Valve chamber cover vibration damping connection device

A valve chamber and vibration connection technology, which is applied to valve devices, non-rotating vibration suppression, engine components, etc., can solve the problems of gasket life impact and NVH impact, and achieve the effect of reducing NVH and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

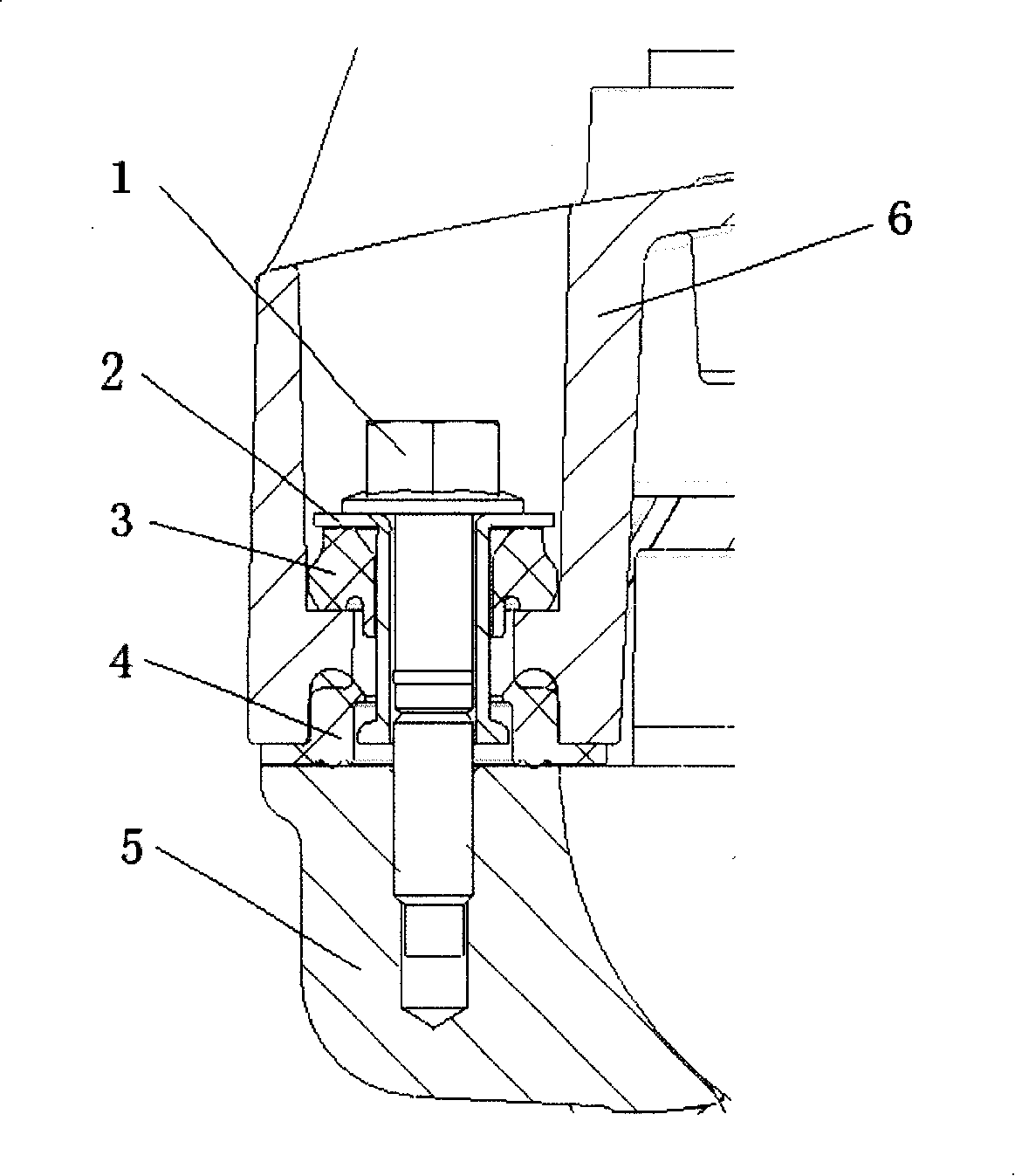

[0011] Example 1 in figure 1 Among them, a damping connection device for a valve chamber cover, which includes a fastening bolt 1 and a valve chamber cover gasket 4 for connecting a cylinder head 5 and a valve chamber cover 6 . A rubber damping unit 3 is placed between the nut of the bolt 1 and the valve chamber cover 6 .

Embodiment 2

[0012] Embodiment 2 A bushing 2 is sleeved on the bolt 1, and the bushing 2 is covered with a rubber damping unit 3; sum of thicknesses. To ensure that the rubber damping unit 3 and the valve chamber cover gasket 4 have a certain amount of compression. The vibration damping unit 3 can be a part connected in one body. All the other are with embodiment 1.

[0013] After the ordinary hexagon flange bolt 1 is tightened, the vibration of the valve chamber cover 6 itself is gradually eliminated by the buffering and absorption of the two rubber parts of the rubber damping unit 3 and the valve chamber cover gasket 4 . Noise due to vibration of the valve cover itself is reduced. At the same time, the vibration of the engine operation is greatly reduced by the amount of the vibration transmitted to the valve cover due to the absorption of the valve cover gasket 4 between the cylinder head 5 and the valve cover 6 . The occurrence of resonance between the valve cover 6 and the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com