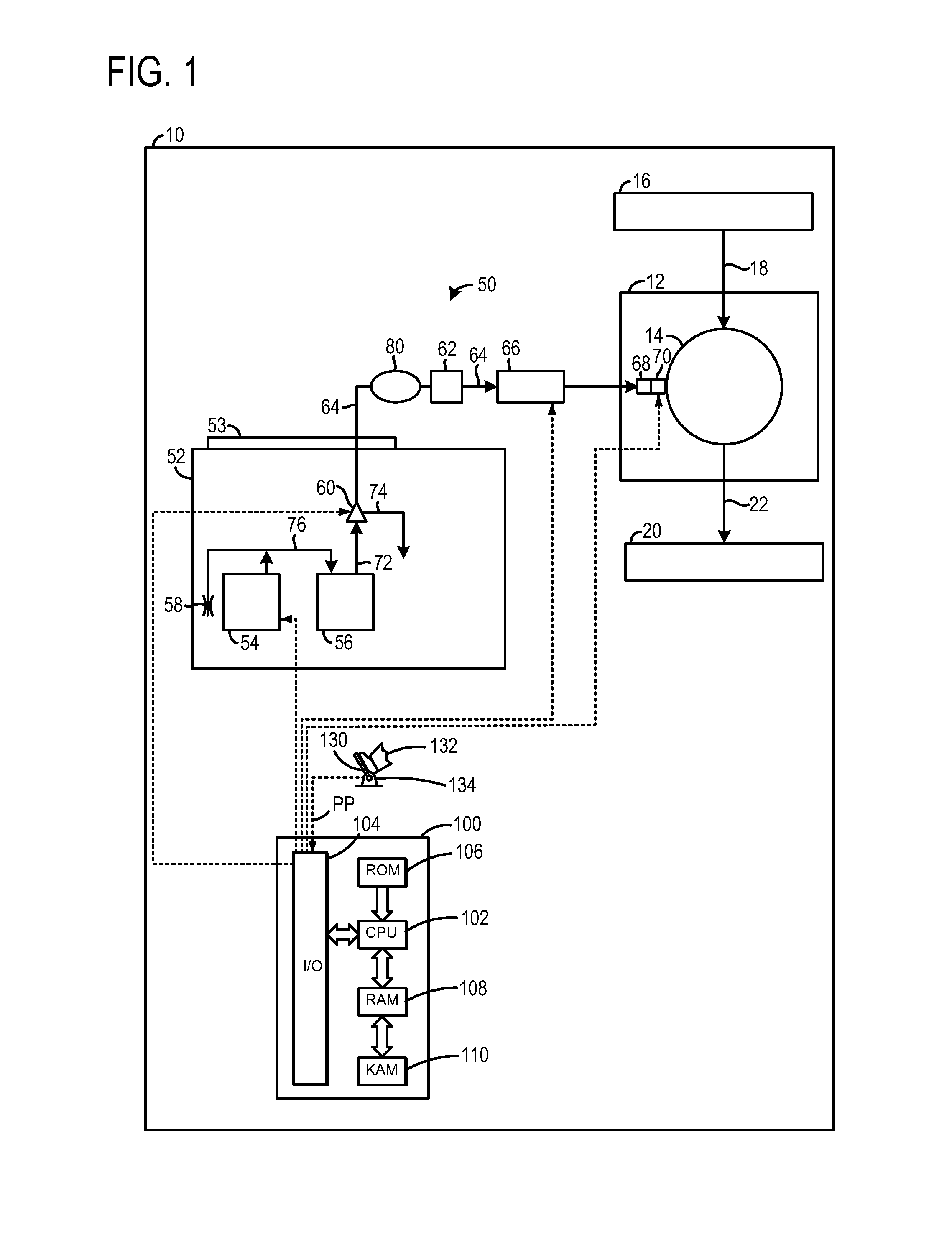

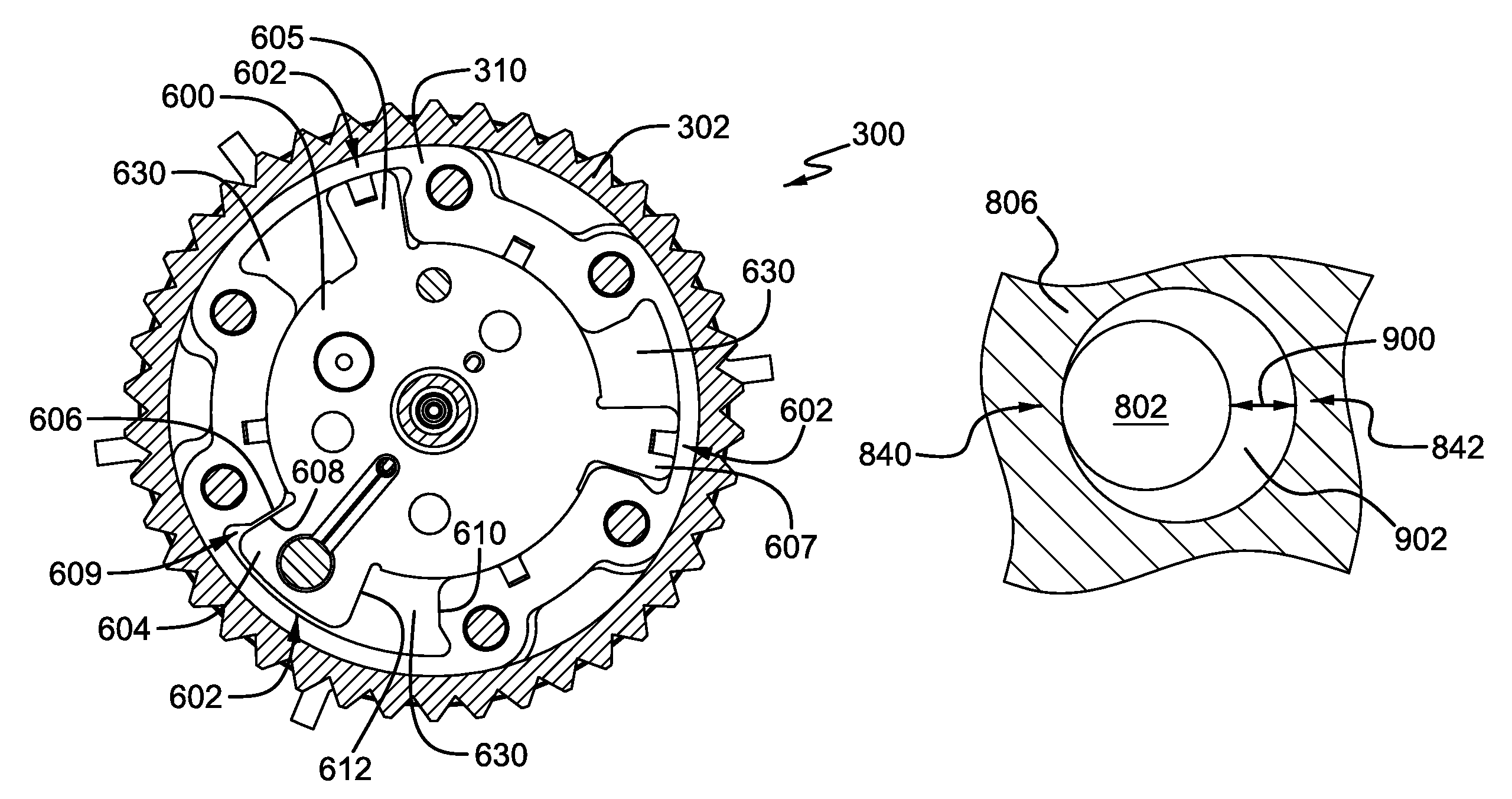

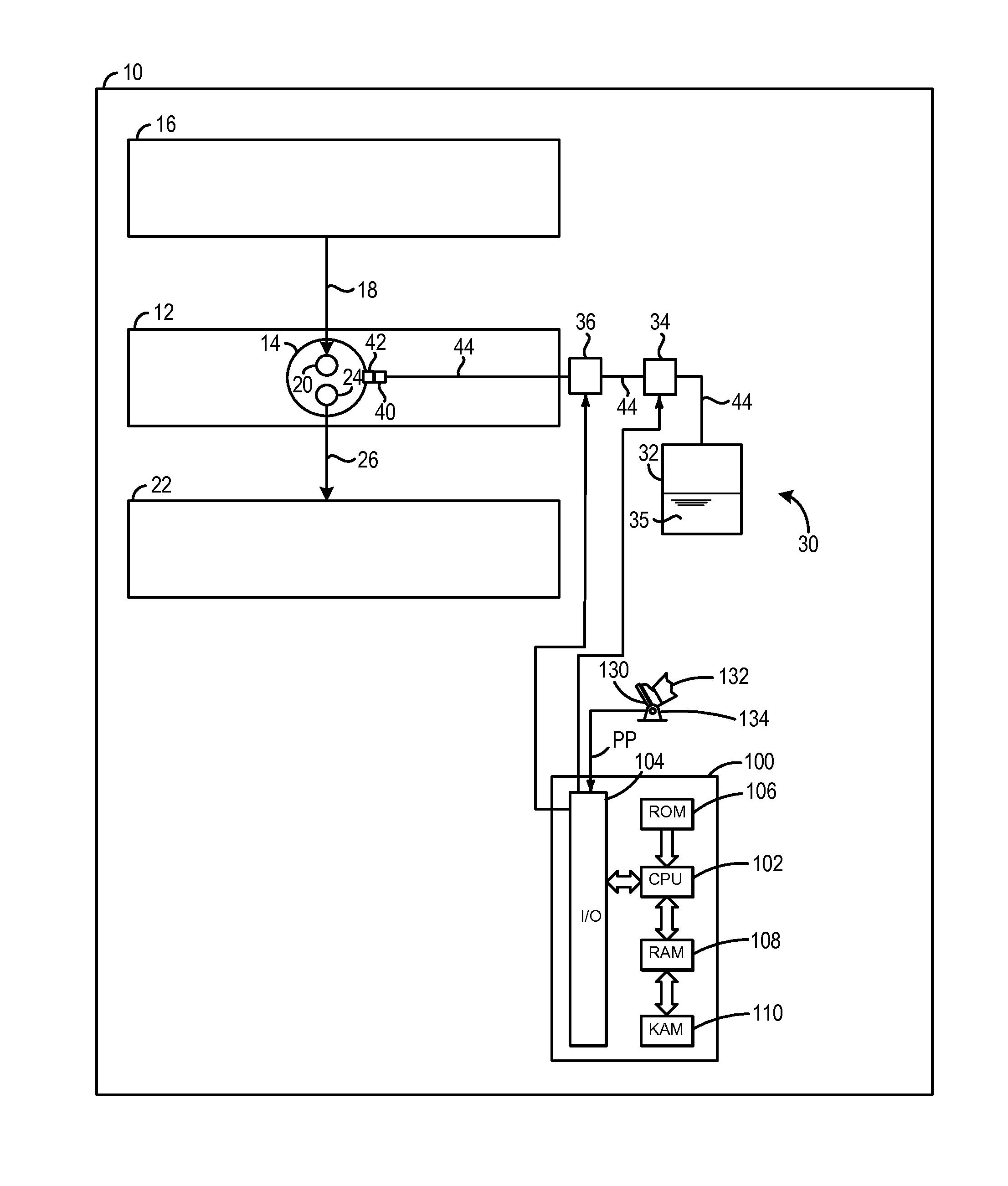

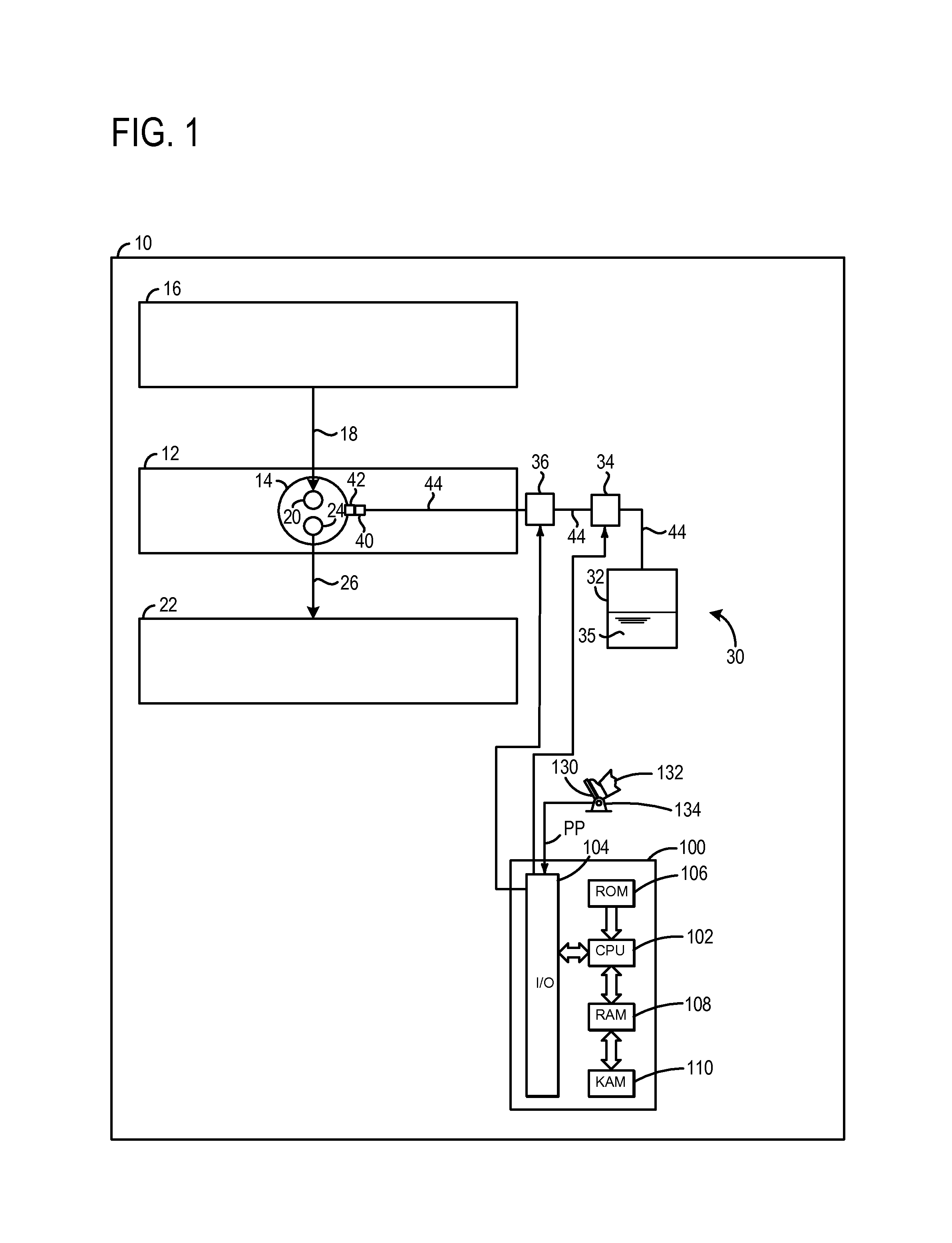

Vibration-based NVH control during idle operation of an automobile powertrain

ActiveUS7174879B1Affect customer satisfactionReduce NVHElectrical controlNon-fuel substance addition to fuelVibration basedPowertrain

A system and method of operating a vehicle powertrain that employs active control to reduce NVH, particularly during idle. The method includes selectively operating the powertrain in at least a non-idle condition and an idle condition; receiving vibration signals from a sensor disposed on an internal combustion engine; controlling spark timing of the internal combustion engine based on vibration signals received from the sensor; and during the idle condition, modifying a speed and / or a load of the internal combustion engine based on vibration signals received from the sensor.

Owner:FORD GLOBAL TECH LLC

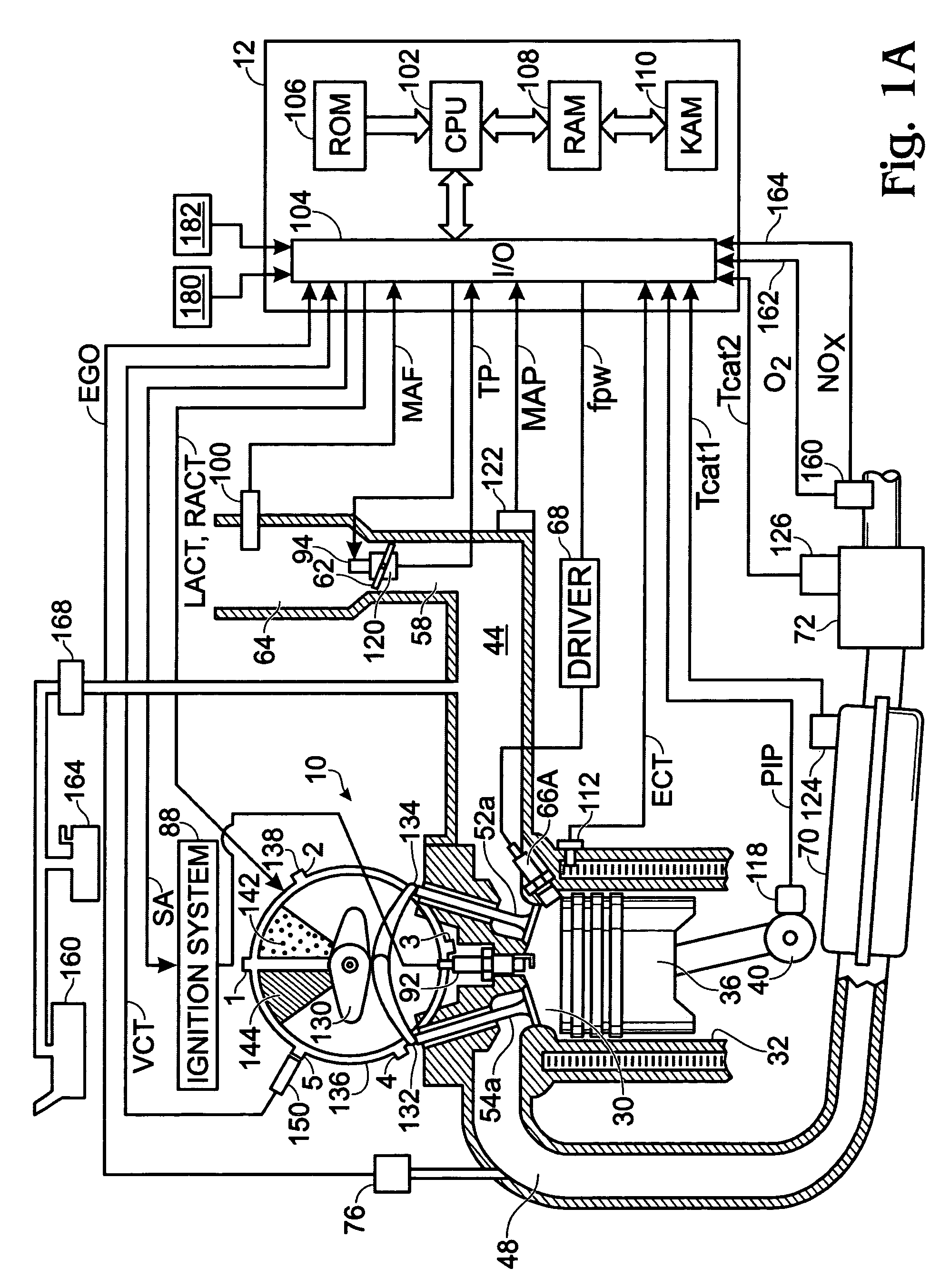

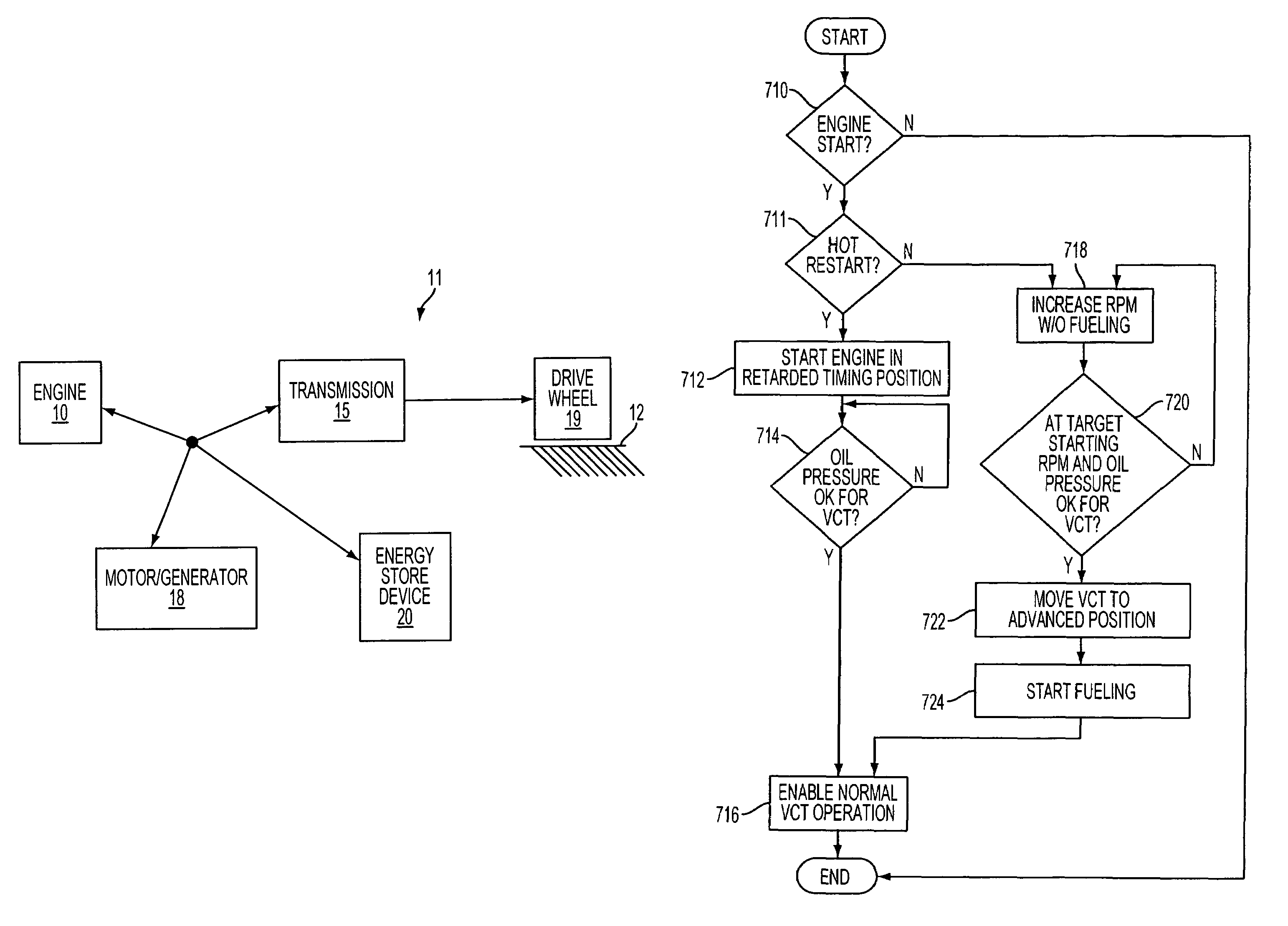

Hybrid vehicle system having engine with variable valve operation

ActiveUS7527028B2Improve operationReduce vibrationHybrid vehiclesYielding couplingExhaust valveVariable valve timing

Owner:FORD GLOBAL TECH LLC

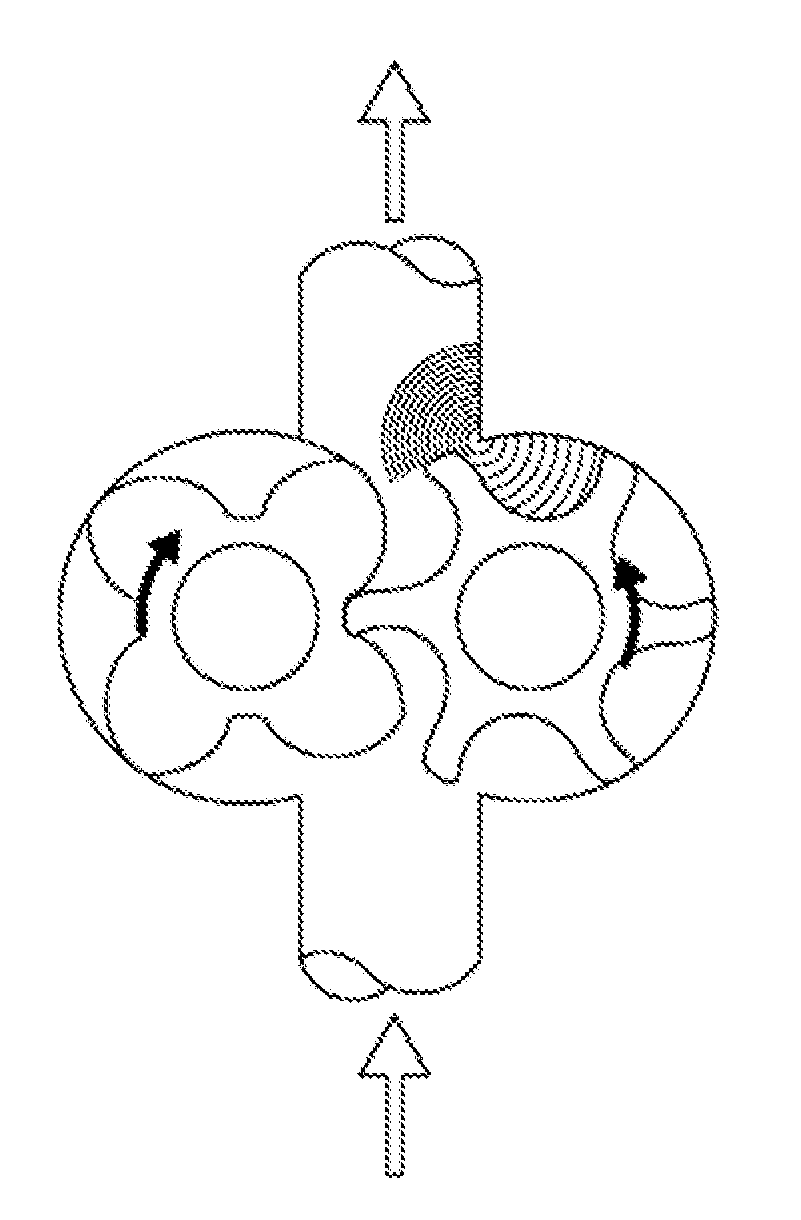

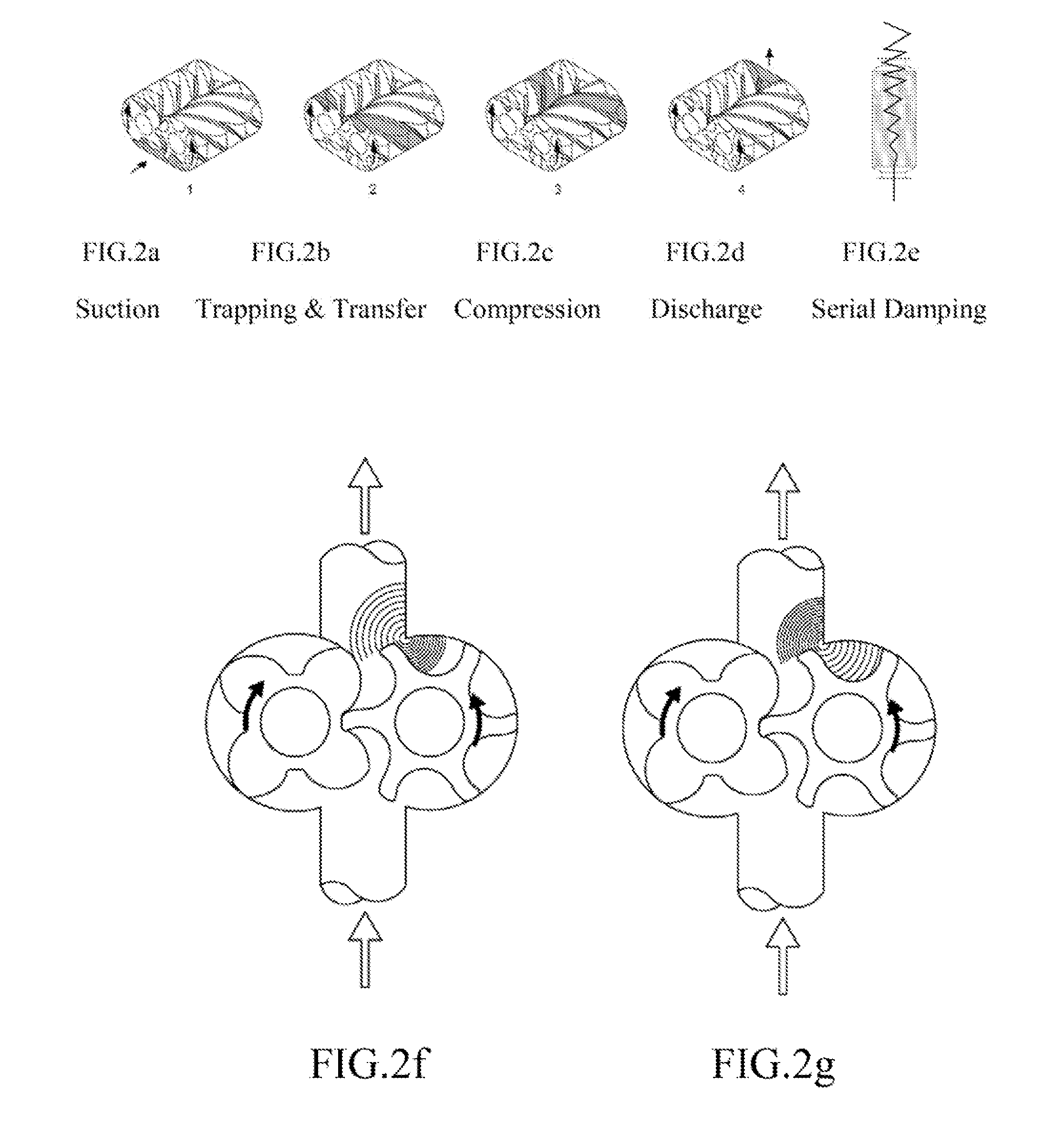

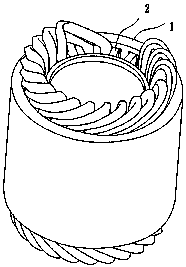

Screw compressor with a shunt pulsation trap

ActiveUS20120171069A1Reducing gas pulsationSimple structurePositive displacement pump componentsOscillating piston enginesInjection portOff design

A shunt pulsation trap for a screw compressor reduces gas pulsation, NVH and improves off-design efficiency without using a traditional serial pulsation dampener and a sliding valve. Generally, a screw compressor with the shunt pulsation trap has a pair of multi-helical-lobe rotors housed in a compressor chamber for propelling gas flow from a suction port to a discharge port of the compressor chamber with internal compression. The shunt pulsation trap comprises an inner casing as an integral part of the compressor chamber, and an outer casing oversized surrounding the inner casing, therein housed various gas pulsation dampening means or gas pulsation energy recovery means or gas pulsation containment means, at least one injection port (trap inlet) branching off from the compressor chamber into the pulsation trap chamber and a feedback region (trap outlet) communicating with the compressor outlet.

Owner:HI BAR BLOWERS

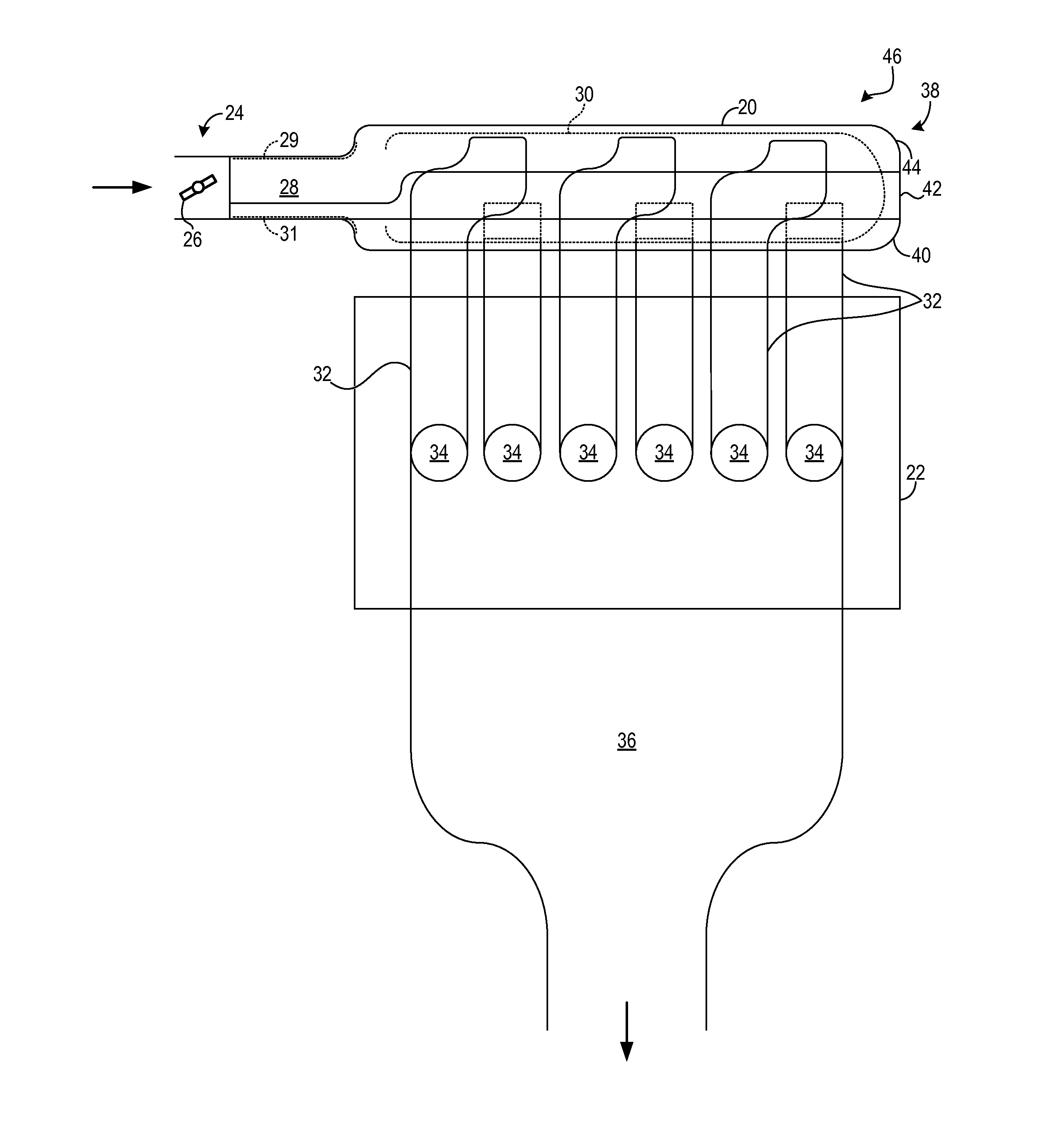

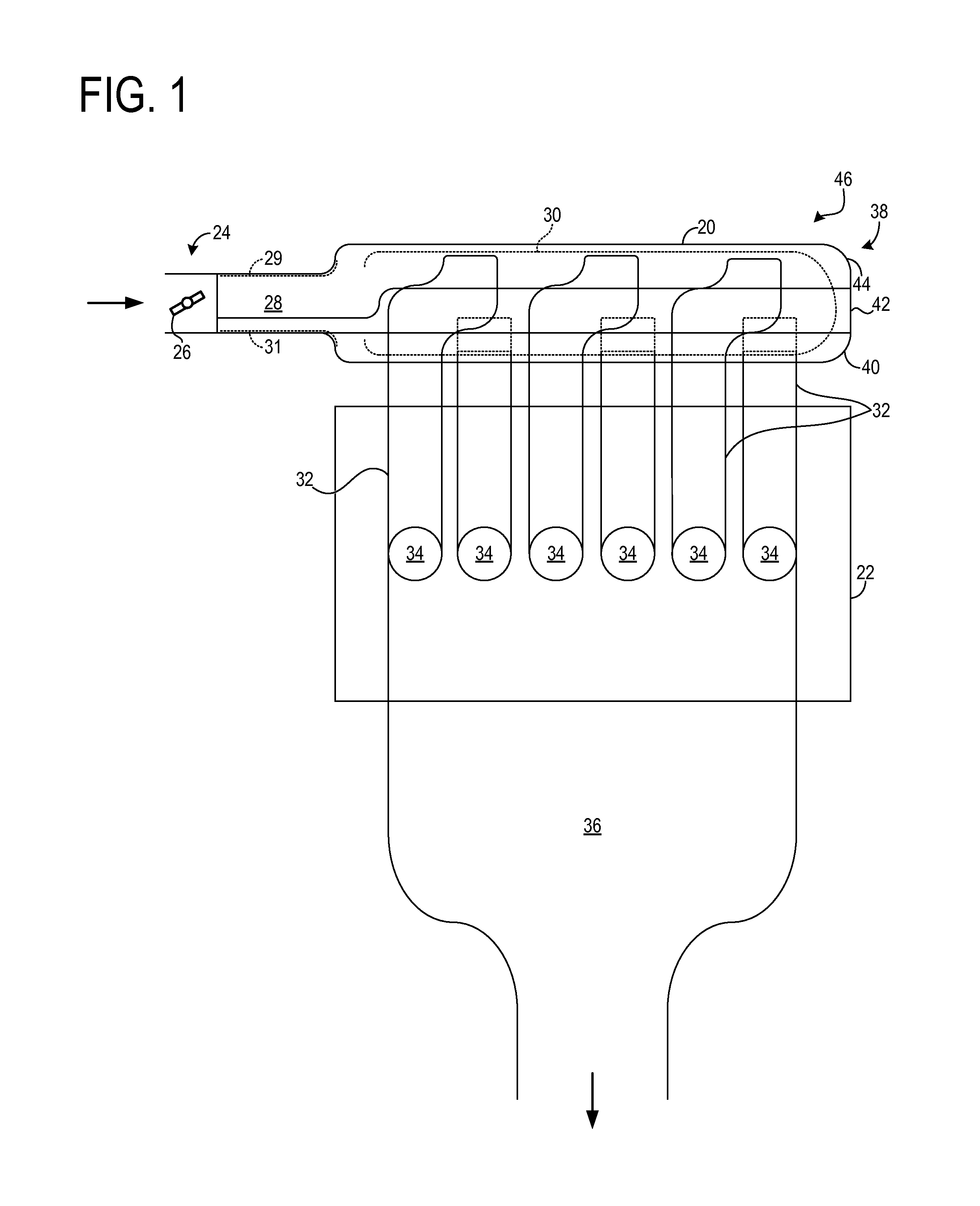

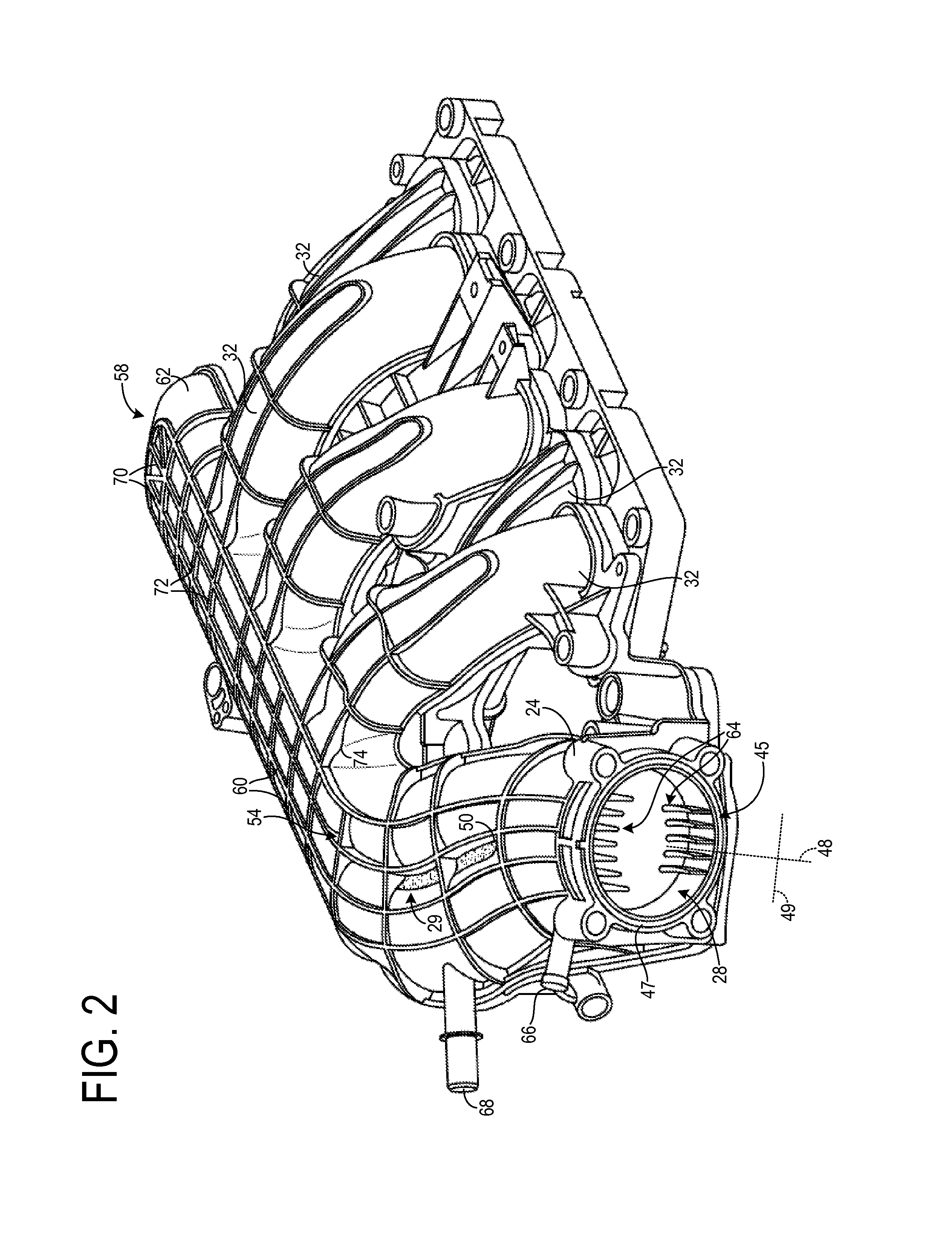

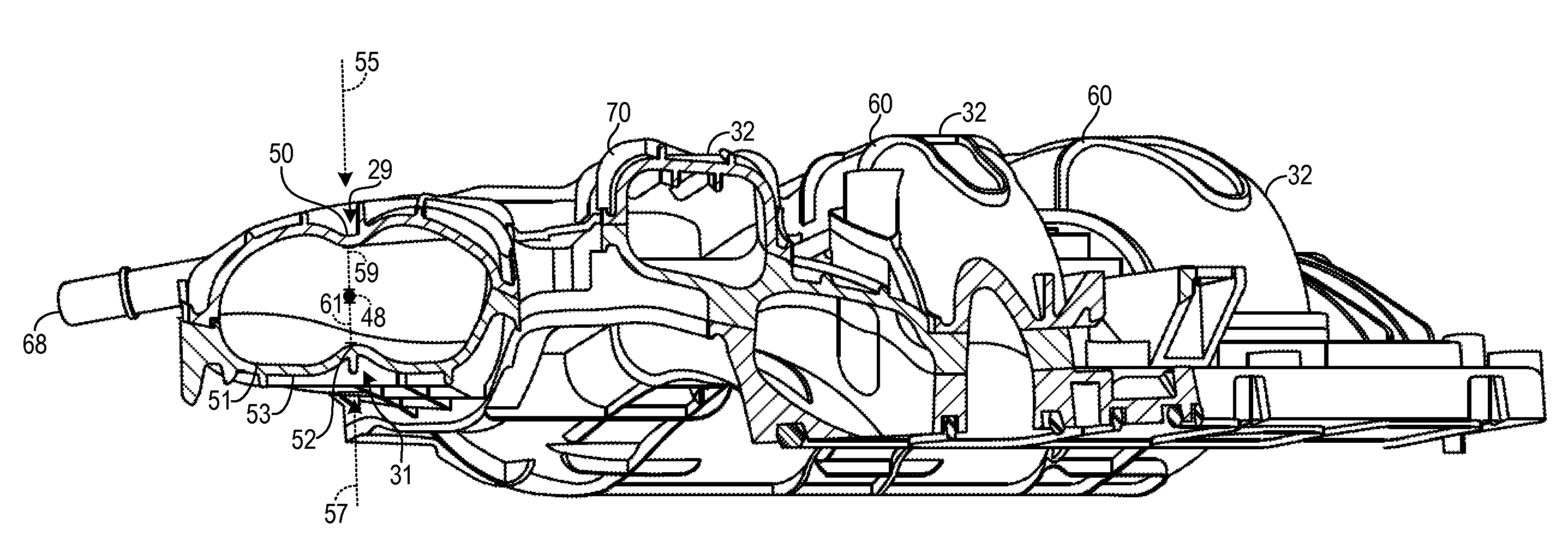

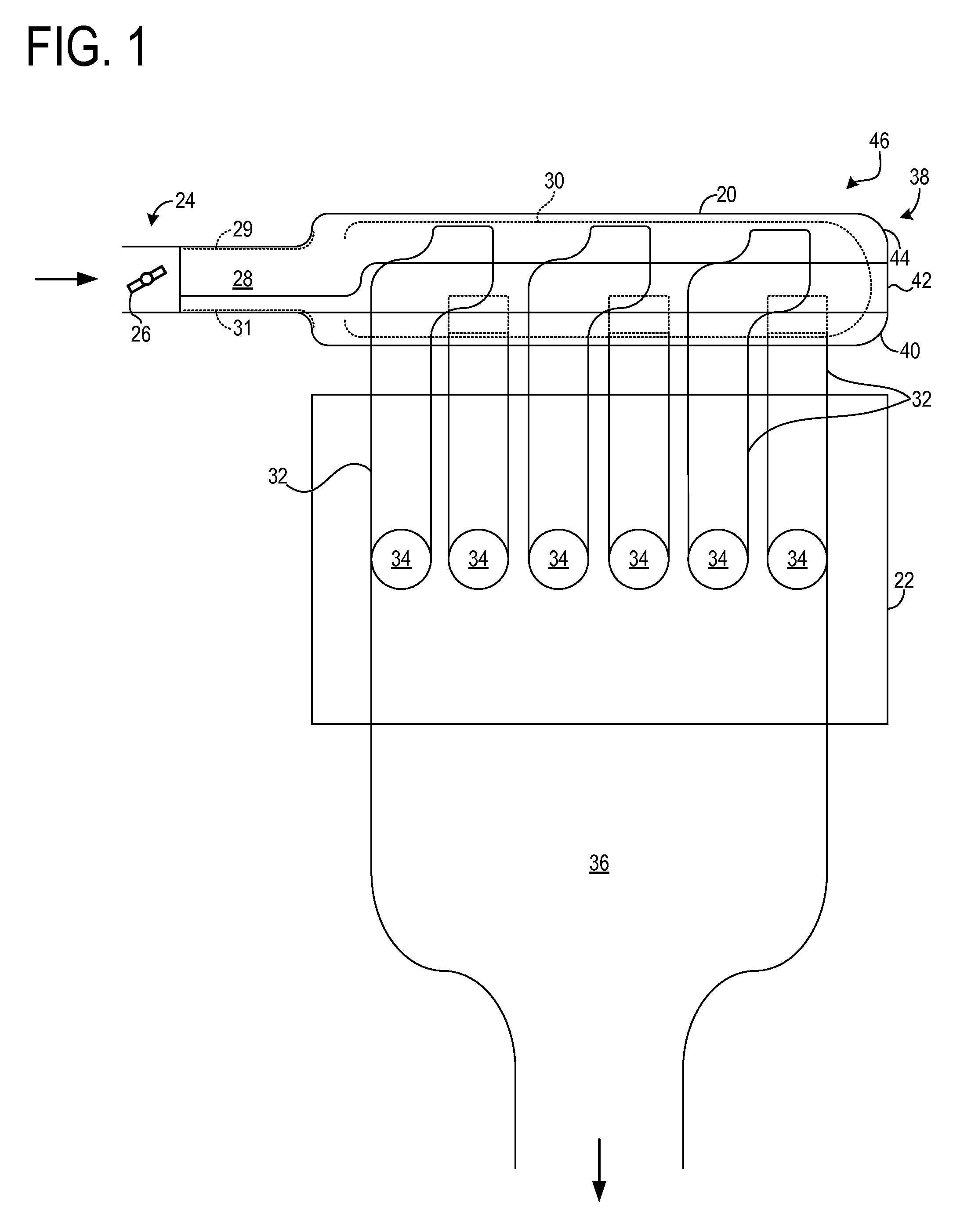

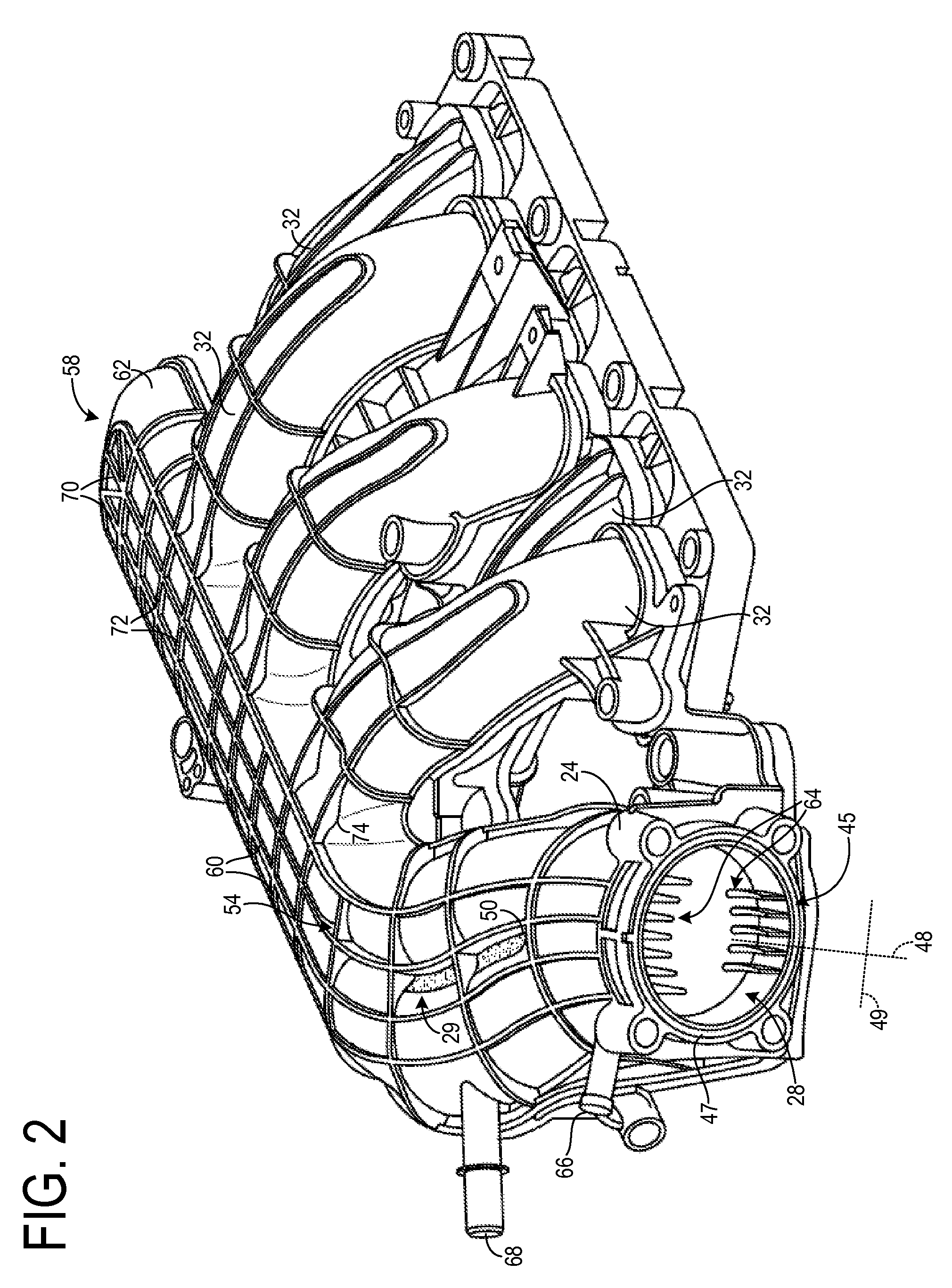

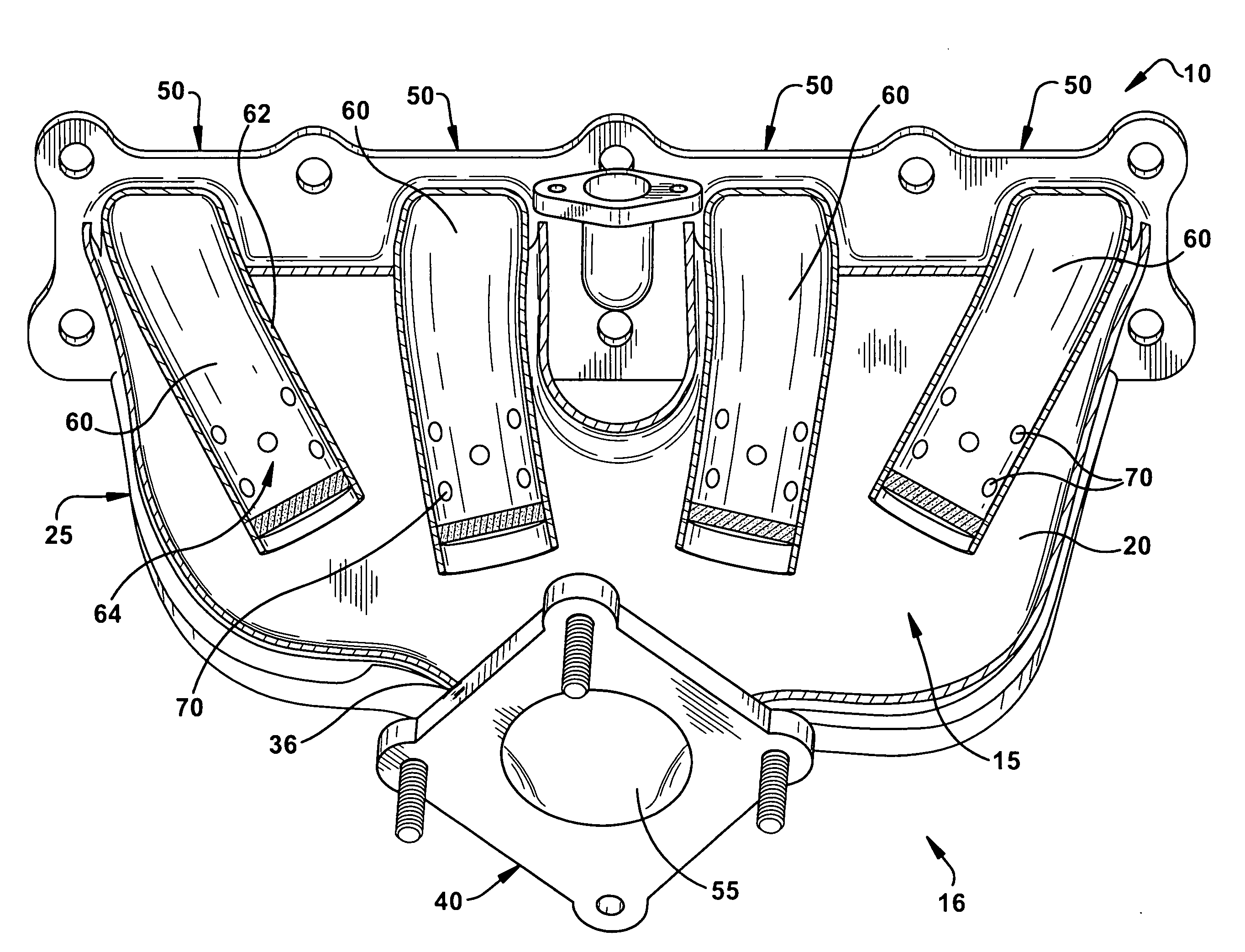

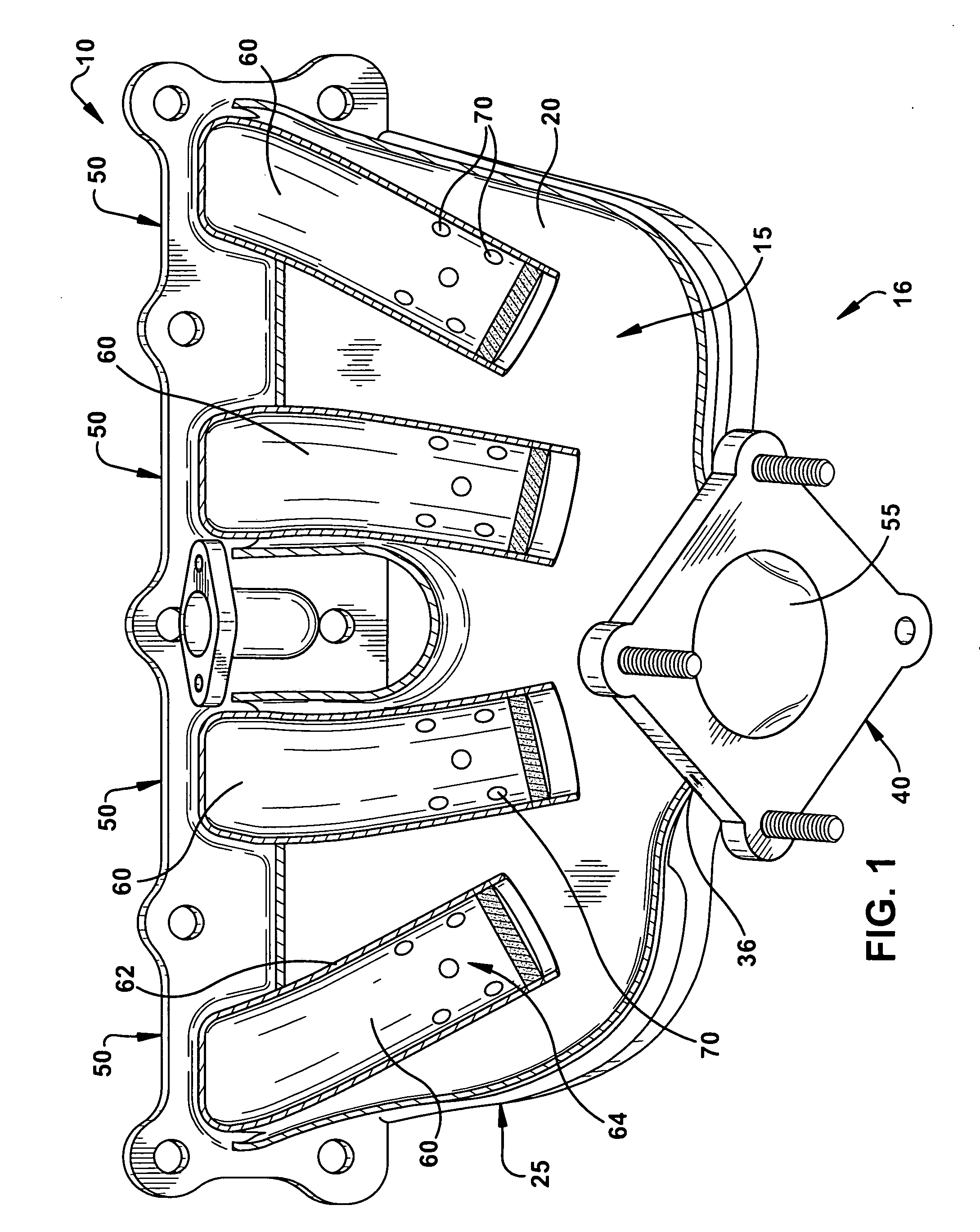

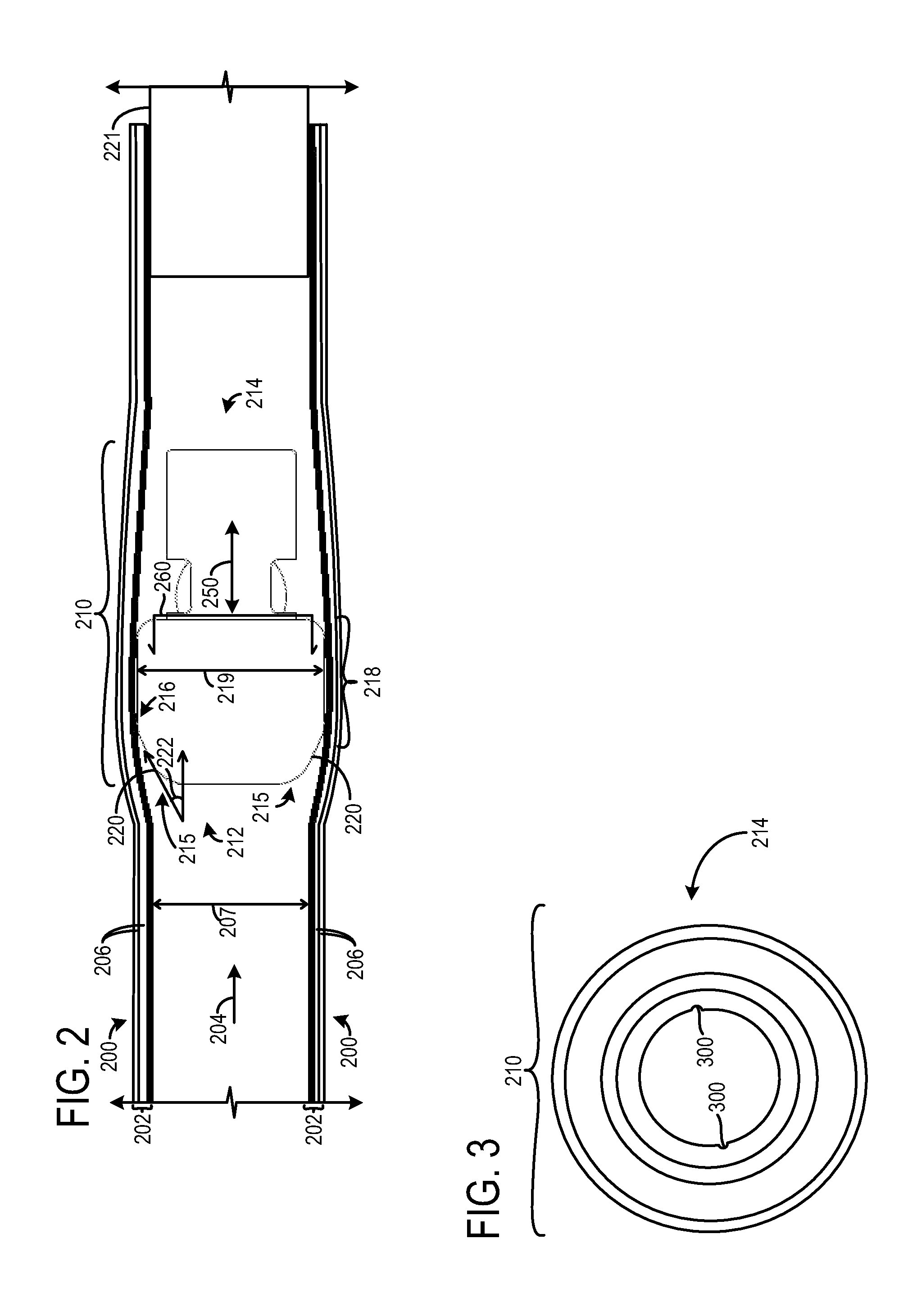

Intake manifold

ActiveUS20140216387A1Reduce noiseReduce vibrationCombustion enginesAir intakes for fuelEngineeringInlet manifold

Various systems for reducing noise, vibration, and harshness in an intake manifold are provided. In one example, an intake manifold includes one or more runners, a plenum fluidically coupled to the one or more runners, an inlet having a wall thickness, and a first and a second indentation, where the first indentation protrudes radially inward at a first inflection point in a first direction, the second indentation protrudes radially inward at a second inflection point in a second direction substantially anti-parallel to the first direction, and the wall thickness is maintained at the first and second inflection points. In this way, noise, vibration, and harshness associated with the intake manifold and its inlet may be reduced without additional weight, cost, or complexity.

Owner:FORD GLOBAL TECH LLC

Adaptive torque mitigation by micro-hybrid system

ActiveUS10344692B2Minimize consumptionAcceptable vibrationElectrical controlMachines/enginesHybrid systemControl system

A variety of methods and arrangements for reducing noise, vibration and harshness (NVH) in a skip fire engine control system are described. In one aspect, a firing sequence is used to operate the engine in a dynamic firing level modulation manner. A smoothing torque is determined by adaptive control that is applied to a powertrain by an energy storage / release device. The smoothing torque is arranged to at least partially cancel out variation in torque generated by the firing sequence. Various methods, powertrain controllers, arrangements and computer software related to the above operations are also described.

Owner:TULA TECH INC

Intake manifold

ActiveUS8955485B2Reduce noiseReduce vibrationCombustion enginesAir intakes for fuelEngineeringInlet manifold

Owner:FORD GLOBAL TECH LLC

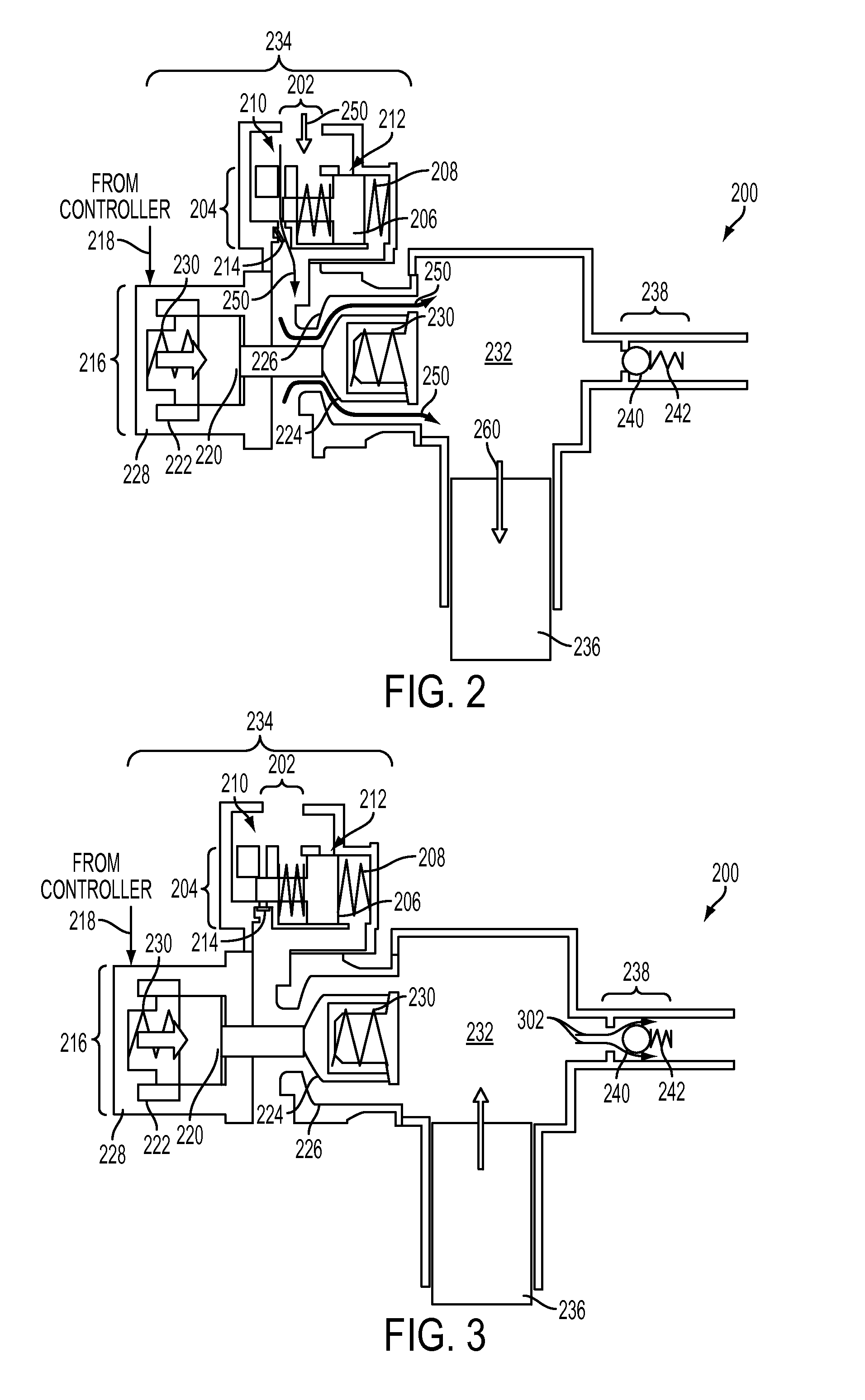

Engine fuel pump and method for operation thereof

ActiveUS20150027416A1Decrease NVHReduce NVHElectrical controlNoise reducing fuel injectionEngineeringFuel pump

A method of pressuring fuel for a direct injection fuel system via a fuel pump in an engine is provided. The method includes, during a first mode, adjusting a magnetic solenoid valve (MSV) to control pump outlet pressure and during a second mode, deactivating the MSV and controlling pump outlet pressure via a noise-reducing valve assembly on an inlet side of the fuel pump.

Owner:FORD GLOBAL TECH LLC

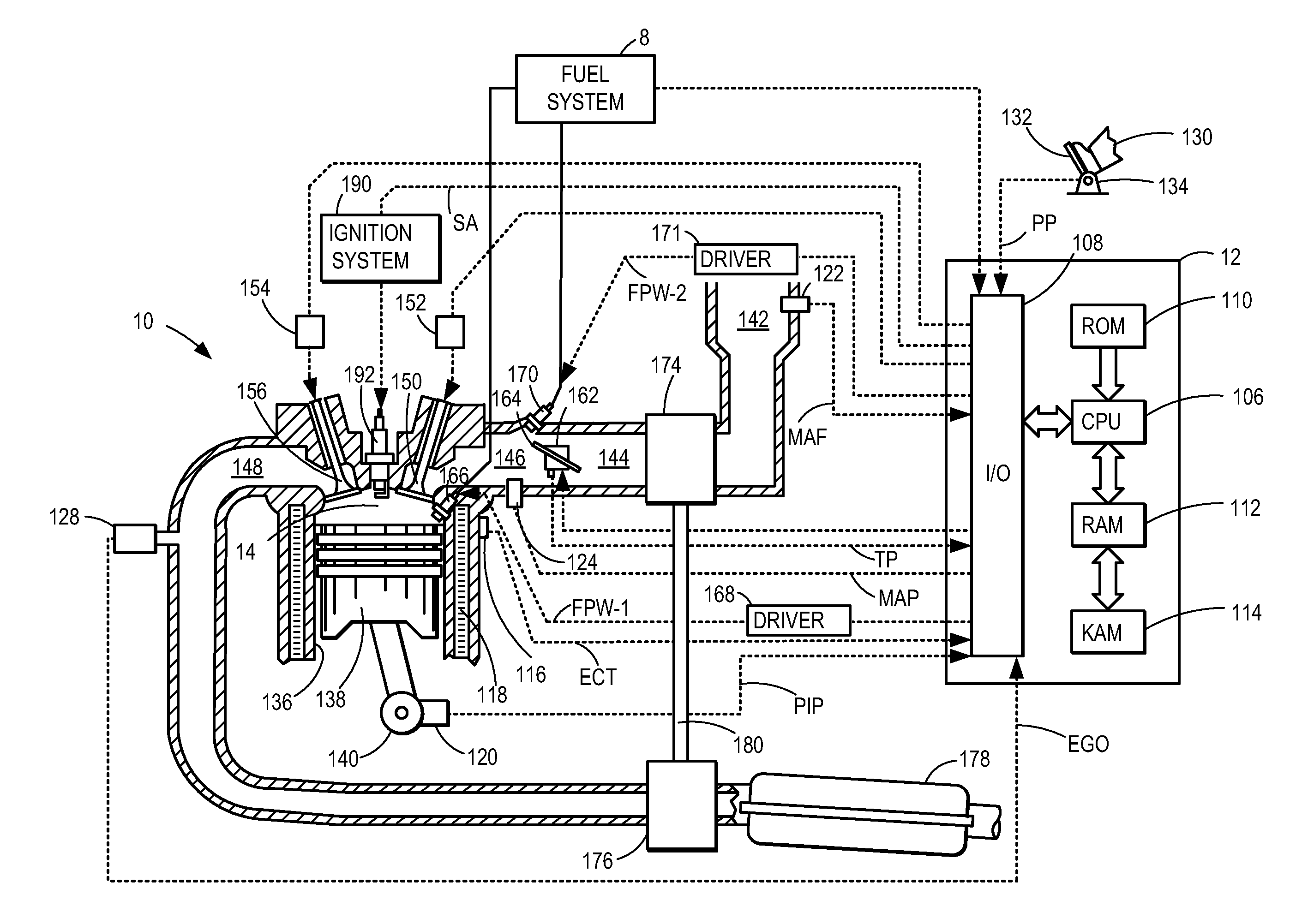

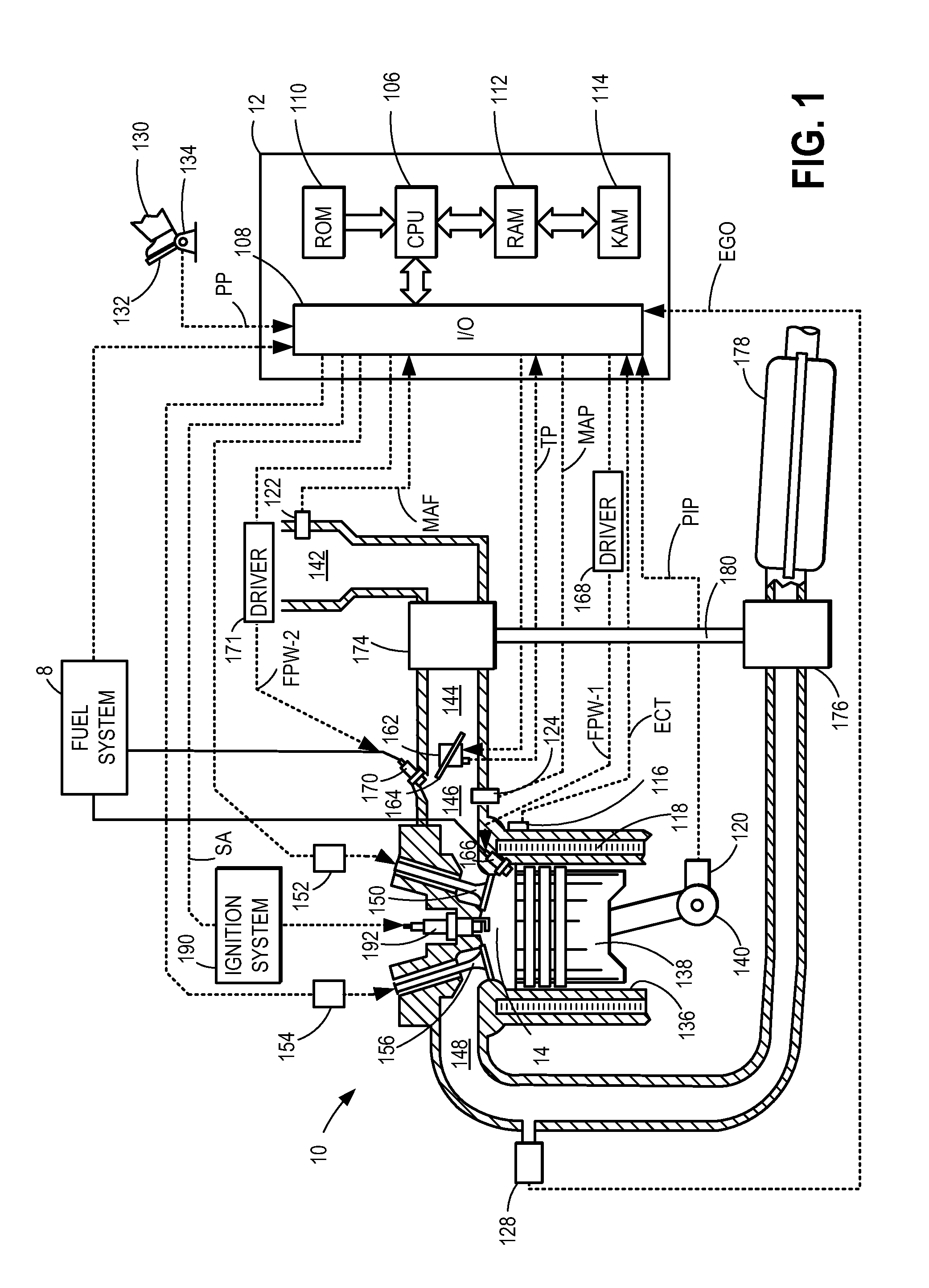

Robust direct injection fuel pump system

ActiveUS20150198081A1Improve engine performanceReducing vehicle emissionElectrical controlCombustion enginesPressure differencePump pressure

A method for a PFDI engine may comprise, during a first condition, comprising direct-injecting fuel to the PFDI engine, estimating a fuel vapor pressure, and setting a fuel lift pump pressure greater than the fuel vapor pressure by a threshold pressure difference, and during a second condition, comprising port-fuel-injecting fuel to the PFDI engine, setting a DI fuel pump command signal greater than a threshold DI fuel pump command signal without supplying fuel to a DI fuel rail.

Owner:FORD GLOBAL TECH LLC

Exhaust manifold having improved NVH characteristics

InactiveUS20090007552A1Easy to assembleReduce NVHSilencing apparatusMachines/enginesCombustionCylinder head

An exhaust manifold and method of manufacturing the same is provided that includes at least one tube within shells of an exhaust manifold. The tube limits fluid communication from the tube into the shells of the exhaust manifold. An inlet flange is connectable to the exhaust manifold and is attachable to a cylinder head of a combustion engine. Exhaust gases expelled from the cylinder head are transmitted into the exhaust manifold. At least a portion of the exhaust gases pass through the tube. The exhaust manifold reduces NVH and cures emission control issues.

Owner:METALDYNE TUBULAR COMPONENTS

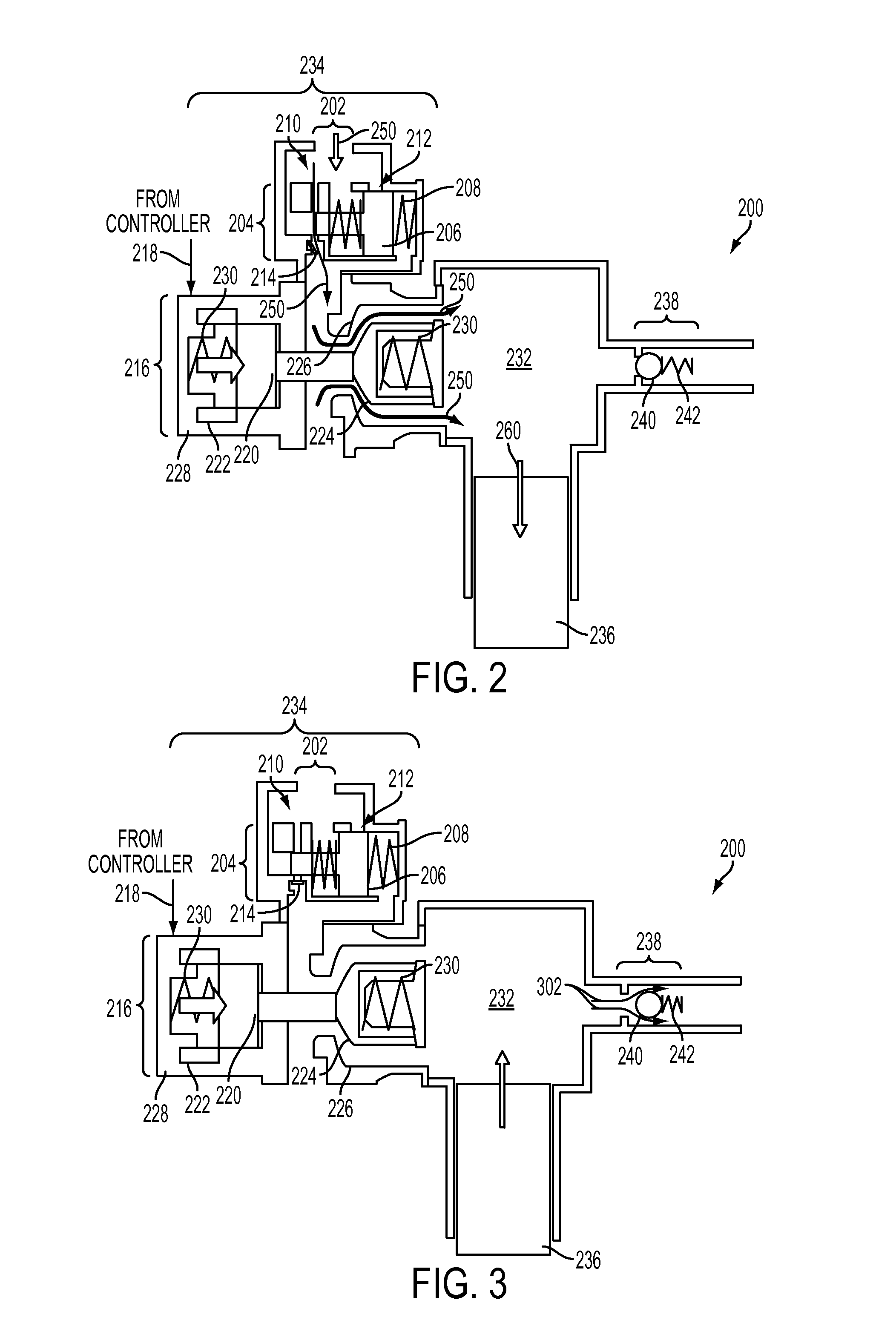

Controller for a motor vehicle and method

ActiveUS20180312081A1Reduce vehicle costReduced Tolerance RequirementsHybrid vehiclesSpeed controllerMobile vehicleMotorized vehicle

A controller for a motor vehicle powertrain, the controller being configured to control the amount of torque generated by each of a plurality of drive torque sources, each drive torque source being coupled via a respective torque transfer arrangement to a respective group of one or more wheels, the controller being configured to cause a first of the drive torque sources, during acceleration, deceleration and substantially constant speed operation, substantially continually to apply a drive torque to a first group of one or more wheels to which the first drive torque source is coupled acting in a first direction relative to a longitudinal axis of the vehicle and causes a second of the drive torque sources, during acceleration, deceleration and substantially constant speed operation, substantially continually to apply a drive torque to a second group of one or more wheels to which the second drive torque source is coupled, the direction of drive torque applied to the second group being in a second direction opposite the first such that a net drive torque applied to the first and second group in combination corresponds substantially to a predetermined drive torque demand value, the predetermined torque demand value being determined at least in part by reference to a torque demand signal received by the controller.

Owner:JAGUAR LAND ROVER LTD

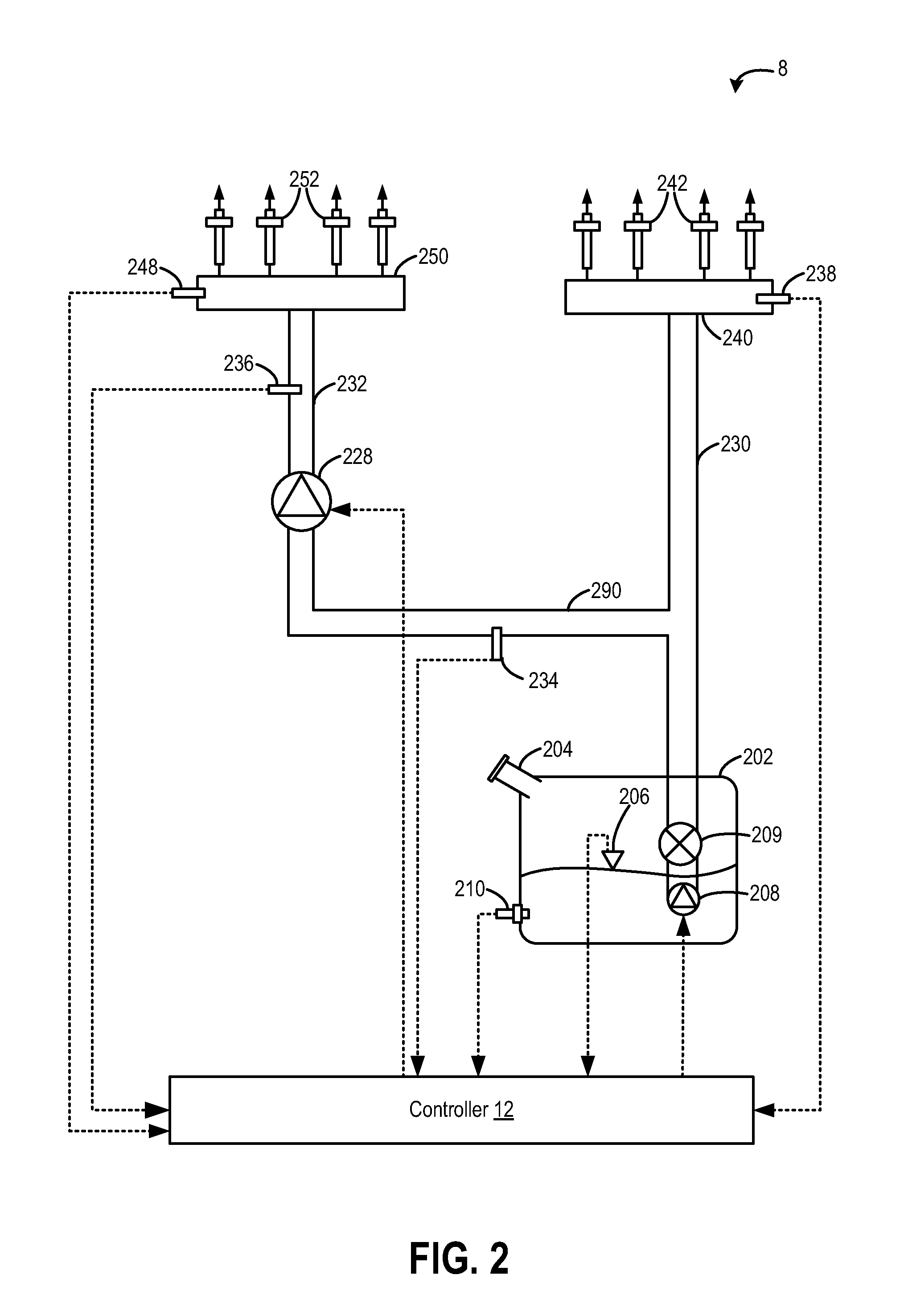

Fuel delivery system including integrated check valve

ActiveUS20150068491A1Reduce fuel consumptionNegatively affectedValve members for absorbing fluid energyCombustion enginesNoise, vibration, and harshnessEngineering

A fuel delivery system is provided to reduce the pressure pulsations and noise vibration and harshness of direct injection systems. The fuel delivery system includes an elastic fuel line positioned between a first fuel pump and a second fuel pump and a check valve positioned in the elastic fuel line near the inlet of the high pressure pump, the check valve including an external housing having a peripheral surface with a greater diameter than an unstretched inner diameter of the elastic fuel line.

Owner:FORD GLOBAL TECH LLC

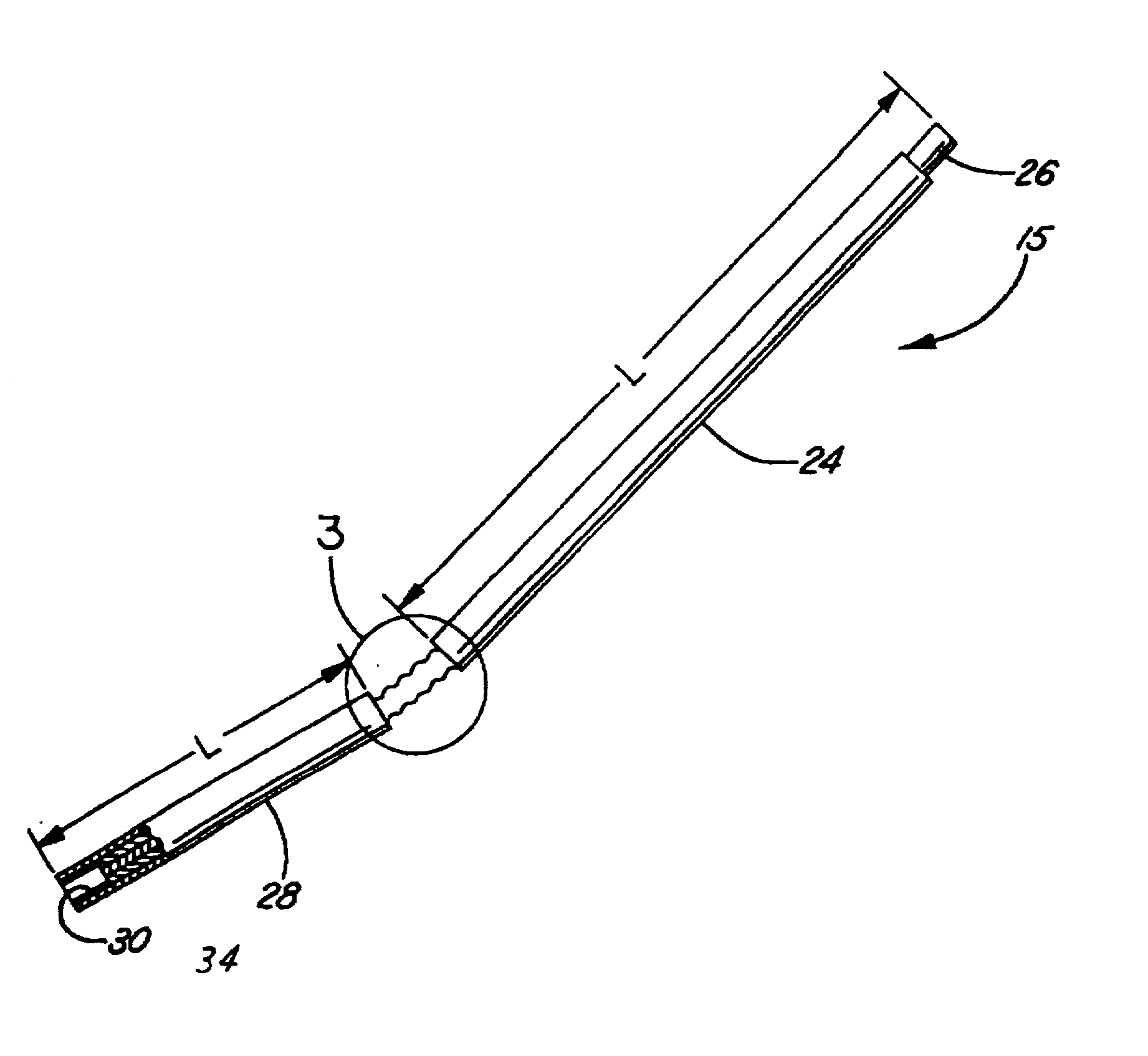

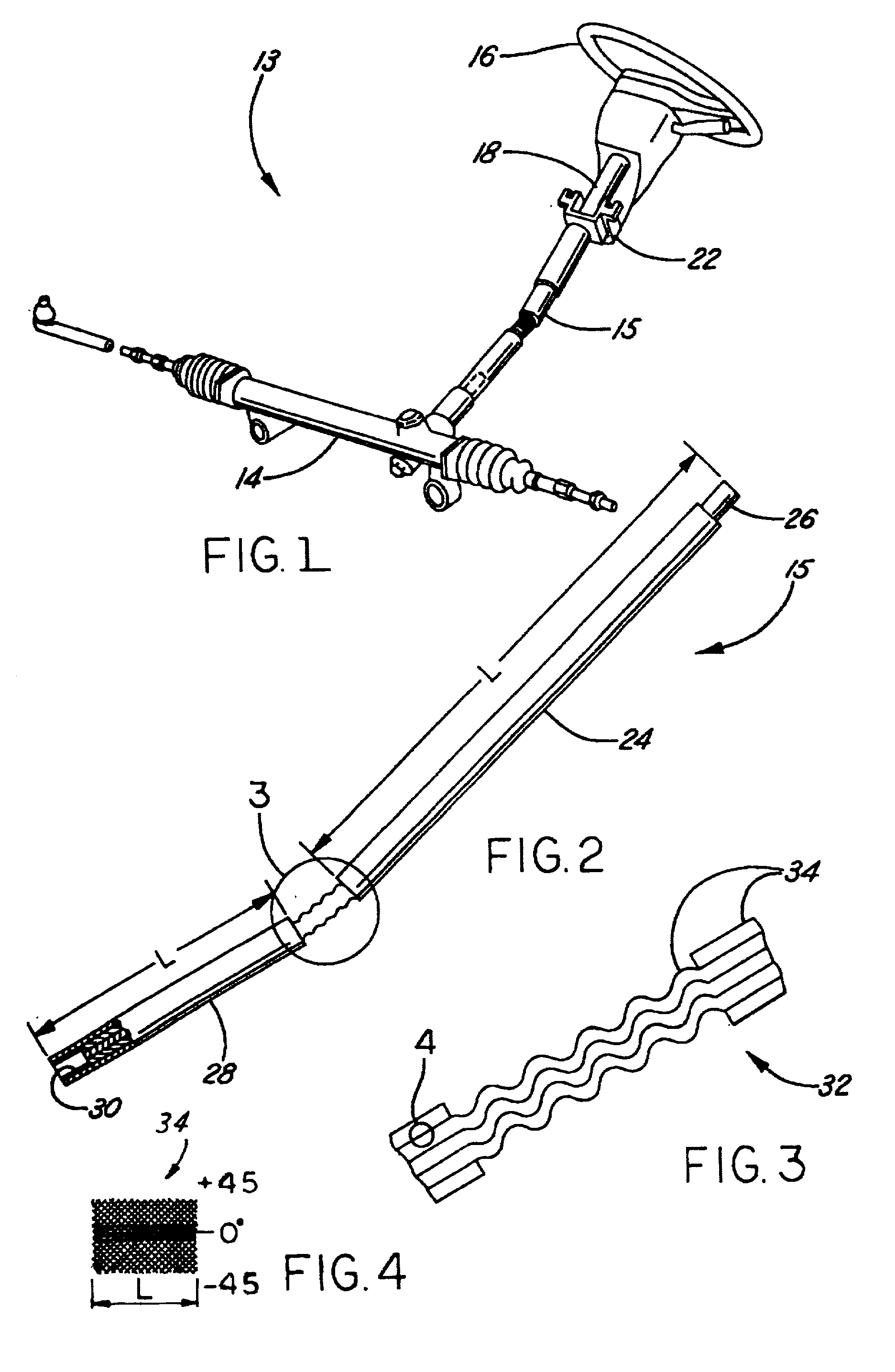

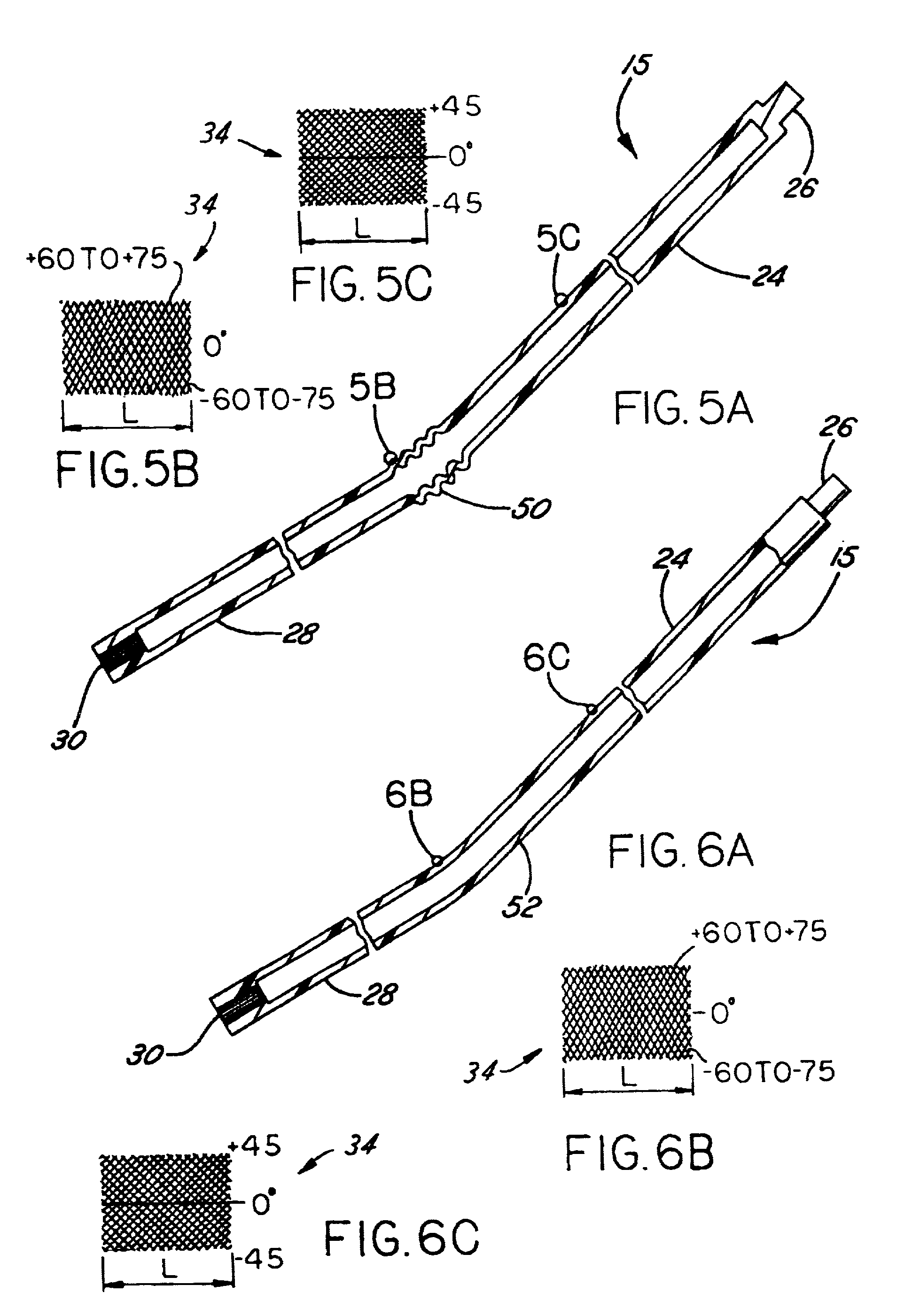

Composite steering shaft with u-jointless tiltsteer joint

InactiveUS20020081147A1Improved crash energy managementImprove NVH characteristicsYielding couplingCosmonautic vehiclesFiberEngineering

A composite steering shaft that replaces traditional metal steering shafts in a steering system. The composite steering shaft is made of layers of braided fiber contained within a polymer matrix resin. Stiffness and torsional strength within the non-tilting and tilting regions may be controlled as a function of the number of layers of braided fiber, the orientation of fiber within those layers, and the type and amount of curing of the polymer matrix resin. The composite shaft may be a one-piece shaft having a compliant middle region and a stiff upper and lower portion or may be a two-piece shaft coupled together using an I-protec metal joint.

Owner:VISTEON GLOBAL TECH INC

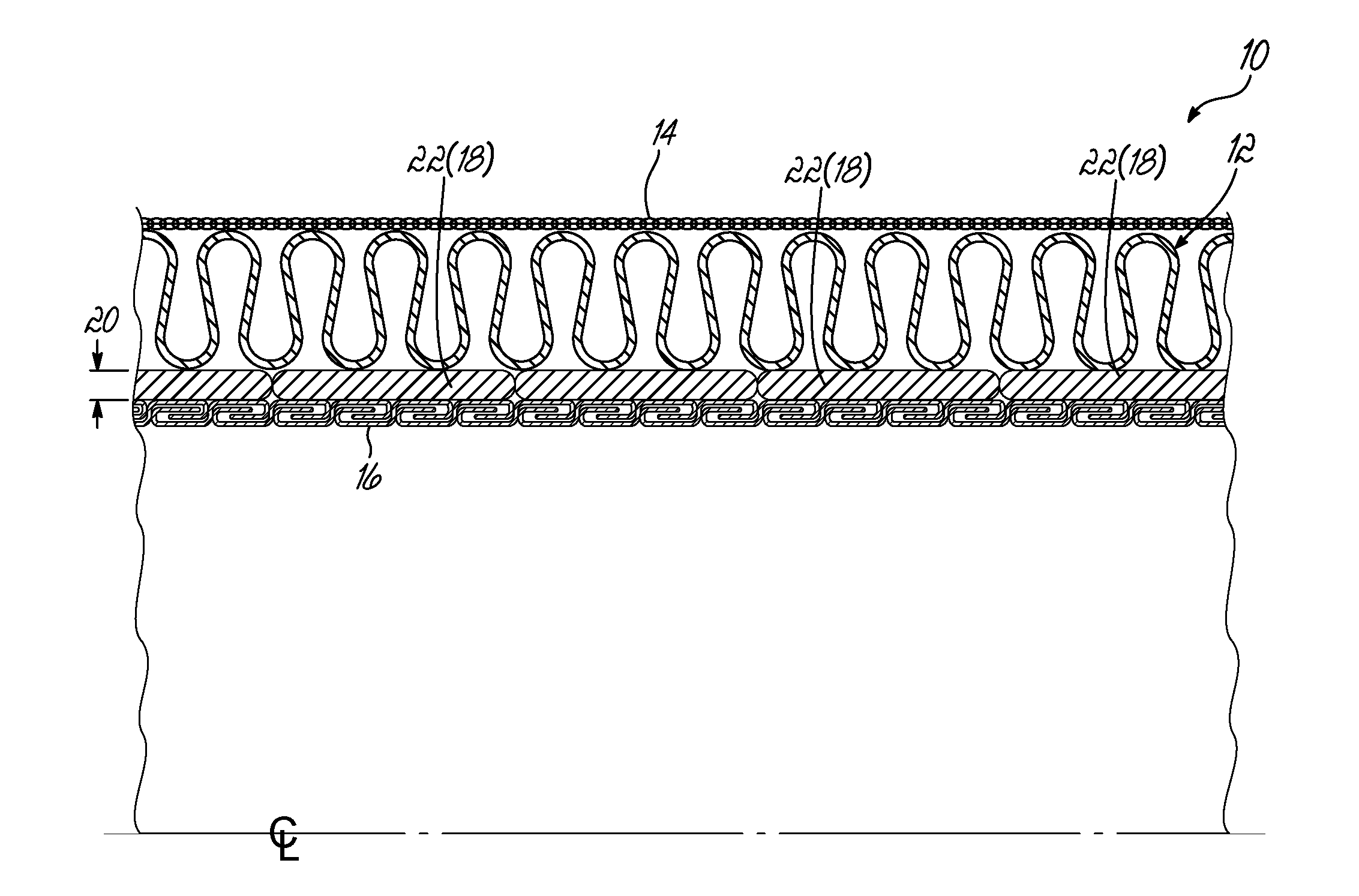

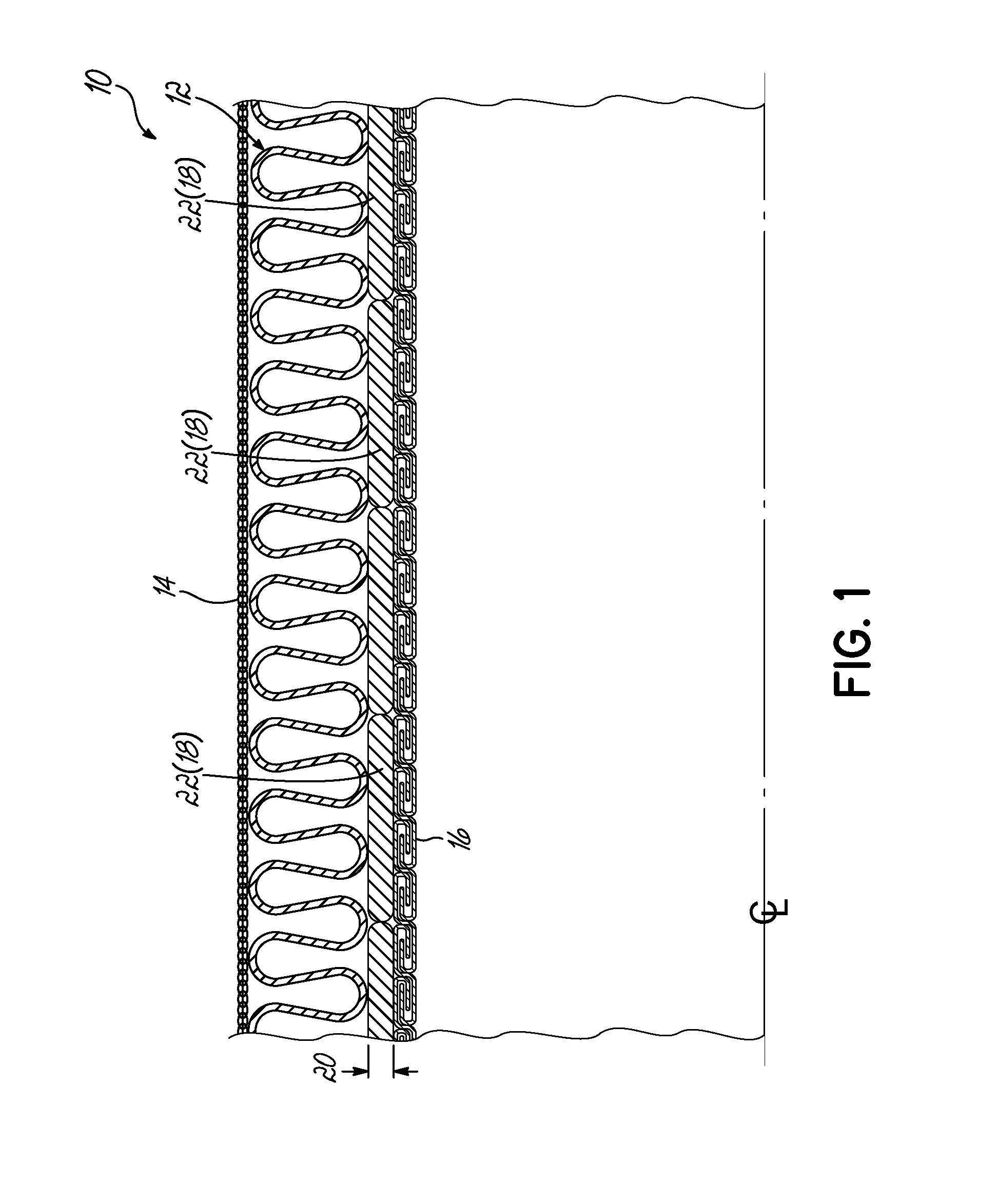

Dynamic liner sleeve for flexible coupling

ActiveUS20160003388A1Dampens natural vibration and frequencyReduce NVHSleeve/socket jointsPipeline expansion-compensationCouplingEngineering

A flexible coupling includes a liner, a bellow, and a liner sleeve preferably defined by a compressed woven mesh strip spirally wound around the liner between bellow and liner and moveable longitudinally with respect to the bellow and liner when the coupling expands linearly. An alternate sleeve in the form of a cylinder is disposed about the liner, under the bellow and is formed of a woven non-compressed mesh.

Owner:AMERICAN BOA

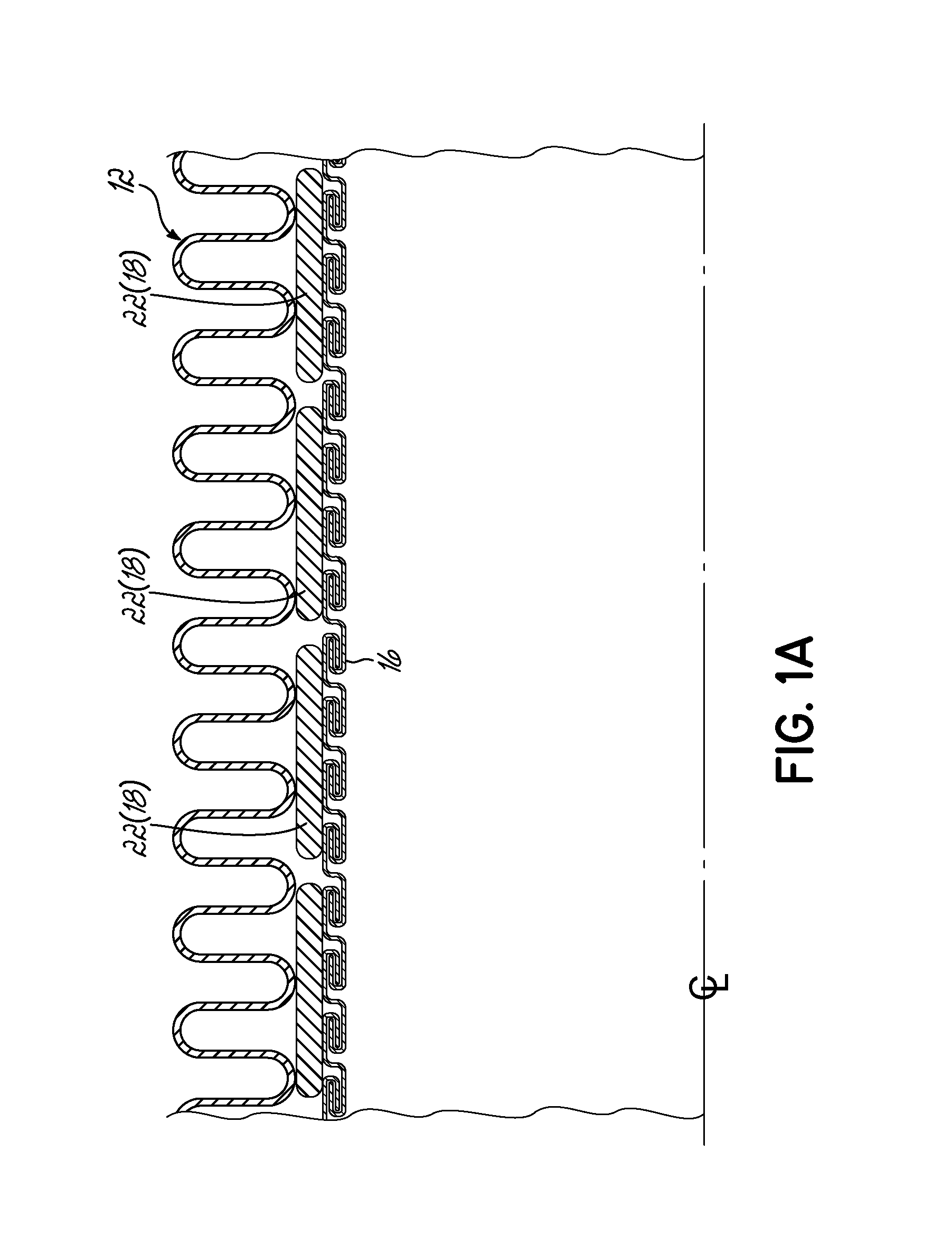

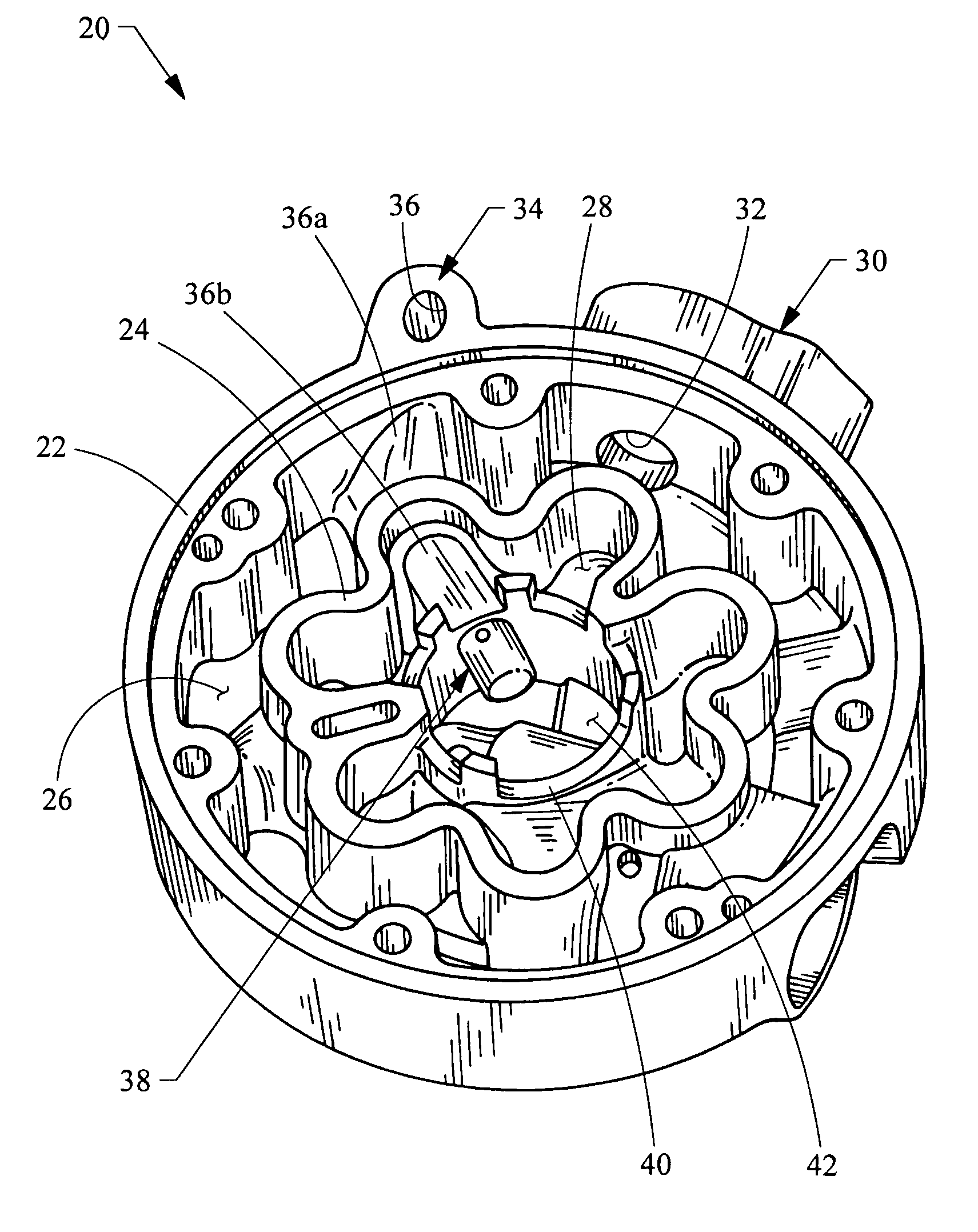

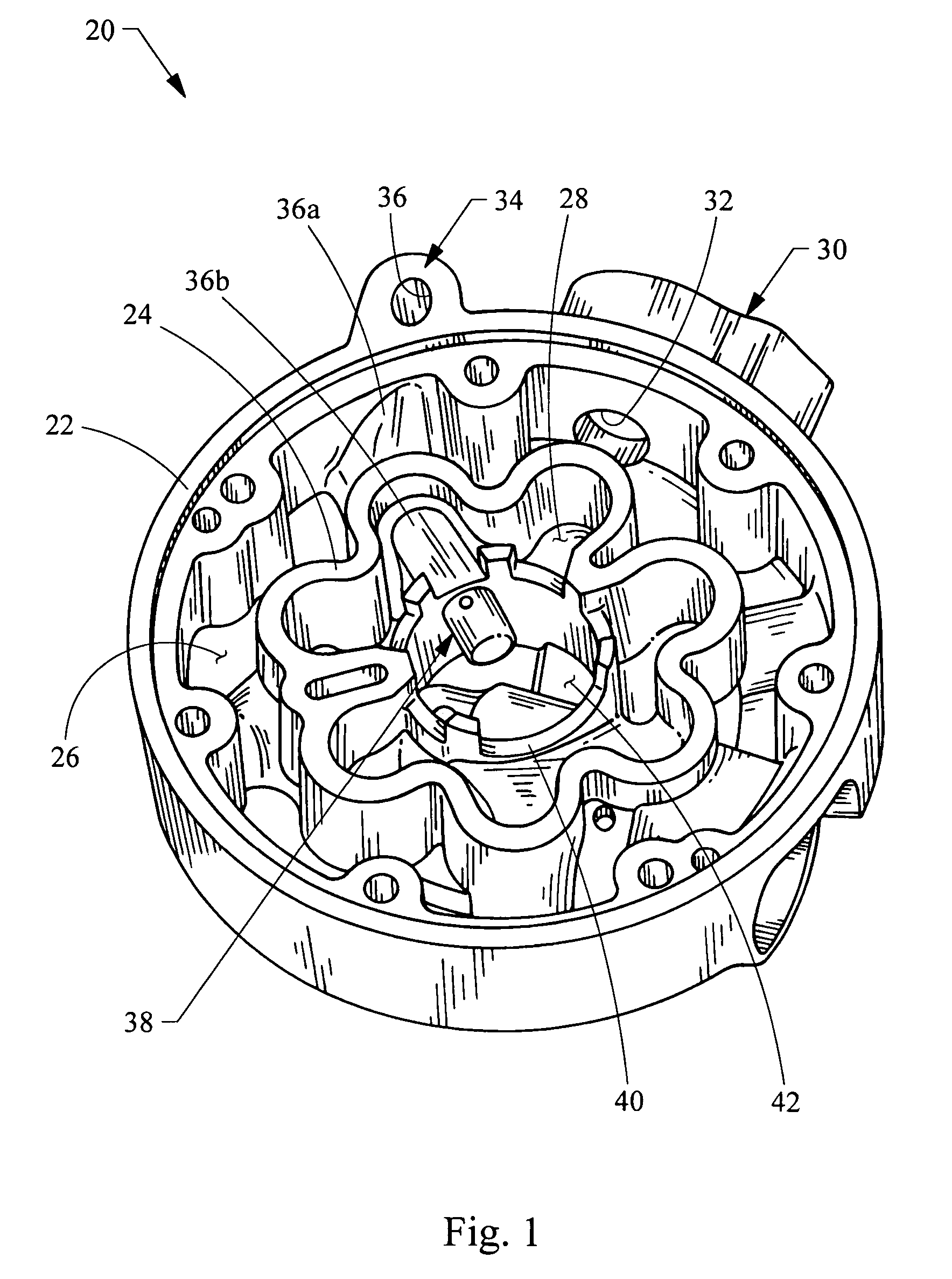

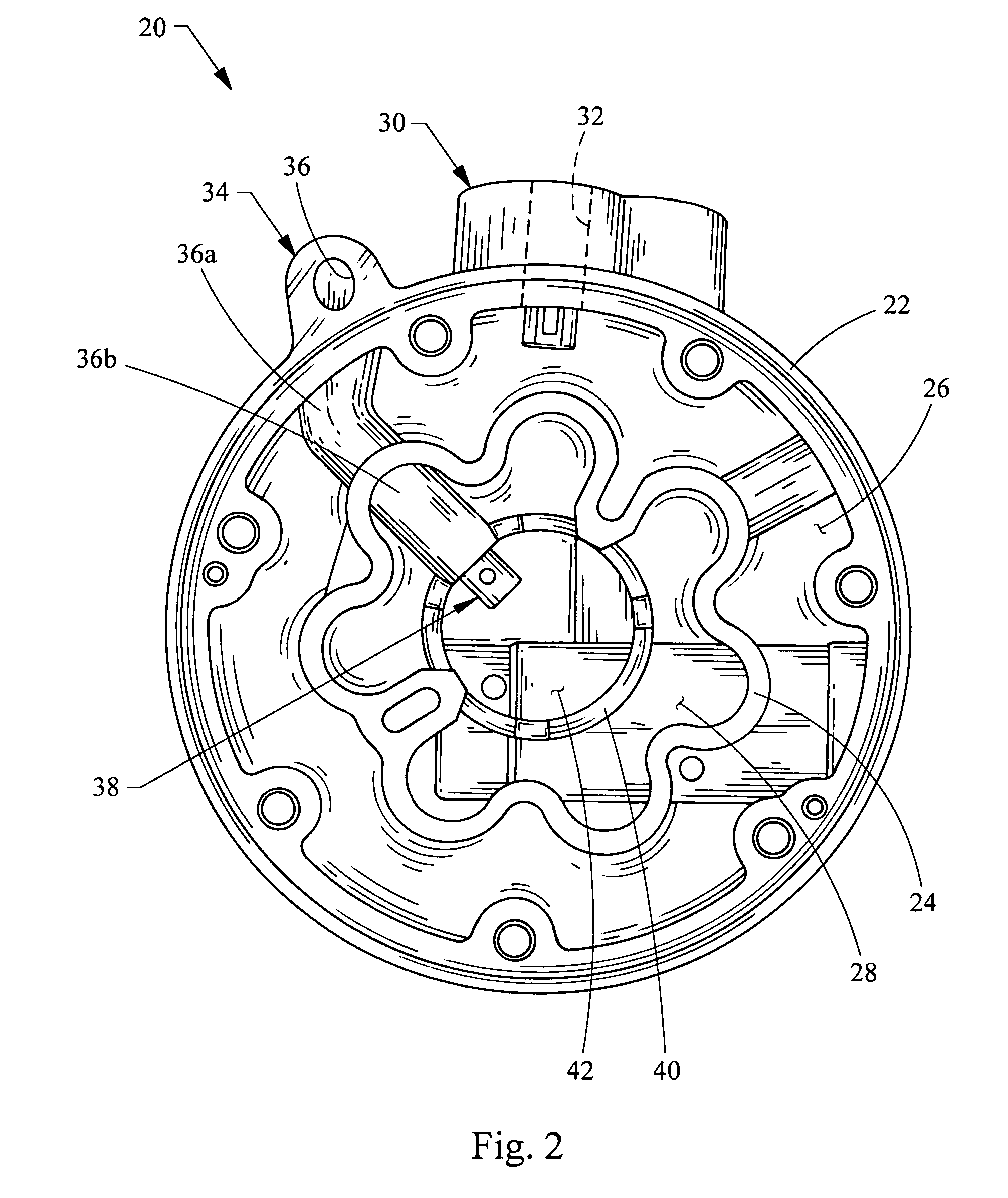

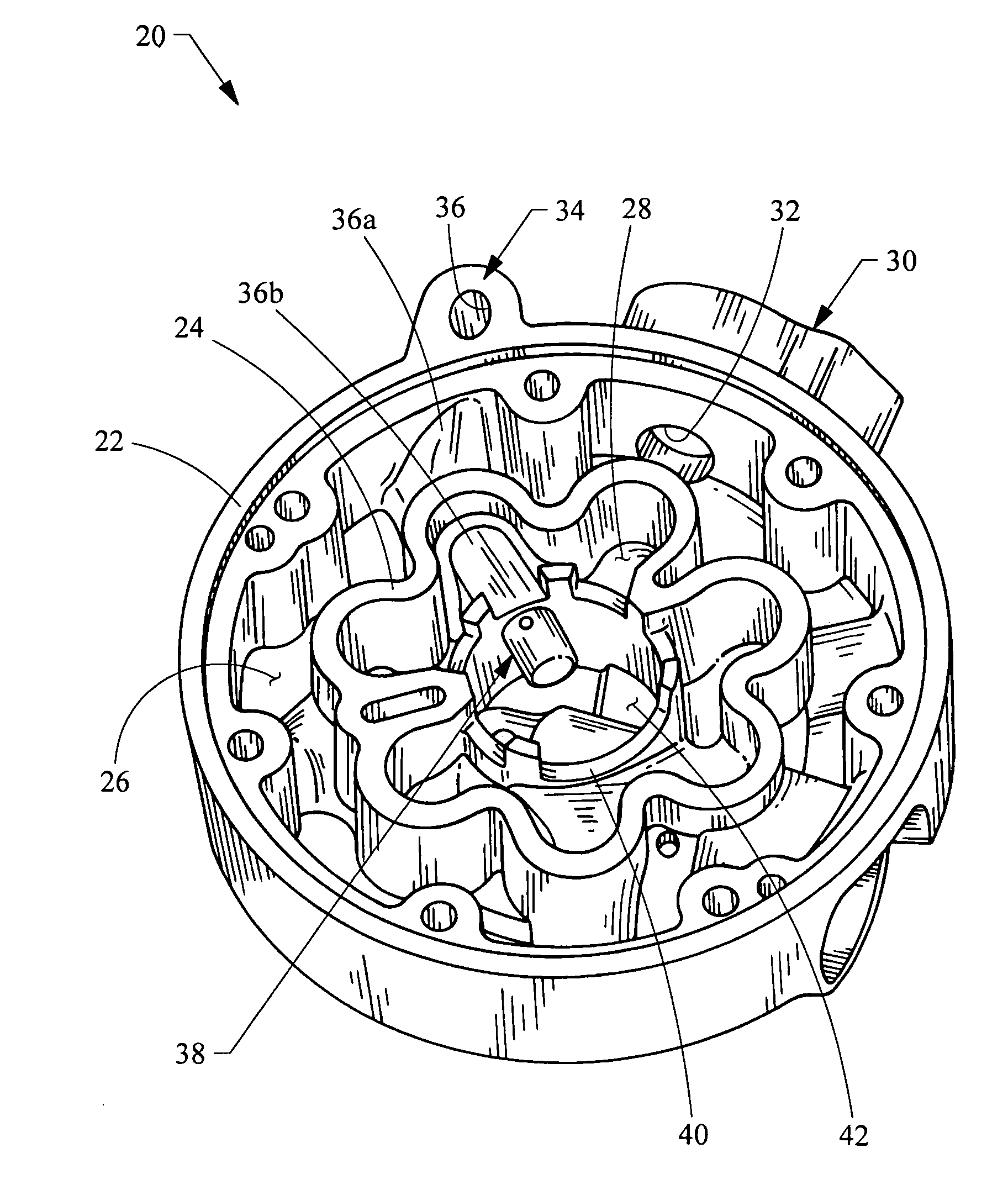

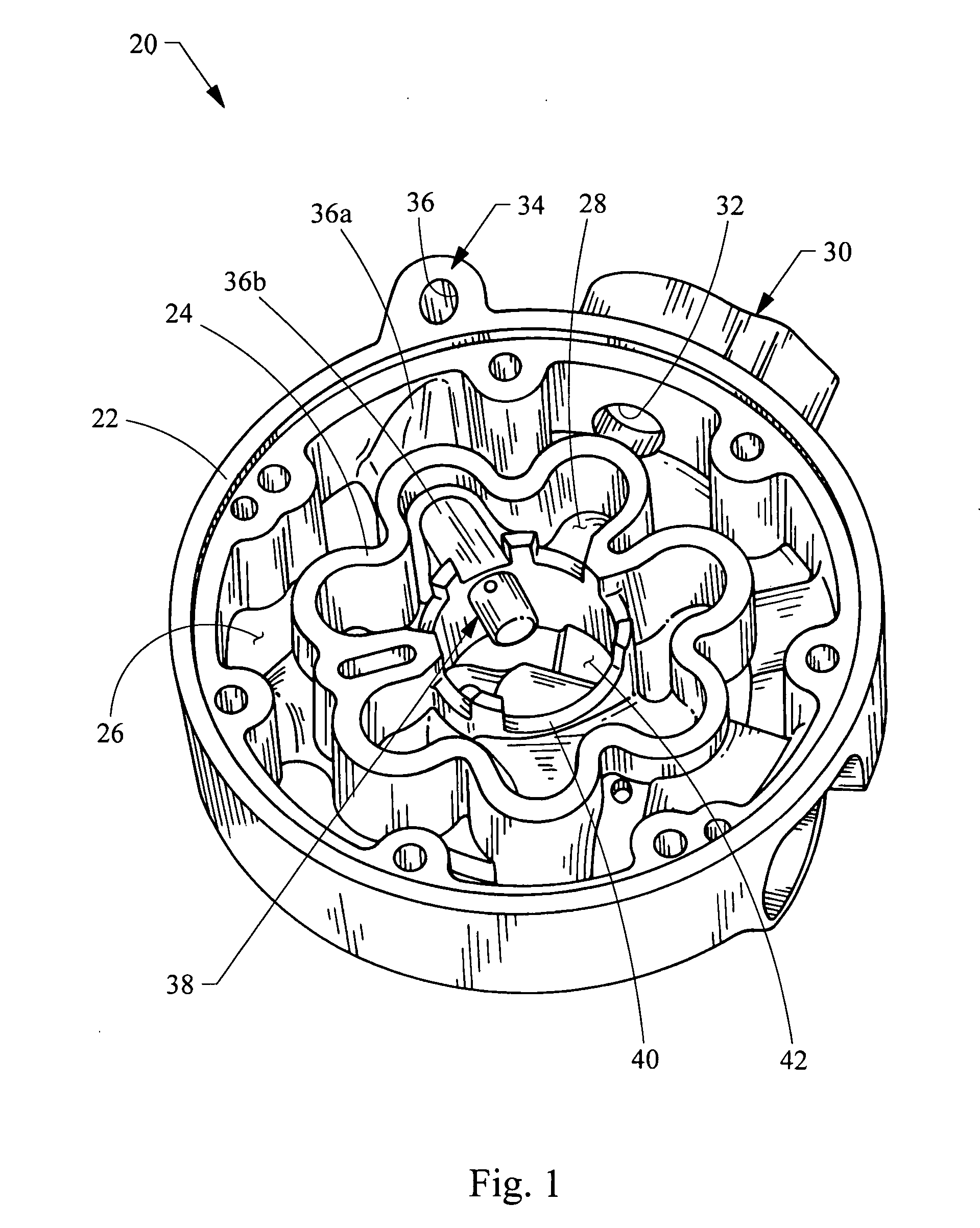

Variable cam timing system and method

ActiveUS9021998B2Improve combustion efficiencyEmission reductionValve arrangementsYielding couplingEngineeringPhase control

A phase control apparatus in a variable cam timing (VCT) system of an engine is described herein. The phase control apparatus includes a locking pin coupled to a vane, the locking pin extending into a locking pin recess in a cover plate in a locked configuration, the locking pin and locking pin recess having a backlash and a housing at least partially enclosing the vane and spaced away from the vane forming a gap in the locked configuration.

Owner:FORD GLOBAL TECH LLC

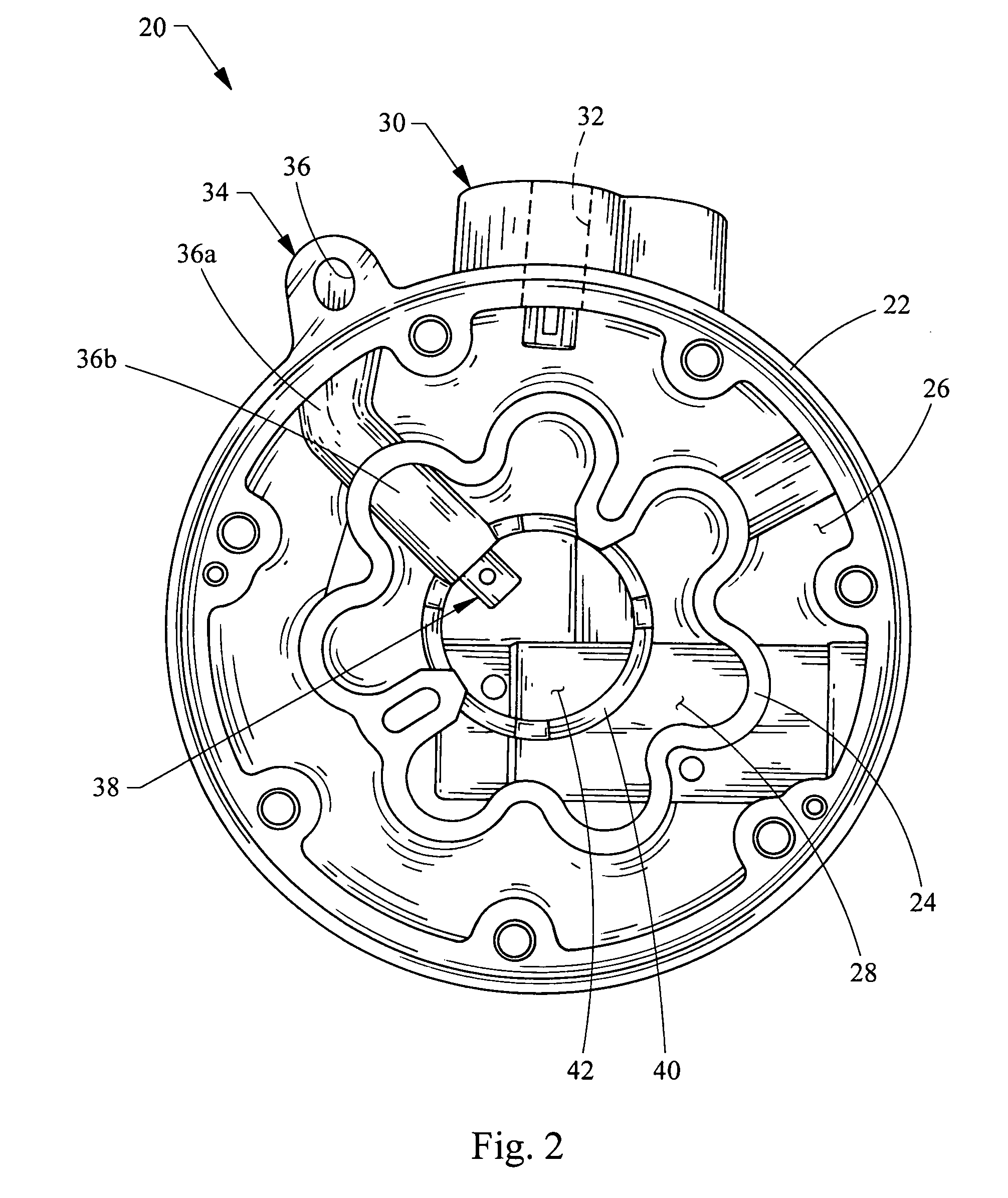

NVH and gas pulsation reduction in AC compressor

ActiveUS7494328B2Reduce NVHIncreasing of flowPositive displacement pump componentsMulti-stage pumpsGas compressorEngineering

A rear housing for a compressor reduces NVH without increasing the overall size of the compressor or inducing flow loss. Generally, the compressor includes a cylinder block receiving lower pressure fluid from the rear housing and providing higher pressure fluid back to the rear housing. The rear housing includes an annular outer wall and an annular inner wall defining a suction chamber and a discharge chamber. An inlet is in fluid communication with the suction chamber. An outlet is in fluid communication with the discharge chamber. The outlet includes a discharge passageway having a tubular member projecting into the discharge chamber. The tubular member is defined by a side wall and a closed end wall. The side wall includes a plurality of holes fluidically connecting the discharge chamber and the discharge passageway.

Owner:HANON SYST

Vehicle register air flow straightener

ActiveUS8480461B2Reduce NVHReduce noiseAir-treating devicesFluid dynamicsProcessor registerForced-air

An HVAC duct system of a vehicle includes an air duct for providing a passageway for forced conditioned air. The air duct having a first imaginary axis extending substantially parallel with the passageway. An air duct register having plurality of vane-like members for directing the flow of air as it exits the register is coupled to the air duct. An opening of the air duct register defines an imaginary plane. The register has a second imaginary axis extending perpendicular to the imaginary plane of the register. An air flow straightener disposed within the air duct juxtaposed to the register and includes an air guide member. The air guide member receives the forced air flowing through the air duct in a direction substantially parallel with the first imaginary axis and redirects the forced air in a direction substantially parallel with the second imaginary axis for reducing noise as air passes the vanes.

Owner:FORD GLOBAL TECH LLC

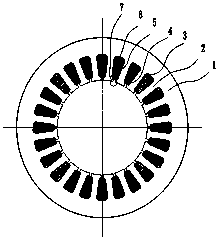

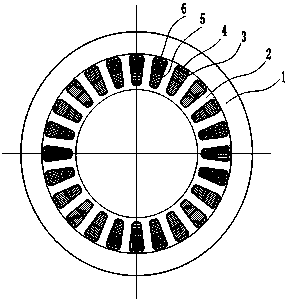

Combined permanent magnet brushless motor stator and manufacturing method thereof

PendingCN110011436AReduce NVHIncrease profitMagnetic circuit stationary partsManufacturing stator/rotor bodiesBrushless motorsCircular surface

The invention provides a combined permanent magnet brushless motor stator and a manufacturing method thereof. A stator core is formed by a tooth part iron core formed by winding and a yoke part iron core, the tooth part iron core is located inside, the yoke part iron core is located outside, an inner circular surface of the tooth part iron core has no notch, a winding is placed into a groove froman outer circular surface or is wounded tooth by tooth, a tooth part winding is sleeved in the yoke part iron core to form a stator assembly after being manufactured, the invention is suitable for a fractional slot winding is also suitable for a distributed winding, the iron core has no slot and almost has no cogging torque, the motor running performance is good, the material utilization rate is high, the design is optimized and flexible, the motor efficiency and specific power are easy to improve, and the automatic production is easy to achieve.

Owner:杨世国

Engine fuel pump and method for operation thereof

ActiveUS9284931B2Improve noiseIncrease vibrationElectrical controlNoise reducing fuel injectionSolenoid valveEngineering

A method of pressuring fuel for a direct injection fuel system via a fuel pump in an engine is provided. The method includes, during a first mode, adjusting a magnetic solenoid valve (MSV) to control pump outlet pressure and during a second mode, deactivating the MSV and controlling pump outlet pressure via a noise-reducing valve assembly on an inlet side of the fuel pump.

Owner:FORD GLOBAL TECH LLC

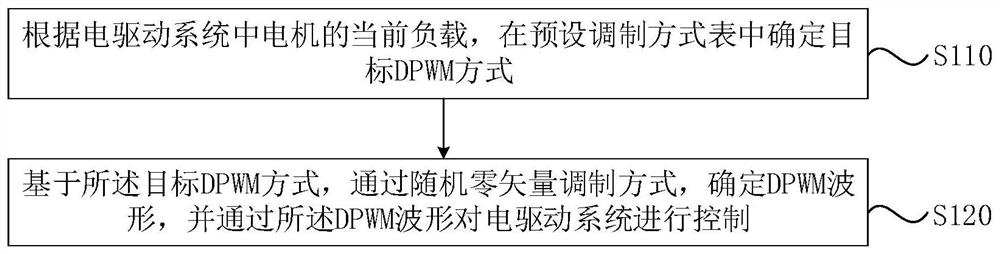

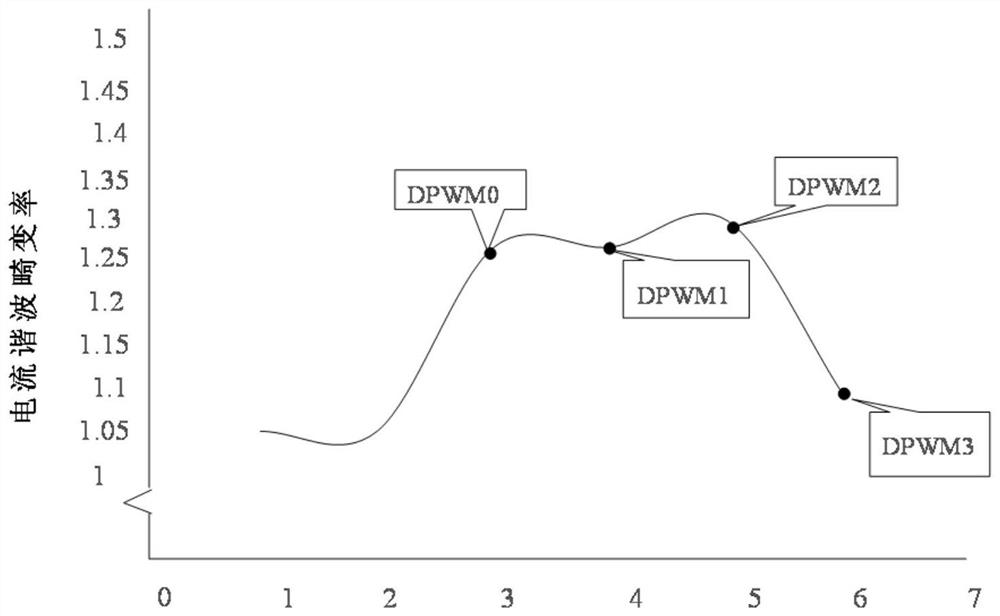

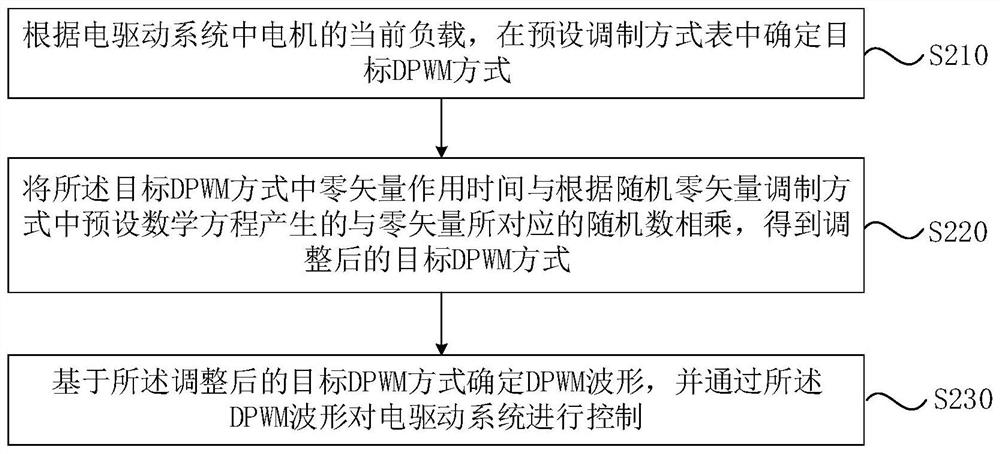

Electric drive system control method and device, vehicle and storage medium

ActiveCN112187124AImprove efficiencyImprove Inverter EfficiencyElectronic commutation motor controlSpeed controllerElectric driveEngineering

The embodiment of the invention discloses an electric drive system control method and device, a vehicle and a storage medium. The method comprises the steps of: according to the current load of a motor in the electric drive system, determining a target discontinuous pulse width modulation DPWM mode in a preset modulation mode table, wherein the preset modulation mode table comprises the corresponding relation between the load and a preset number of DPWM modes; and based on the target DPWM mode, determining a DPWM waveform through a random zero vector modulation mode, and controlling the electric drive system through the DPWM waveform. According to the technical scheme provided by the embodiment of the invention, the efficiency of the electric driving system can be improved, and the noise,vibration and acoustic vibration roughness of the whole vehicle can be reduced.

Owner:CHINA FIRST AUTOMOBILE

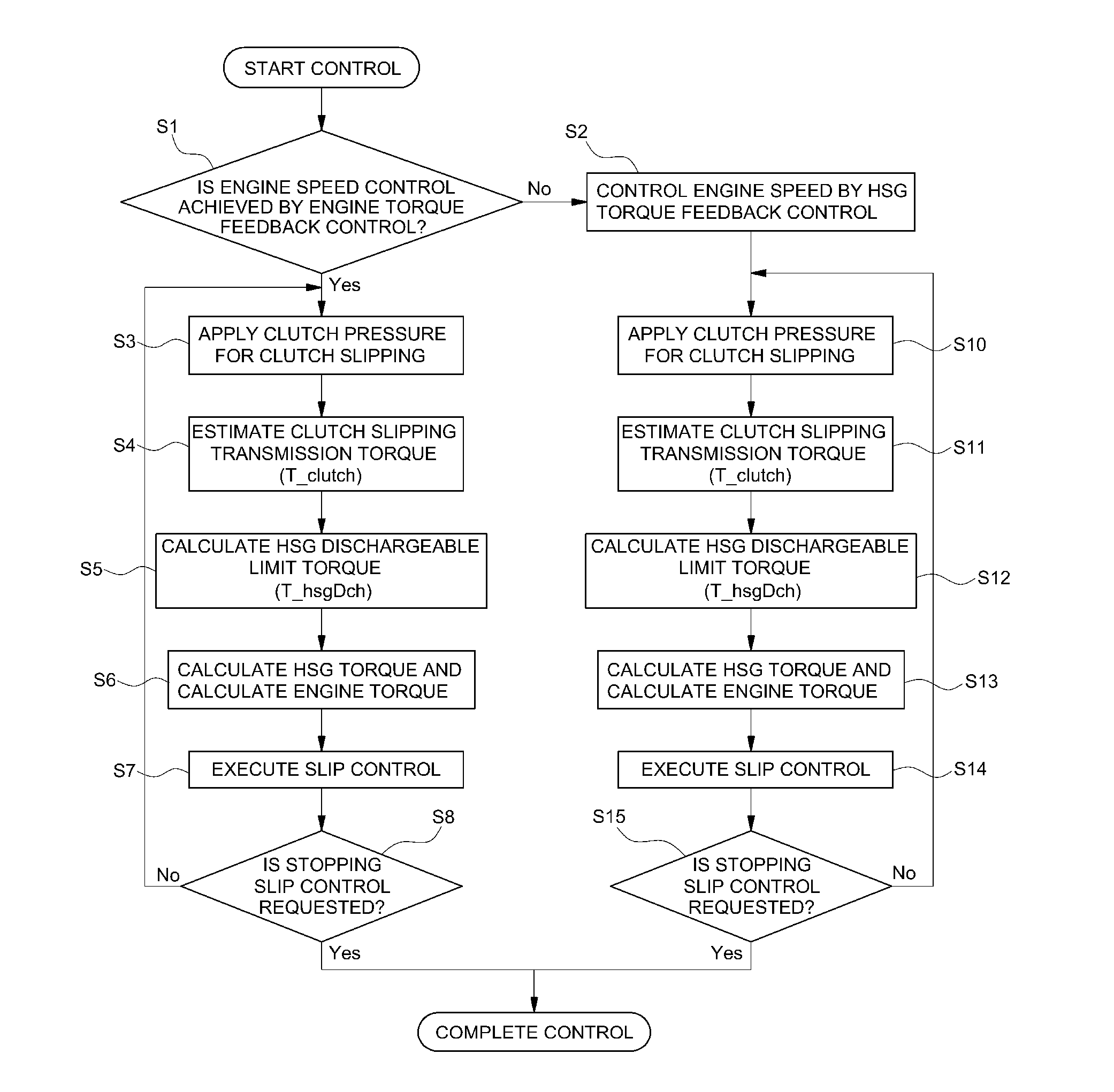

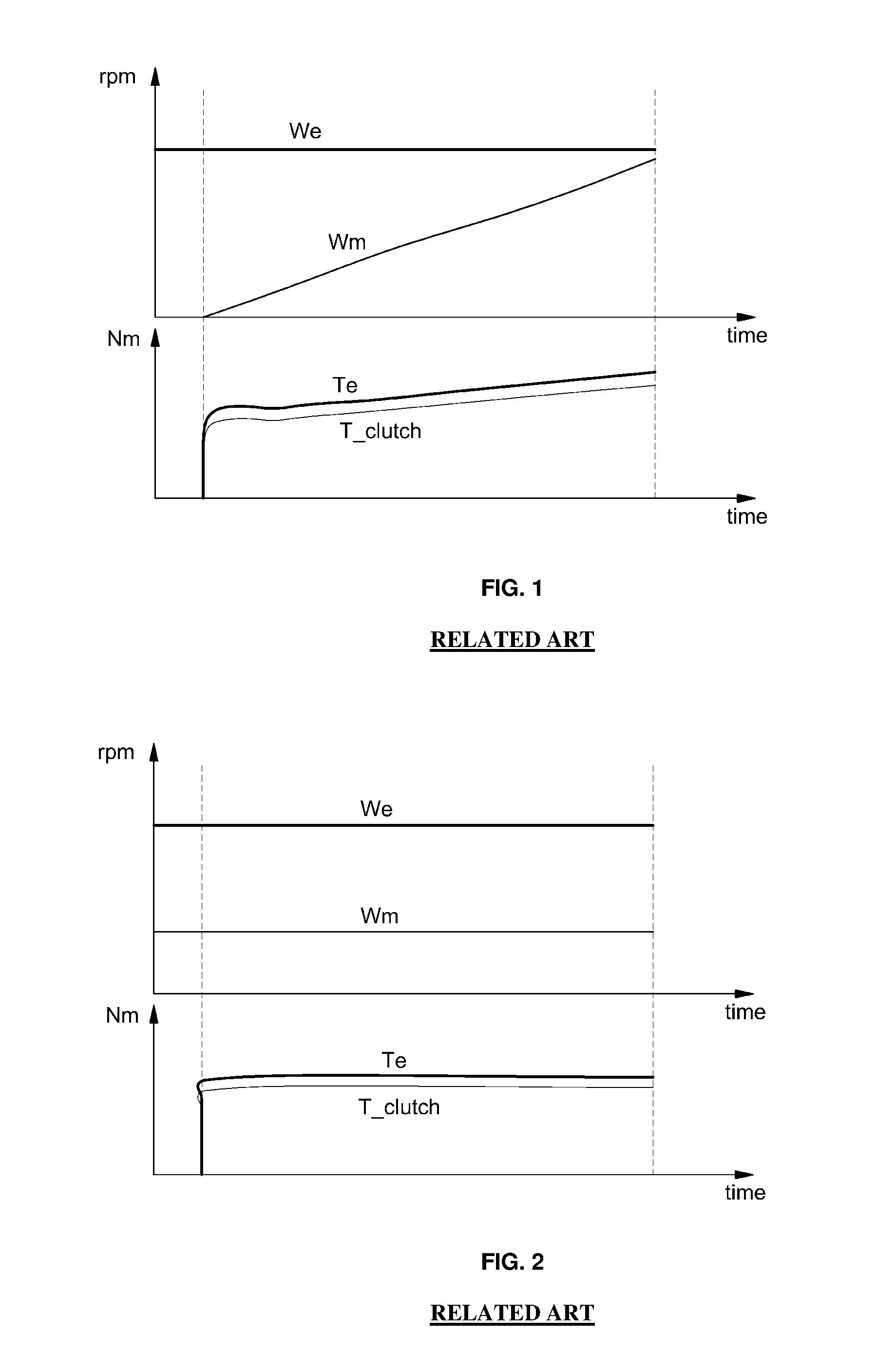

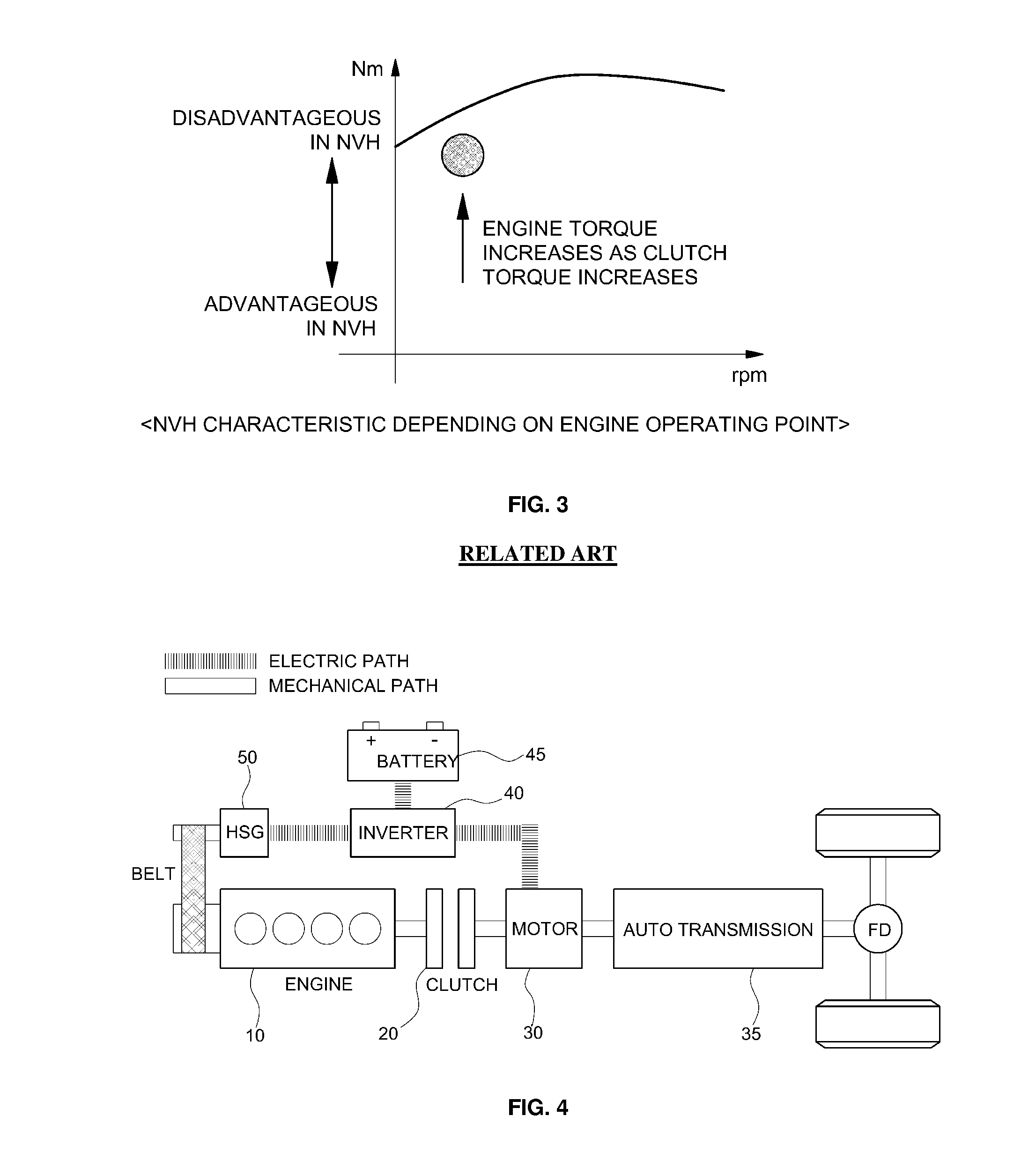

Driving force control method during engine clutch slipping of tmed hev

ActiveUS20160375889A1Reduce NVHEngine torque Te may be significantly decreasedHybrid vehiclesClutchesEngineeringFeedback control

A driving force control method is provided for engine clutch slipping of a TMED HEV that includes an engine 10 and a second motor 50, a first motor 30 disposed at a transmission side, an engine clutch 20 interposed between the engine 10 and the first motor 30, and a multi-clutch transmission 35 connected with an output terminal of the first motor 30. The method includes verifying whether a control for maintaining a target speed of the engine is achieved by an engine feedback control or by a second motor torque feedback control and applying clutch pressure for the clutch slipping with hydraulic pressure. When the clutch pressure is applied clutch slipping transmission torque is estimated. Torque of the engine clutch is equivalent to the pressure as a load. Second motor dischargeable limit torque, second motor assist torque, and engine torque are calculated to then execute a slip control.

Owner:HYUNDAI MOTOR CO LTD

Adaptive torque mitigation by micro-hybrid system

ActiveUS10578037B2Reduce NVHFuel efficiencyElectrical controlOutput powerHybrid systemControl system

A variety of methods and arrangements for reducing noise, vibration and harshness (NVH) in a skip fire engine control system are described. In one aspect, a firing sequence is used to operate the engine in a dynamic firing level modulation manner. A smoothing torque is determined by adaptive control that is applied to a powertrain by an energy storage / release device. The smoothing torque is arranged to at least partially cancel out variation in torque generated by the firing sequence. Various methods, powertrain controllers, arrangements and computer software related to the above operations are also described.

Owner:TULA TECH INC

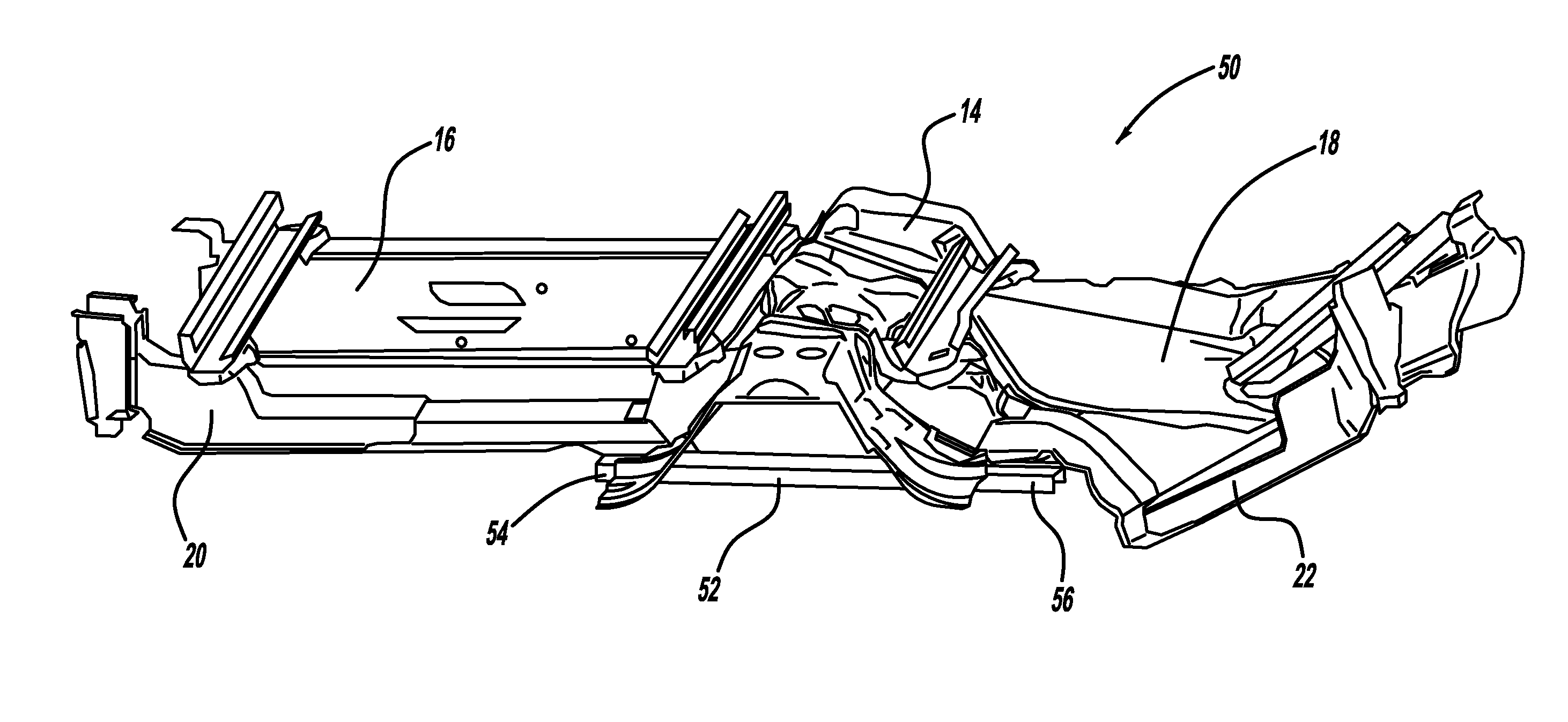

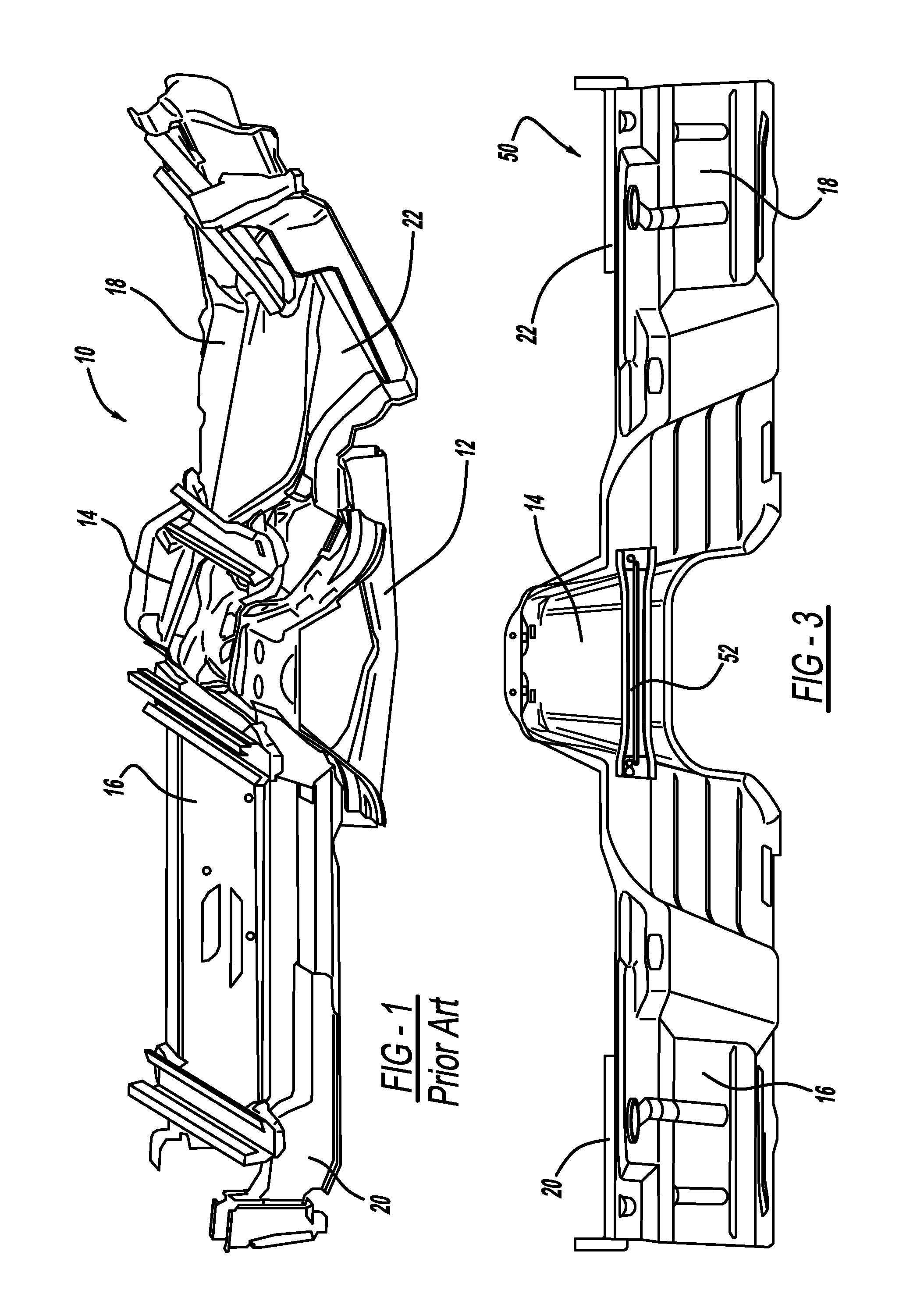

Releasable tunnel brace for a vehicle

ActiveUS8752885B2Reduce deflectionReduce NVHVehicle seatsSuperstructure subunitsEngineeringSide impact

A releasable tunnel brace for releasably connecting a first side panel to a second panel of a vehicle is disclosed. One or both ends of the brace include a fastener-receiving aperture. The aperture has a round portion and an elongated slot extending therefrom. The round portion can allow the head of a shoulder bolt fastener to pass therethrough. The elongated slot is defined by a pair of opposed walls. The shoulder of the shoulder bolt fastener can pass between the opposed walls. In the event of a side impact, the brace is pushed vehicle inward and the bolt slides through the elongated slot and into the round portion where it is allowed to be released from its attachment position. The brace provides maximum torsion stiffness while withstanding only a minimum amount of lateral force before it releases and thus minimizes local deflection in the event of a side impact.

Owner:FORD GLOBAL TECH LLC

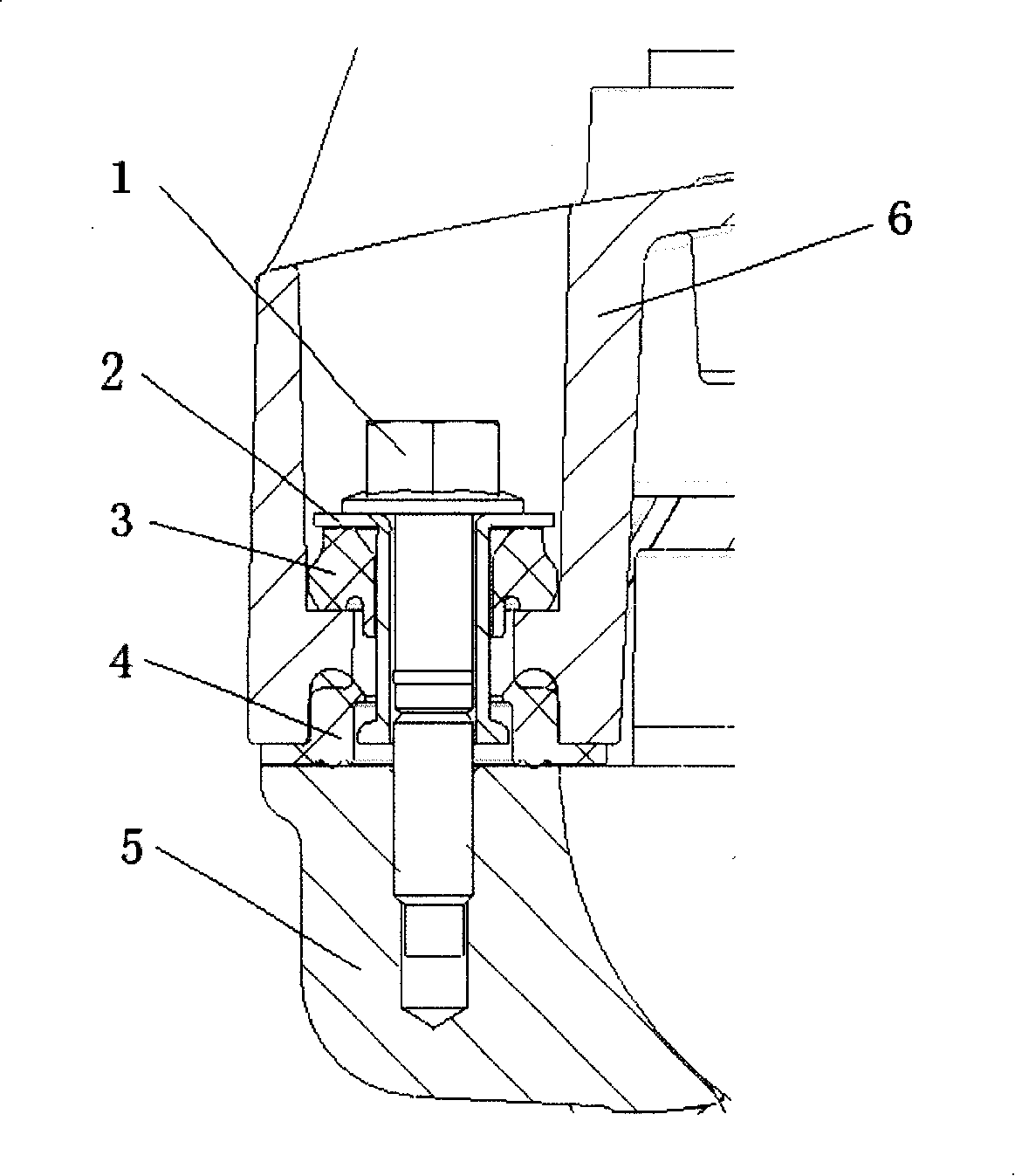

Valve chamber cover vibration damping connection device

A valve chamber cover vibration-reduction and connection device comprises a fastening bolt connecting a cylinder head with a valve chamber cover and a washer of the valve chamber cover. A rubber vibration-reduction unit is arranged between the screw cap of the bolt and the valve chamber cover. The bolt is sheathed with a bush, and the outer casing of the bush is provided with the rubber vibration-reduction unit; the height of the bush is less than the total thickness of the rubber vibration-reduction unit, the valve chamber cover and the washer thereof, thereby ensuring the rubber vibration reduction unit and the washer of the valve chamber cover have certain compression. In virtue of only adopting the rubber vibration reduction unit in a simple structure, vibration of the valve chamber cover is greatly reduced and the washer thereof is effectively protected. By adopting a vibration-reduction bolt unit as a buffer between the cylinder head and the valve chamber cover, integral NVH is reduced.

Owner:CHERY AUTOMOBILE CO LTD

NVH and gas pulsation reduction in AC compressor

ActiveUS20070020132A1Minimal lossReduce NVHPositive displacement pump componentsMulti-stage pumpsGas compressorEngineering

A rear housing for a compressor reduces NVH without increasing the overall size of the compressor or inducing flow loss. Generally, the compressor includes a cylinder block receiving lower pressure fluid from the rear housing and providing higher pressure fluid back to the rear housing. The rear housing includes an annular outer wall and an annular inner wall defining a suction chamber and a discharge chamber. An inlet is in fluid communication with the suction chamber. An outlet is in fluid communication with the discharge chamber. The outlet includes a discharge passageway having a tubular member projecting into the discharge chamber. The tubular member is defined by a side wall and a closed end wall. The side wall includes a plurality of holes fluidically connecting the discharge chamber and the discharge passageway.

Owner:HANON SYST

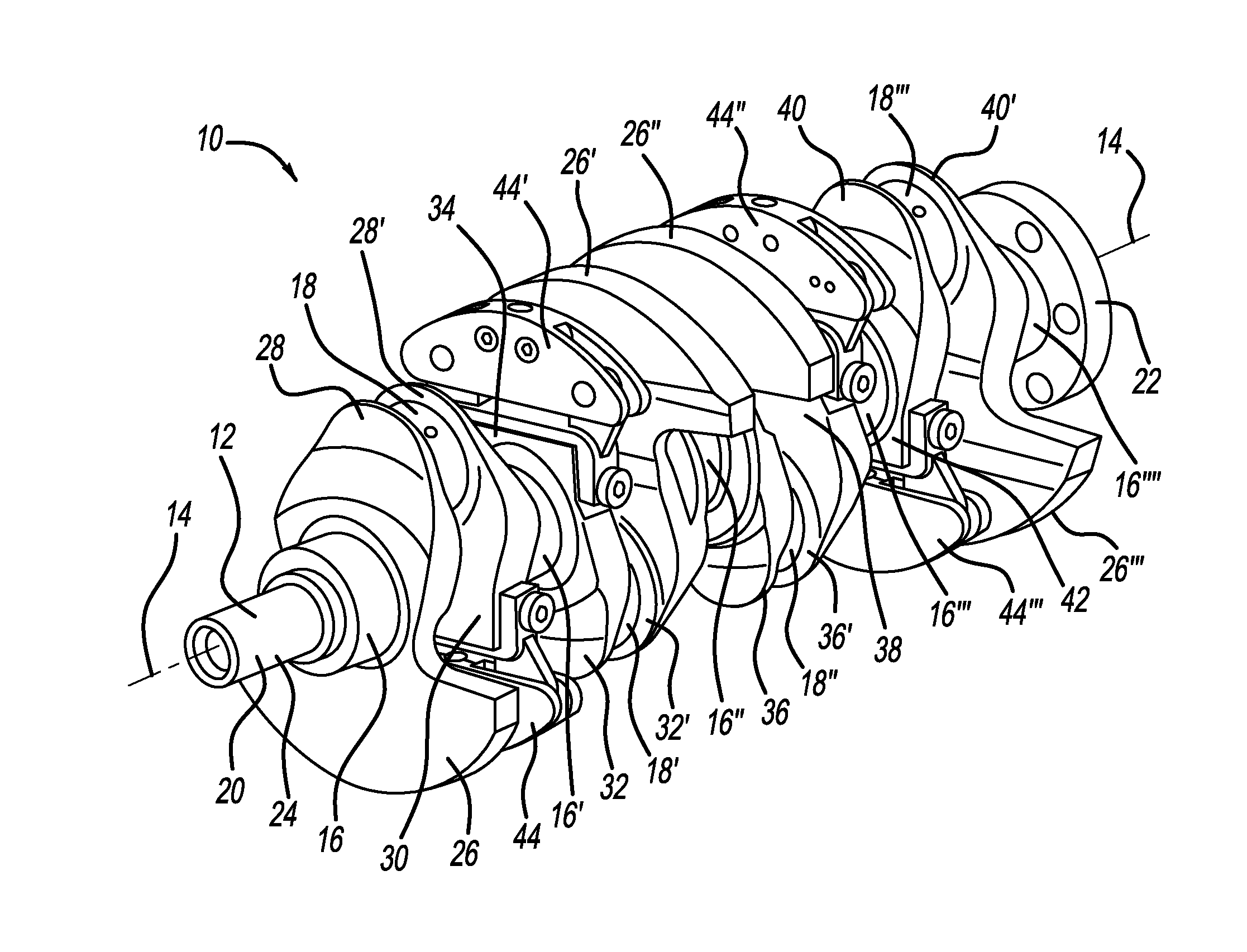

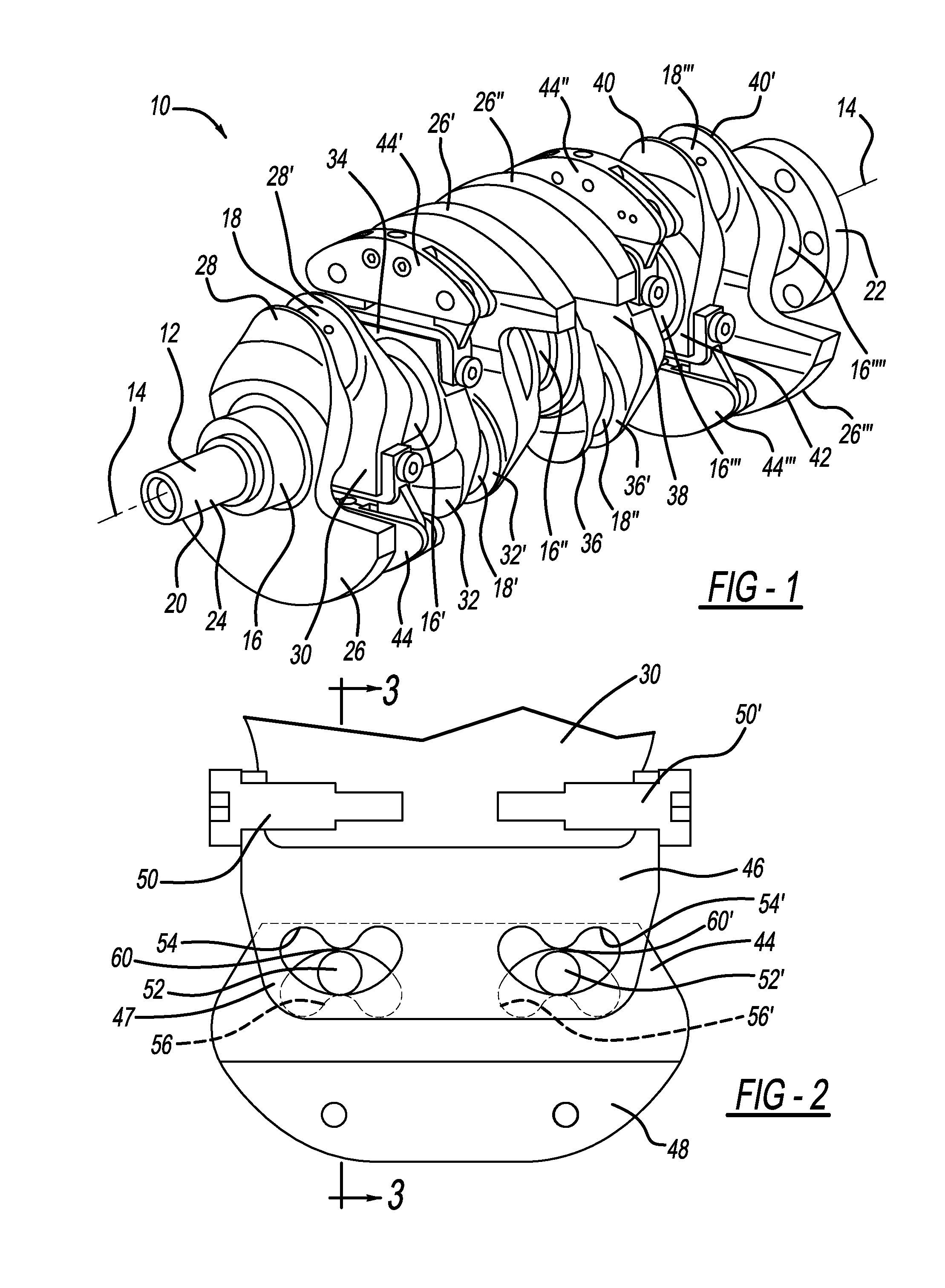

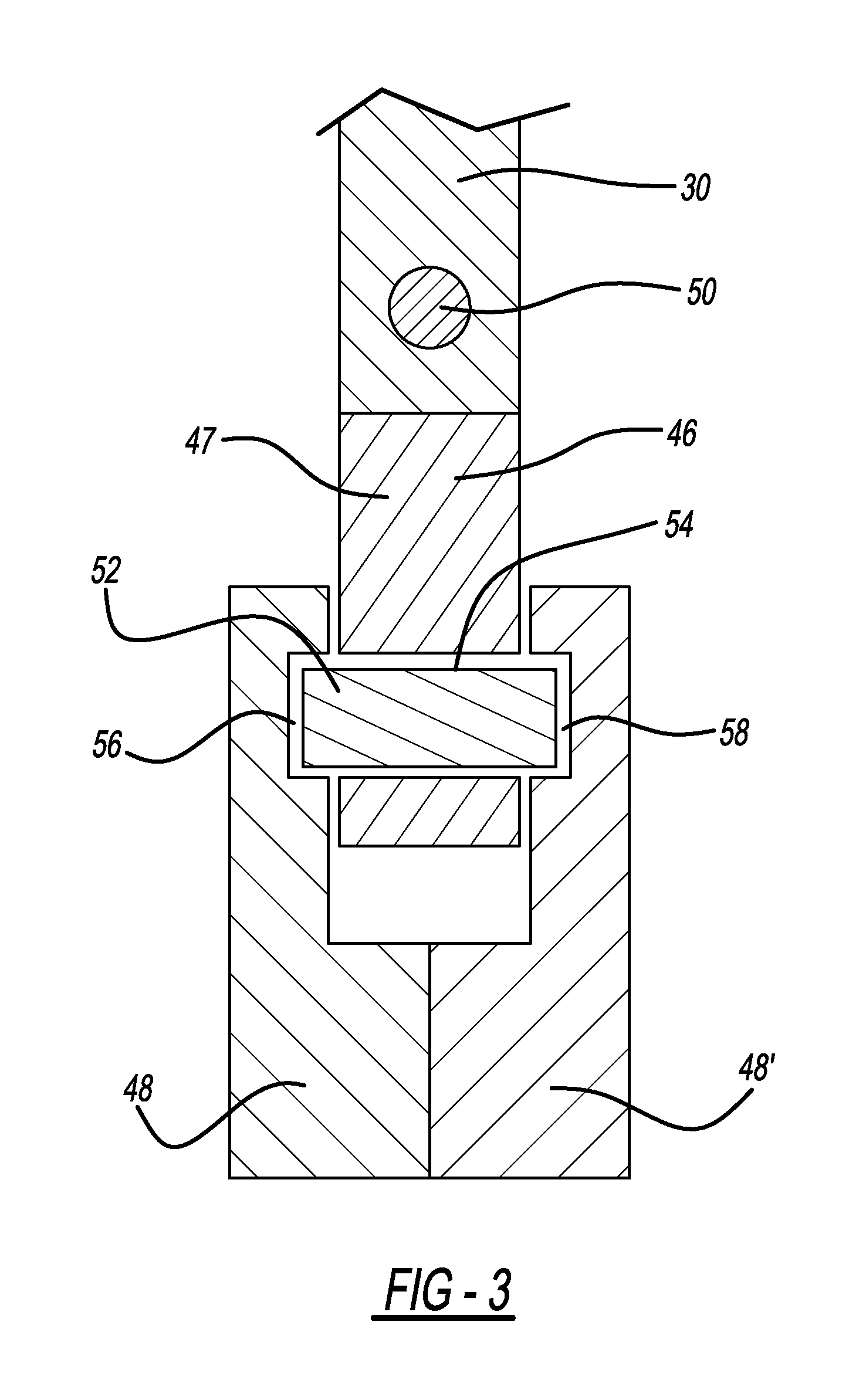

Crankshaft pendulum assembly having kidney-shaped track

ActiveUS20160010720A1Reduce NVHChallenge can be overcomeRotating vibration suppressionShaftsEngineeringInternal combustion engine

A pendulum crankshaft assembly for an internal combustion engine includes a pendulum carrier, a pendulum and rolling pins. The carrier and the pendulum have kidney-shaped rolling pin tracks. The rolling pin tracks are kidney-shaped and thus are defined by opposed curved side walls and opposed end walls. The pendulum carrier has an ear extending therefrom to which the pendulum is attached. The pendulum comprises a first half and a second half, each half being positioned on the sides of the ear. At any given time in operation, the gap between the rolling pin and the opposed walls of the rolling pin tracks is never greater than 0.5 mm. The pendulum carrier is attached to a cheek of the crankshaft by a pair of opposed fasteners.

Owner:FORD GLOBAL TECH LLC

Dynamic liner sleeve for flexible coupling

ActiveUS9970578B2Dampens natural vibration and frequencyReduce NVHSleeve/socket jointsPipeline expansion-compensationCouplingEngineering

A flexible coupling includes a liner, a bellow, and a liner sleeve preferably defined by a compressed woven mesh strip spirally wound around the liner between the bellow and liner and moveable longitudinally with respect to the bellow and liner when the coupling expands linearly. An alternate sleeve in the form of a cylinder is disposed about the liner, under the bellow and is formed of a woven non-compressed mesh.

Owner:AMERICAN BOA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com