Combined permanent magnet brushless motor stator and manufacturing method thereof

A technique of permanent magnet brushless motor and manufacturing method, which is applied in the manufacture of motor generators, stator/rotor bodies, magnetic circuits, etc., and can solve the problem of low material utilization rate, inability to use three-phase permanent magnet synchronous motors, and material utilization rate. Not high problems, to achieve the effect of improving utilization rate, high slot full rate, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

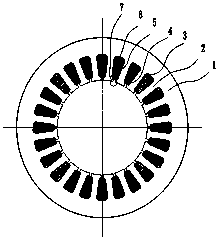

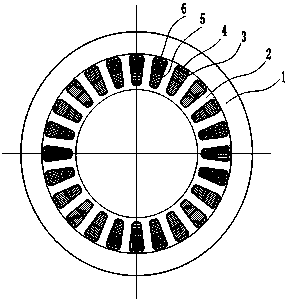

[0028] The following takes a 3-phase 24-slot combined permanent magnet brushless motor stator as an example to illustrate the specific design and manufacturing method. This 3-phase 24-slot stator can be used to make fractional slots with a permanent magnet rotor with a pole pair number 2p=10-20. Permanent magnet brushless motors are also suitable for distributed winding motors with integral slots made of permanent magnet rotors with 2p=2-8, as follows.

[0029] Example 1, 2p=16 fractional slot motor, the number of phases m=3, the number of slots Q=24, then the number of slots per pole and phase q=0.5. Rotor diameter D1=99, stack thickness L=60, stator inner diameter 100, outer diameter 160, air gap δ=0.5, tooth width 8, radial tooth height 22, radial yoke width 8.

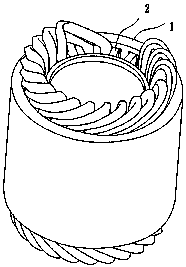

[0030] Production of tooth core 2 ( Figure 4 ). First, the silicon steel strip is punched out into a long strip with teeth and grooves according to the design requirements; then the toothed strip is spirally sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com